Environment-friendly gold extraction agent and preparation method thereof

A gold extracting agent and environmental protection technology, applied in the field of environmental protection gold extracting agent and its preparation, can solve the problems of endangering the life safety of humans and animals, polluting the ecological environment, restricting and other problems, achieving green environmental protection and good economic benefits, simple production method and low production cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

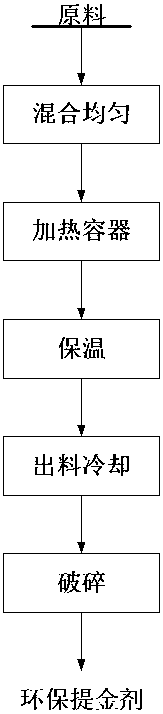

[0020] A preparation method of an environment-friendly gold extracting agent, comprising the steps of:

[0021] ①Uniform mixing of raw materials: use a mixer to evenly mix dry sodium carbonate, urea, sodium chloride, sodium sulfide, iodine, potassium ferricyanide, sodium thiocyanate, sodium bromide and sodium thiosulfate, the mass of each component The ratio is: sodium carbonate 20%-50%, urea 10%-50%, sodium chloride 1%-10%, sodium sulfide 1%-5%, iodine 1%-5%, potassium ferricyanide 1%-5 %, sodium thiocyanate 1%-5%, sodium bromide 1%-5% and sodium thiosulfate 1%-5%;

[0022] ②Put the above-mentioned uniformly mixed raw materials in a heatable airtight container;

[0023] ③Heating and keeping warm: heat the airtight container to 700-800°C and keep warm for 1-5h;

[0024] ④Discharge cooling: Pour out the fired environmental protection gold extraction agent into an open container and cool it down to room temperature naturally;

[0025] ⑤ Crushing: crush the cooled environment-...

Embodiment 1

[0027] refer to figure 1 , using a mixer to mix dry sodium carbonate, urea, sodium chloride, sodium sulfide, iodine, potassium ferricyanide, sodium thiocyanate, sodium bromide and sodium thiosulfate evenly, wherein the mass ratio of each component is : 35% sodium carbonate, 30% urea, 5% sodium chloride, 5% sodium sulfide, 5% iodine, 5% potassium ferricyanide, 5% sodium thiocyanate, 5% sodium bromide and 5% sodium thiosulfate %, after mixing, put it in a stainless steel container and heat it to 750°C for 3 hours, then pour out the environmental protection agent and place it in an open stainless steel container to cool naturally to room temperature, and use a jaw crusher to crush it to 30mm for later use.

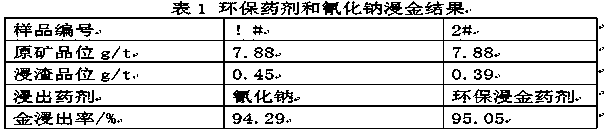

[0028] Use this environment-friendly gold extraction agent and sodium cyanide to leach gold from a gold ore in Hebei Province. The gold grade of the ore sample is 7.88g / t, the grinding fineness is -200 mesh, accounting for 95.5%, and the pulp concentration is 38%, adjusted by...

Embodiment 2

[0031] refer to figure 1 , use a mixer to mix dry sodium carbonate, urea, sodium chloride, sodium sulfide, iodine and potassium ferricyanide evenly, wherein the mass ratio of each component is: sodium carbonate 35%, urea 30%, sodium chloride 5% , Sodium sulfide 5%, Iodine 5%, Potassium ferricyanide 5%, Sodium thiocyanate 5%, Sodium bromide 5%, Sodium thiosulfate 5%, After mixing, put it in a stainless steel container and heat it to 760°C for 4 hours , and then pour out the environmental protection agent and place it in an open stainless steel container to cool naturally to room temperature, and use a jaw crusher to crush it to 30mm for later use.

[0032] Use this environment-friendly gold extraction agent and sodium cyanide to leach gold from a gold mine ore in Hebei Province. The gold grade of the ore sample is 5.74g / t, the grinding fineness is -200 mesh, accounting for 93%, the pulp concentration is 38%, and it is adjusted by CaO The pH of the pulp is 11, the dosage of CaO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com