Method for treating gold production sewage

A technology for the production of sewage and treatment methods, which is applied in metallurgical wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It can solve the problems of high difficulty in gold production sewage treatment and large economic investment, and achieve a balance The effect of sewage treatment cost, low construction cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

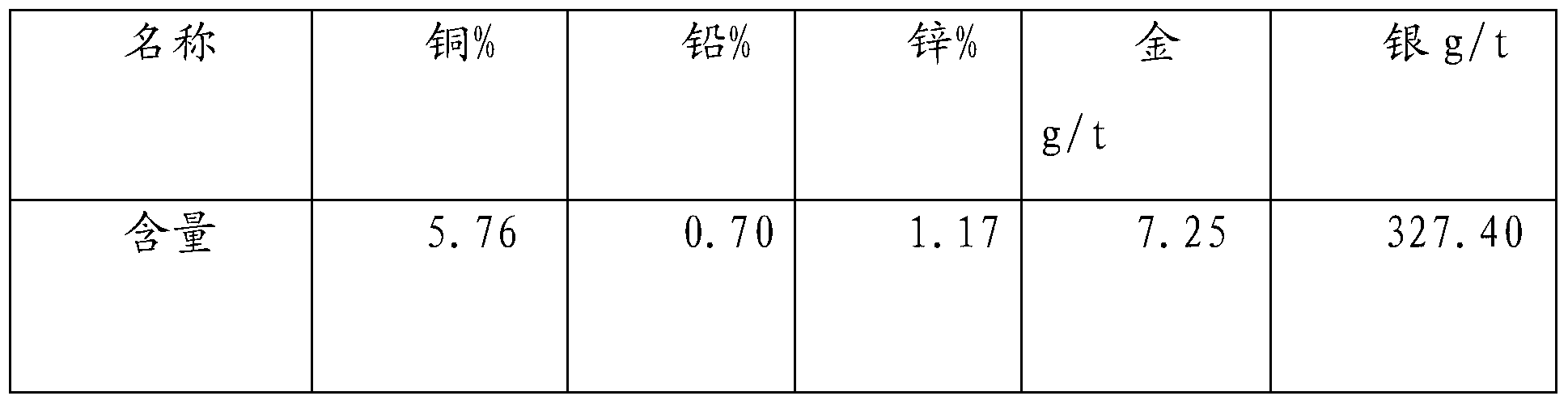

Embodiment 1

[0042] The mineral processing wastewater is about 800 cubic meters, which is filtered through the grille to remove impurities such as weeds, and then enters the mineral processing wastewater pool and is exposed to the sun for 4 hours to obtain the primary mineral processing wastewater.

[0043] About 50 cubic meters of acidic wastewater, PH = 0.7, and 1,000 cubic meters of alkaline wastewater, PH = 11, were filtered with grids to remove impurities such as weeds, and then mixed in the acid-base comprehensive wastewater pool to obtain acid-base mixed wastewater , its PH=4 was determined.

