Cable weaving tin dipping device and method

A cable and tin dipping technology, which is applied in the field of cable processing equipment, can solve the problems of solder position drop, uneven braid tin dipping, easy solidification, etc., achieve consistent length, improve tin dipping effect, and ensure quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

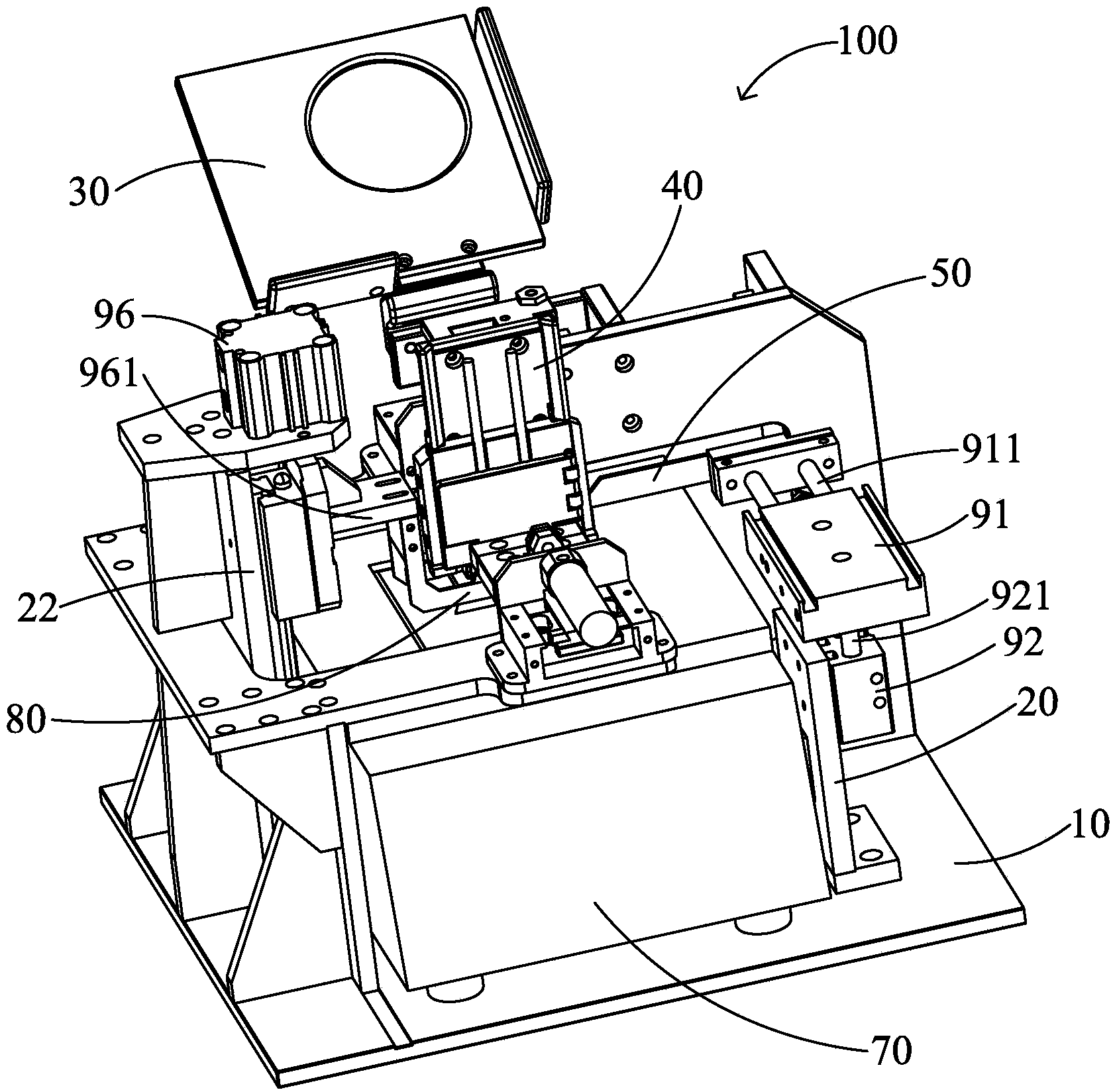

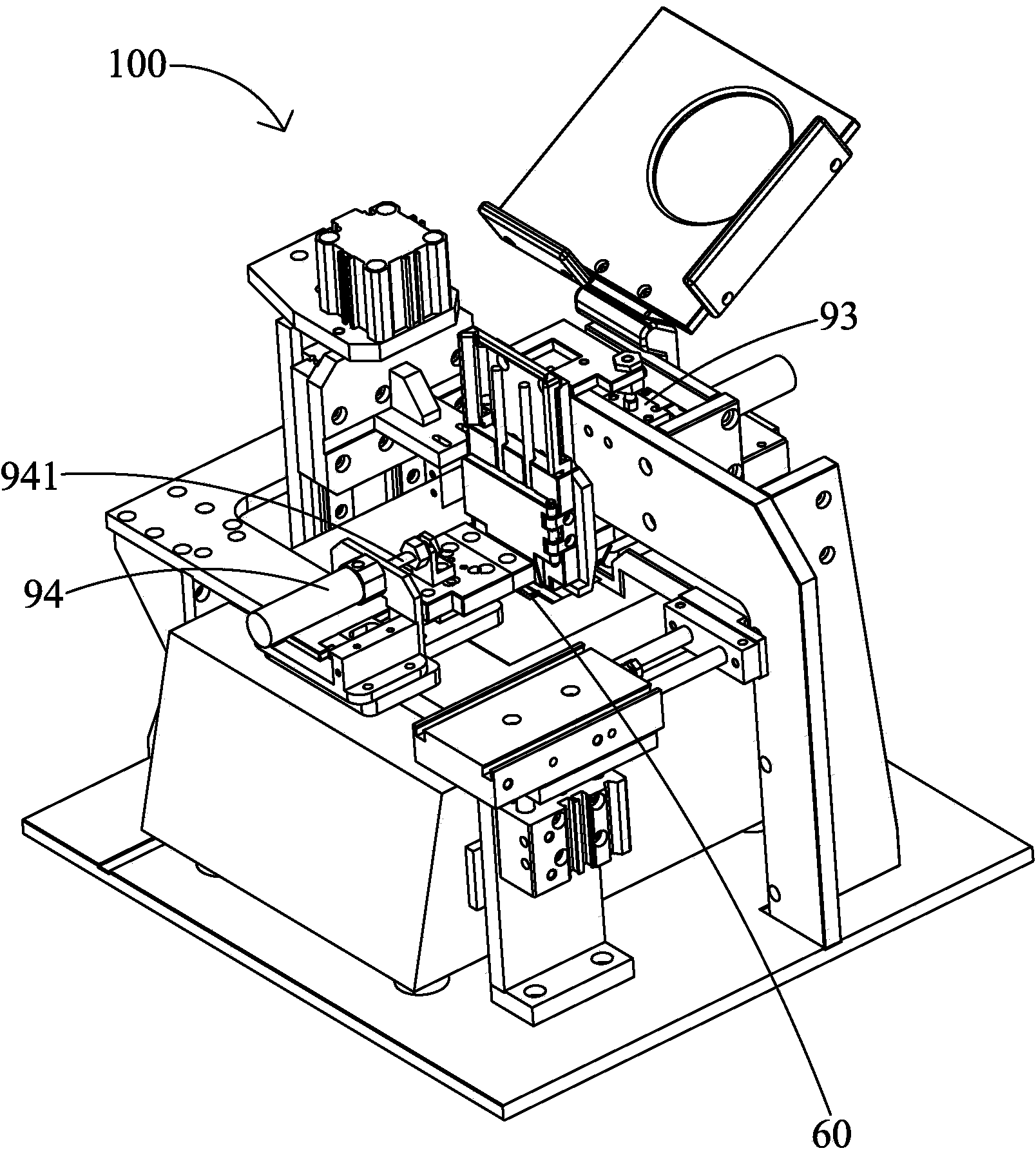

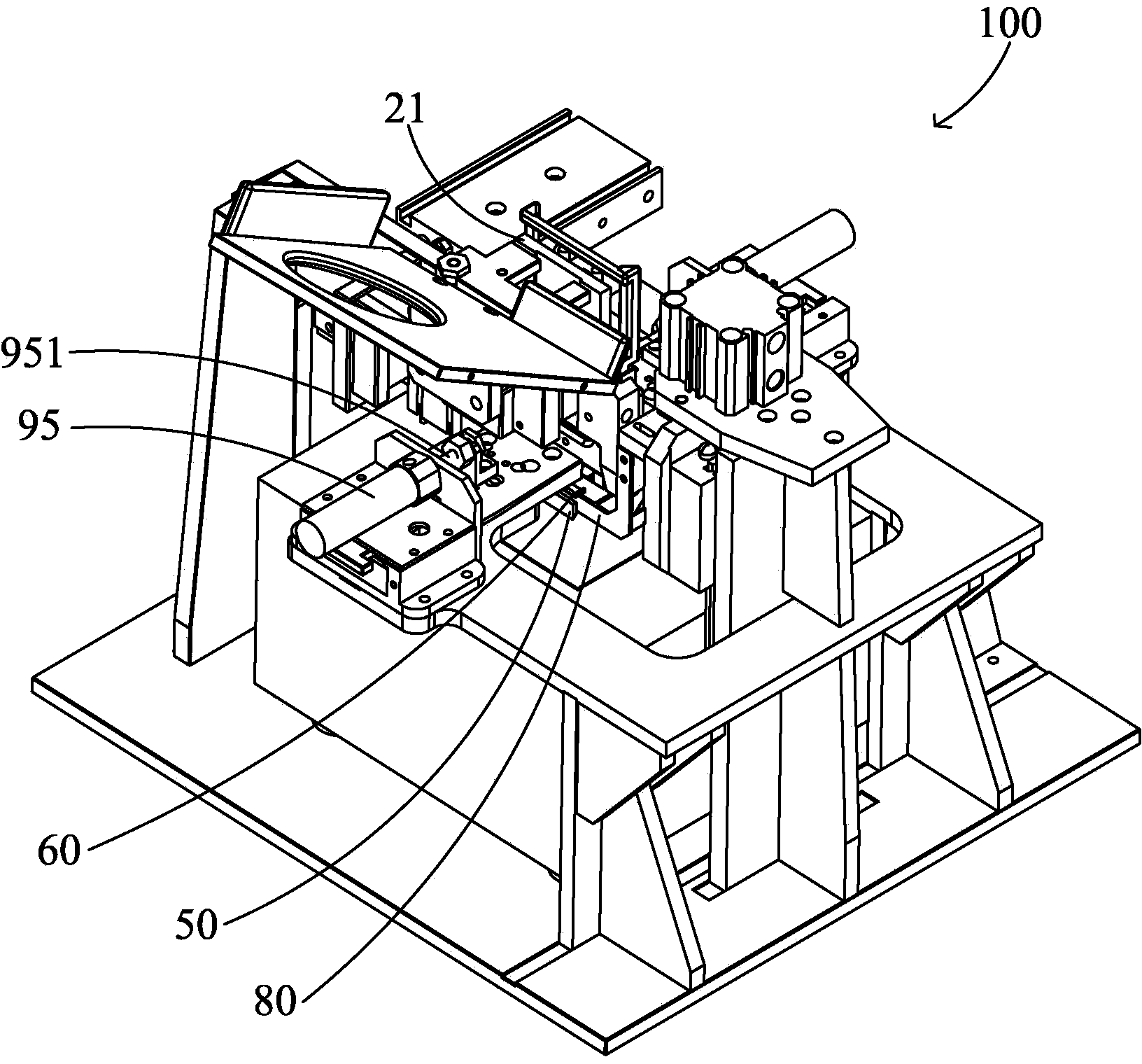

[0021] see Figure 1 to Figure 8 As described above, the weaving tin dipping device 100 of the present invention includes a base 10, a bracket 20, a tray 30, a positioning carrier 40, a tin scraping knife 50, a pair of scraping knitting knives 60 spaced apart from front and back, a tin furnace 70, a tin spoon 80, Several air cylinders and electric control boxes (not shown), the electric control boxes are connected with each air cylinder 91-96, and are used to control the running state of the weaving tin dipping equipment 100.

[0022] Support 20 is installed on the base 10, and each cylinder 91-96 is installed on the support 20, and cylinder 91-96 is provided with six altogether, namely the first, the second, the third, the fourth, the fifth, the sixth cylinder 91, 92, 93, 94, 95, 96, the first cylinder 91 is connected with the tin scraper 40 through a connecting rod 911, which can drive the tin scraper 40 to move back and forth, so that the tin scraper 40 cleans the tin surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com