A method for extracting gold from ore and special molten gold mixture

A technology for mixing and melting gold, applied in the field of gold production, can solve the problems of poor metal ore body yield, difficult recovery, cumbersome application methods, etc., to achieve the effect of highlighting environmental protection awareness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

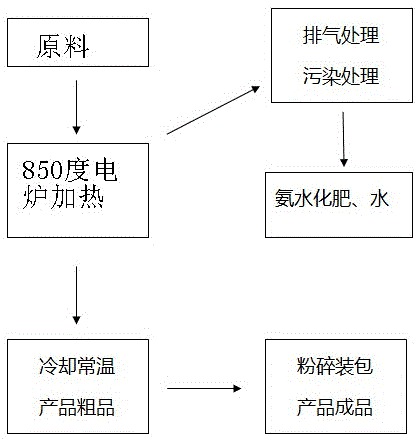

[0014] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

[0015] With reference to the accompanying drawings, a special molten gold mixture for extracting gold from ores is synthesized by thermal reaction of sodium carbonate, urea, sodium bromide, sodium sulfide, sodium thiosulfate, yellow blood salt sodium, sodium fluoride, and sodium chloride. The mass ratio of each component is: sodium carbonate 0.26, urea 0.28, sodium bromide 0.03, sodium sulfide 0.06, sodium thiosulfate 0.2, yellow blood salt sodium 0.05, sodium fluoride 0.06, sodium chloride 0.06. It is made by heat reaction and concentration in a stirring furnace at a high temperature of 850 degrees.

[0016] The special molten gold mixture is cooled to normal temperature, crushed and packaged to become a product.

[0017] The exhaust gas produced by the production of special molten gold mixture is processed to produce ammonia fertilizer.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com