Patents

Literature

73results about How to "Automatic and accurate positioning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Unbalanced ship classification method based on deep convolutional neural network

ActiveCN111461190AStrong application valueAccuracy close toCharacter and pattern recognitionNeural architecturesModel learningClassification result

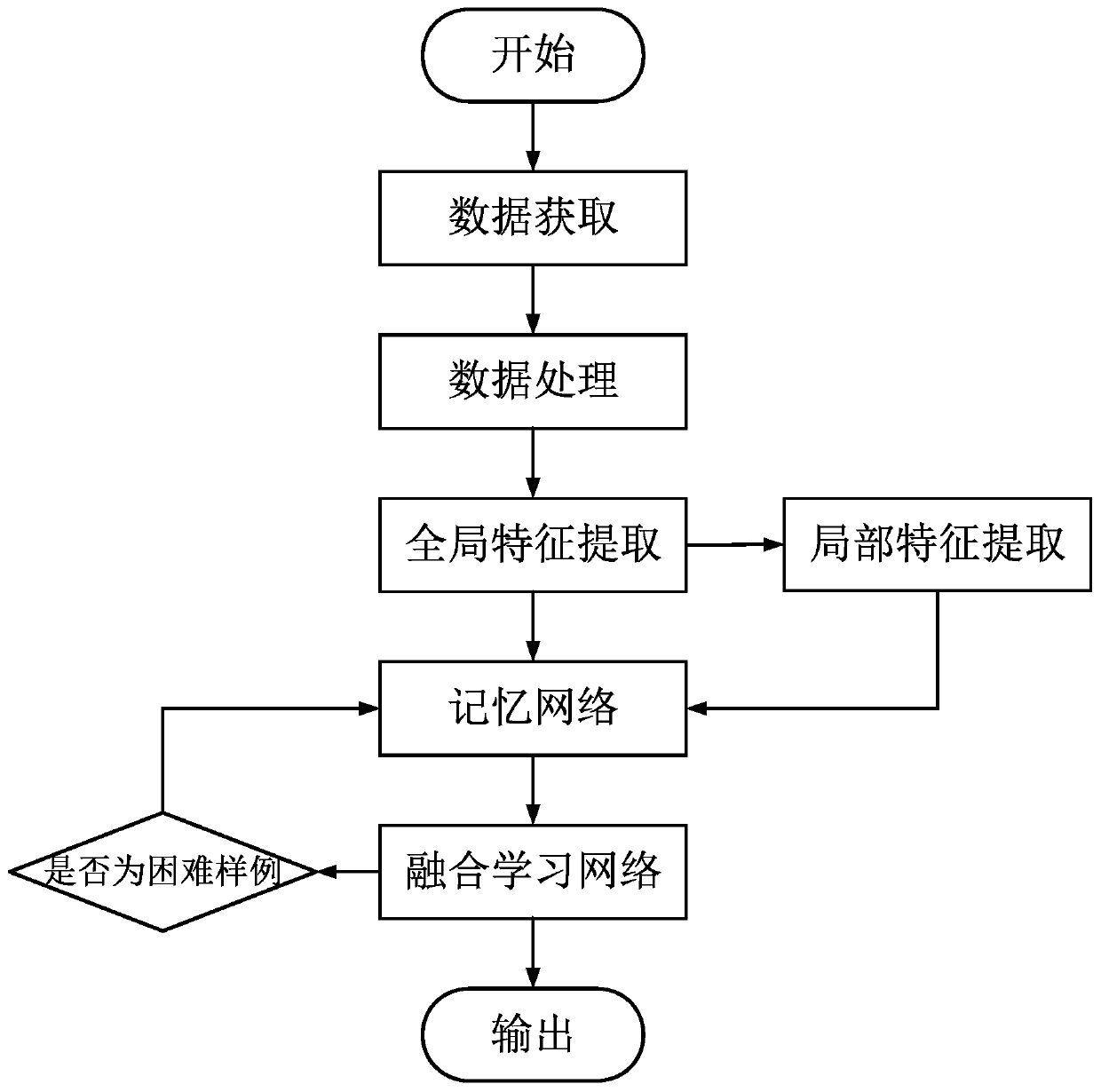

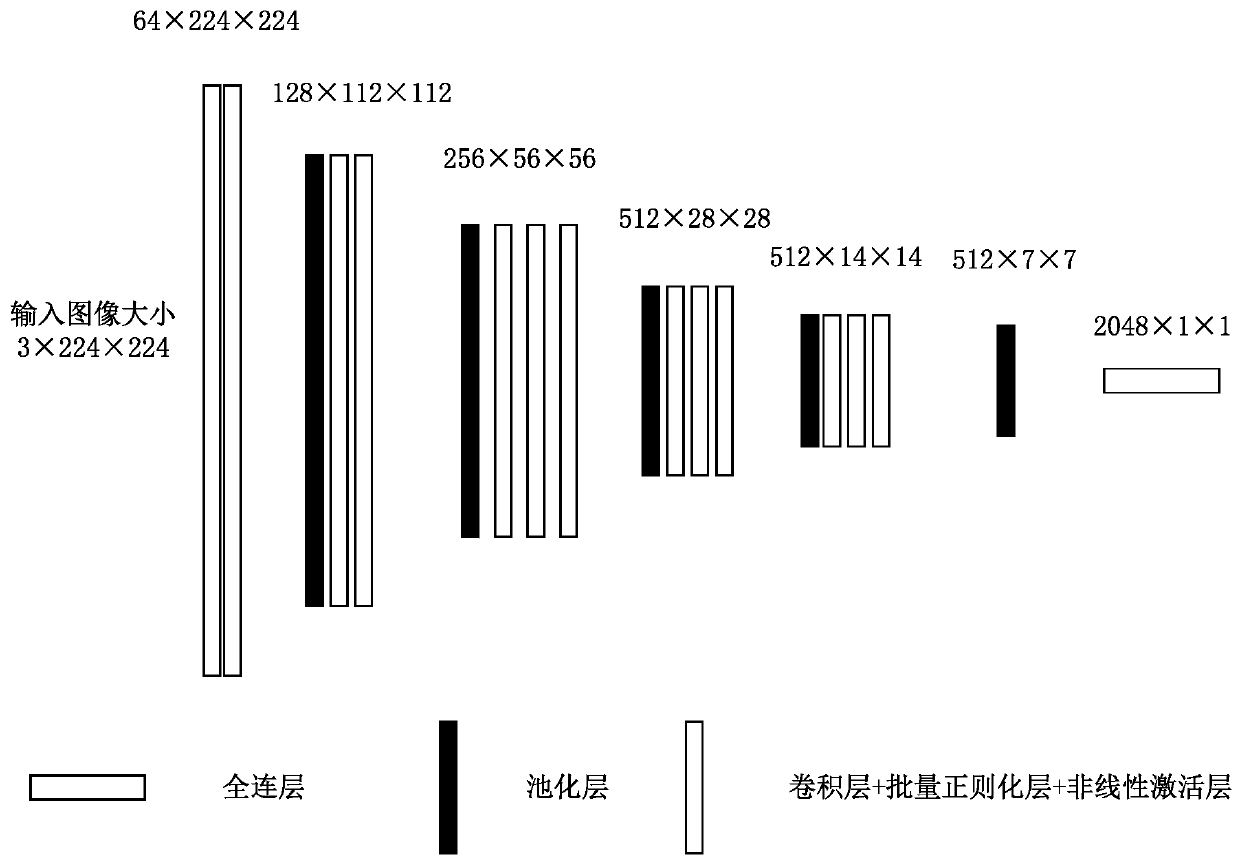

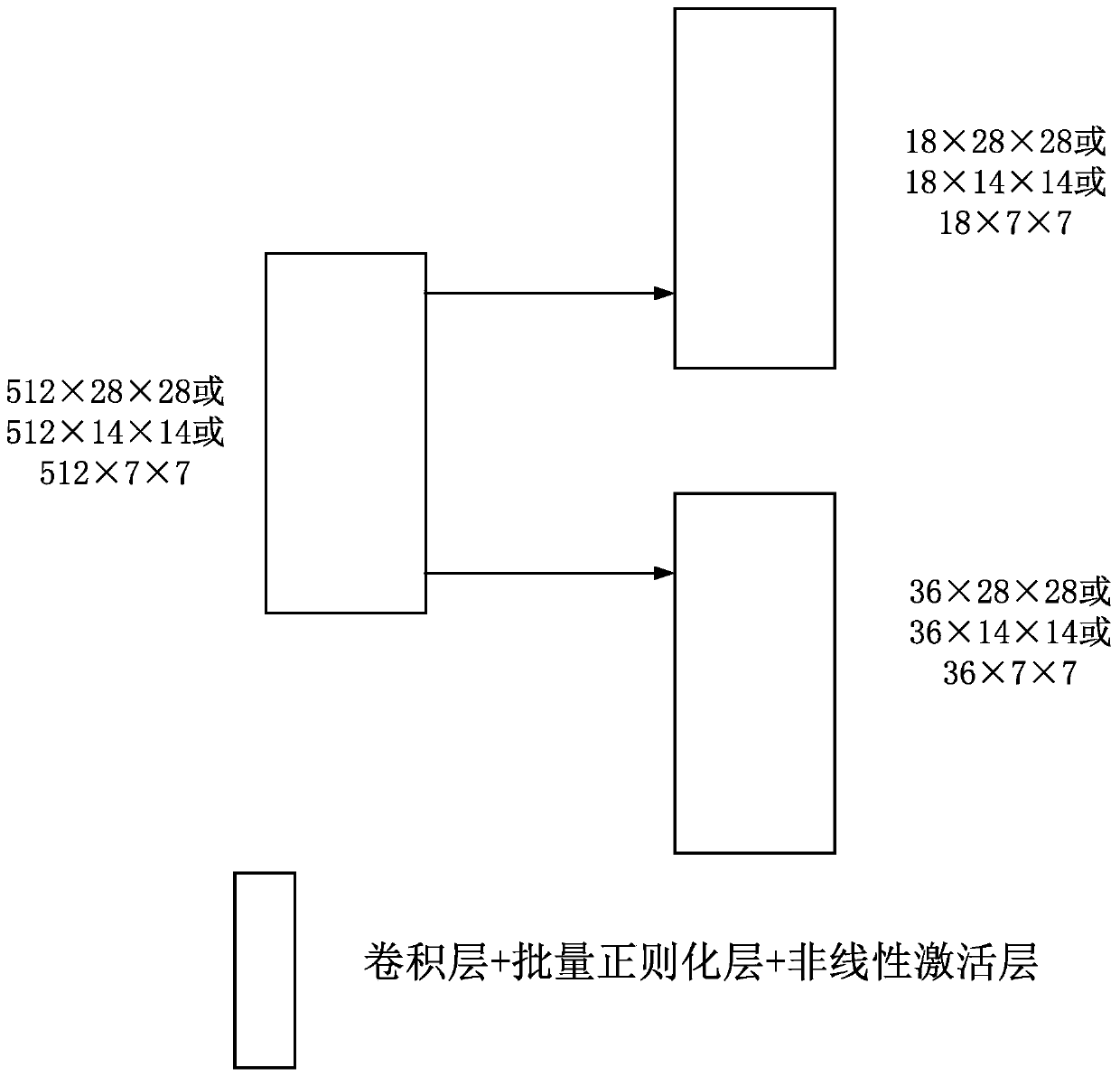

The invention discloses an unbalanced ship classification method based on a deep convolutional neural network. The method comprises the steps of 1) obtaining basic data; 2) carrying out data processing; 3) constructing a model; 4) defining a loss function; 5) training a model; 6) applying the model. According to the invention, fine classification of ships and solving of the problem of unbalanced category data distribution are combined; on the basis of extracting the global features of the ship, the local features with category discrimination of the ship are introduced, so that the model learnsdetails of the ship, and the classification result is more accurate; a memory network and a fusion learning network are used for storing and emphatically learning samples which are difficult to learn; the learning of the samples is improved while the new samples are learned, the effect of rebalancing the category data distribution is also achieved, and the adverse effect on model training causedby unbalanced category data distribution in an actual scene is effectively avoided.

Owner:SOUTH CHINA UNIV OF TECH

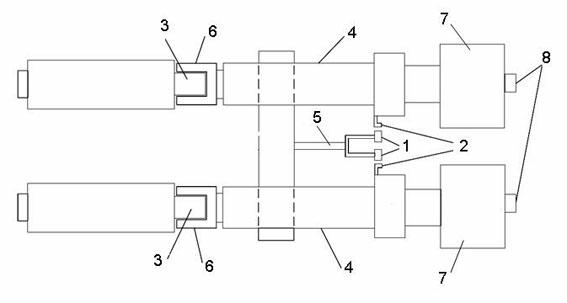

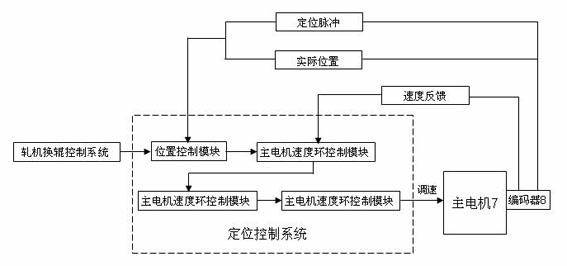

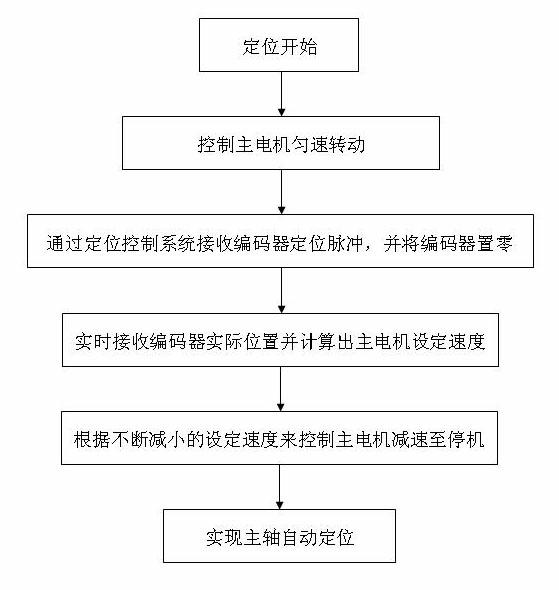

Method for automatically positioning main shaft during roller exchange of finishing mill

ActiveCN102463263ARealize automatic positioningAutomatic and accurate positioningMetal rolling stand detailsMetal rolling arrangementsDrive shaftControl engineering

The invention discloses a method for automatically positioning a main transmission shaft of a finishing mill. In the method, the control speed of a main motor is calculated by using a zero position pulse of an encoder of the main motor as a positioning pulse through the difference between an actual rotation position and a target rotation position of the encoder, so that the main motor is controlled in a deceleration manner to automatically position the main shaft; therefore, the main shaft can be automatically and accurately positioned, and the improvement on roller exchange operation efficiency of the finishing mill is facilitated.

