Material with double functional groups, namely silica gel-supported chelating amine and thiourea, and preparation method of material

A dual-function, composite material technology, applied in the direction of chemical instruments and methods, other chemical processes, process efficiency improvement, etc., can solve the problem that the preparation method has not yet been reported, achieve excellent adsorption and desorption of gold performance, easy industrial production, process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

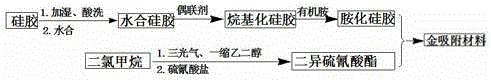

Method used

Image

Examples

Embodiment 1

[0047] Preparation of CP silica gel.

[0048] Physically humidify the spherical coarse-porous silica gel until the weight gain of the silica gel reaches 20%. Put the humidified silica gel into a single-necked round bottom flask, add 0.5-2.0mol / L hydrochloric acid whose mass is 4 times the mass of silica gel, turn on the rotary stirring, the speed is 30 rpm, the temperature is controlled at 105°C, condensed and refluxed, and the alkali The liquid absorbs the tail gas, and the reaction time is 6 hours. After the reaction, the temperature is naturally lowered to below 40°C, filtered, and the mother liquor is recovered and recycled, and then the silica gel is washed with deionized water until it is neutral, filtered, and dried in a drying oven at 120°C until constant Heavy. Quickly transfer the silica gel dried to constant weight into the hydration column, and the air is provided by the oil-free air compressor, and the air enters the airtight container filled with saturated potas...

Embodiment 2

[0055] The preparation of aminated material is as embodiment 1

[0056] Preparation of silica gel-loaded chelating amine and thiourea bifunctional composite adsorption materials.

[0057] Take 5 g of triphosgene, 30 ml of dichloromethane, and 0.2 ml of N,N-dimethylformamide in a reaction flask, stir mechanically at a speed of 140 rpm, and a reaction temperature of 2°C, and add 5 ml of diethylene glycol, tail gas absorption with lye, the reaction time is 15 hours, 20 g of thiocyanate is added to the reaction bottle in 6 times within 2 hours, the reaction temperature is controlled at 5 °C, and the reaction time is 8 h, after the reaction was completed, the solid salt was filtered off, and then the product was washed with 80 ml 0°C potassium chloride aqueous solution for 4 times, separated, and the lower organic phase was taken. Take 25g of the aminated material and place it in a three-necked flask, add 60 ml of absolute ethanol, let it soak for 0.5h, then add the lower organic ...

Embodiment 3

[0060] Preparation of CP silica gel.

[0061] Physically humidify the spherical coarse-porous silica gel until the weight gain of the silica gel reaches 25%. Add the humidified silica gel into a single-necked round bottom flask, add 1.5 mol / L hydrochloric acid whose mass is 3 times that of the silica gel, turn on the rotary stirring at a speed of 40r / min, control the temperature at 100°C, condense and reflux, and the lye absorbs the tail gas , The reaction time is 8 hours. After the reaction, the temperature is naturally lowered to below 40°C, filtered, and the mother liquor is recovered and recycled, and then the silica gel is washed with deionized water until it is neutral, filtered, and dried in a drying oven at 120°C to constant weight. Quickly transfer the silica gel that has been dried to constant weight into the hydration column, and the air is supplied by an oil-free air compressor. The air enters a closed container filled with saturated sodium bromide, and the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com