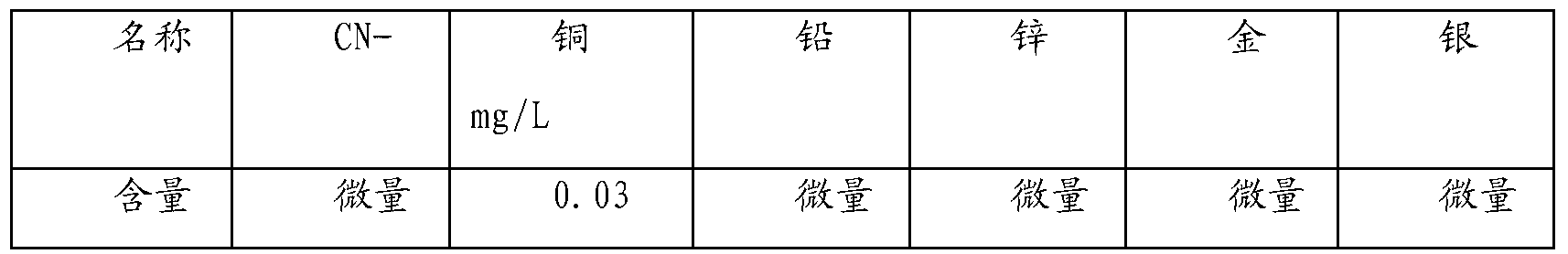

[0044] 20 cubic meters of cyanide-containing wastewater enters the cyanide-breaking reaction pool after passing through the grille to remove impurities such as weeds. After determination, the CN of cyanide - The concentration concentration is 1500mg / L. Air is introduced into the cyanide-breaking reaction tank, and then sodium metabisulfite is added to make it mix with the CN in the cyanide w...

Embodiment 2

[0055] The mineral processing wastewater is about 500 cubic meters, which is filtered through the grille to remove impurities such as weeds, and then enters the mineral processing wastewater pool and is exposed to the sun for 5-6 hours to obtain the primary mineral processing wastewater.

[0056] About 20 cubic meters of acidic wastewater, PH = 1, and 600 cubic meters of alkaline wastewater, PH = 11, were filtered with grids to remove impurities such as weeds, and then mixed in the acid-base comprehensive wastewater pool to obtain acid-base mixed wastewater , its PH=4 was determined.

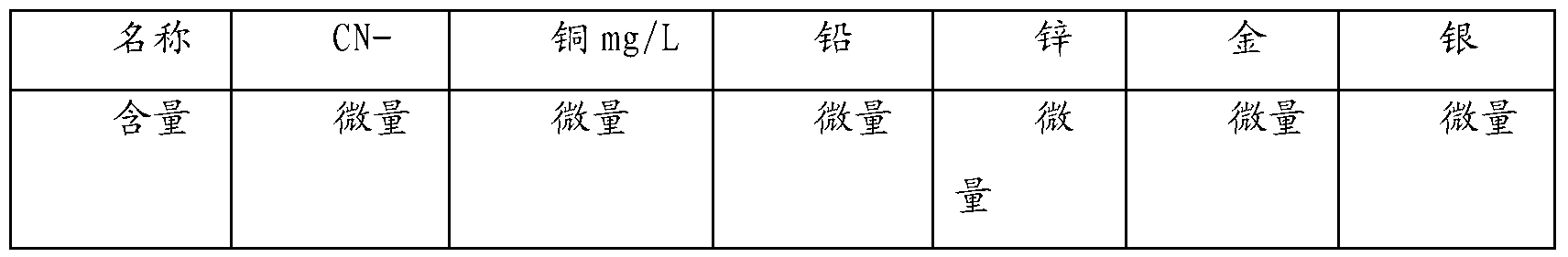

[0057] 10 cubic meters of cyanide-containing wastewater enters the cyanide-breaking reaction pool after passing through the grid to remove impurities such as weeds. After determination, the CN of cyanide - The concentration concentration is 1500mg / L. Air is introduced into the cyanide-breaking reaction tank, and then sodium metabisulfite is added to make it mix with the CN in the cyanide waste...

Embodiment 3

[0067] About 600 cubic meters of beneficiation wastewater is filtered through a grid to remove impurities such as weeds, and then enters the beneficiation wastewater pool and is exposed to the sun for 8 hours to obtain primary beneficiation wastewater.

[0068] About 10 cubic meters of acidic wastewater, PH = 1, and 200 cubic meters of alkaline wastewater, PH = 11, were filtered with grids to remove impurities such as weeds, and then mixed in the acid-base comprehensive wastewater pool to obtain acid-base mixed wastewater , its PH=4 was determined.

[0069] 15 cubic meters of cyanide-containing wastewater enters the cyanide-breaking reaction pool after passing through the grille to remove impurities such as weeds. After determination, the CN of cyanide - The concentration concentration is 1500mg / L. Air is introduced into the cyanide-breaking reaction tank, and then sodium metabisulfite is added to make it mix with the CN in the cyanide wastewater. - The mol ratio is 1.2:2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com