Owner:BAOSHAN IRON & STEEL CO LTD

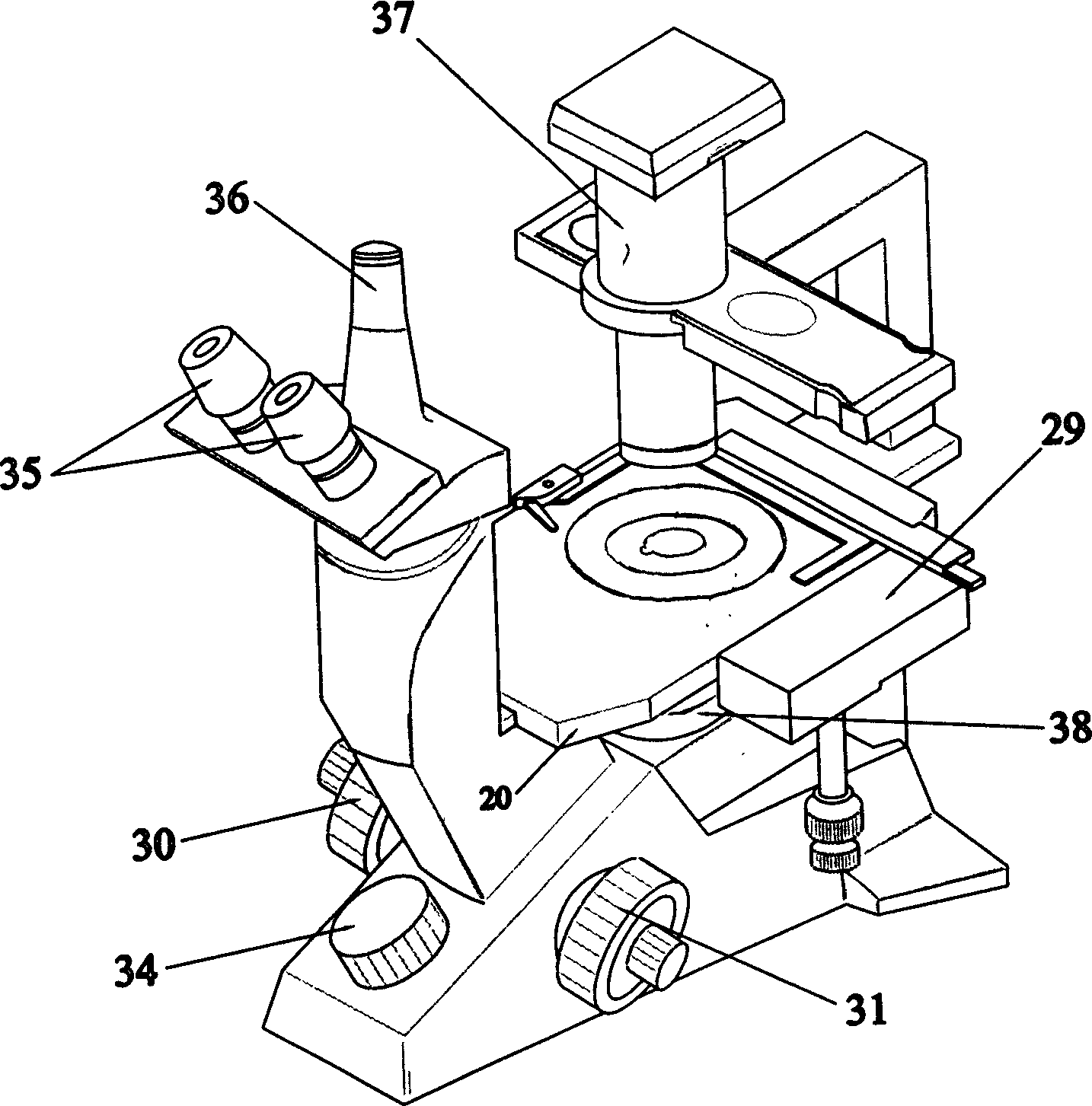

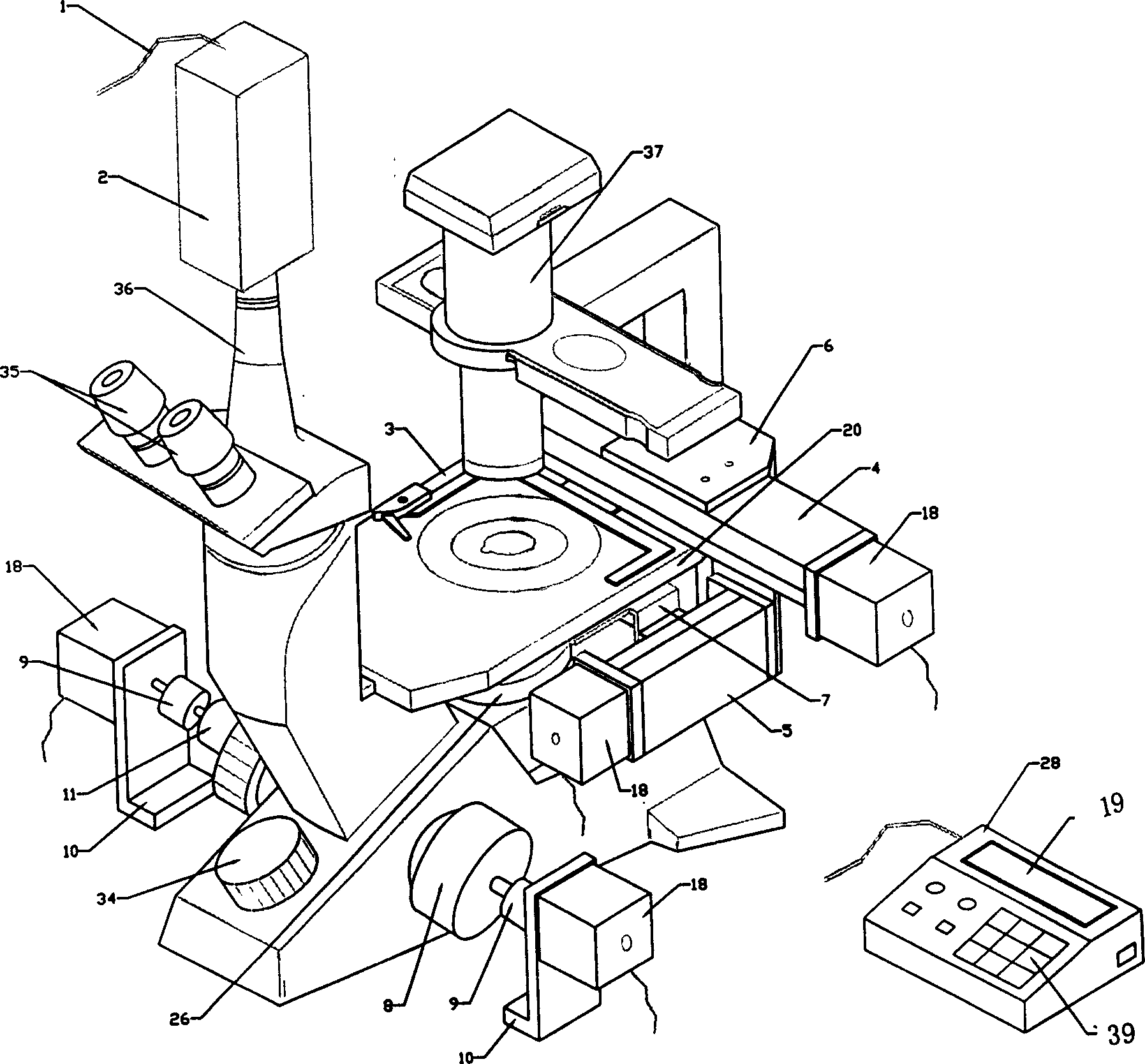

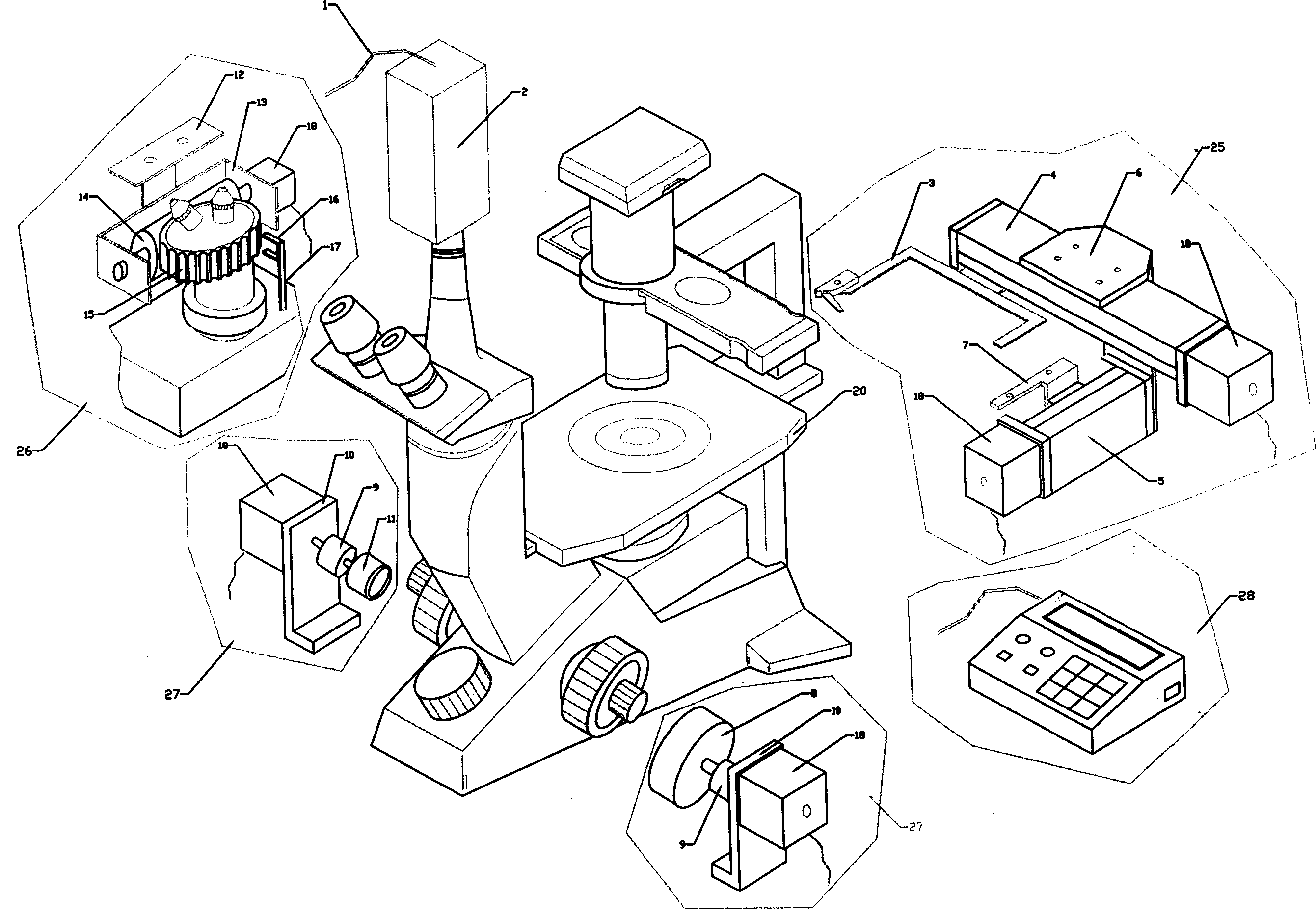

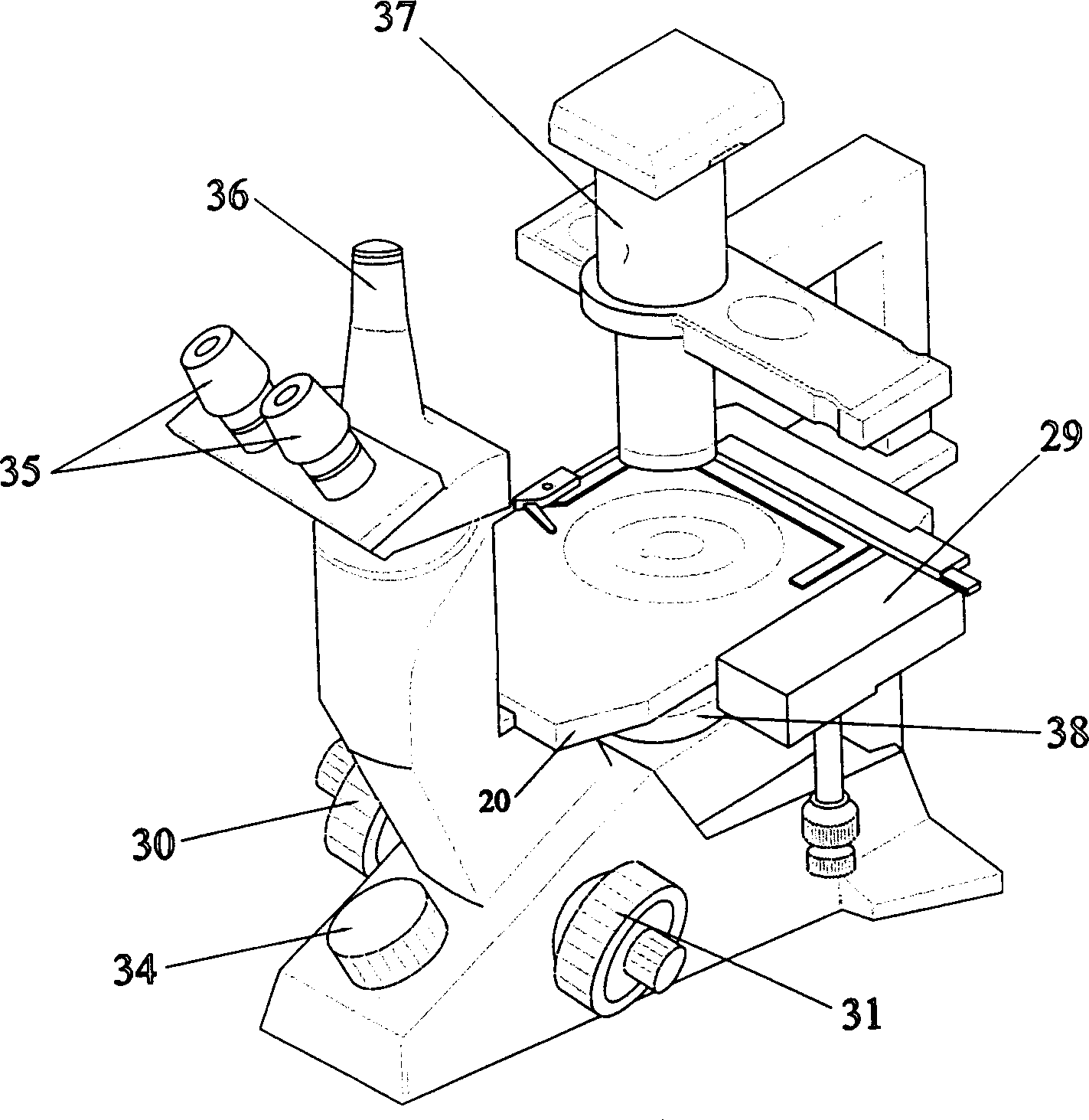

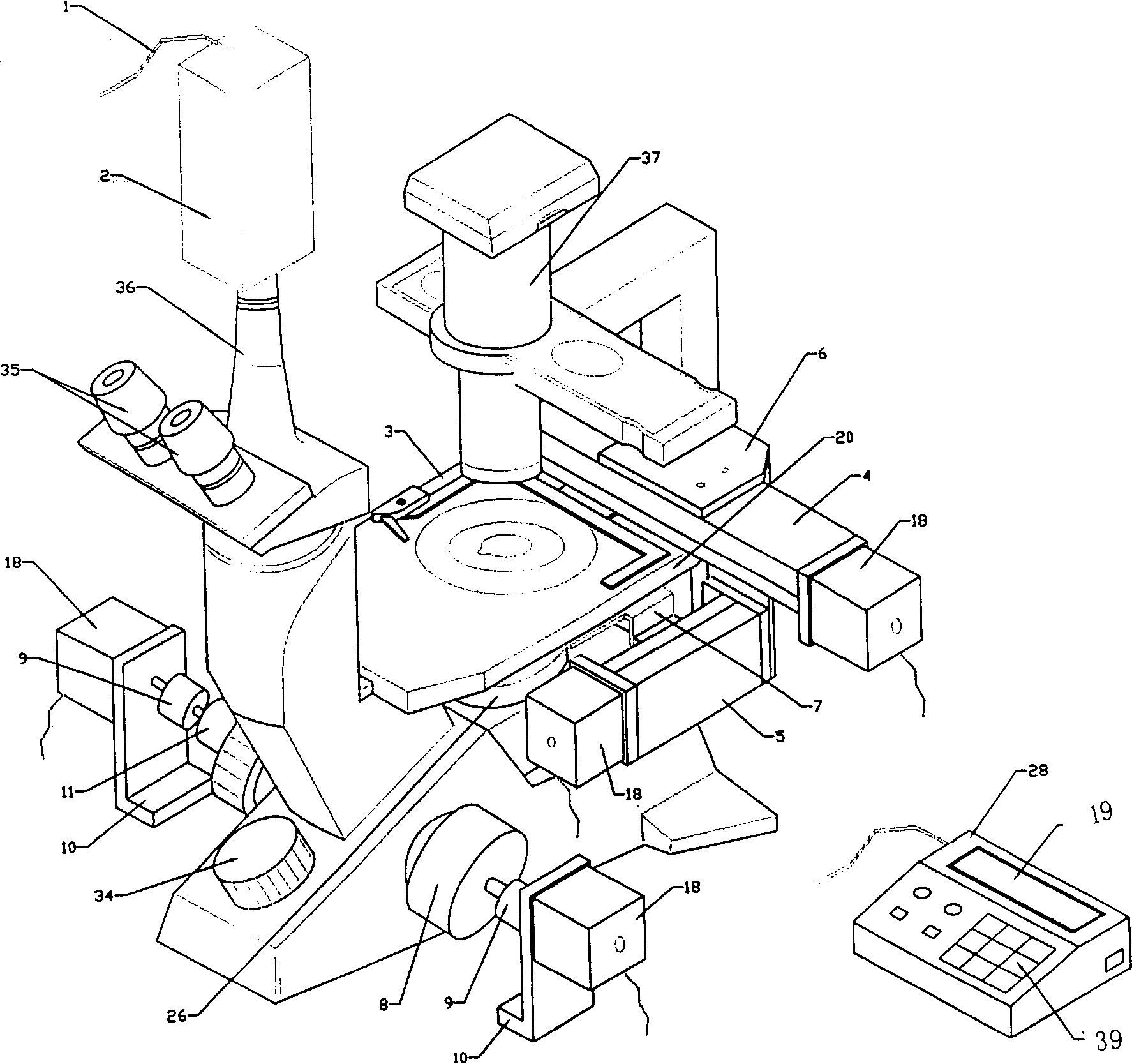

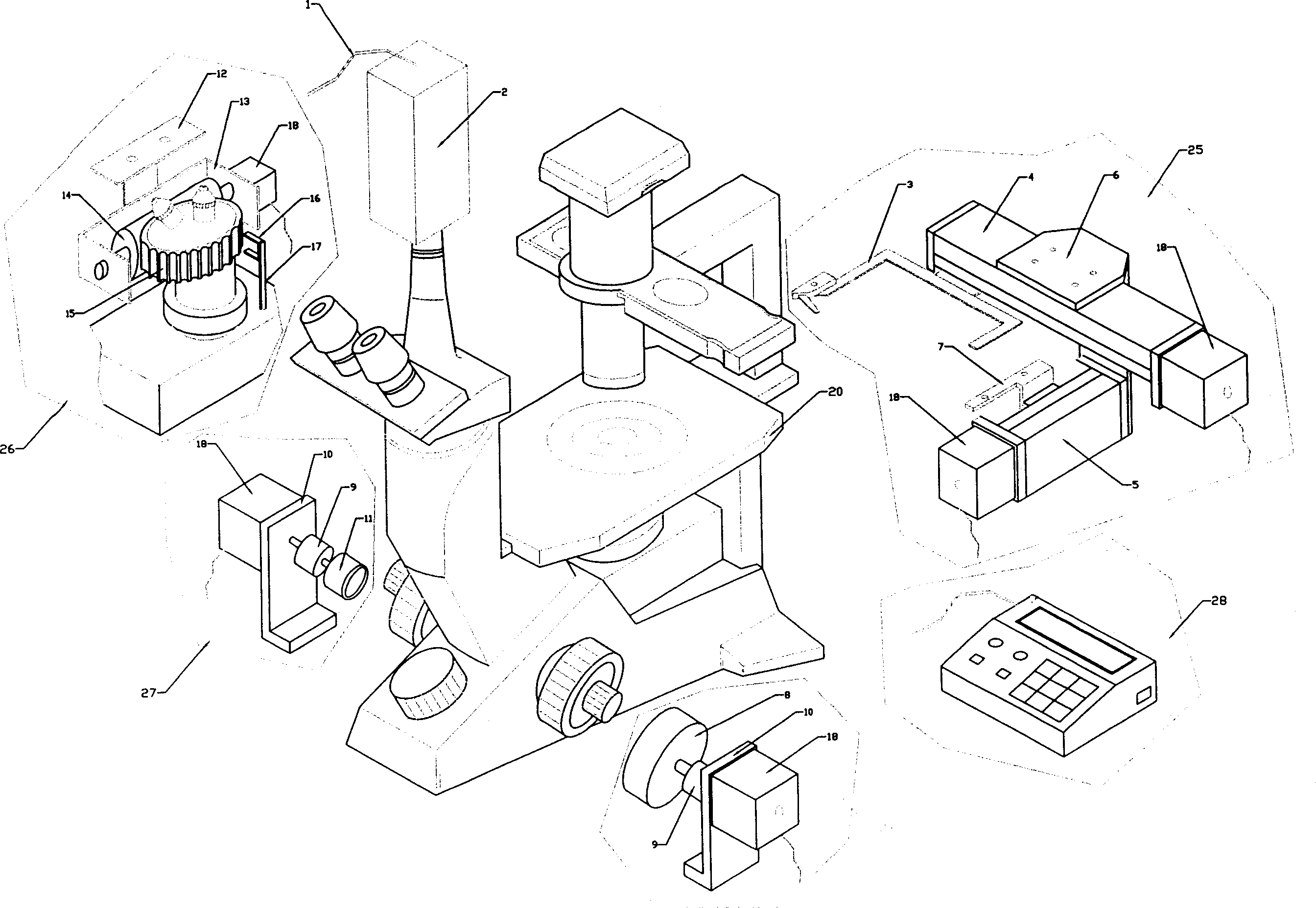

Microscope automatic operation system

InactiveCN1529194AMeet and exceed accuracy requirementsExceed the accuracy requirementTelevision system detailsColor television detailsMotor driveOperational system

The invention changes manual operation for microscope into automatic operation. The invention includes four parts: electrical driving specimen stage, electrical driving revolving nosepiece of object lens, electrical driving focusing mechanism and control box. Automatic operation system reconstructs the specimen stage, the revolving nosepiece, and the focusing mechanism, making observation operation under object lens be changed from traditional manual operation to automatic operation. The system through step motor drives each degree of freedom to reach accuracy control. Advantages of the system are automatic intelligent operation, features of fast, accuracy and intelligence, high observation efficiency, simple structure, reliable and high level of manufacturing production.

Owner:NANKAI UNIV

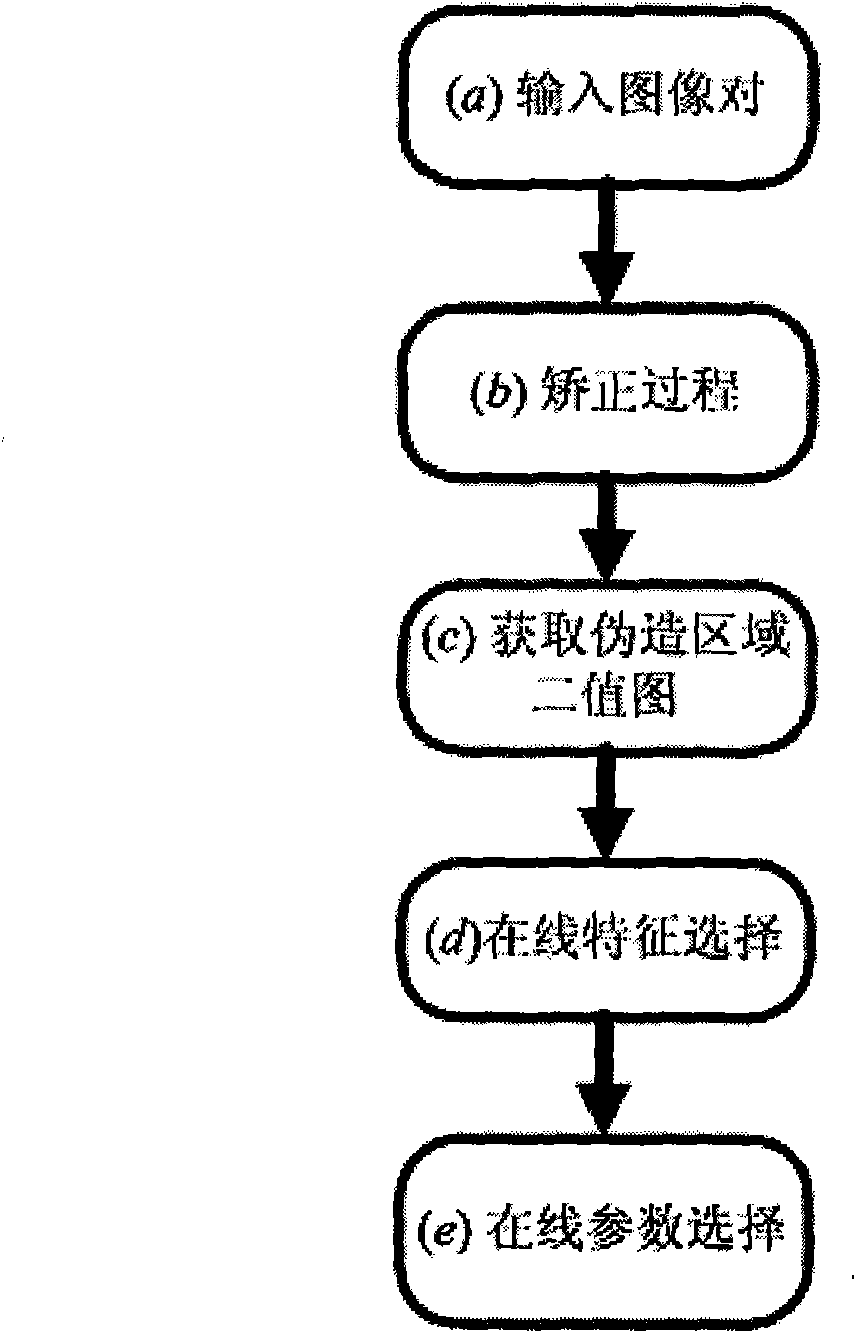

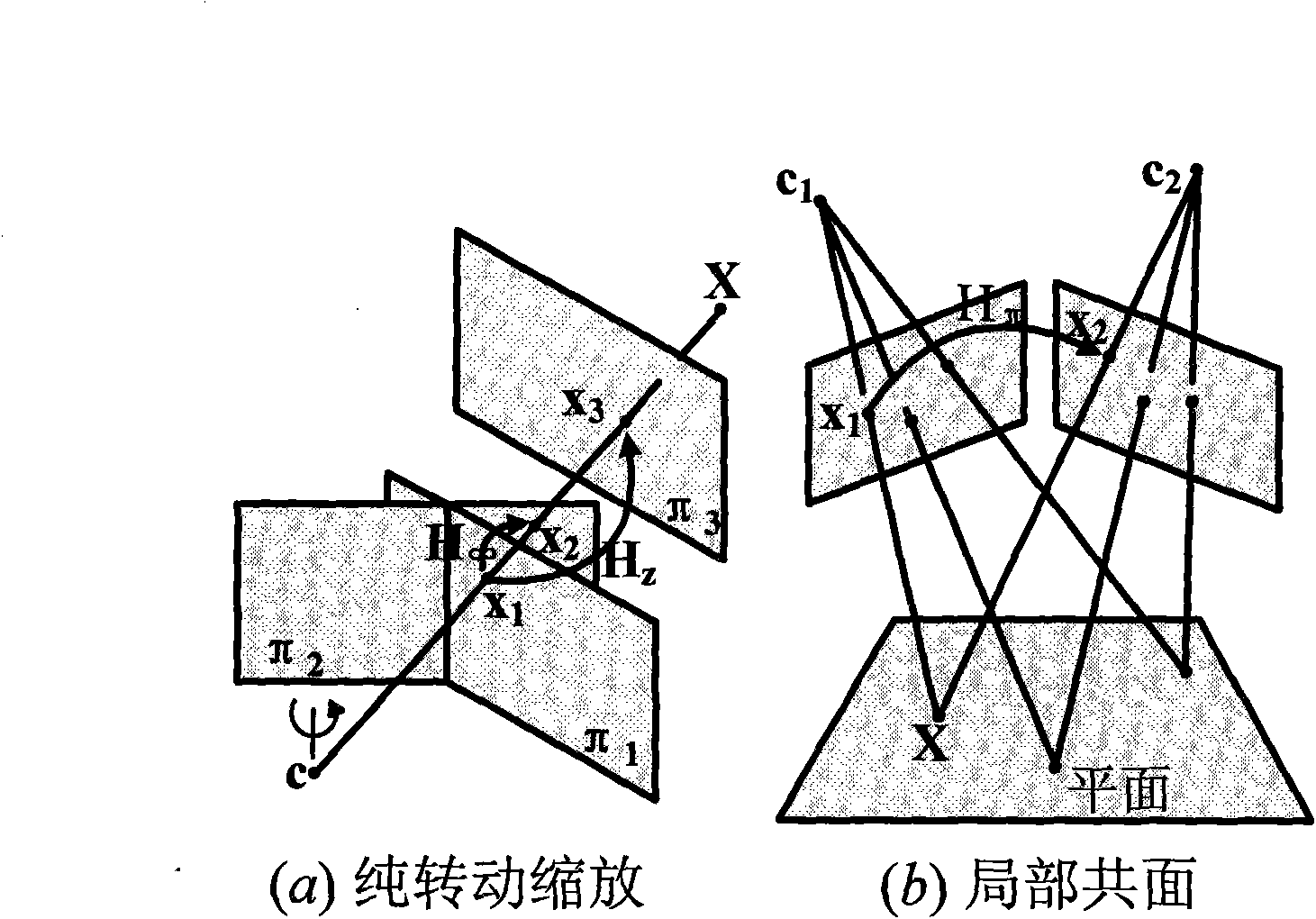

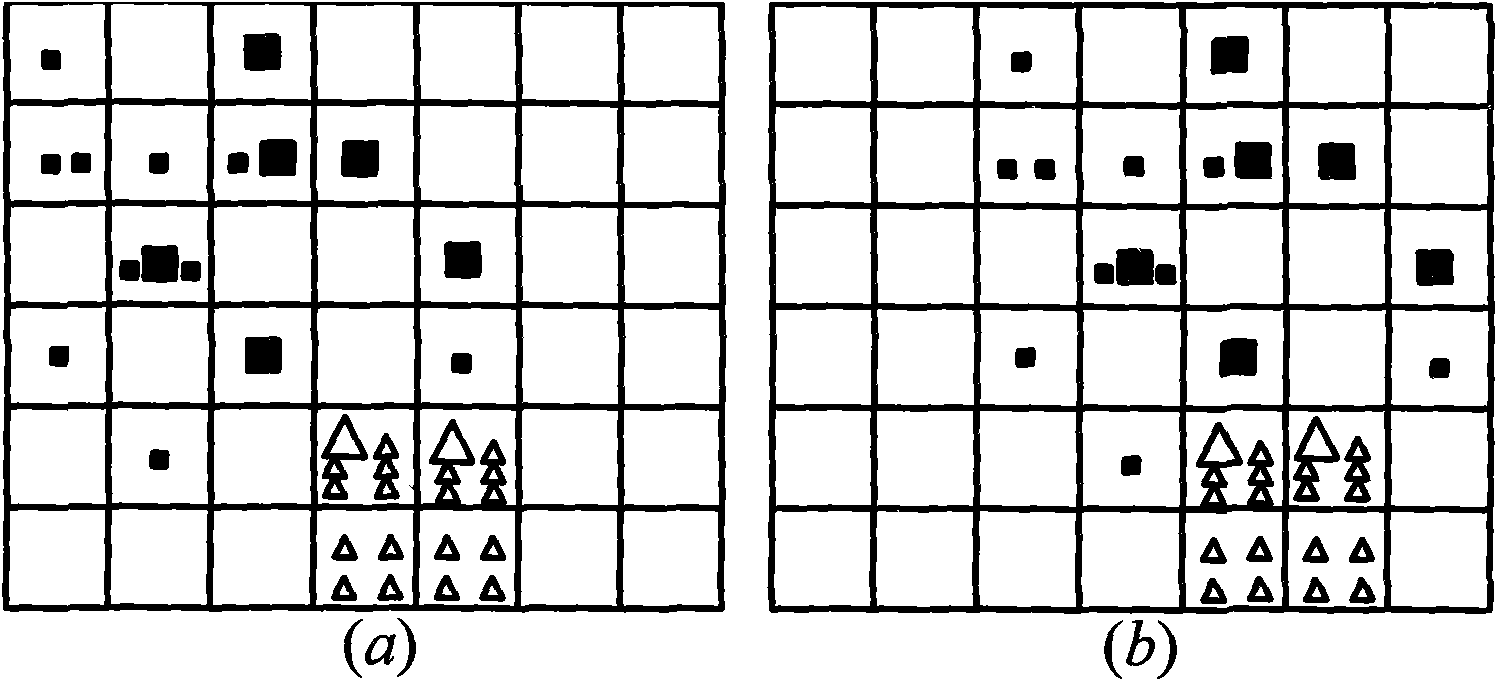

Method for positioning forged region based on two view geometry and image division

InactiveCN101630407AChoose accuratelyPrecise positioningImage analysisImaging processingDigital image

The invention belongs to the technical field of authenticity identification of digital image and image processing, relating to a method for precisely positioning a forged region based on two view geometry and image division. The method is on the basis of two-view geometry theory in camera imaging process, respectively uses strong geometric constraint (H constraint) and weak geometric constraint (F constraint) as feature constraints to accurately evaluate the authenticity of the image through online selection and map segmentation techniques. The invention can carry out identification when only a plurality of images with overlapped parts are found, thereby having very wide applicability.

