Method for producing high-purity gold and copper sulphate from gold-bearing copper sludge

A technology of copper sludge and sludge, which is applied to the improvement of process efficiency, photography technology, instruments, etc., to achieve the effect of reduction, good separation effect and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

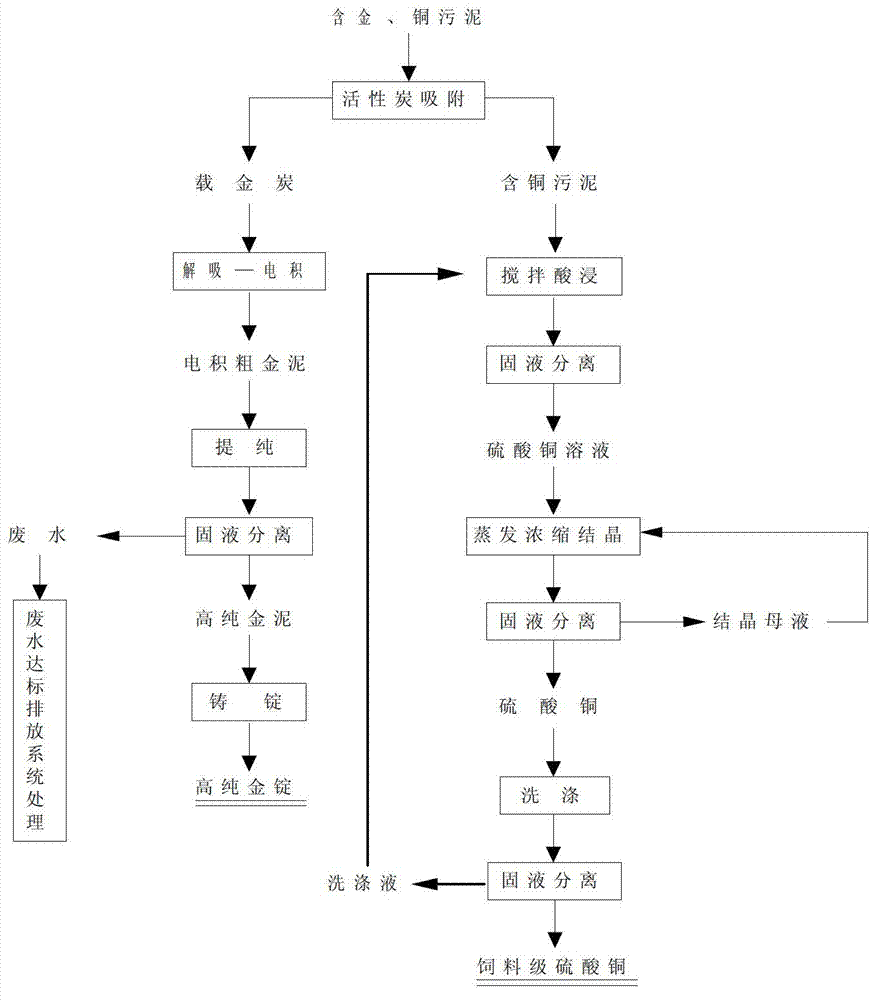

Image

Examples

Embodiment 1

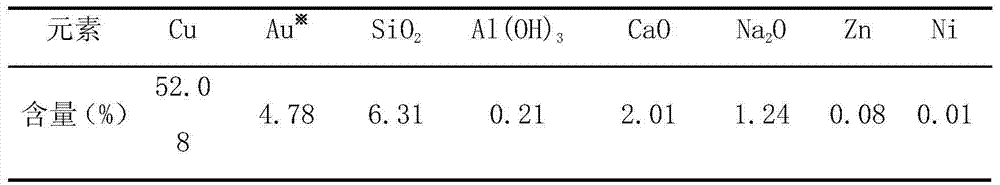

[0038] The phase analysis of the gold-bearing copper sludge produced by a copper-bearing gold ore in the cyanide-rich solution in the process of oxidizing and removing cyanide with hydrogen peroxide shows that copper mainly exists in the form of copper hydroxide and basic copper carbonate, and A small amount of precipitates in other forms of copper exists, and the analysis results of the main elements of the sludge are shown in Table 1.

[0039] Table 1 Analysis results of main elements of a gold-bearing copper sludge / % (dry basis)

[0040]

[0041] Note:" ※ "The unit is g / t, the same below.

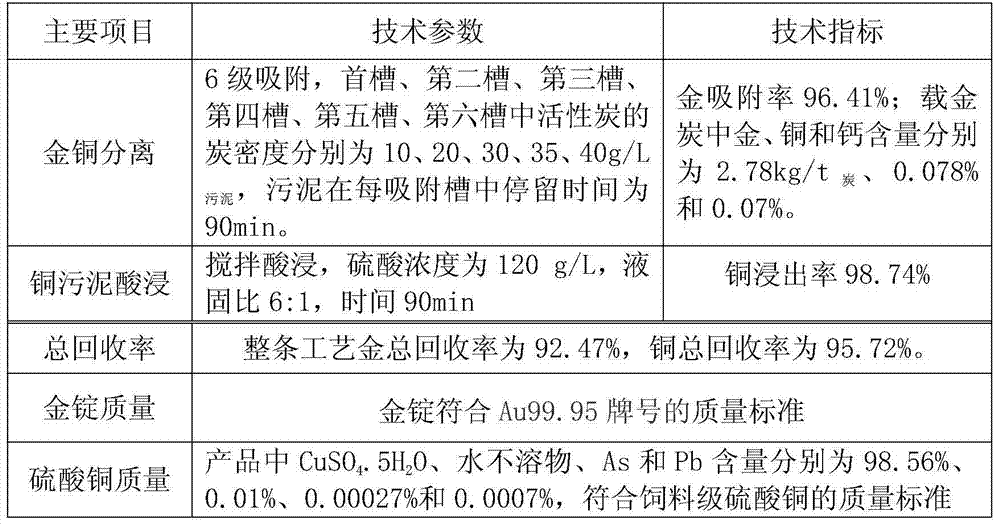

[0042] The method for producing high-purity gold and copper sulfate with gold-bearing copper sludge comprises the following process steps in sequence:

[0043] The first step of separation of gold and copper: the above-mentioned gold and copper sludge with a moisture content of 96.31% is sent to the carbon adsorption system, and activated carbon is used to adsorb gold to realize th...

Embodiment 2

[0055] The phase analysis of the gold and copper sludge produced by a copper-bearing gold ore in the process of cyanide-rich solution using ozone oxidation to remove cyanide shows that copper mainly exists in the form of copper hydroxide precipitation, and a small amount exists in the form of basic carbonic acid The main element analysis results of the sludge are shown in Table 3.

[0056] Table 3 Analysis results of main elements of a gold-bearing copper sludge / % (dry basis)

[0057]

[0058] A method for producing high-purity gold and feed-grade copper sulfate by utilizing gold-containing copper sludge comprises the following process steps in sequence:

[0059] The first step of separation of gold and copper: the above-mentioned gold and copper sludge with a moisture content of 97.21% is sent to the carbon adsorption system, and activated carbon is used to adsorb gold to realize the separation of gold and copper. The carbon adsorption system is composed of 4-stage iron ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com