Tin soldering machine

A soldering machine and soldering head technology, applied in tin feeding devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of high labor intensity, low soldering precision, low productivity, etc., to simplify human operation, improve production efficiency, The effect of improving the soldering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

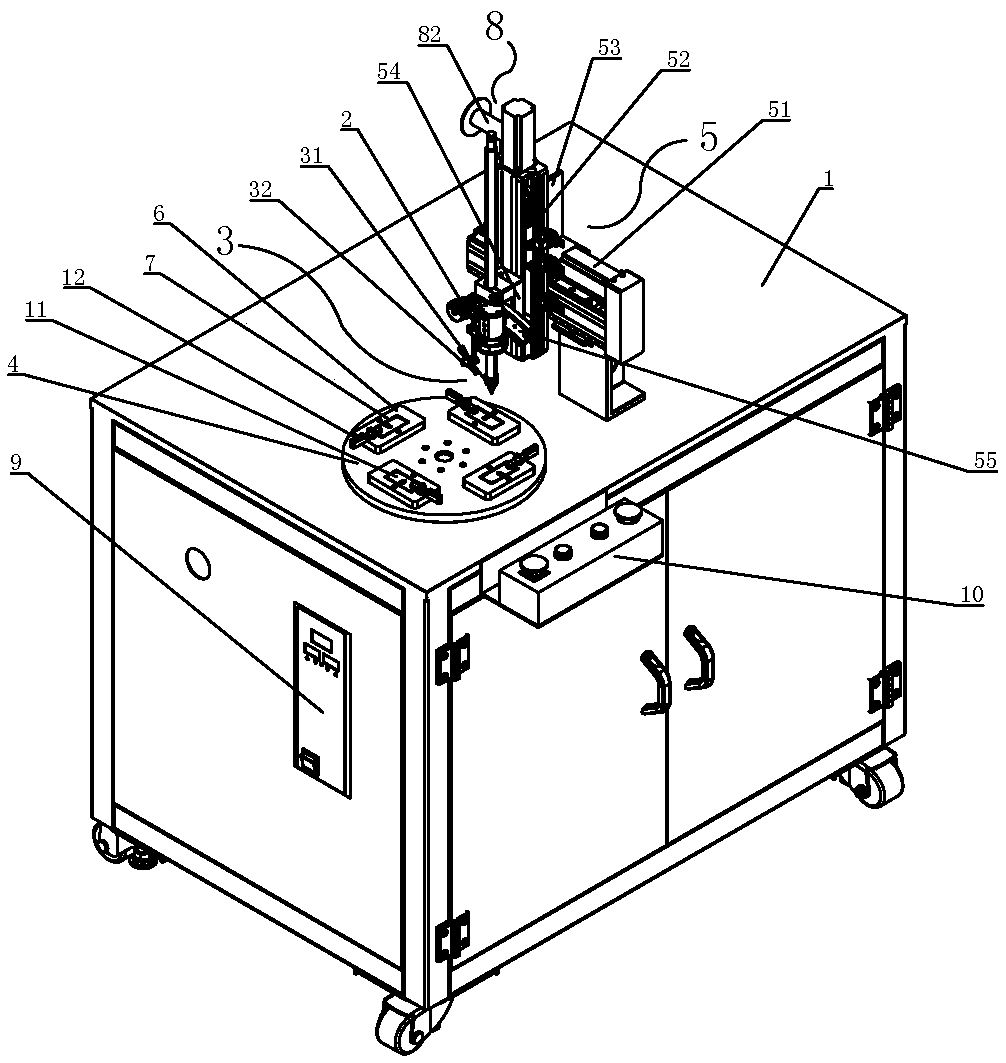

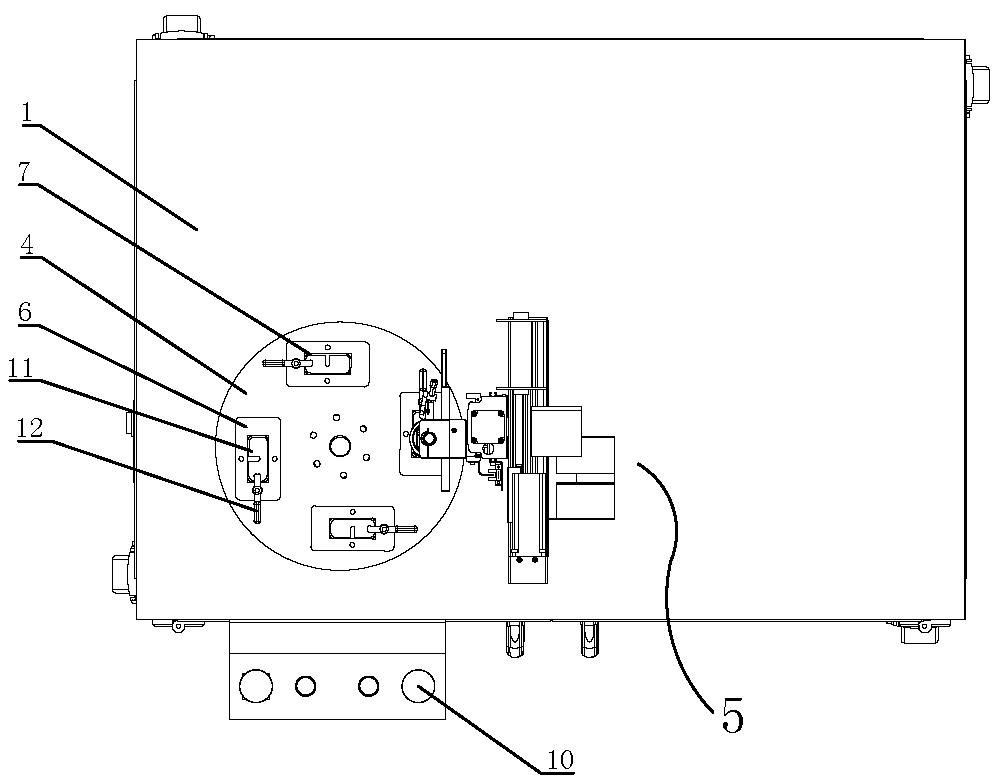

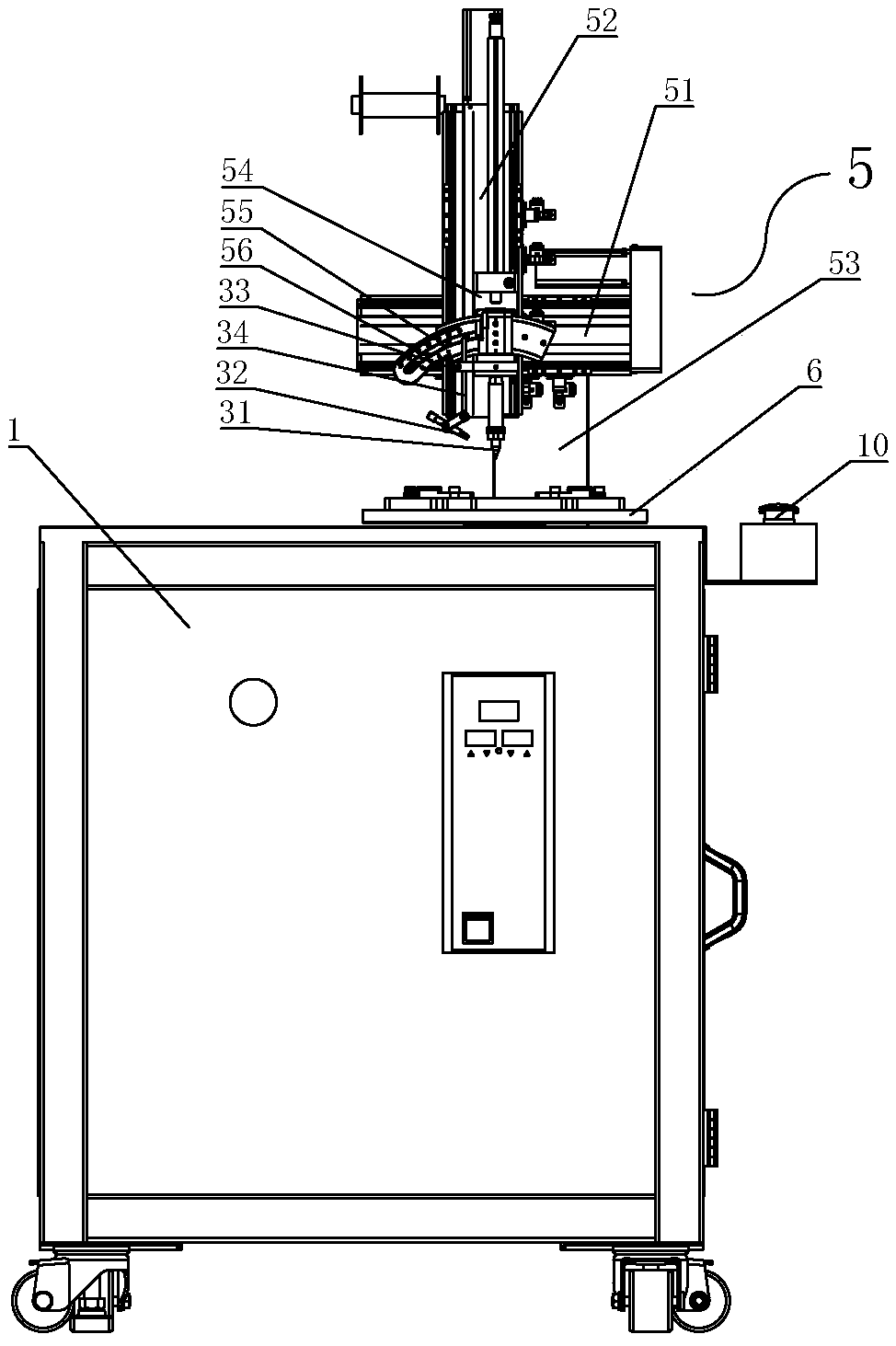

[0016] Such as figure 1 , figure 2 , image 3 As shown, a soldering machine includes a workbench 1, a soldering iron mechanism is installed on the workbench 1, the soldering iron mechanism includes a soldering iron 2, the soldering iron 2 is installed on the soldering iron bracket 5, the soldering head of the soldering iron 2 3 is provided with a multi-station turntable 4 underneath. The turntable 4 is provided with a product carrier 6. The turntable 4 is circular. The product carrier 6 is installed on the top end surface of the turntable 4 by screws, and the middle bottom end of the turntable 4 passes through the shaft Installed on the surface of the workbench 1, four product carriers 6 are installed on the turntable 4, and the four product carriers 6 are respectively located at the four corners of the parallelogram. The product carrier 6 is a quadrilateral flat plate, and the top of the flat plate The middle part of the end face is provided with a groove 11 corresponding to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com