Owner:TIANJIN UNIV

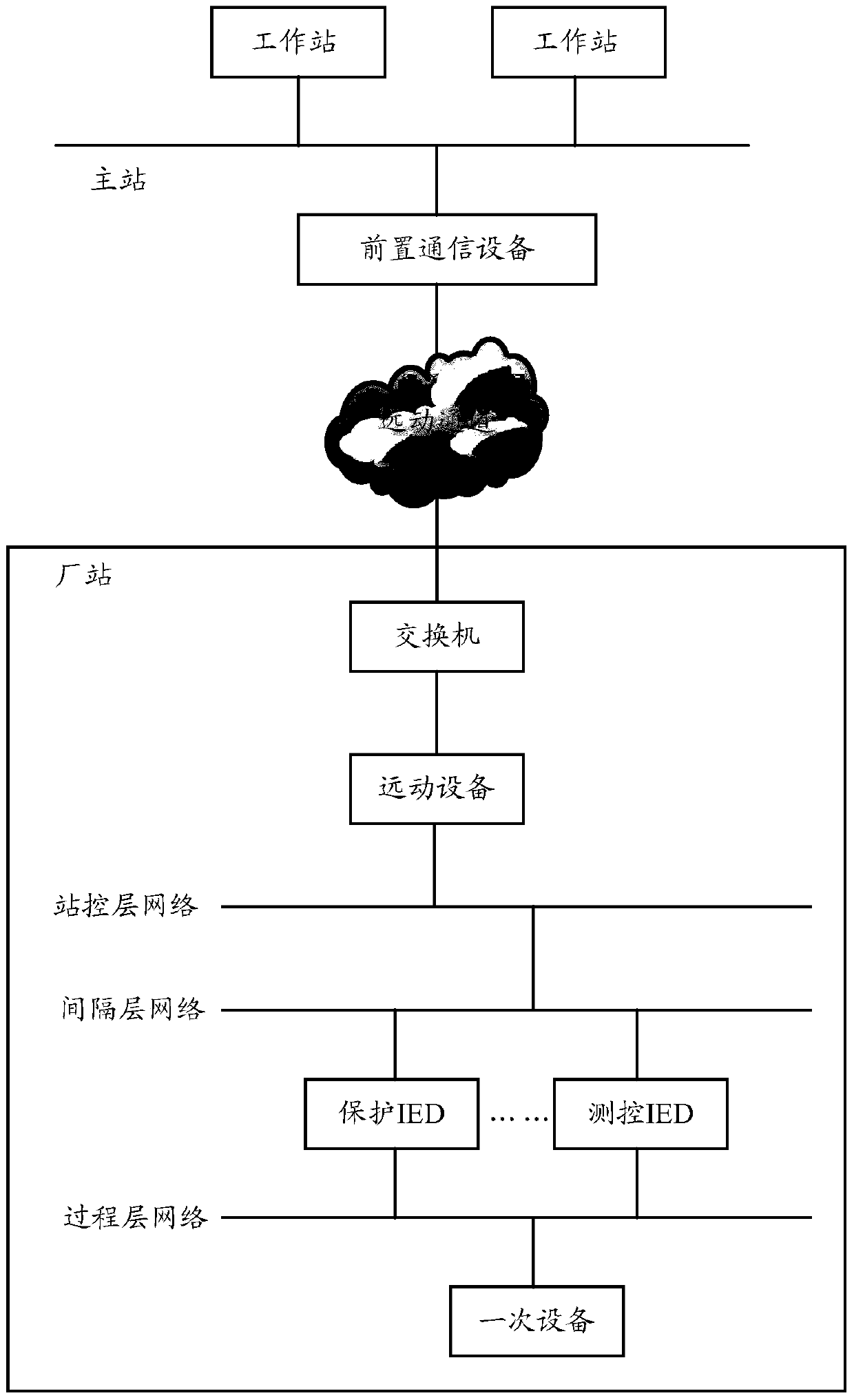

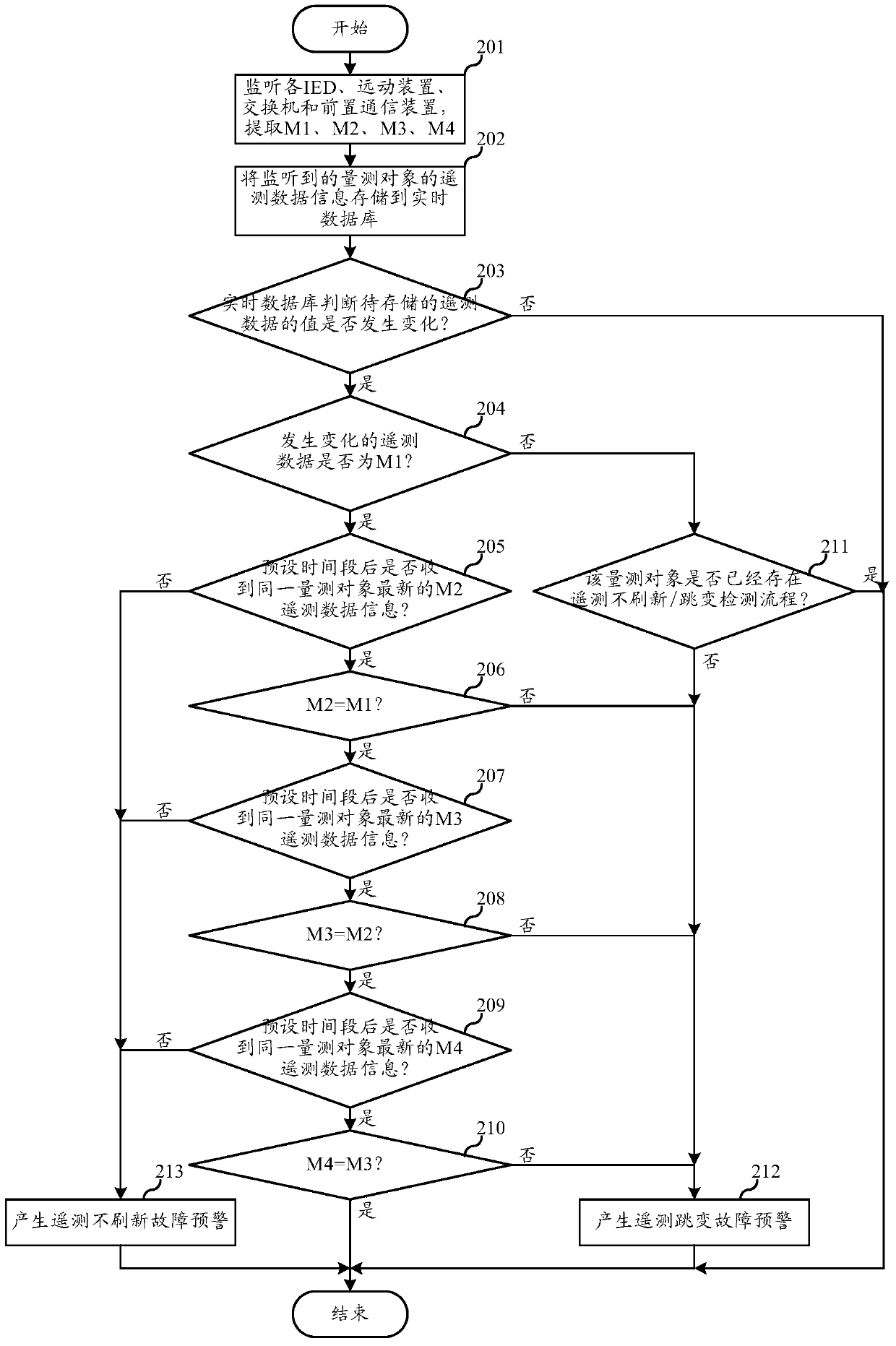

Method for automatically diagnosing telemeasuring data transmission failure of power grid energy manage system

ActiveCN104753173AAutomatic and accurate positioningReduce the burden onCircuit arrangementsInformation technology support systemMaster stationPower grid

The invention discloses a method for automatically diagnosing telemeasuring data transmission failure of a power grid energy manage system (EMS). The method comprises the steps: through monitoring each protecting / measuring intelligent electronic device (IED) of a factory station, telecontrol equipment, an exchanger and a pre-communicator of a master station in real time, after monitoring that the telemetering data value is changed, triggering the telemetering non-refreshing / jumping detection flow, detecting whether the telemetering data M2 at the telecontrol equipment side, the telemetering data M3 at the exchanger side, and the telemetering data M4 at the master station pre-communicator side of the same measuring object are normally obtained after receiving the telemetering data M1 at the IED side, and judging whether the values of the M1, M2, M3 and M4 are the same; according to the monitoring result, generating the telemetering non-refreshing / jumping pre-warning of the corresponding device; and discovering the existent telemetering non-refreshing and jumping situations in the EMS system in first time, and automatically accurately positioning the non-refreshing or jumping node. The transmission accuracy of the measuring information in the power grid EMS is ensured, and the load of the operator is greatly relieved.

Owner:ASAT CHINA TECH

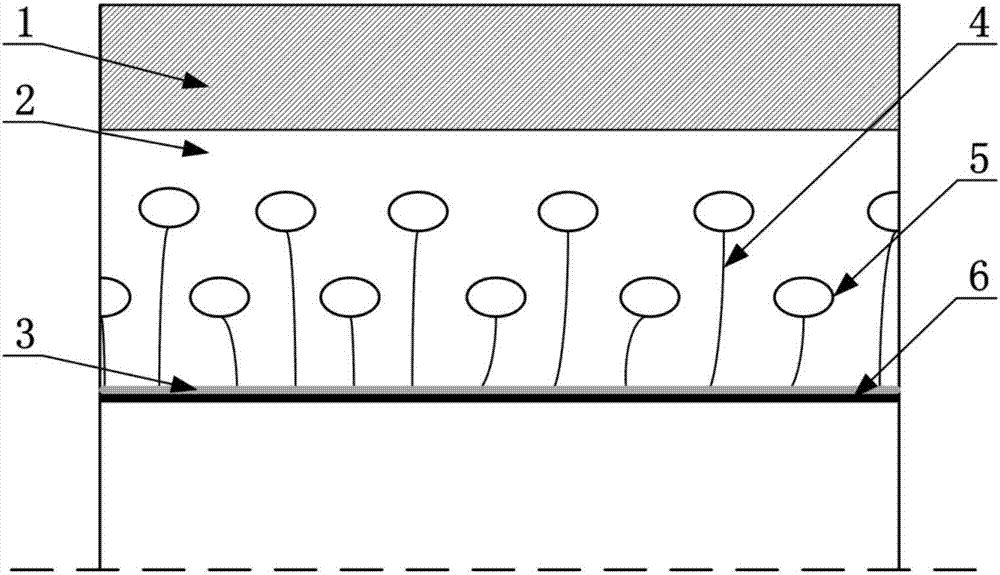

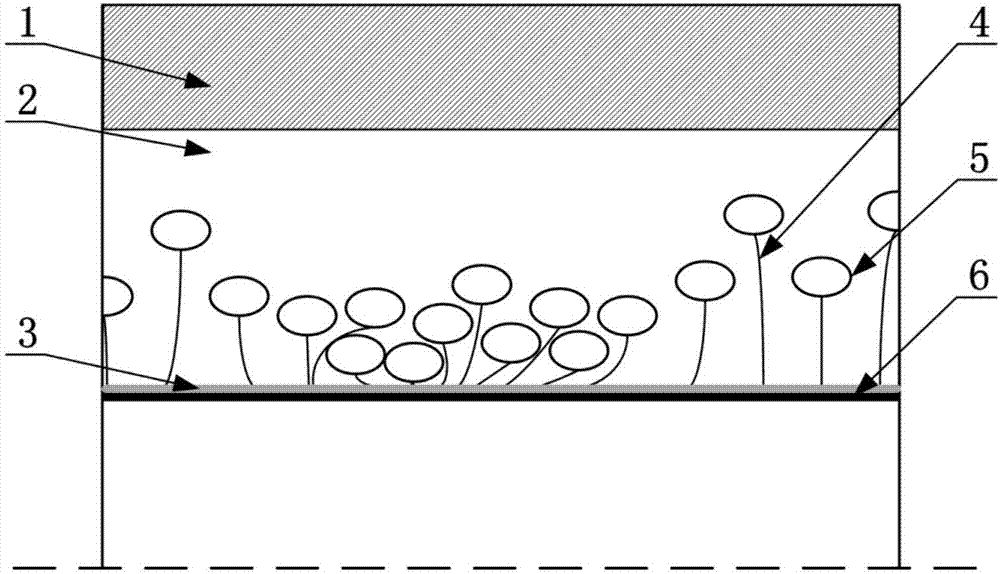

Clod/hot two-way protecting device and method for steam and pipeline

ActiveCN106885089AAvoid corrosionStable temperaturePipe heating/coolingSteam condensationThermal insulation

The invention discloses a clod / hot two-way protecting device and a clod / hot two-way protecting method for steam and a pipeline. The clod / hot two-way protecting device is applied to the technical field of pipeline transport and condensation and overheating prevention. The clod / hot two-way protecting device comprises a thermal insulation material layer, a phase-change material layer, a memory alloy layer, memory alloy wires and phase-change material capsules. The influence on the pipeline and the steam from an outer circumstance temperature is reduced by employing the thermal insulation material layer; the temperatures of the pipeline and the steam are kept unchanged in a low temperature environment for a long time by employing solidification heat release of the phase-change material layer, and the pipeline is prevented from being corroded by steam condensation; and an overheating phenomenon is avoided since a memory alloy net attached to the outer wall of the pipeline and the phase-change material capsules connected with the memory alloy net via the memory alloy wires undergo shrinkage deformation, the phase-change material capsules are pulled to be enriched in a heating zone, heat transfer of the heating zone is strengthened and heat is absorbed in a large amount rapidly. The steam is effectively prevented from condensing and overheating, and the problem that a steam working condition is not stable is solved.

Owner:ZHEJIANG UNIV

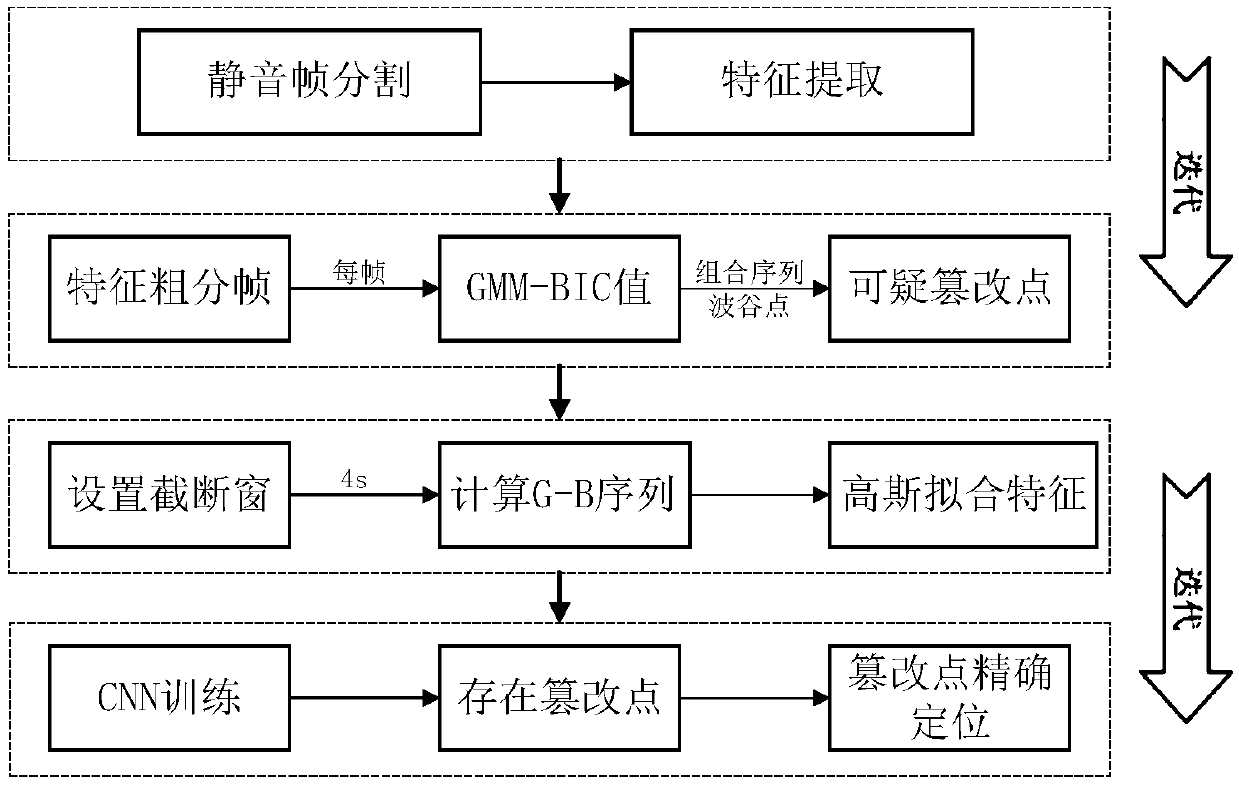

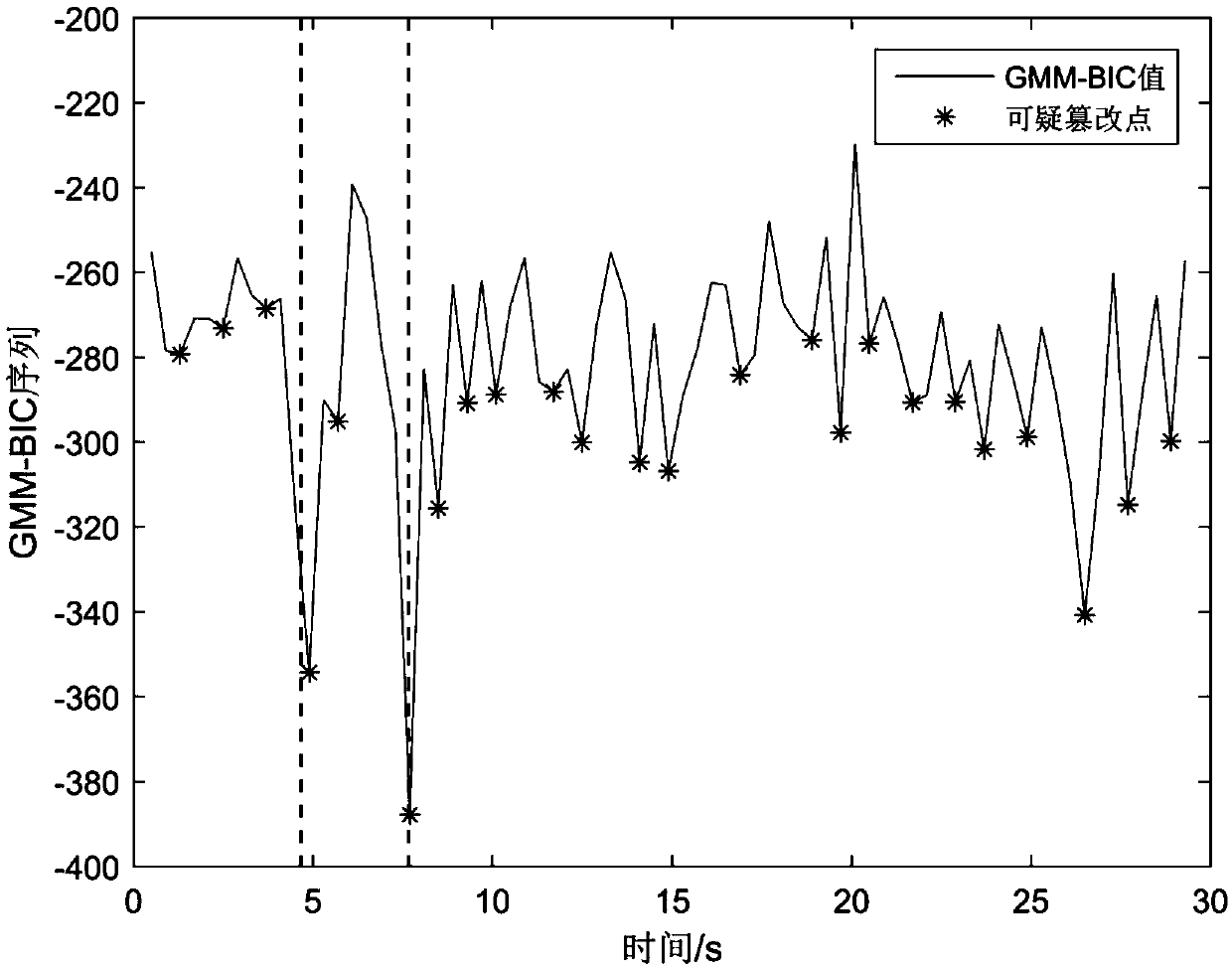

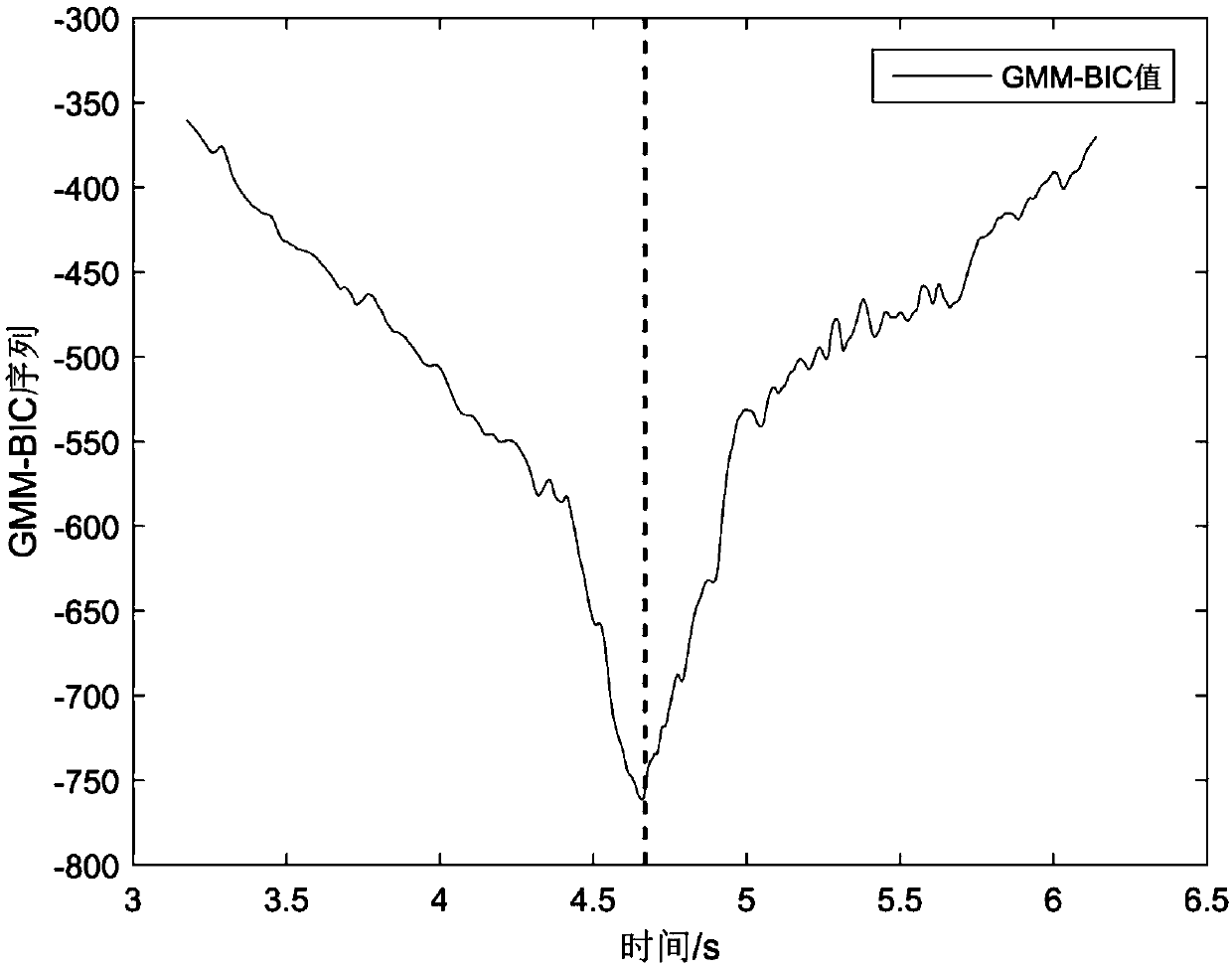

Digital audio tampered point detection method and system based on GMM-BIC

ActiveCN108831506AAutomatic and accurate positioningImprove detection accuracySpeech recognitionDigital audio signalsSpeech sound

The invention belongs to the technical field of digital audio signal processing, and discloses a digital audio tampered point detection method and system based on GMM-BIC. The method and system use aGMM-BIC method for digital audio tampered point detection instead of a traditional SGM-BIC method. In virtue of the characteristics of the GMM, the method and system can represent more information, and have a good representation effect on both long and short voice segments. A neural network is configured to classify fitted features to obtain a better classification effect. The method and system can automatically position the digital audio tampered points, have good adaptability, have good robustness to tampering operations of splicing close tampered points and concealing the tampered points byusing various noises, and provide a universal algorithm for the accuracy and the automation of digital audio tampered point detection.

