Vertical cell immobilized reactor for producing ferric irons by biological oxidation

A biological oxidation and reactor technology, applied in the direction of improving process efficiency, can solve the problems of slow oxidation rate of ferrous iron and long leaching time, and achieve the effect of easy suspension and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

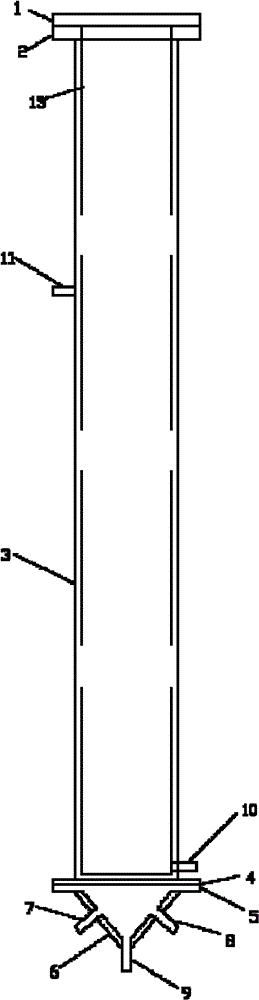

[0035] Continuous Oxidation of Fe by Immobilized Moderate Thermophilic Rheobacterium siberia S.s with 1 / 2 Loading Volume 2+ The rate determination of:

[0036] Cut the polyurethane foam into cubes of a certain size and fill them into the reactor cylinder 3 with a filling volume of 1 / 2. Configuration contains 10g / LFe 2+ , 0.2g / L yeast extract powder, leathern medium of 10% S.s bacterial liquid, with 1:1 H 2 SO 4 Adjust the pH to 1.5, use a pump to add the prepared medium into the reactor cylinder 3 through the feed port 7, turn on the air compressor pump, adjust the air rotameter to an appropriate flow rate, and set it between 30 and 100 °C At a good temperature, run the reactor for bacteria immobilization experiments. When the load of bacteria on the carrier is stable, continuous operation is carried out. The pump continuously inputs the culture medium from the feed port 7 into the reactor cylinder 3, and the feed port 11 is at the same time. Drain liquid at the same rate,...

Embodiment 2

[0038] Continuous Oxidation of Fe by Immobilized Moderate Thermophilic Rheobacterium siberia S.s with 3 / 4 Loading Volume 2+ The rate determination of:

[0039]Cut the polyurethane foam into cubes of a certain size and fill them into the reactor cylinder 3 with a filling volume of 3 / 4. Configuration contains 10g / LFe 2+ , 0.2g / L yeast extract powder, leathern medium of 10% S.s bacterial liquid, with 1:1 H 2 SO 4 Adjust the pH to 1.5, use a pump to add the prepared medium into the reactor cylinder 3 through the feed port 7, turn on the air compressor pump, adjust the air rotameter to an appropriate flow rate, and set it between 30 and 100 °C At a good temperature, run the reactor for bacteria immobilization experiments, and when the bacteria load on the carrier is stable, proceed to continuous operation. The pump continuously inputs the culture medium from the feed port 7 into the reactor cylinder 3, while the discharge port 11 drains at the same rate, and samples are taken a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com