Collecting method for monomer gold particles

A particle and monomer technology, applied in the field of mining engineering, can solve the problems of complex equipment configuration, pollution of production environment, difficult connection, etc., and achieve the effect of saving capital construction investment, strong operability, and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

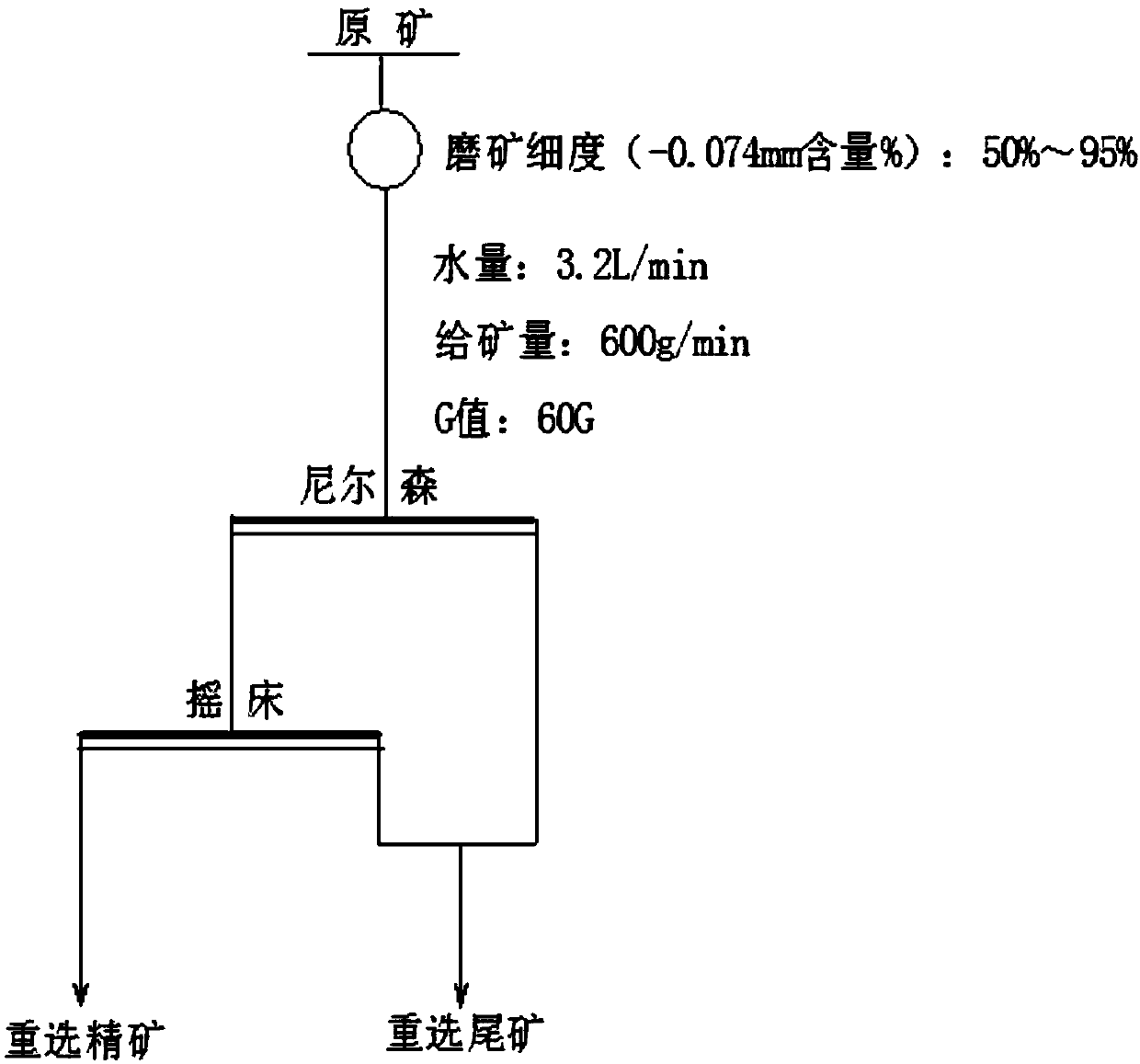

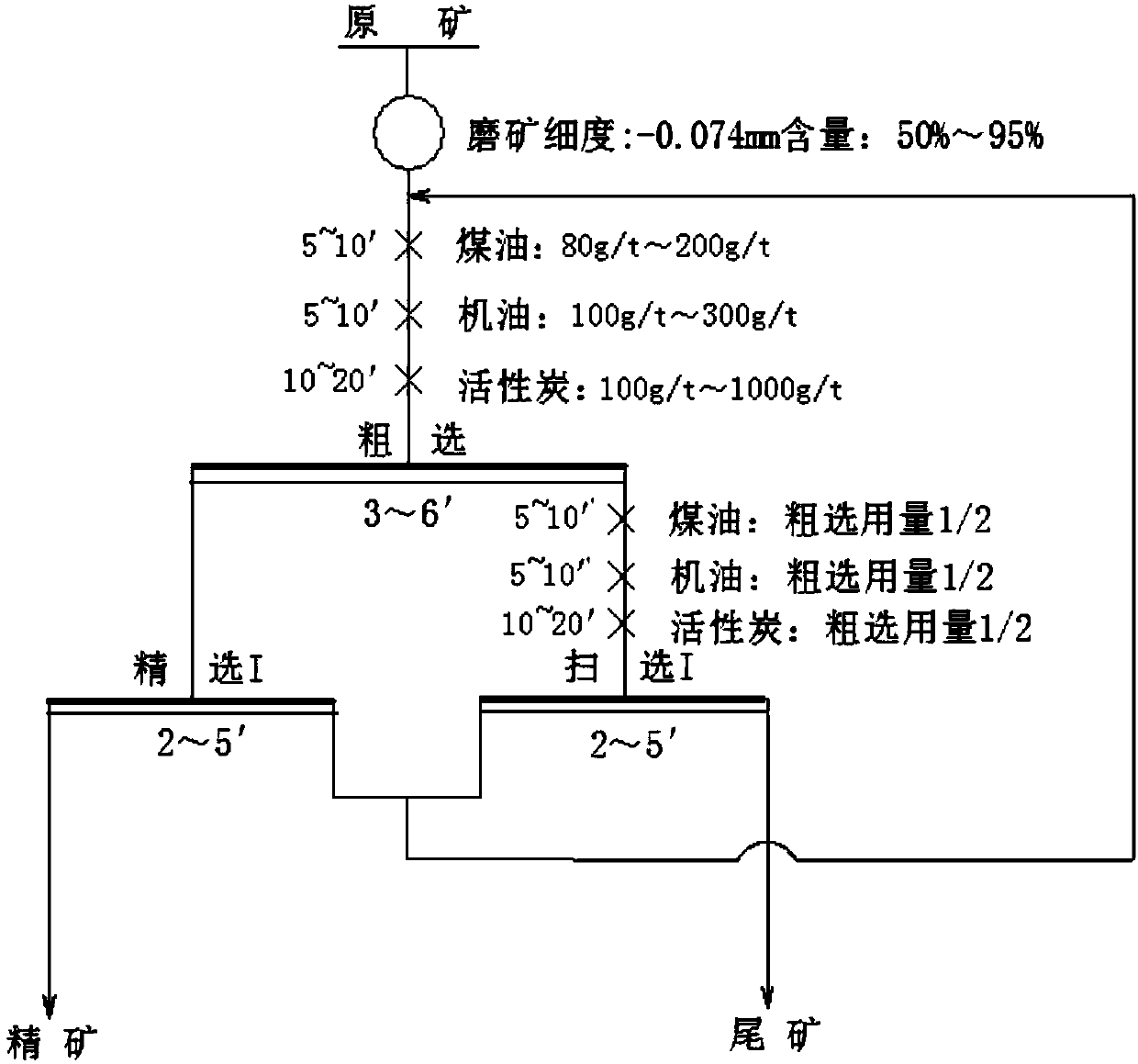

Method used

Image

Examples

Embodiment 1

[0020] A gold-bearing ore in a mine, the metal minerals in the ore are mainly pyrite, a small amount of chalcopyrite, a very small amount of sphalerite, galena, and occasionally toxic sand, as well as bismuthite, bismuthite, Bismuthite, natural bismuth, bismuth tellurite, bismuth tellurite, tetrahedrite, chalcocite, copper blue, magnetite, limonite, etc.; gangue minerals are mainly quartz and feldspar, followed by silk Mica, muscovite, chlorite, carbonate (calcite, dolomite), kaolin, carbonaceous minerals, etc;

[0021] Table 1 Results of chemical analysis of raw ore

[0022]

[0023] The gold minerals in the ore are natural gold and silver-gold ore, and the silver minerals are natural silver, sulfur-antimony-copper-silver ore, and cadmium-silver ore. The particle size of gold minerals is relatively coarse, with +0.074mm coarse-grained accounting for 2.06%, 0.037mm-0.074mm medium-grained gold accounting for 27.64%, 0.010mm-0.037mm fine-grained gold and -0.010mm fine-graine...