Owner:HUAZHONG NORMAL UNIV

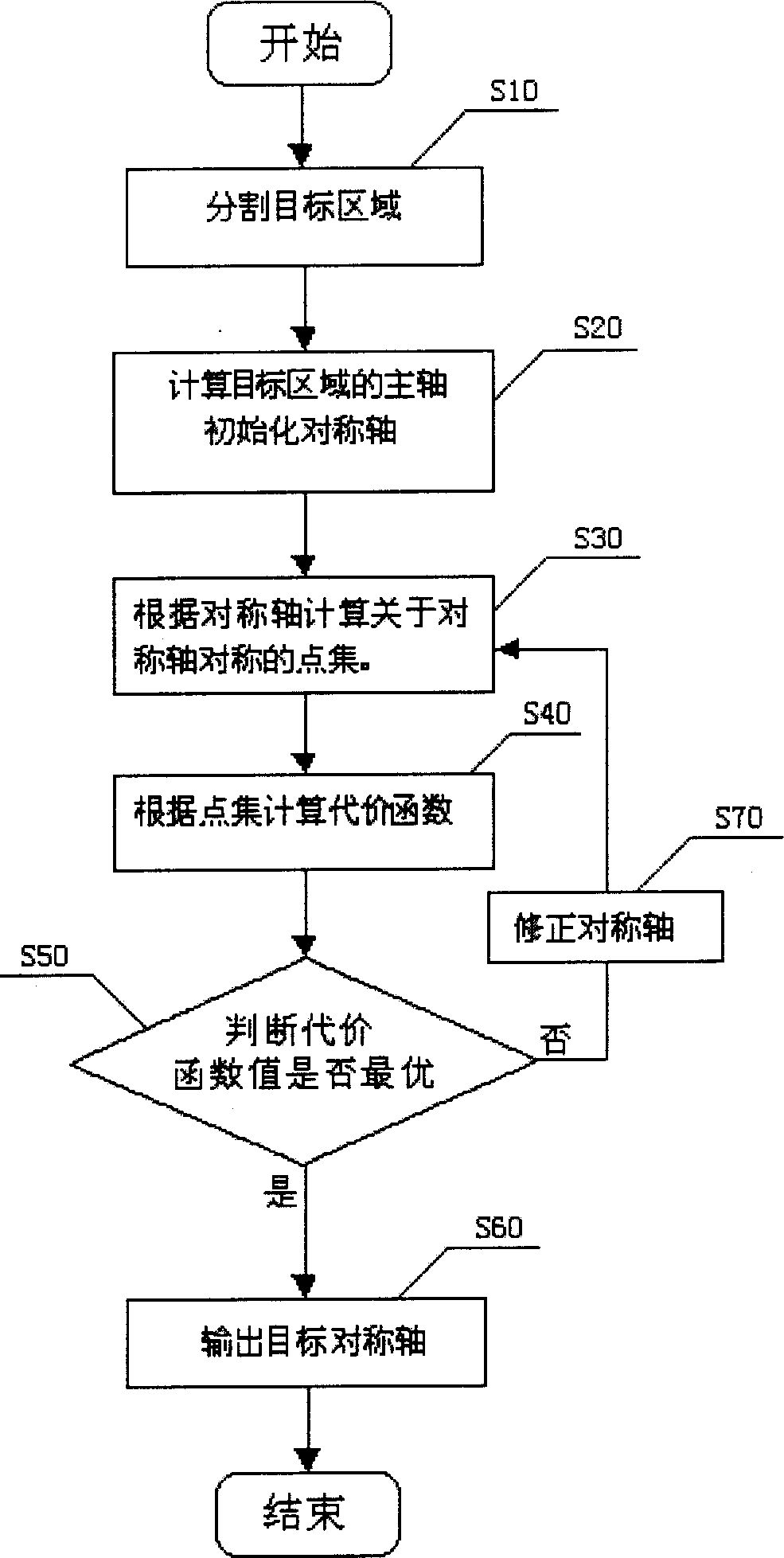

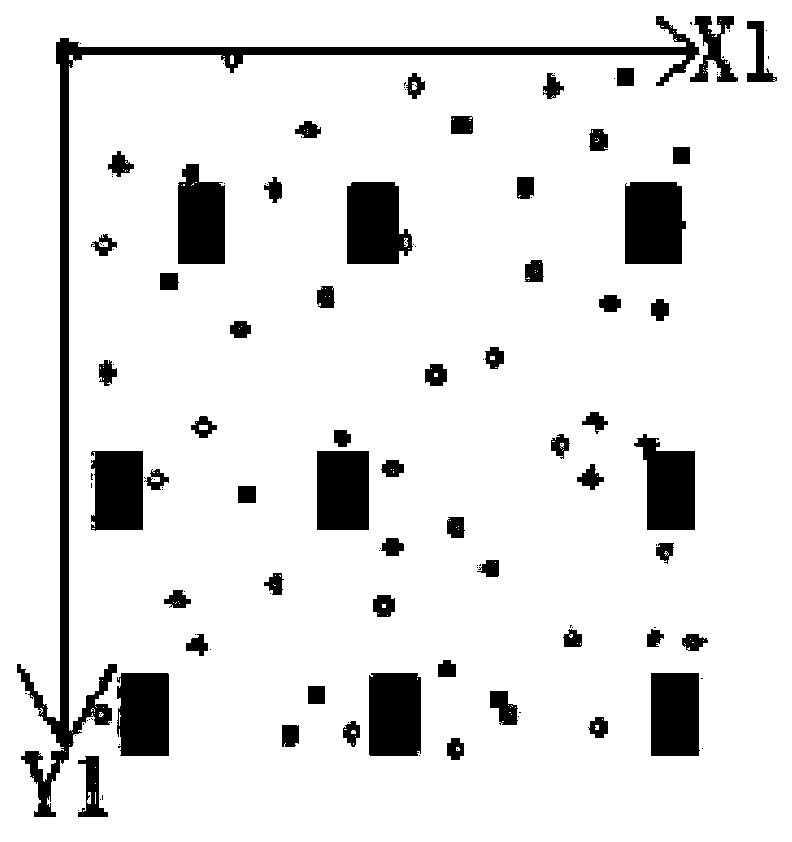

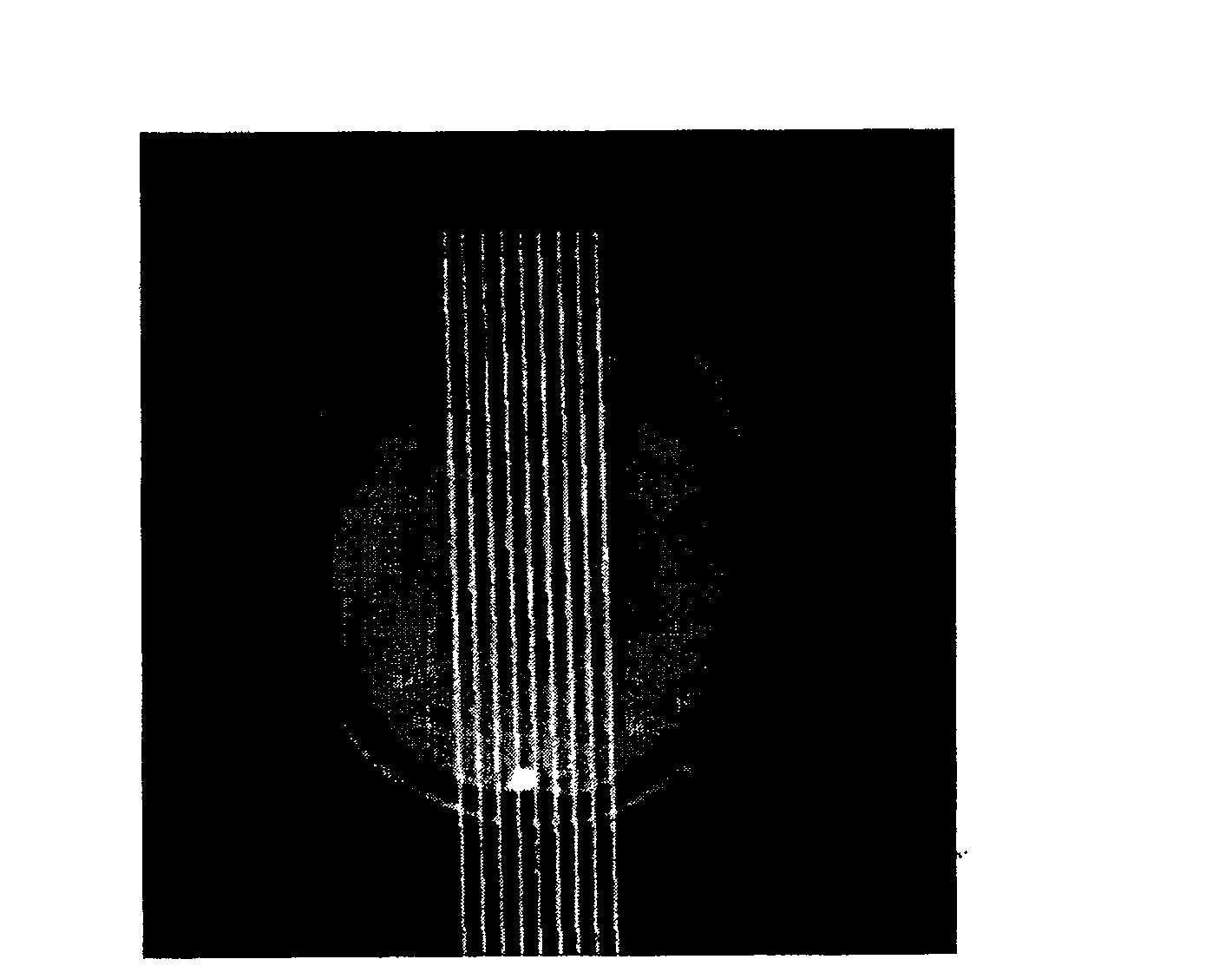

Magnetic resonance image scanning automatic positioning method based on human anatomic structure symmetry

ActiveCN1843295AAutomatic and accurate positioningMeet clinical positioning needsSurgeryMagnetic property measurementsStructural symmetryResonance

The invention discloses a method of automatic location for magnetic resonance imaging scanning based on the symmetry of dissect structure of human body. It comprises following steps: (a) getting MRT location image; (b) calculating location information of different position on MRT location image by using the symmetry of dissect structure of human body; (c) outputting location information of MRT location image; and step (b) also comprises steps: (1) dividing target zone on whole image; (2) initiating symmetrical axis of target zone; (3) calculating the point set of said target zone symmetry with said symmetrical axis; (4) defining price function according to said point set, and getting optimum value of price function through optimization; (5) getting the symmetrical axis used as location information in relative with said optimum value. The invention realizes automatic location of MRT scanning, guarantees uniformity of fault scanning image and increases location accuracy and work efficiency.

Owner:NEUSOFT MEDICAL SYST CO LTD

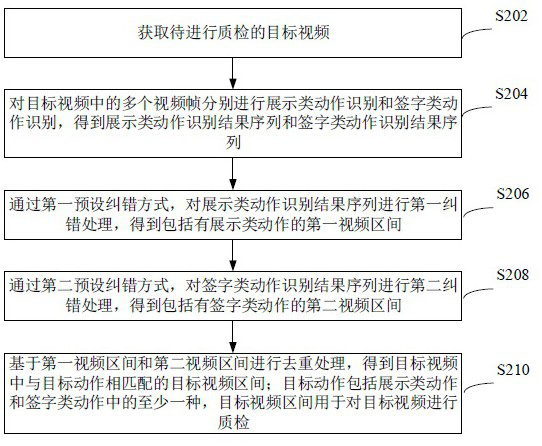

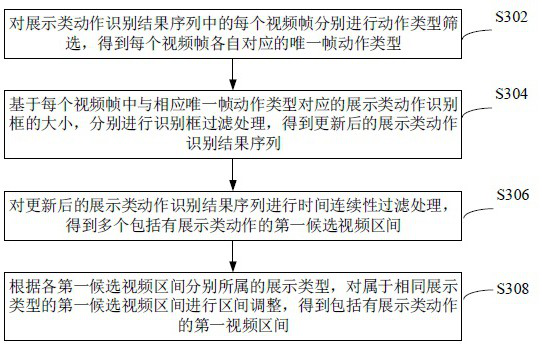

Video processing method and device, computer equipment and storage medium

ActiveCN112016538AImprove quality inspection efficiencyAutomatic and accurate positioningCharacter and pattern recognitionComputer graphics (images)Video processing

The invention relates to a video processing method and device, computer equipment and a storage medium. The method comprises the following steps: acquiring a target video to be subjected to quality inspection; performing display type action recognition and signature type action recognition on a plurality of video frames in the target video to obtain a display type action recognition result sequence and a signature type action recognition result sequence; performing first error correction processing on the display type action recognition result sequence through a first preset error correction mode to obtain a first video interval including display type action; performing second error correction processing on the signature type action recognition result sequence through a second preset errorcorrection mode to obtain a second video interval including signature type actions; and performing deduplication processing based on the first video interval and the second video interval to obtain atarget video interval matched with the target action in the target video. The method can be realized through cloud computer equipment. By adopting the method, the video quality inspection efficiencycan be improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

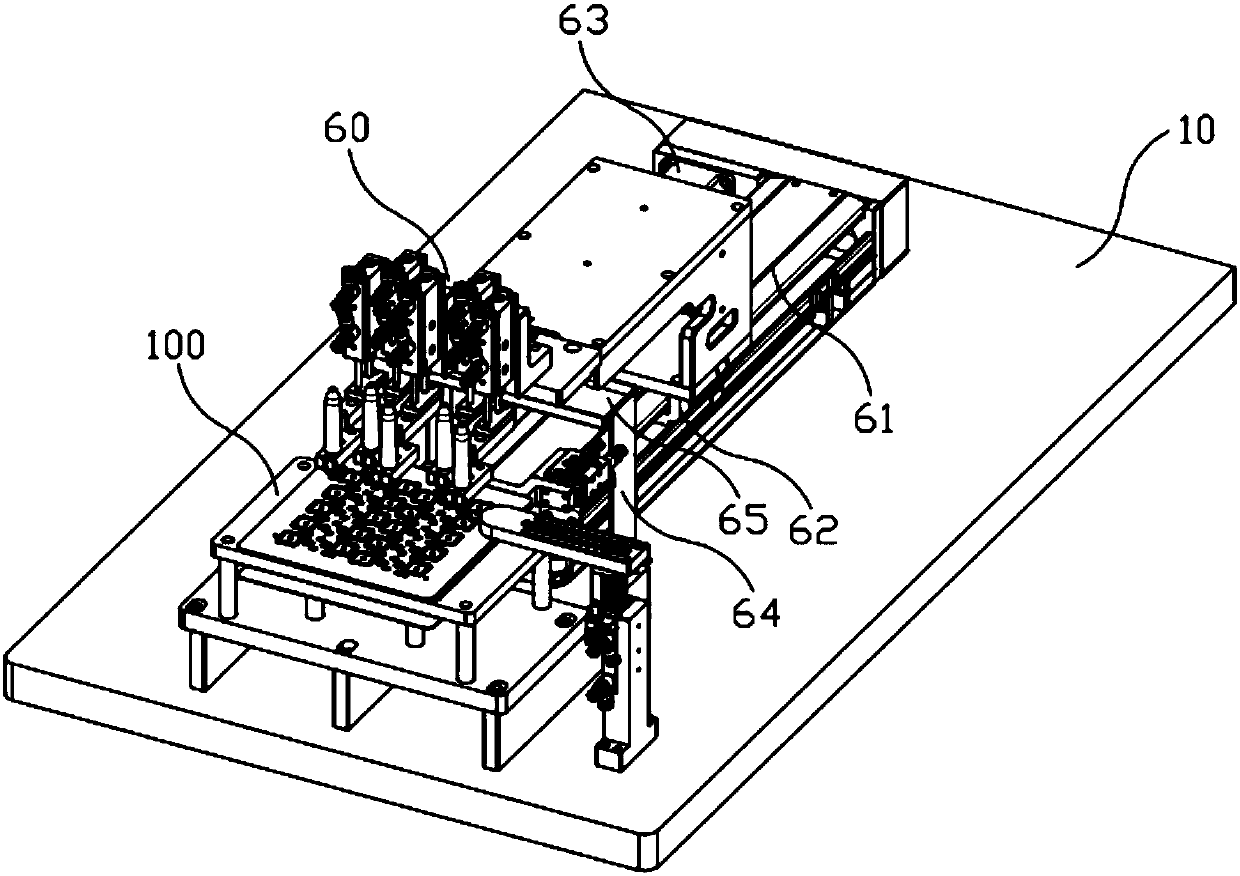

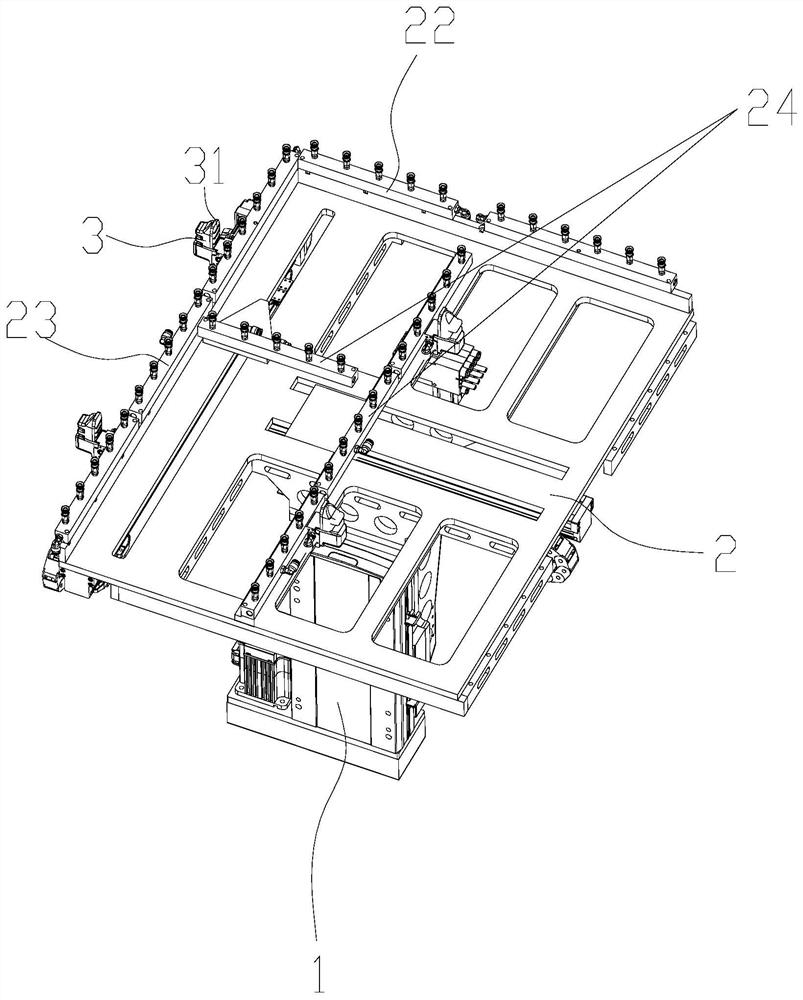

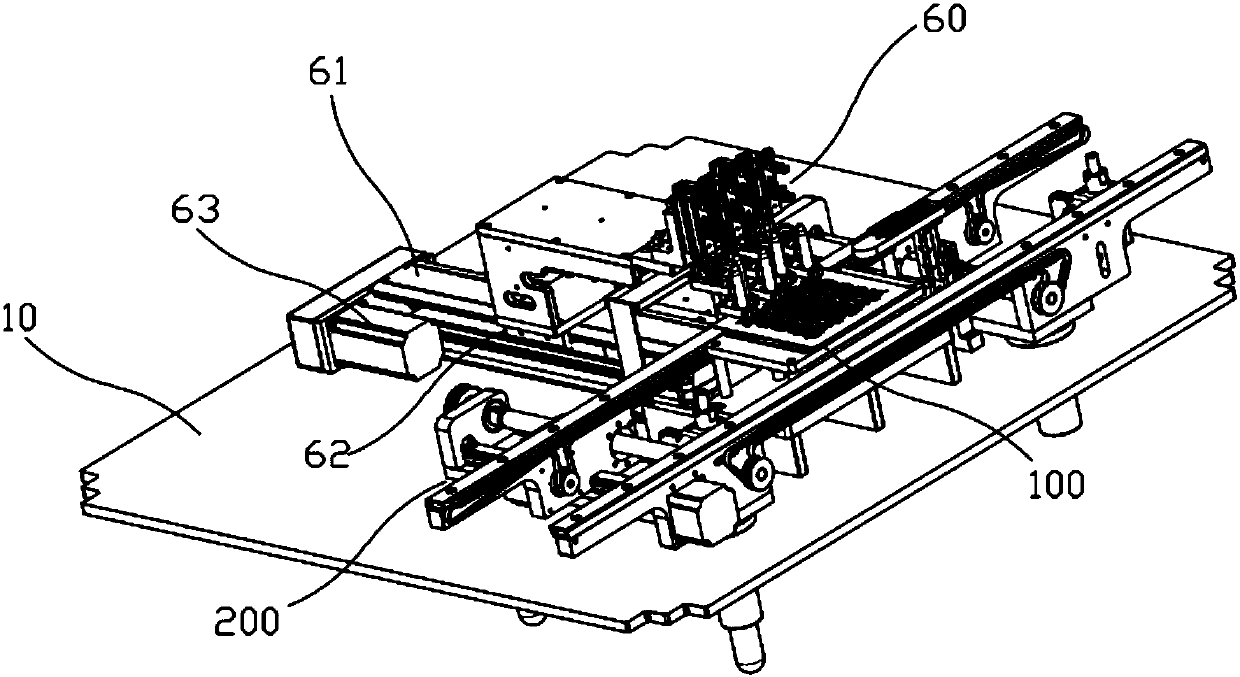

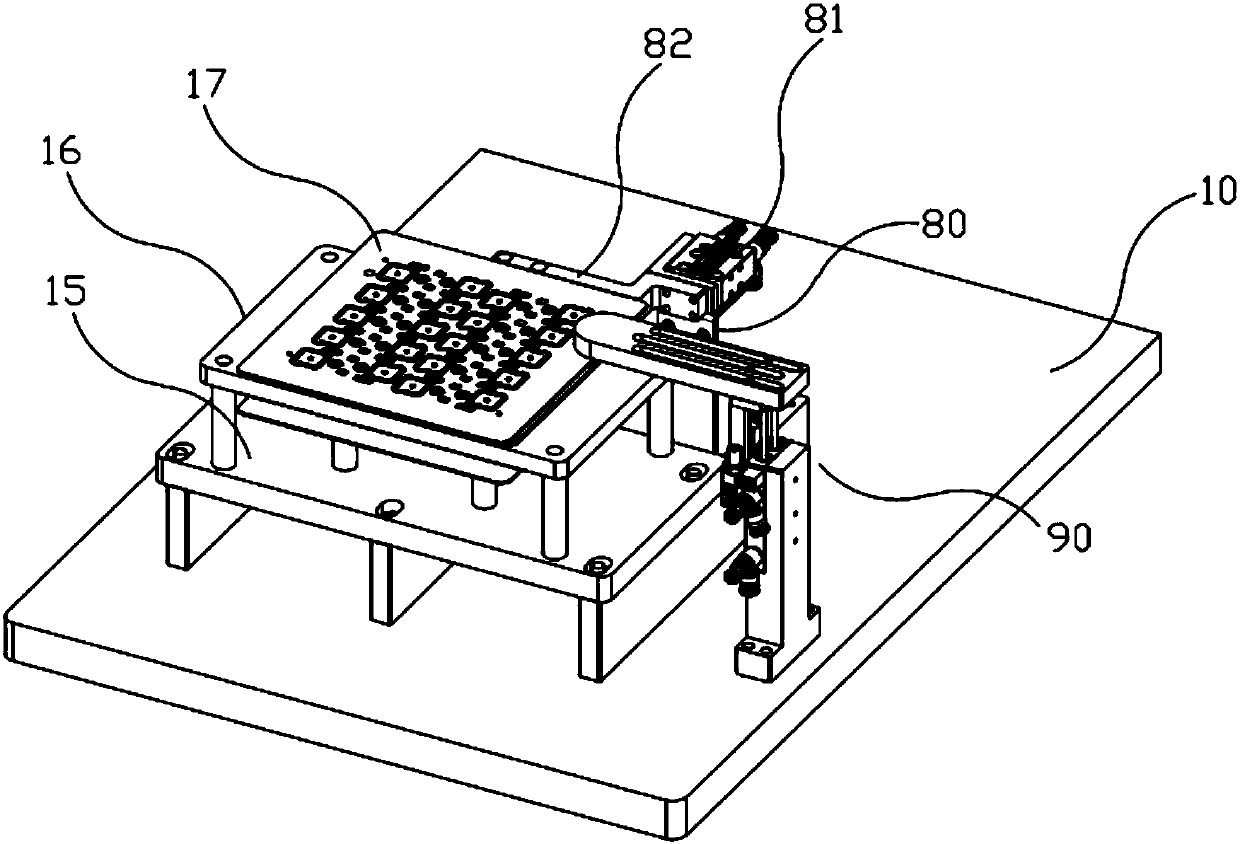

Fingerprint module group testing platform

PendingCN107680196ALabor savingImprove detection efficiencyRegistering/indicating quality control systemsElectrical testingFingerprint detectionFingerprint

The invention discloses a fingerprint module group testing platform. Through a mode of material pushing and material blocking, when an entire fingerprint module group is transferred to a positioning bench, continuous and forward conveying of the entire fingerprint module group can be blocked at a front end through a baffle plate, and the entire fingerprint module group is pushed to a position corresponding to a probe base plate by a push plate at a side edge, so that the fingerprint module group can be accurately positioned; when certain or several fingerprint module groups can be detected asdefective products, a motor is turned on, the cylinders are driven to move above the entire fingerprint module group, the cylinder over the defective products is turned on, a marking pen head is driven for marking the corresponding fingerprint module group, then the cylinder drives the marking pen head for collapsing, the motor drives the cylinders for returning, so that the adverse fingerprint module group can be automatically marked, manual work is saved, and the detection efficiency of the fingerprint module group is increased.

