Full-automatic tinning machine used for tinning of induction transformer

A transformer and fully automatic technology, applied in the field of tin dipping machines, can solve the problems of inappropriate tin dipping operation of inductive transformers, unstable quality of manual tin dipping, reducing market competitiveness, etc., to achieve good tin dipping effect and high tin dipping efficiency. , The effect of improving the efficiency of tin dip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0031] Example.

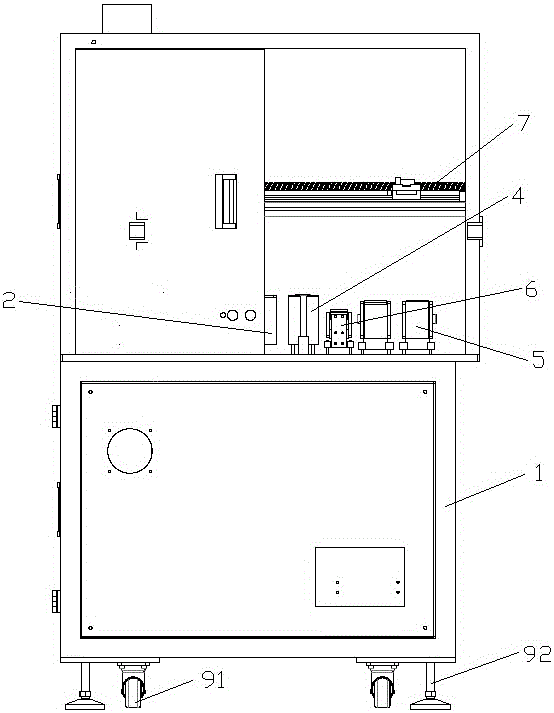

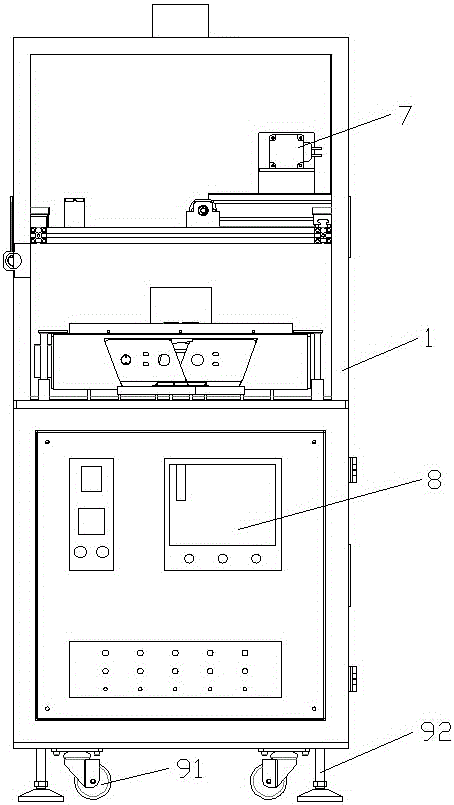

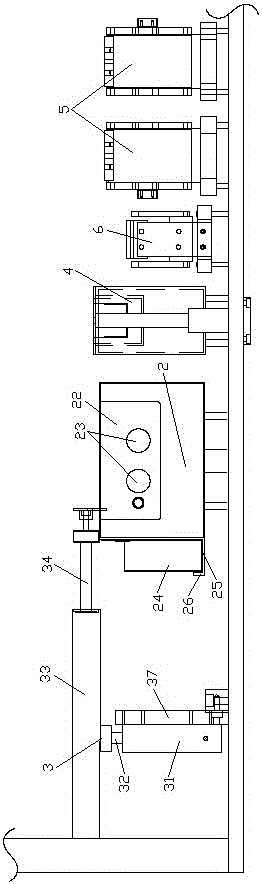

[0032] see Figure 1 to Figure 10 In this embodiment, the fully automatic tin dipping machine used for tinning the inductance transformer includes a frame 1, a tin melting device 2, a tin slag scraping device 3, a flux containing device 4, an inductance transformer input device 5, and an inductance transformer output device 6. The inductance transformer grabs the tin dipping device 7 and the controller 8 .

[0033] The tin melting device 2 in this embodiment comprises a tin furnace body 21, an electric heating tube 23, a tin slag collection tank 24, a collection tank support platform 25, a collection tank limit bar 26 and a tin slag introduction piece 27, and the tin furnace body 21 is fixed on O...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com