Embodiment 2

[0039] Gold-bearing ore in a mine, the content of metallic minerals in the ore is 13.56%, of which the content of pyrite and pyrrhotite is 4.18%, and the content of chalcopyrite, copper indigo, bornite, tetrahedrite and chalcocite is 1.49%. The content of sphalerite and galena is 0.16%, the content of bismuthite is 0.03%, and the total content of metal sulfide is 5.86%; the metal oxide is composed of magnetite, hematite, limonite, etc., with a content of 7.70%; gangue The main minerals are quartz, garnet, magnesia, followed by albite, orthoclase, plagioclase, biotite, calcite, etc., with a content of 86.44%. The ore process type is medium sulfide primary copper-bearing gold ore. The chemical analysis results of the ore are shown in Table 4.

[0040] Table 4 Results of chemical analysis of raw ore

[0041]

[0042] The gold mineral in the ore is natural gold, and the gold mineral particle size +0.295mm giant gold and +0.074mm coarse gold content are less, 1.35%, 8.62% resp...

Embodiment 3

[0058] The main metal minerals in the ore are pyrite, very little pyrrhotite, chalcopyrite, tetrahedrite, limonite, very little tellurite, bismuth tellurite, lead-bearing natural tellurium, bismuth-bearing natural tellurium , silver tetrahedrite, silver-bearing tetrahedrite, chalcocite, argentite, silver tellurite, hexagonal tellurite, etc.; the gangue minerals in the ore are mainly quartz, feldspar (mainly albite), secondary It is dolomite (mainly iron dolomite), calcite, sericite, apatite, etc. The ore process type is less sulfide gold-bearing ore. The multi-element analysis results of the raw ore are shown in Table 7.

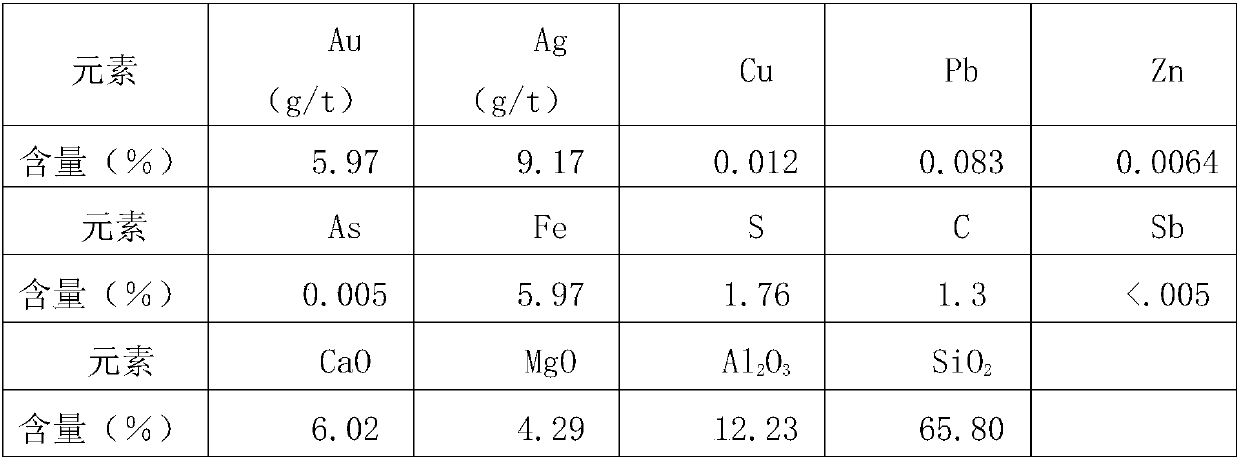

[0059] Table 7 Results of multi-element analysis of raw ore

[0060]

[0061] The gold minerals in the ore are mainly natural gold, accounting for 76.2%, followed by silver-gold ore, accounting for 19.4%, and a small amount of tellurium gold ore and tellurium gold-silver ore; the gold mineral particle size + 0.074mm coarse-grained gold in the ore account...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com