Owner:JIANGSU A KERR BIOLOGICAL RECOGNITION TECH CO LTD

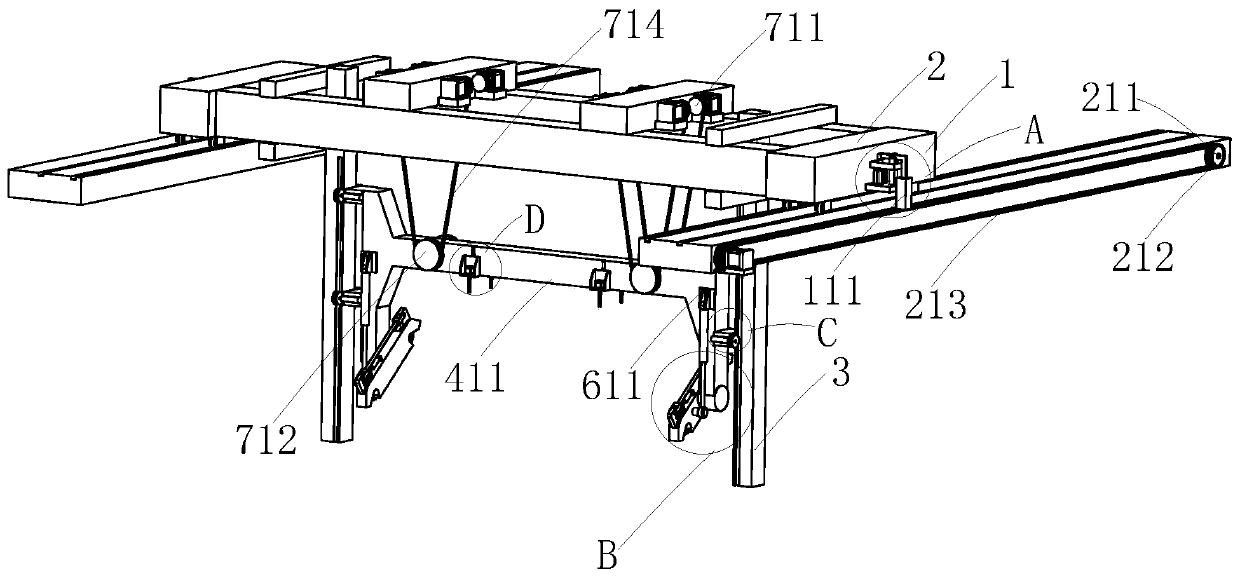

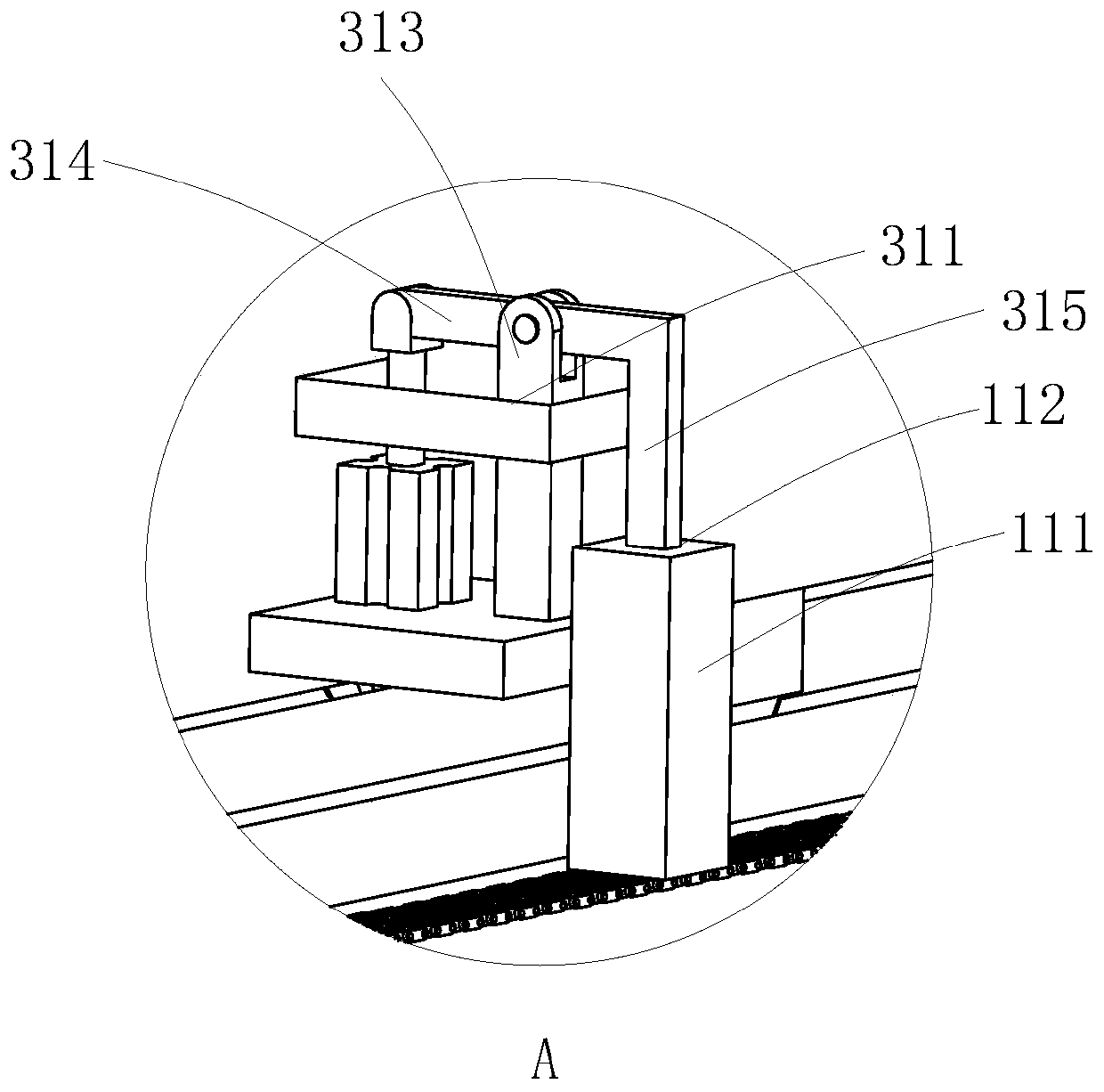

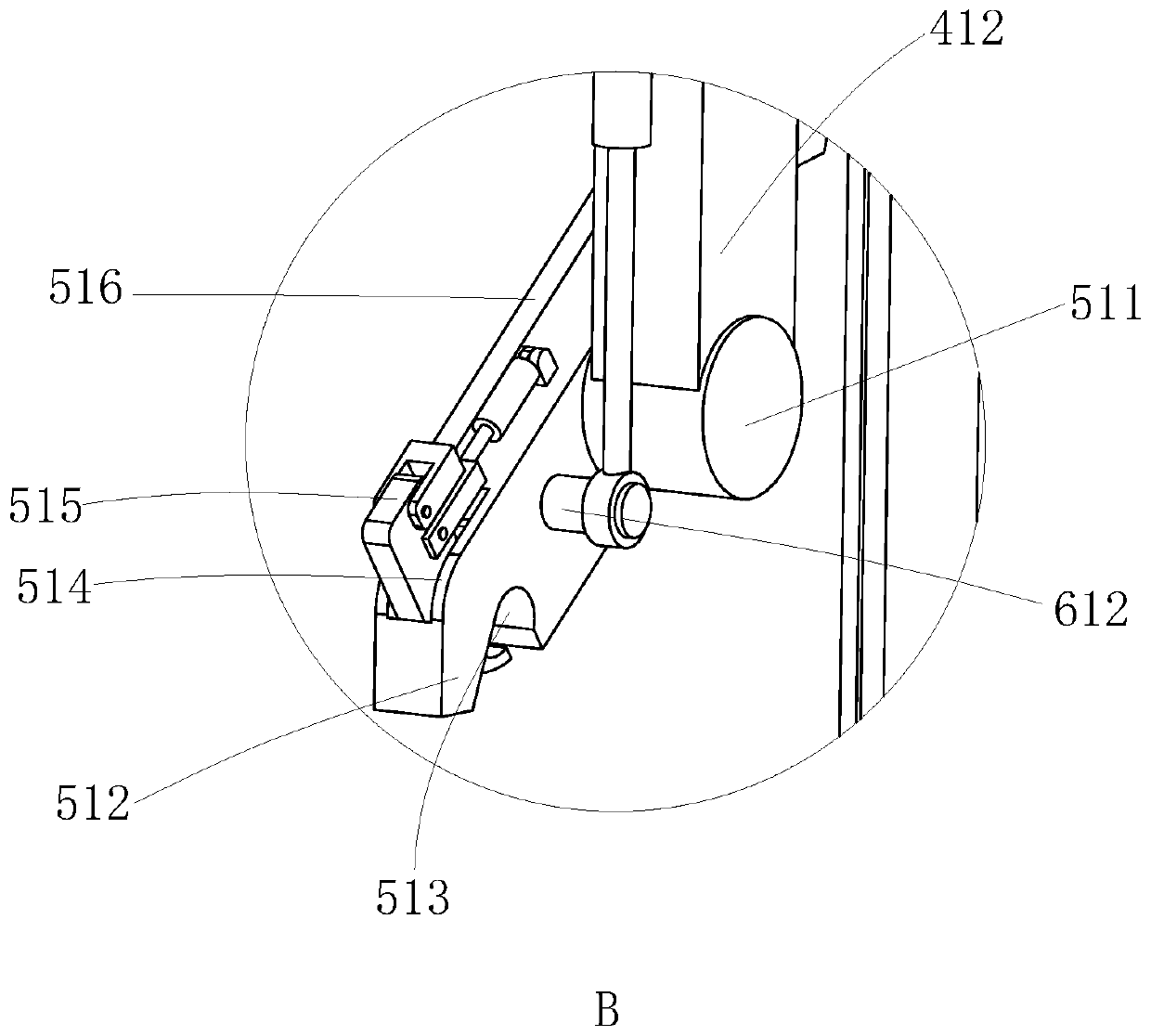

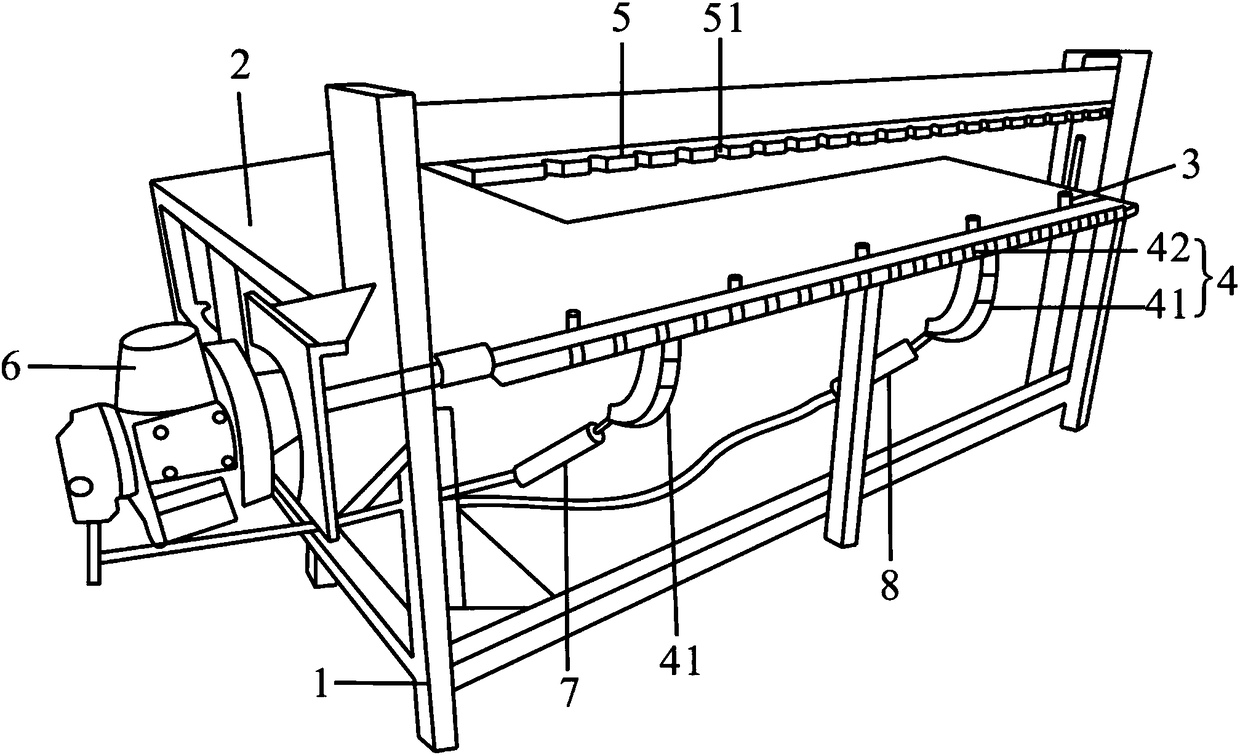

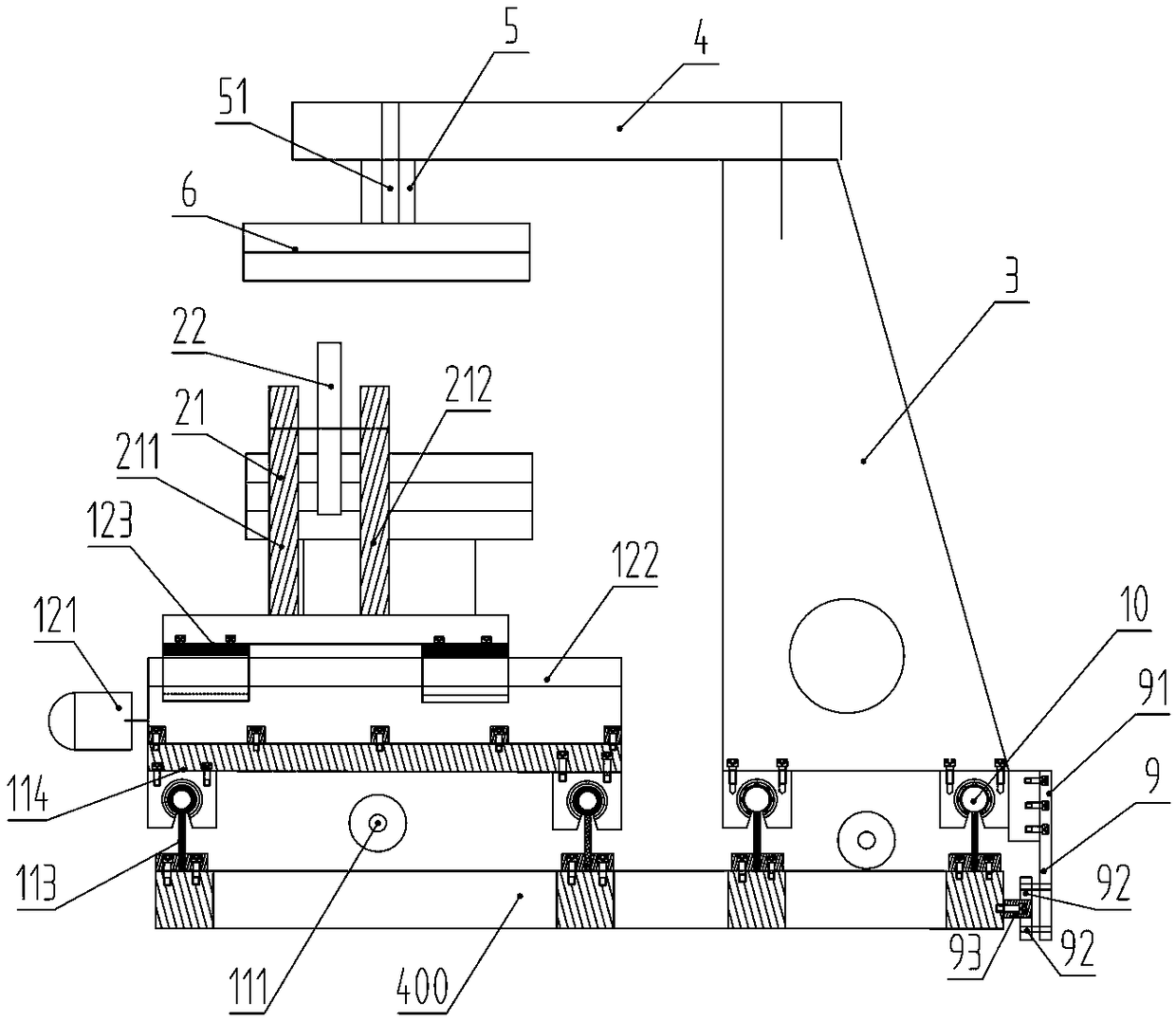

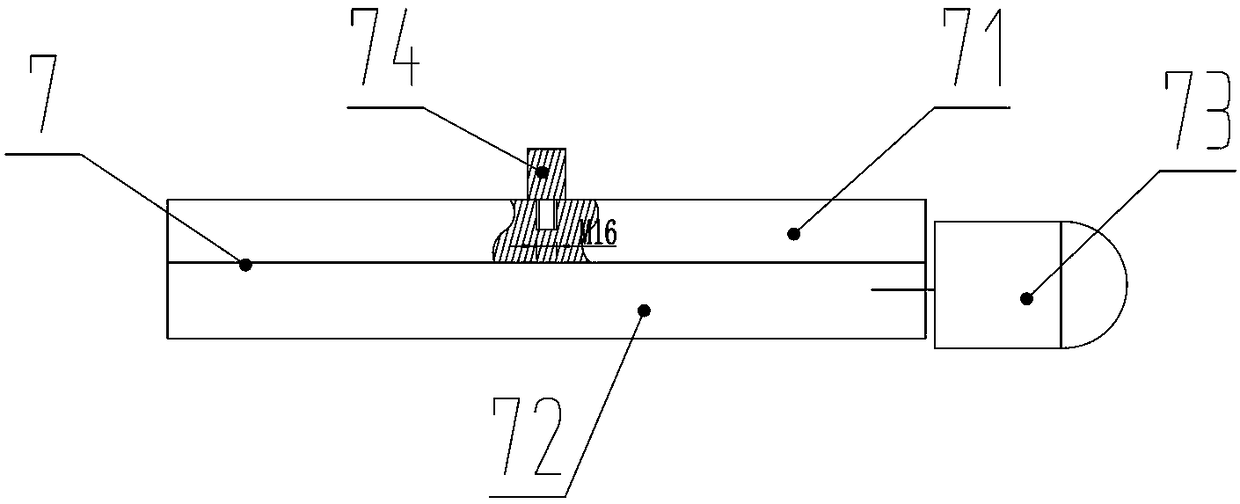

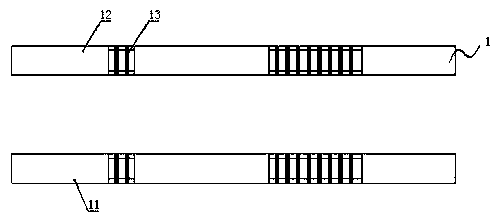

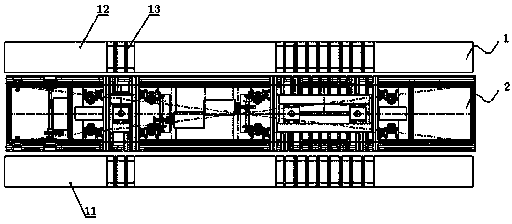

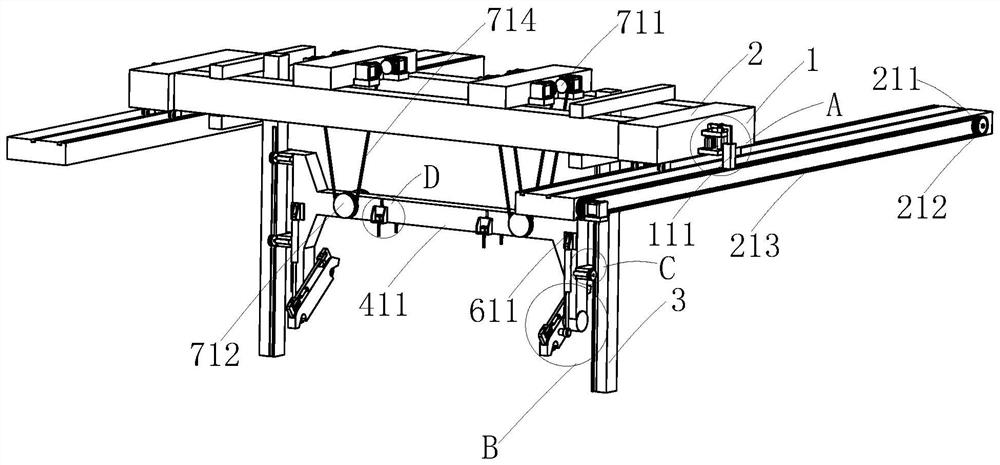

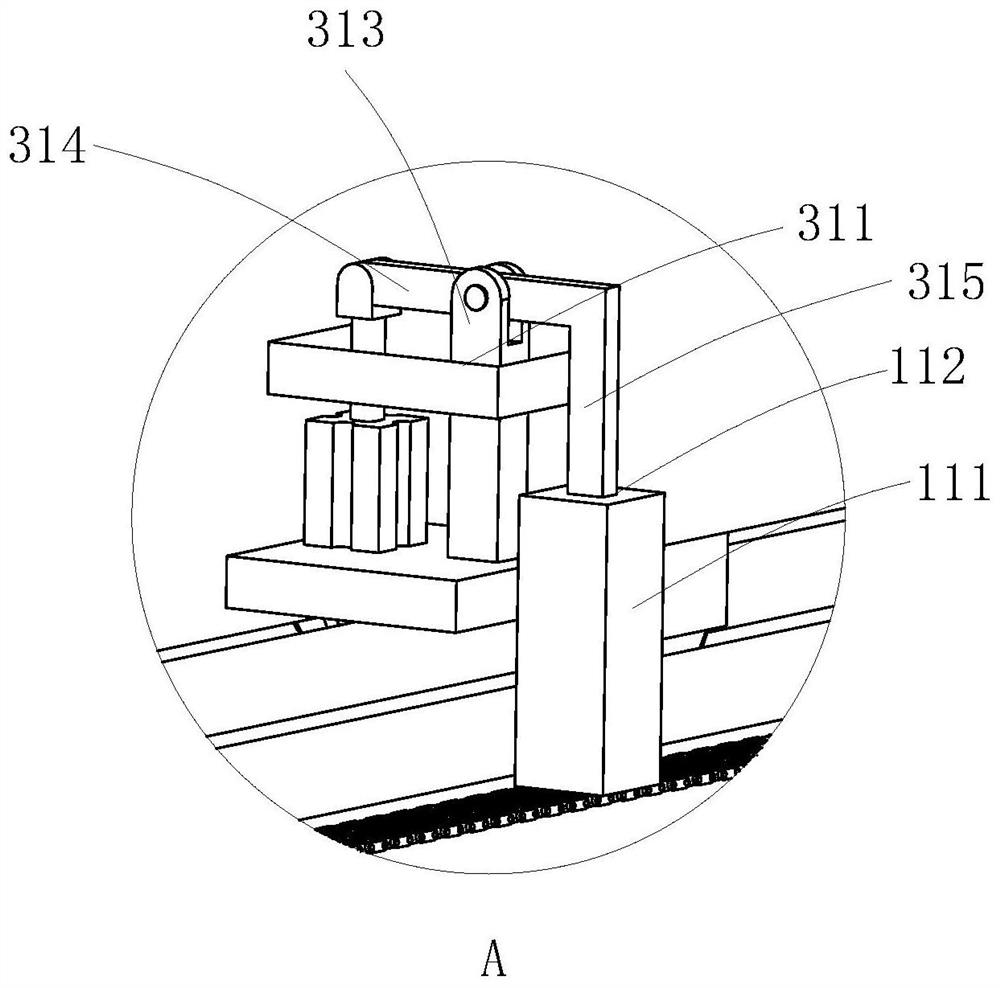

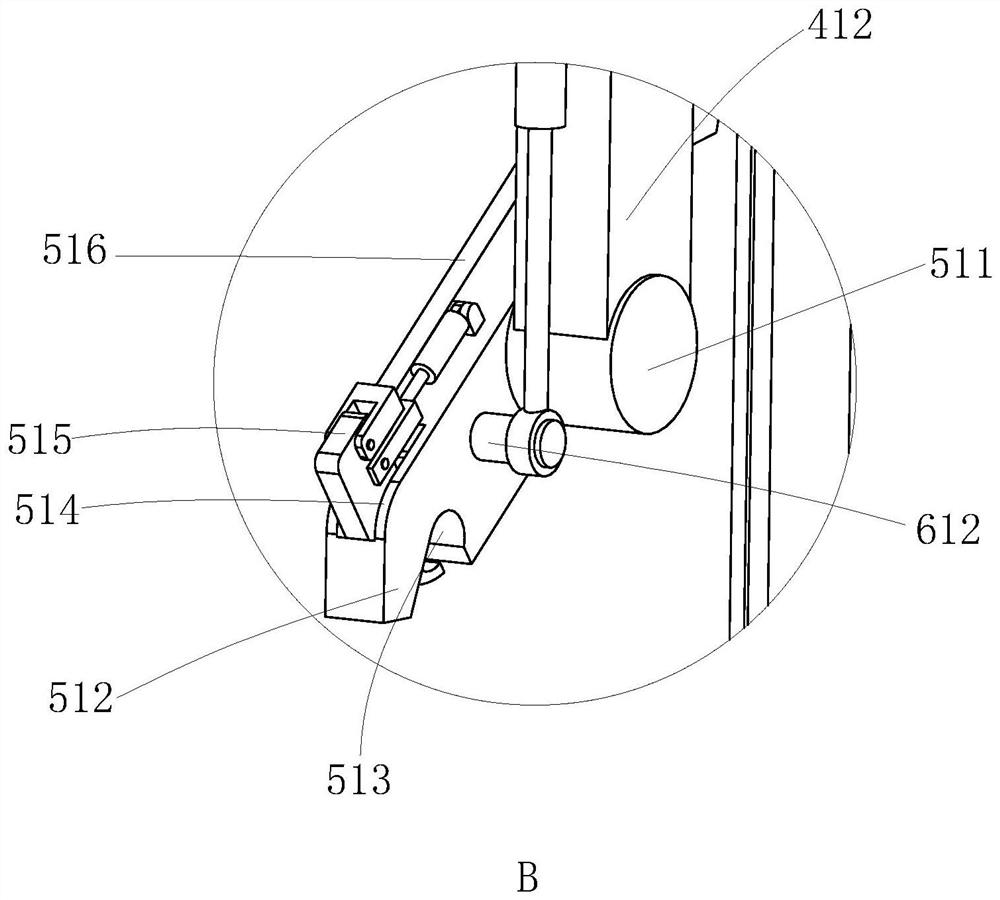

Full-automatic efficient autoclaved aerated concrete block mold stripping device

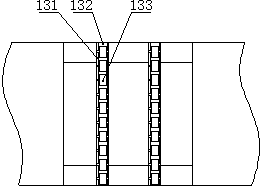

The invention relates to a full-automatic efficient autoclaved aerated concrete block mold stripping device, and belongs to the technical field of aerated brick production devices. The full-automaticefficient autoclaved aerated concrete block mold stripping device comprises a rack, a travelling trolley arranged at the top of the rack, and supporting frames arranged at the bottom of the rack and parallel to each other, wherein a positioning mechanism for automatically positioning the travelling trolley is arranged at the top of the rack, a clamping mechanism for clamping a mold is arranged between the supporting frames, and a driving mechanism for driving the clamping mechanism to slide in the vertical direction is arranged at the top of the rack. According to the full-automatic efficientautoclaved aerated concrete block mold stripping device, the automatic precise positioning function can be realized, so that the clamping mechanism can precisely align the position of the mold, and the time for aligning the mold by the clamping mechanism is greatly reduced.

Owner:惠州市鑫业建材有限公司

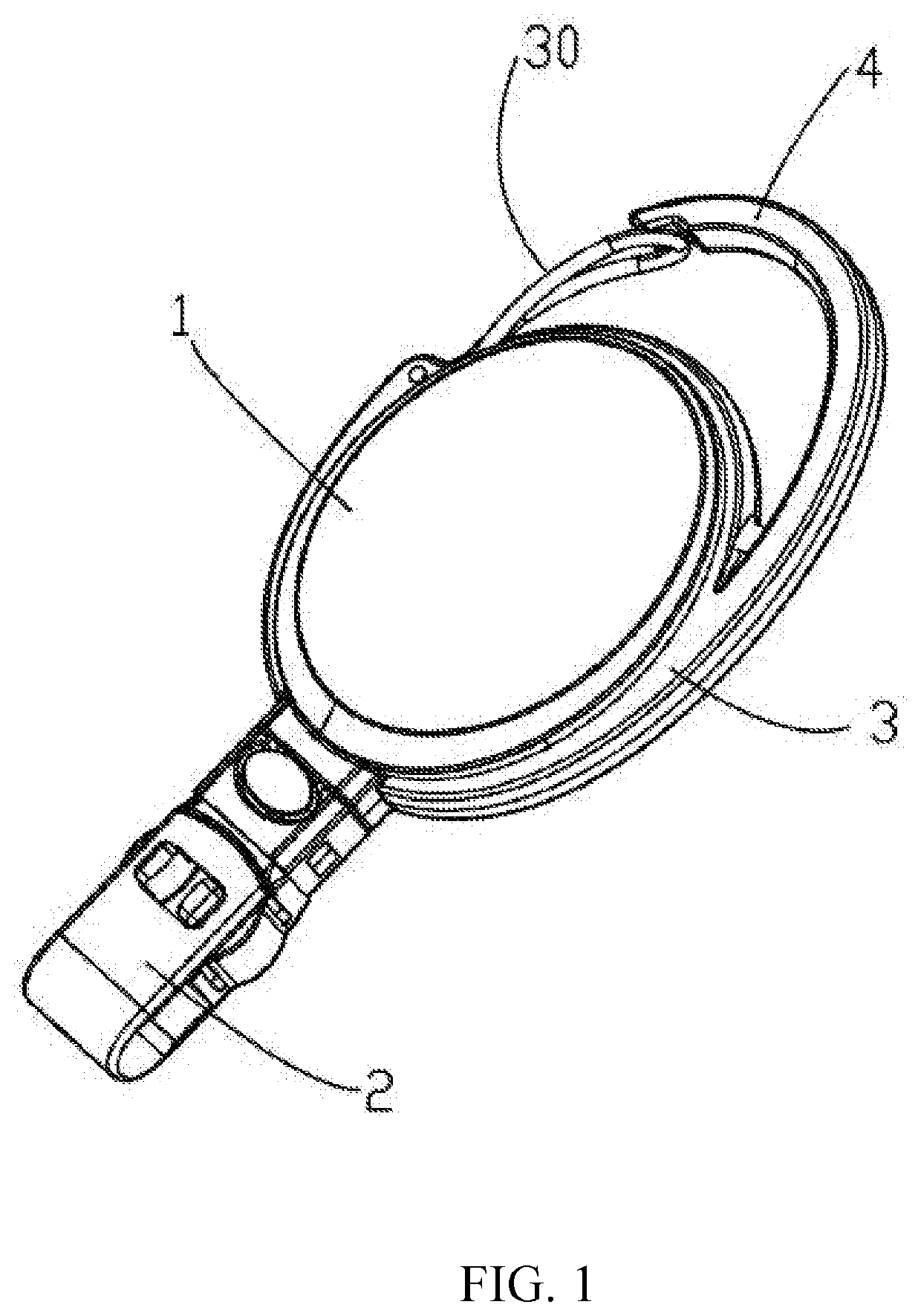

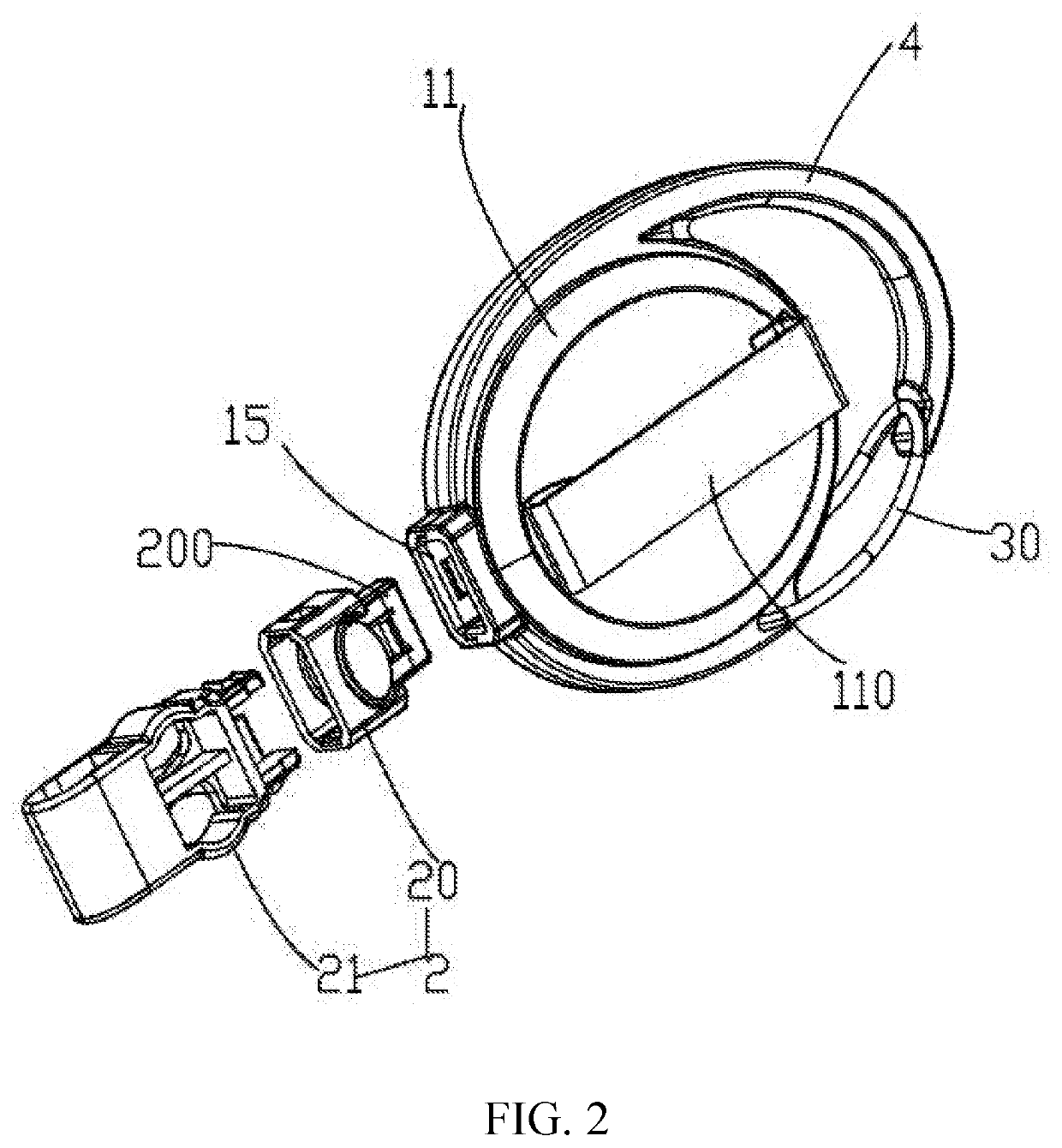

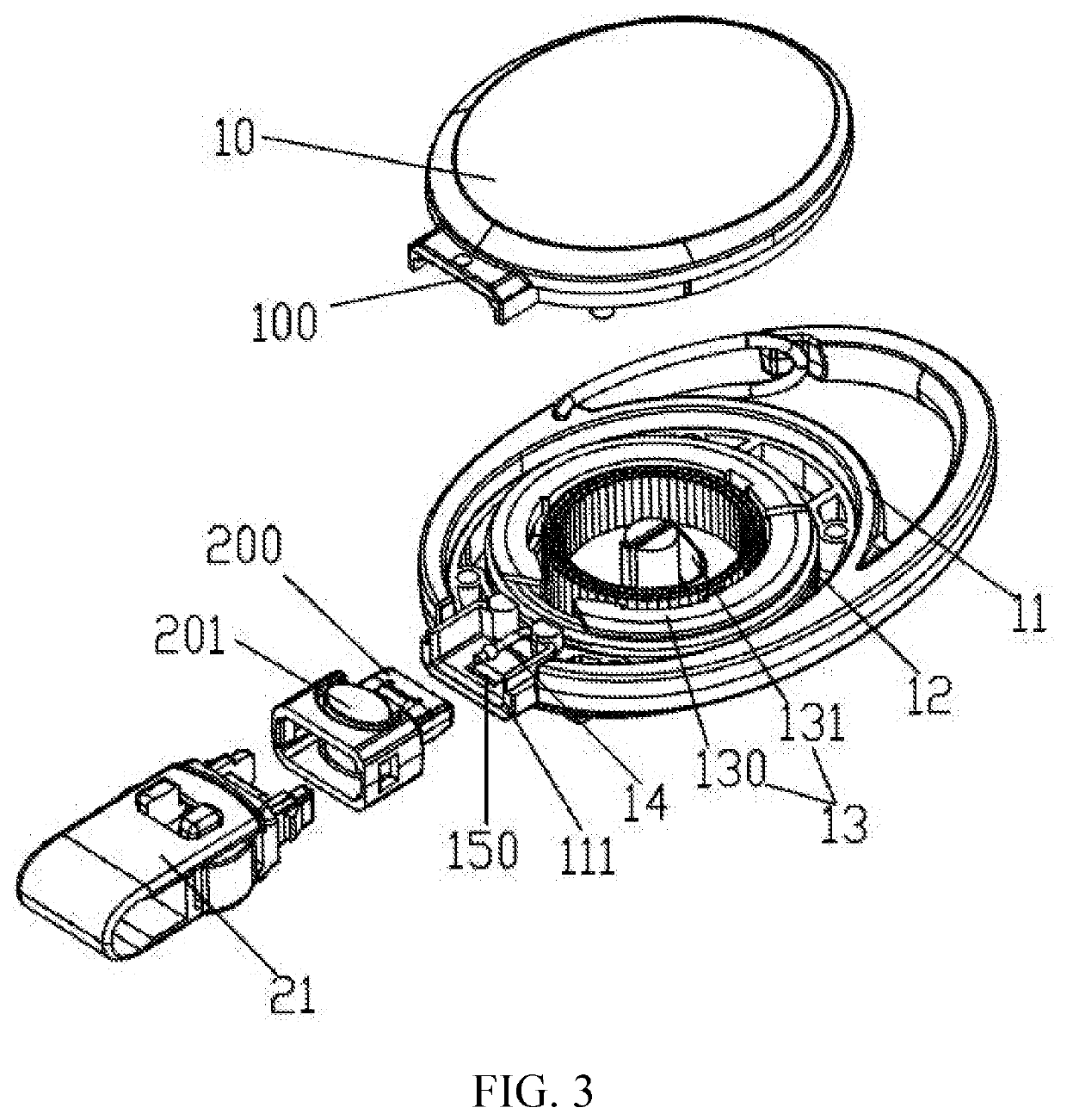

Buckle belt assembly

ActiveUS20200054118A1Easy to operateOpens and closes easilyTravelling carriersHoldersStructural engineeringMechanical engineering

The present disclosure relates to a buckle belt assembly, including: a main body and a buckle belt. The buckle belt includes a first body and a second body sleeved on the first body. The second body includes a supporting portion, a second movable portion, and a band extending from a bottom of the supporting portion. One end of the second movable portion is connected to the supporting portion, and the other end of the second movable portion is movable relative to the supporting portion. The second movable portion includes a pair of side walls and a pair of fixing walls. The band is configured to hang hanging objects, the band is configured with a fixing hole, and the side walls are pressed to abut the fixing wall to the fixing hole or to detach the fixing wall from the fixing hole, thereby opening or closing the band.

Owner:TSAI HAI PIN

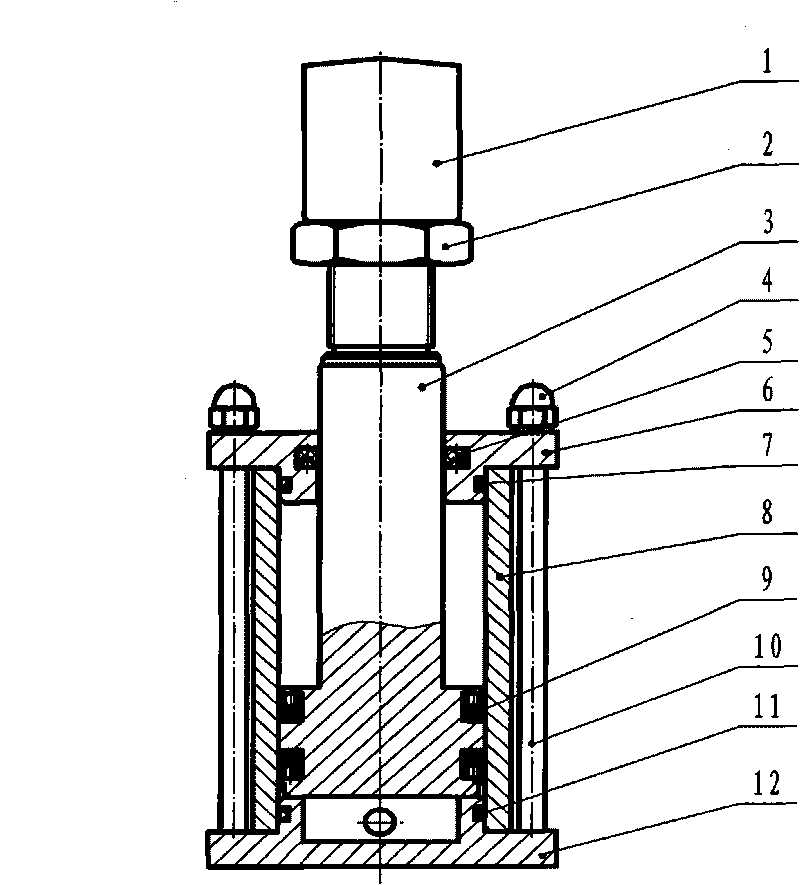

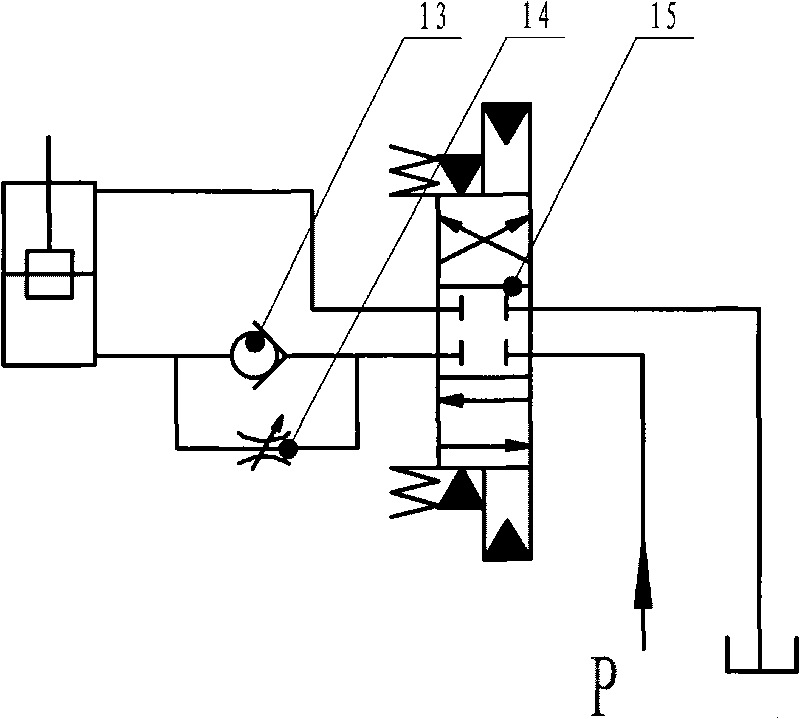

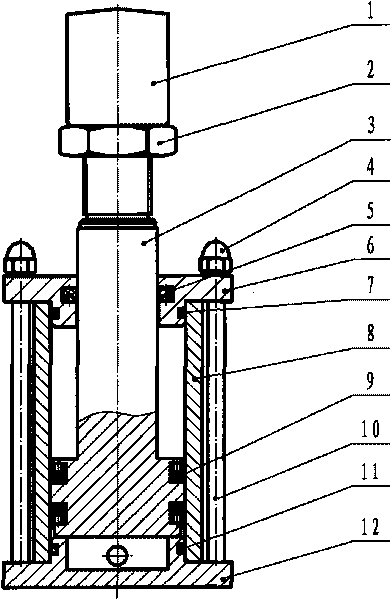

Hydraulic stop iron mechanism of cutting device

InactiveCN101716777AAutomatic and accurate positioningNo manual adjustment requiredMetal working apparatusEngineeringScrew thread

The invention relates to a hydraulic stop iron mechanism of a cutting device, which comprises a stop iron, an upper end cover, locking nuts, a piston rod, a lower end cover, a pull rod, a fixing nut, a cylinder barrel and sealing members, and also comprises a change valve, a check valve, an adjustable restrictor valve and the like. The upper end cover, the cylinder barrel and the lower end cover are connected by the pull rod and are fixed by the locking nuts, the piston rod passes through the upper end cover and is arranged in the cylinder barrel; the stop iron and the piston rod are screwed and locked by the locking nuts; the piston rod, the upper end cover and the cylinder barrel are in sliding fit and the piston rod is provided with the sealing members; the cylinder barrel, the upper end cover and the lower end cover are in transition fit and the cylinder barrel is provided with the sealing member; the upper end cover is provided with an oil hole communicated with an oil outlet of the change valve, the check valve is connected in parallel with the adjustable restrictor valve, an oil outlet of the check valve is communicated with an oil hole on the lower end cover, and an oil inlet is communicated with the other oil outlet of the change valve. The invention can be automatically and accurately positioned through a hydraulic system without manual adjustment, saves time and labor, and improves the working efficiency.

Owner:YANCHENG ZHICHENG MASCH MFG CO LTD

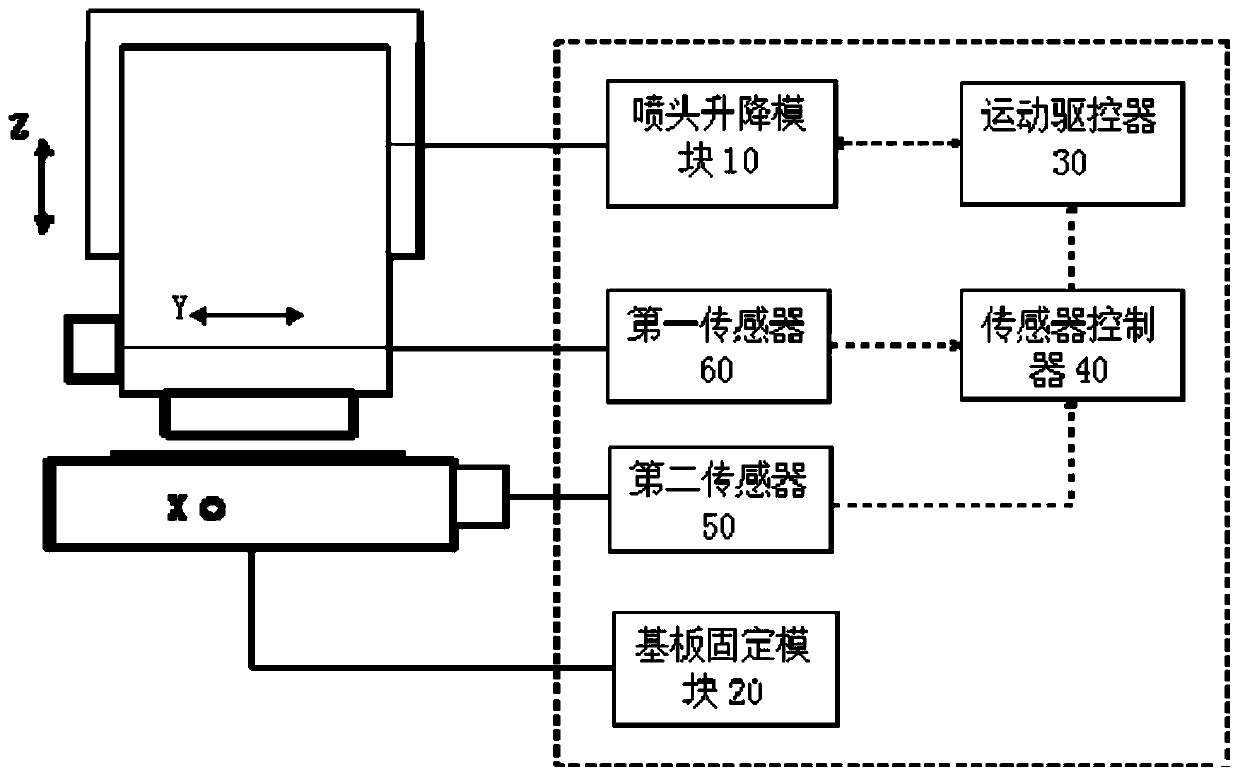

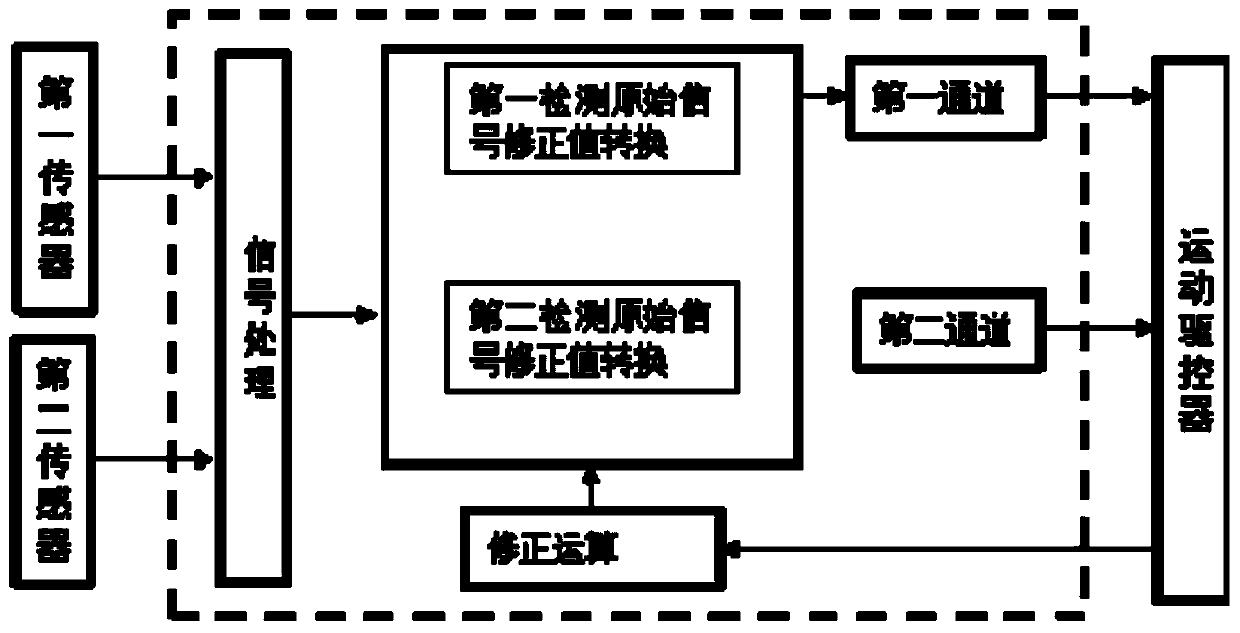

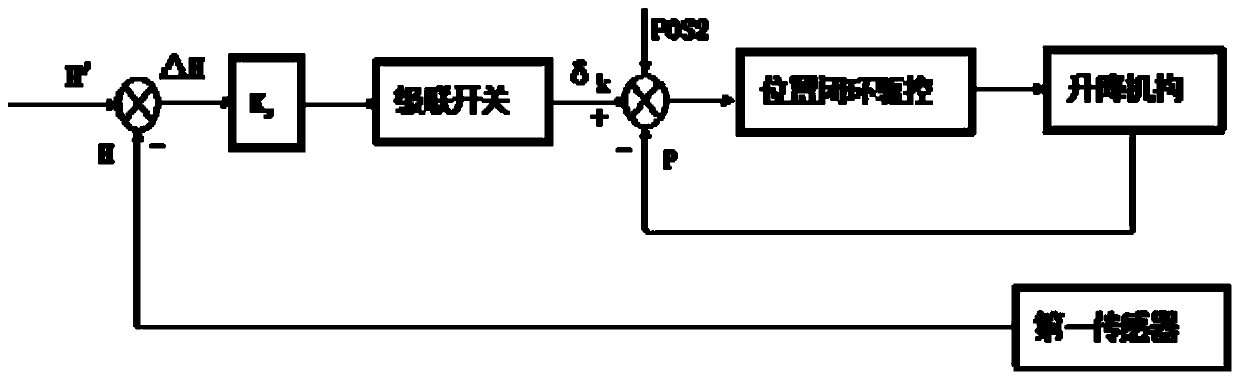

Printing display-oriented printing height control system and method

ActiveCN111591051AHigh degree of automationReduce mistakesTypewritersPower drive mechanismsSelf adaptiveLoop control

The invention provides a printing display-oriented printing height control system and method. The printing display-oriented printing height control system comprises a spray head lifting module, a substrate fixing module, a first sensor, a second sensor, a sensor controller and a motion driving controller; the spray head lifting module comprises a spray head, a spray head clamping device and a lifting mechanism; the substrate fixing module is arranged below the spray head lifting module and comprises an adsorption platform; the first sensor and the second sensor are used for detecting the real-time distance between a nozzle and a substrate and generating a first detection original signal and a second detection original signal; the sensor controller is used for acquiring the first detectionoriginal signal and the second detection original signal and sending the first detection original signal and the second detection original signal to the motion driving controller through signal processing and correction operation; and the motion driving controller is used for carrying out full-closed-loop control and driving on the lifting mechanism. According to the printing display-oriented printing height control system and method, the printing height control system and the two sensors are arranged in a combined mode, measured values of the multiple detected objects are corrected, the height or position relation is established, and non-contact self-adaptive printing height positioning control can be better achieved.

Owner:武汉国创科光电装备有限公司

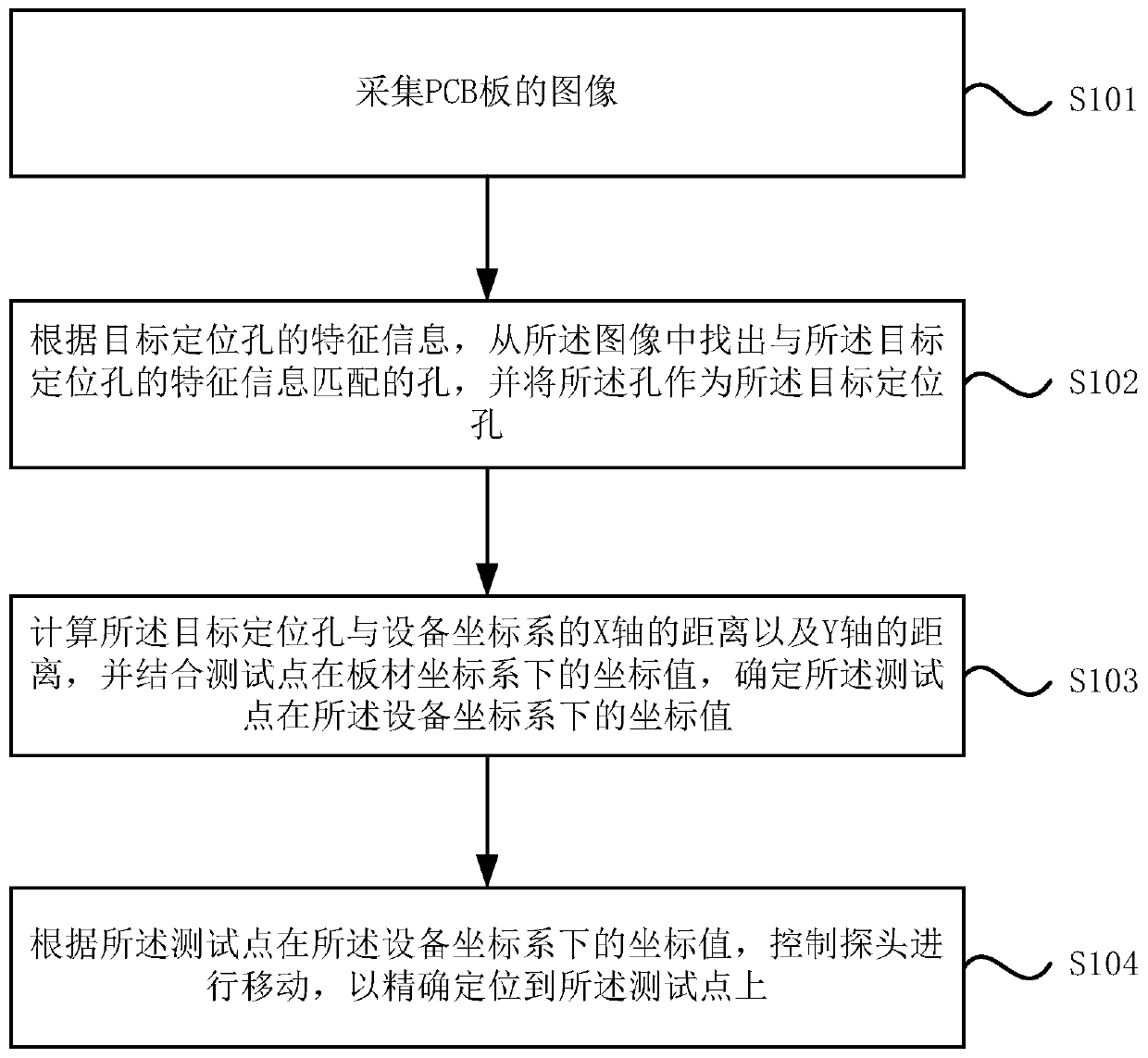

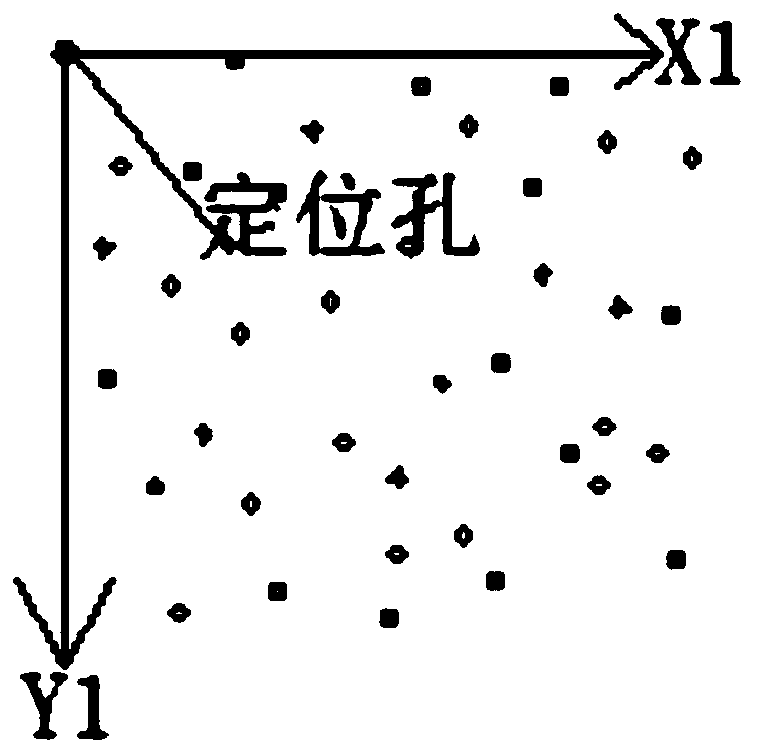

Test point automatic positioning method and copper thickness automatic detection method and system

PendingCN111583222AAutomatic and accurate positioningAccurate and stable measurementImage enhancementImage analysisControl engineeringEngineering

The invention discloses a test point automatic positioning method and a copper thickness automatic detection method and system. The method comprises the steps of collecting an image of a PCB; findingout a hole matched with the feature information of the target positioning hole from the image according to the feature information of the target positioning hole, and taking the hole as the target positioning hole; calculating a distance between the target positioning hole and an X axis and a distance between the target positioning hole and a Y axis of an equipment coordinate system, and determining a coordinate value of a test point in the equipment coordinate system in combination with a coordinate value of the test point in the plate coordinate system; According to the coordinate value ofthe test point under the equipment coordinate system, controlling a probe to move so as to be accurately positioned on the test point. According to the method, the coordinate value of each test pointon the PCB can be determined on the equipment coordinate system by converting the plate coordinate system and the equipment coordinate system, so that the probe can be automatically and accurately positioned on the test point, the accuracy and stability of copper thickness data measurement are ensured, and the production efficiency is improved.

Owner:GUANGDONG ZHENGYE TECH

Magnetic resonance image scanning automatic positioning method based on human anatomic structure symmetry

ActiveCN100586368CAutomatic and accurate positioningMeet clinical positioning needsSurgeryMagnetic property measurementsStructural symmetryResonance

The invention discloses a method of automatic location for magnetic resonance imaging scanning based on the symmetry of dissect structure of human body. It comprises following steps: (a) getting MRT location image; (b) calculating location information of different position on MRT location image by using the symmetry of dissect structure of human body; (c) outputting location information of MRT location image; and step (b) also comprises steps: (1) dividing target zone on whole image; (2) initiating symmetrical axis of target zone; (3) calculating the point set of said target zone symmetry withsaid symmetrical axis; (4) defining price function according to said point set, and getting optimum value of price function through optimization; (5) getting the symmetrical axis used as location information in relative with said optimum value. The invention realizes automatic location of MRT scanning, guarantees uniformity of fault scanning image and increases location accuracy and work efficiency.

Owner:NEUSOFT MEDICAL SYST CO LTD

Microscope automatic operation system

InactiveCN1243270CMeet and exceed accuracy requirementsExceed the accuracy requirementTelevision system detailsColor television detailsMotor driveOperational system

Owner:NANKAI UNIV

Automatic overedging machine and working method thereof

PendingCN108160874AAutomatic and accurate gripAutomatic and accurate positioningWire networkEngineeringMechanical engineering

The invention discloses an automatic overedging machine for an anchor net, comprising a base, a worktable, a limiting device, an overedging mechanism, a compressing device and a hydraulic device. Theworktable is arranged on the base, the limiting device is fixedly arranged on the end part of the worktable and used for positioning the anchor net to be overedged in a correct overedging position, the overedging mechanism is rotatably arranged on the limiting device and used for overedging the anchor net, the compressing device is arranged above the worktable and used for compressing the overedged anchor net, and the hydraulic device is fixedly arranged on the side part of the worktable and drives the overedging mechanism and the compressing device. The invention further discloses a working method of the automatic overedging machine for an anchor net. The automatic overedging machine for an anchor net can be used for automatic and correct positioning and overedging as well as compressing,is high in automatic degree and is suitable for different anchor nets, can effectively overedge the anchor net, and ensures the overedging quality. The production efficiency is improved, the structure is simple, the operation is simple and convenient and the universality is high.

Owner:内蒙古上海庙矿业有限责任公司

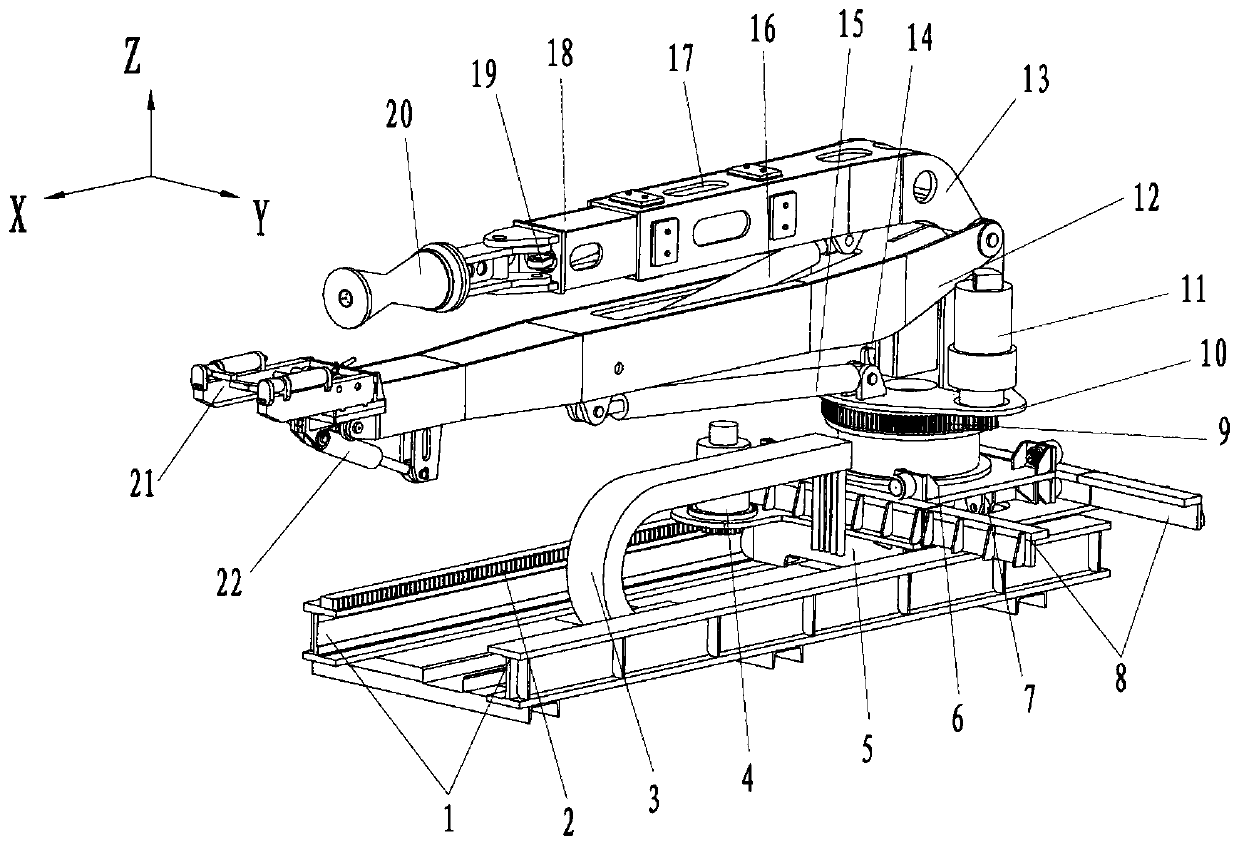

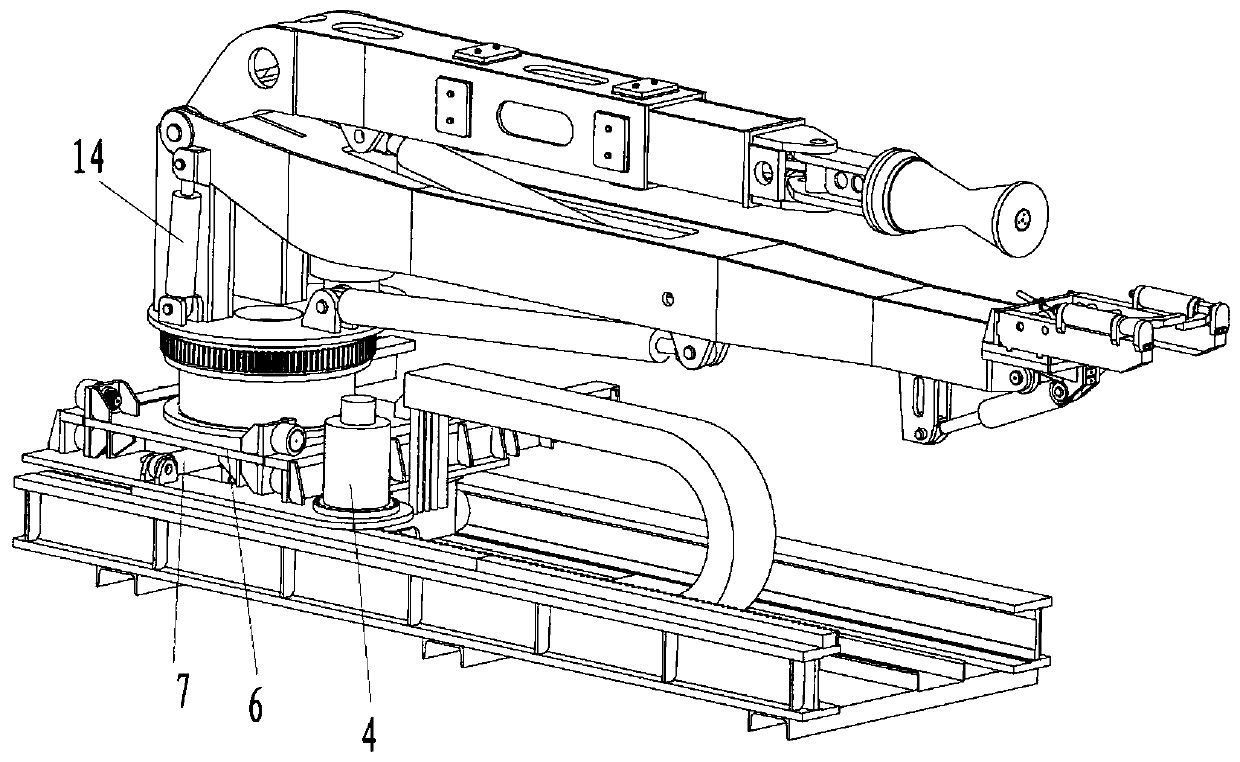

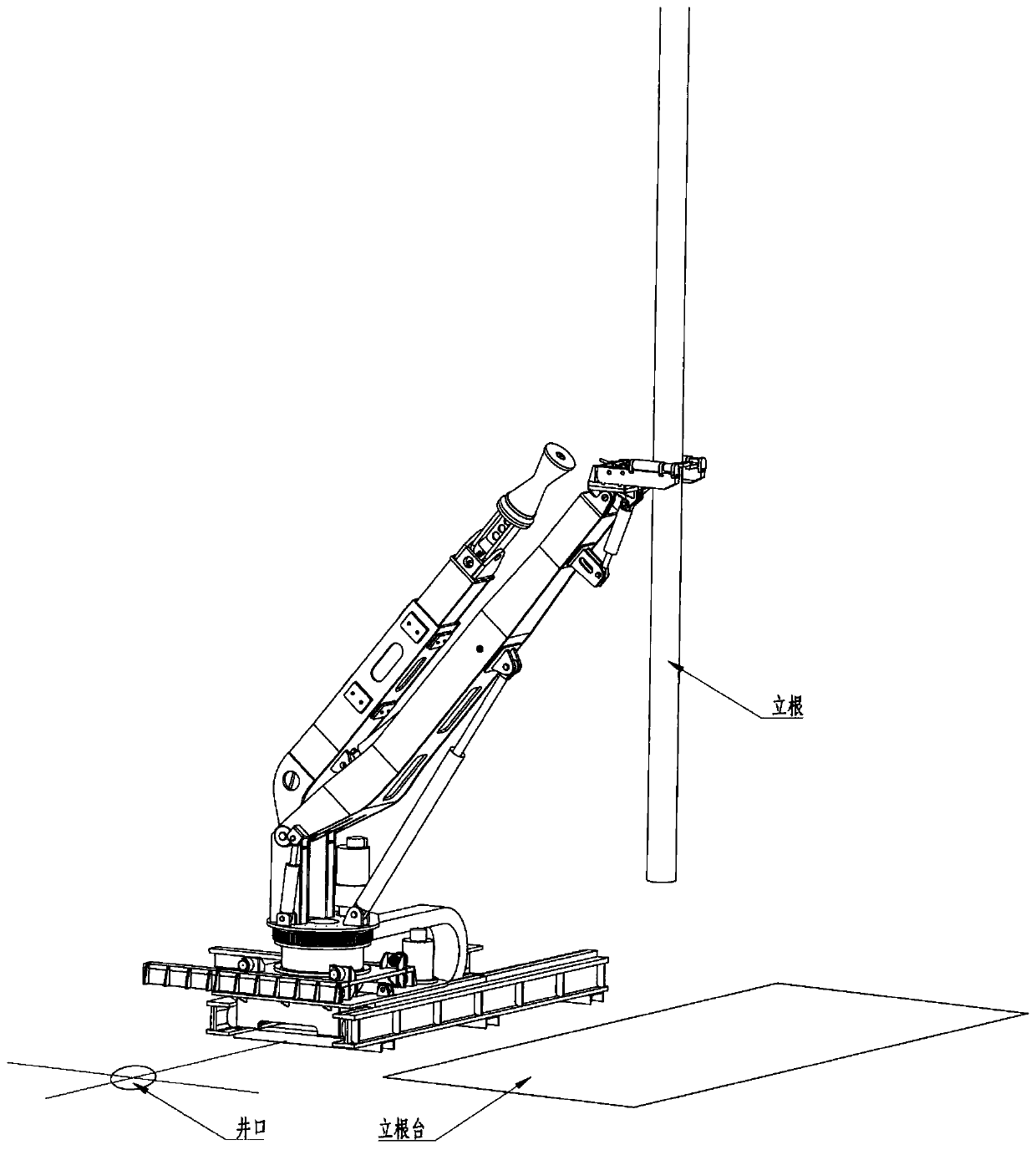

Multifunctional push-support guide manipulator on drilling floor

ActiveCN107859493BReduce in quantityMeet emission requirementsDrilling rodsDrilling casingsRobot handControl engineering

The invention discloses a multifunctional drilling-floor-face pushing and guiding manipulator which comprises X-direction travelling tracks. An X-direction travelling pulley capable of horizontally sliding in a reciprocating mode is arranged on the X-direction travelling tracks in a matched mode, Y-direction travelling tracks perpendicular to the X-direction travelling tracks are fixed to the upper portion of the X-direction travelling pulley, and a Y-direction travelling pulley capable of horizontally sliding in a reciprocating mode is arranged on the Y-direction travelling tracks in a matched mode. A horizontal rotating mechanism is fixed to the upper portion of the Y-direction travelling pulley, and a pushing arm and a guiding righting arm which can rotate in the vertical surface are connected to the upper portion of the horizontal rotating mechanism. The guiding righting arm is located on the upper portion of the pushing arm, the other end of the pushing arm is rotatably connectedwith a righting device, and the other end of the guiding righting arm is rotatably connected with a guiding righting roller. The multifunctional drilling-floor-face pushing and guiding manipulator issimple and compact in structure, comprehensive in function, convenient to use and precise in control, discharging and guiding of drilling-floor-face stands and singles can be effectively completed, and thus drilling operation is successfully completed.

Owner:BAOJI PETROLEUM MASCH CO LTD +2

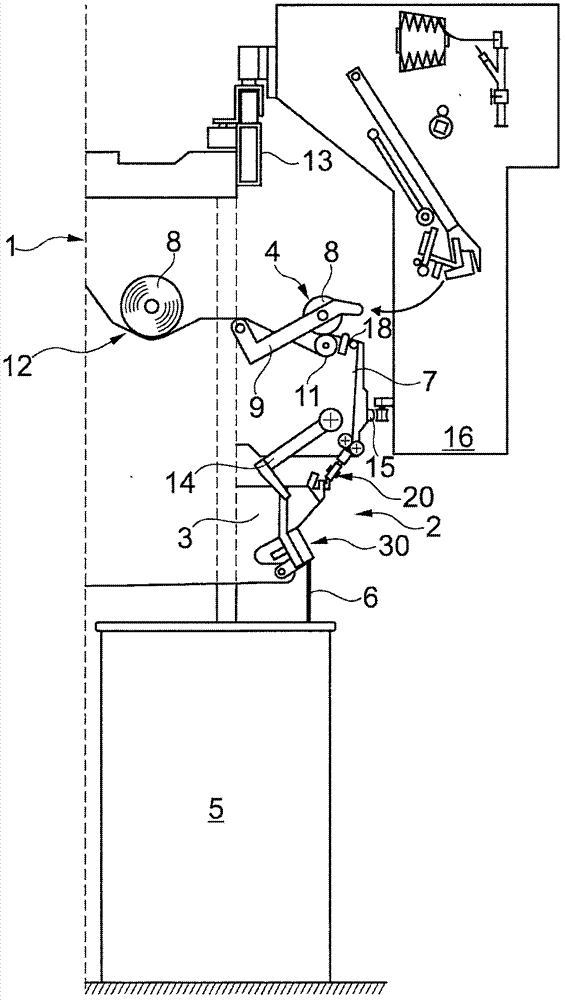

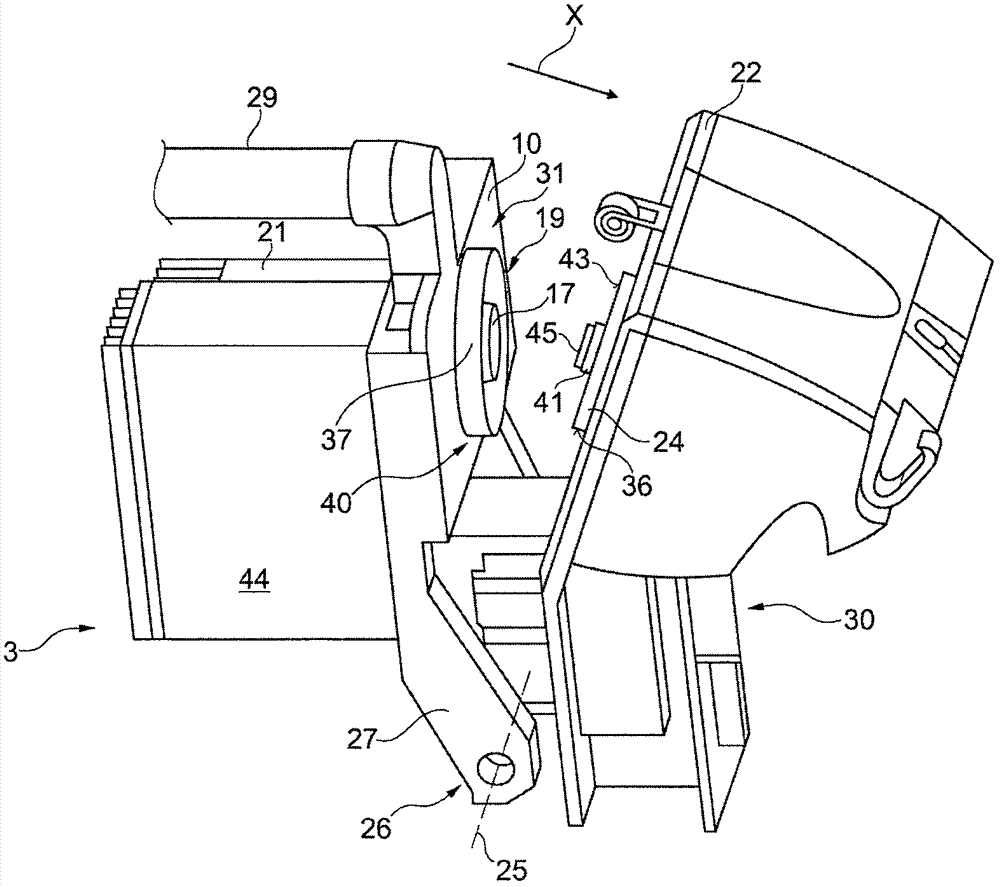

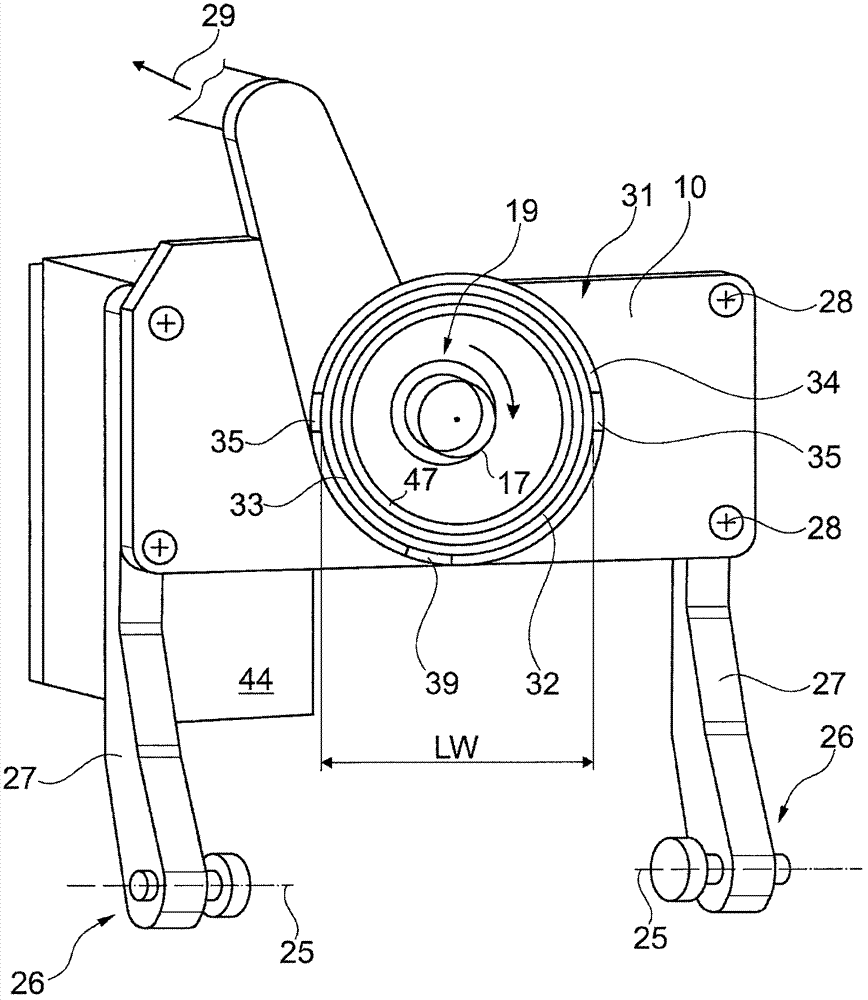

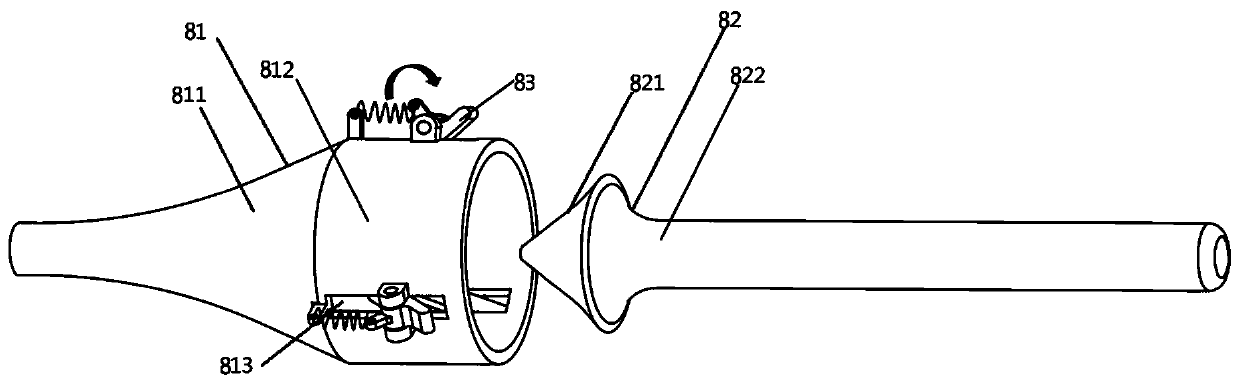

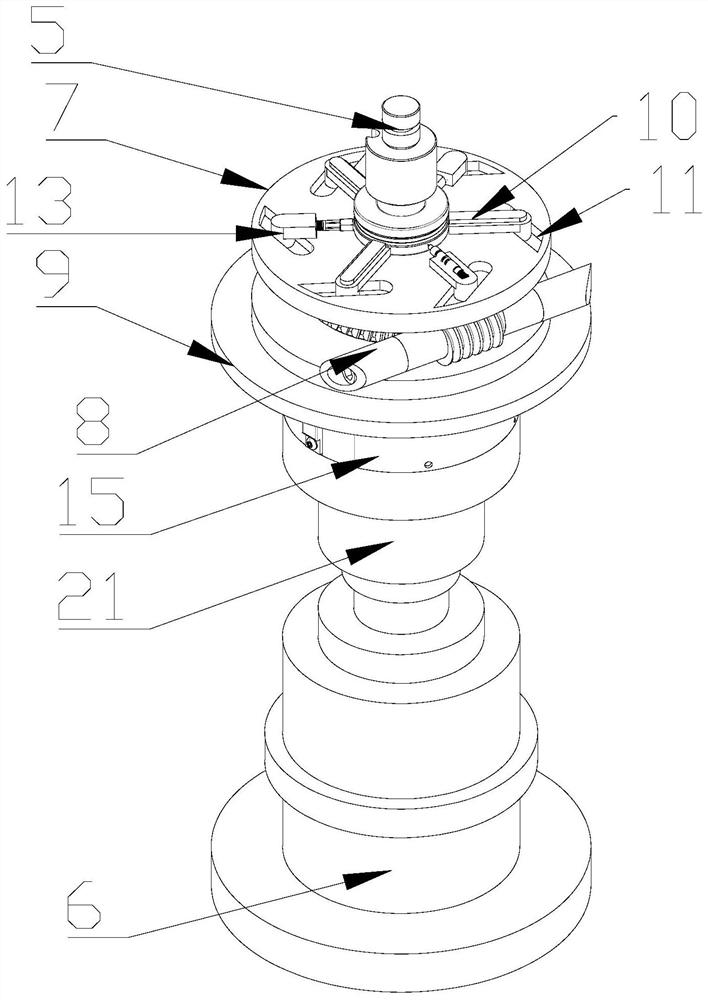

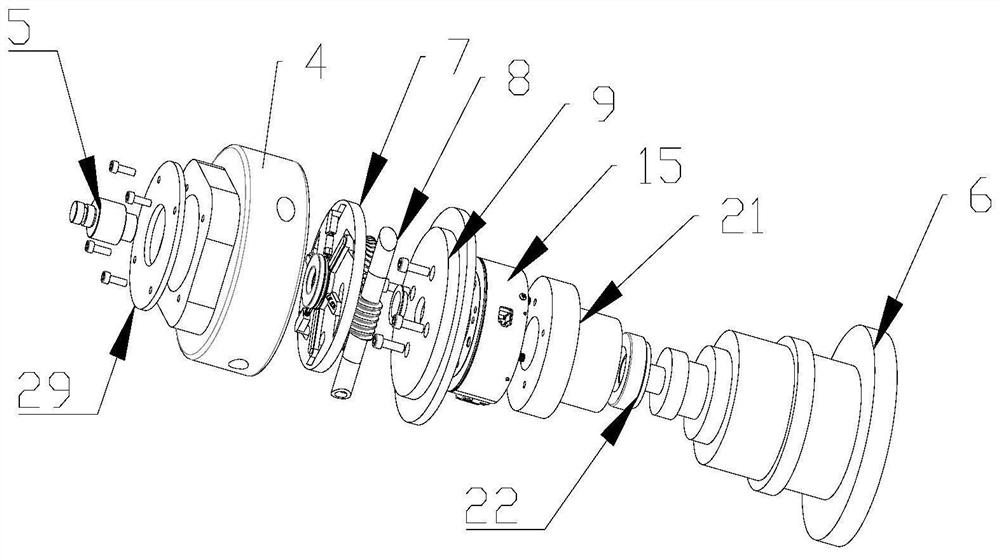

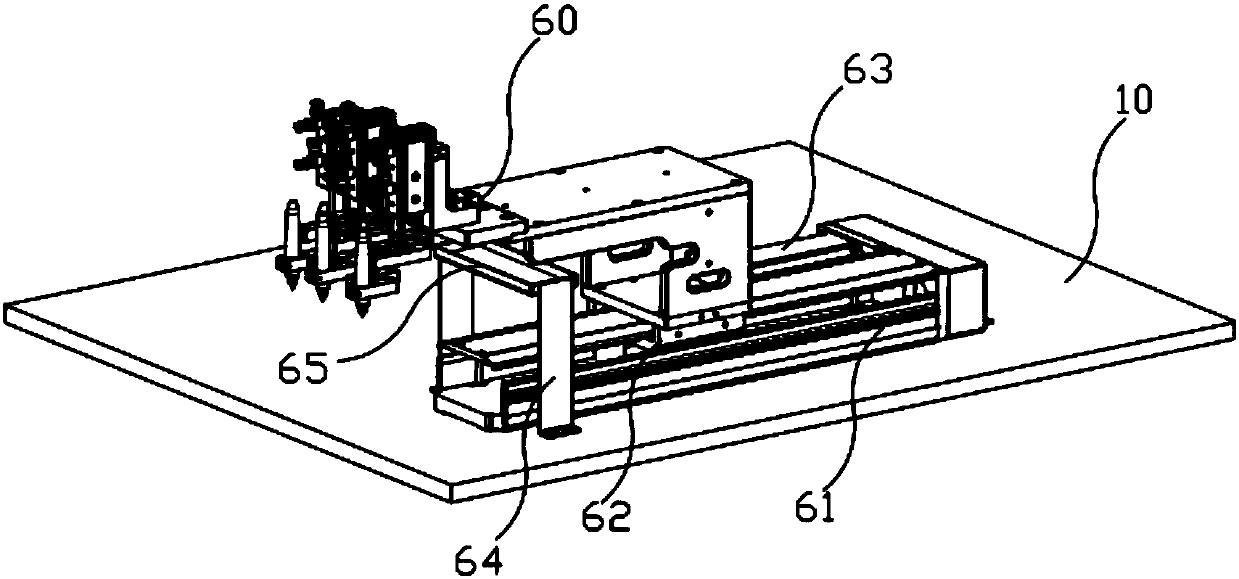

Open-end rotor spinning device

ActiveCN107201575AAutomatic and accurate positioningAutomatically correct misalignmentContinuous wound-up machinesOpen-end spinning machinesEngineeringMechanical engineering

The invention relates to an open-end rotor spinning device (3) with a spinning rotor (19) which can be driven by a single motor, the rotor assembly (17) of which rotates in a rotor housing (10) which can be pressurized and which is driven by a drive (21) for the spinning rotor (19) and bearing arms (27) ) is connected to a cover element (22) having a fiber band dissolving device (30), and which comprises a part of a centering device (40), wherein the forwardly open rotor housing (10) is closed by the cover element (22) during the spinning process , which in turn has a receptacle (23) for a replaceably arranged channel plate adapter (24). According to the invention, the centering device (40) is formed by a guide surface (36) arranged on the channel plate adapter (24), as well as a guide device (31) arranged on the rotor housing (10), wherein the guide surface (36) arranged on the channel plate adapter (24) Closing state of the open-end rotor spinning device (3) in a form-fitting manner with the guide device (31) arranged on the rotor housing (10).

Owner:SAURER GERMANY GMBH & CO KG

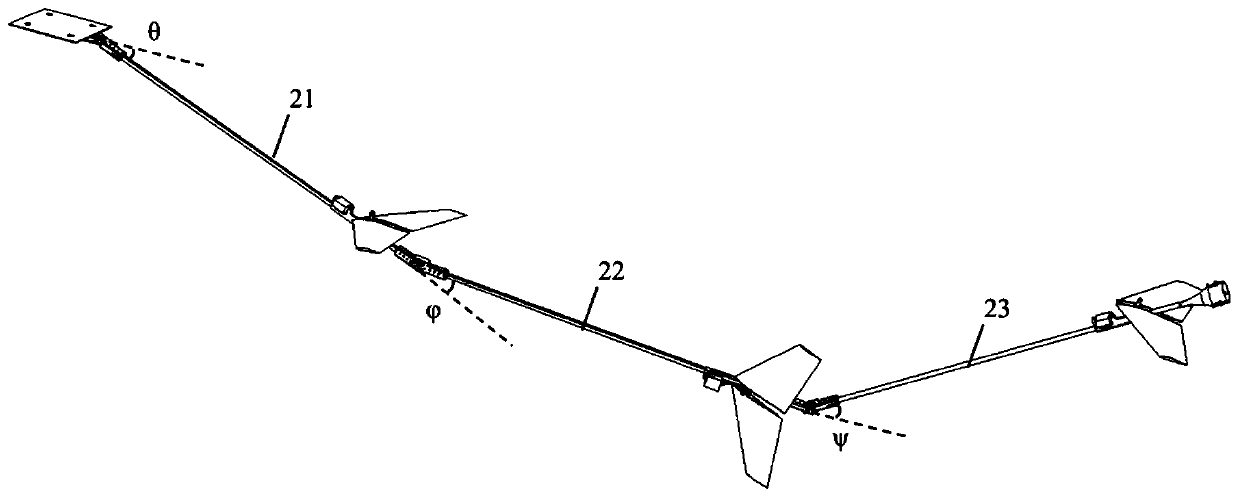

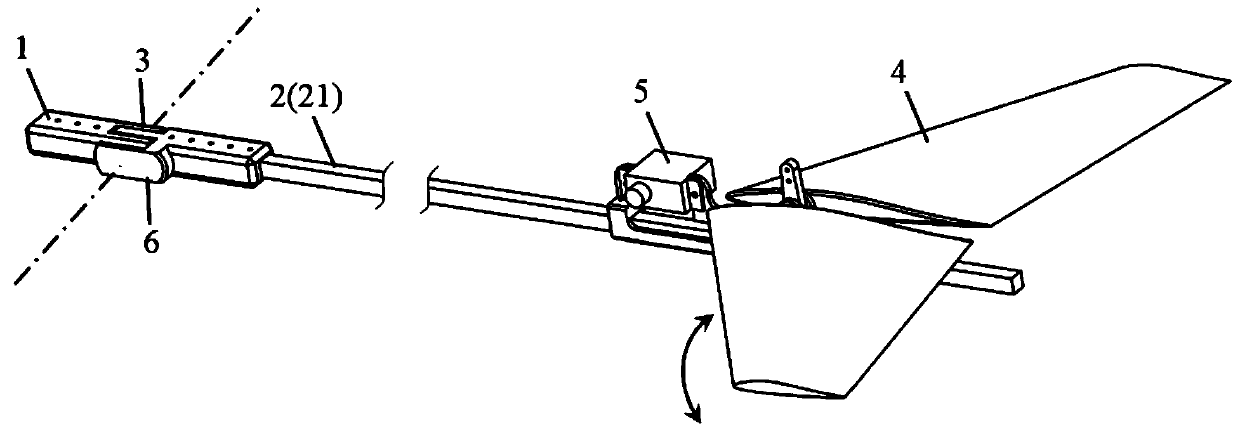

Mechanical arm based on pneumatic control surface and working method thereof

ActiveCN111377060AAvoid the disadvantages of inflexible operationFlexible operationAircraft componentsControllers with particular characteristicsFlight vehicleButt joint

The invention discloses a mechanical arm based on a pneumatic control surface and a working method of the mechanical arm, relates to the field of butt joint of aerospace crafts, can be suitable for various air butt joint operations, is high in control response speed and accurate in butt joint, improves the safety and reliability of air butt joint, and meanwhile improves the butt joint efficiency.The mechanical arm comprises a rigid pipe system, an angle sensor and an operation end. The rigid pipe system is formed by sequentially and movably connecting a plurality of rigid pipes, the control surfaces are installed at the tail ends of part of the rigid pipes, and the control surfaces are at least two of elevators, rudders and rolling rudders. An angle sensor is arranged at the joint of therigid pipes. One end of the rigid pipe system is movably connected with the operation machine, and the other end is provided with a working end which is an oil conveying port or a butt joint lock catch. According to the invention, maneuvering actions of a butt joint aircraft are effectively reduced, and the butt joint safety and reliability are improved. The mechanical arm is applied to aerial refueling and material supply, a complex mechanical structure is not needed, control force is generated by controlling the control surface, mechanism movement is controlled, and then the effect similar to that of a mechanical arm is achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Anti-theft well lid automatic machining equipment

InactiveCN108942534AAutomatic and accurate positioningSolve the problem of verticalityGrinding drivesGrinding machinesEngineeringMachining

The invention discloses anti-theft well lid automatic machining equipment and relates to the technical field of grinding machining. The anti-theft well lid automatic machining equipment comprises a cutting unit, a supporting unit and a feeding and discharging unit. The feeding and discharging unit comprises a driving mechanism, feed guide rails and a moving stand column. The lower end of the moving stand column is in sliding fit with the feed guide rails. The upper end of the moving stand column is provided with a feed cross beam. The lower side of the feed cross beam is provided with a material taking device. The material taking device comprises a sliding support in sliding fit with the feed cross beam. A lifting mechanism is arranged on the sliding support. The lower end of the lifting mechanism is provided with an electromagnetic chuck. The lifting mechanism drives the electromagnetic chuck to move up and down. A workbench comprises a concave table board and locating electromagnetsarranged below the concave table board. The middle portion of the upper end face of the concave table board is sunken downwards to form a working position for storing a workpiece. Under attraction ofthe locating electromagnets, the workpiece slides to a limiting position. The anti-theft well lid automatic machining equipment can automatically complete material taking, locating, grinding, discharging and other working procedures and is stable and accurate in workpiece operation and small in assembly space.

Owner:陶佩林

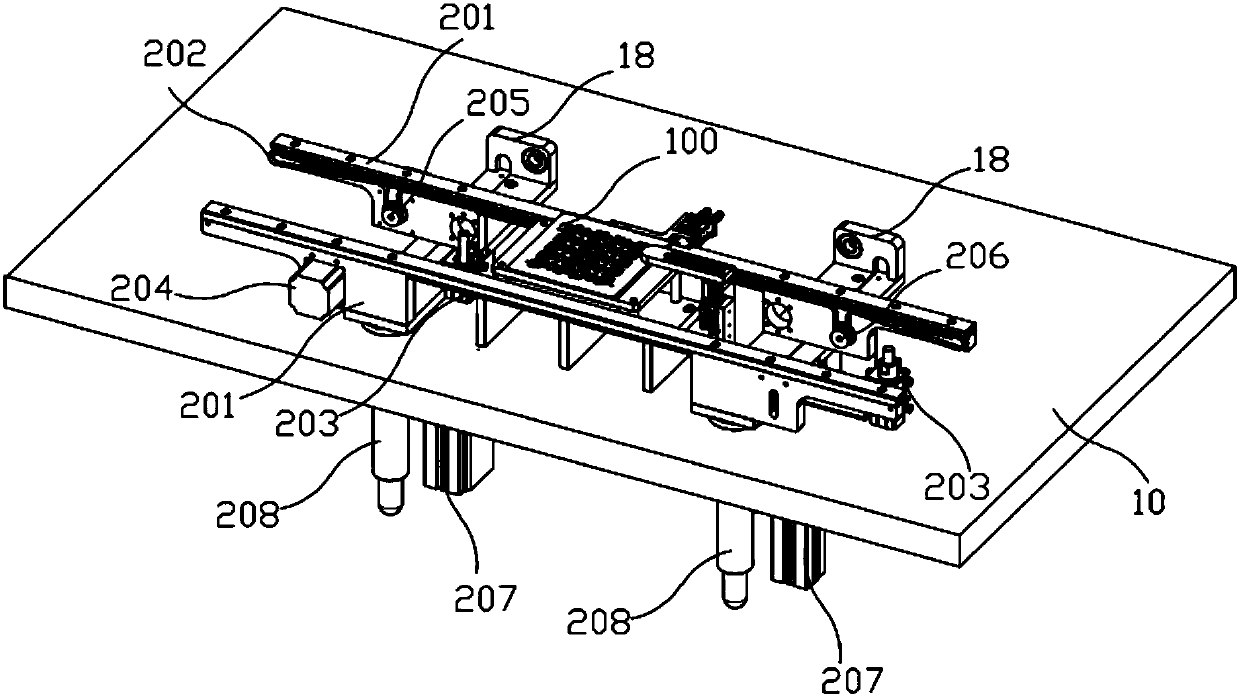

Forward pushing mechanism for annular stacking three-dimensional garage parking and picking trolley

ActiveCN104314344AAutomatic and accurate positioningReduced proficiency requirements for moving carsParkingsDriver/operatorParking space

The invention relates to a forward pushing mechanism for an annular stacking three-dimensional garage parking and picking trolley. The system is characterized by comprising a plurality of parking platforms and at least one pair of jacking platforms, wherein the parking platforms are arranged on parking spaces, an entrance parking space or an exit parking space; supporting platforms of the parking platforms are provided with comb-like supporting components A for supporting front and rear wheels of an automobile respectively; the jacking platforms are arranged on the three-dimensional garage parking and picking trolley and are both provided with a pair of comb-like supporting components B capable of being matched with the comb-like supporting components A and a forward push driving mechanism for driving the comb-like supporting components B to move. The mechanism has the advantages that the automobile is pushed to move transversely under the driving of the forward push driving mechanism on the jacking platforms when the automobile is stopped and positioned in the three-dimensional garage, so that the automobile can be automatically and accurately positioned, and a driver does not need to repeatedly adjust the automobile to a central position of the parking platform; the requirements on automobile movement proficiency of drivers are reduced and the average consumed time for parking is shortened.

Owner:JIANGSU SHUNDA ENG TECH

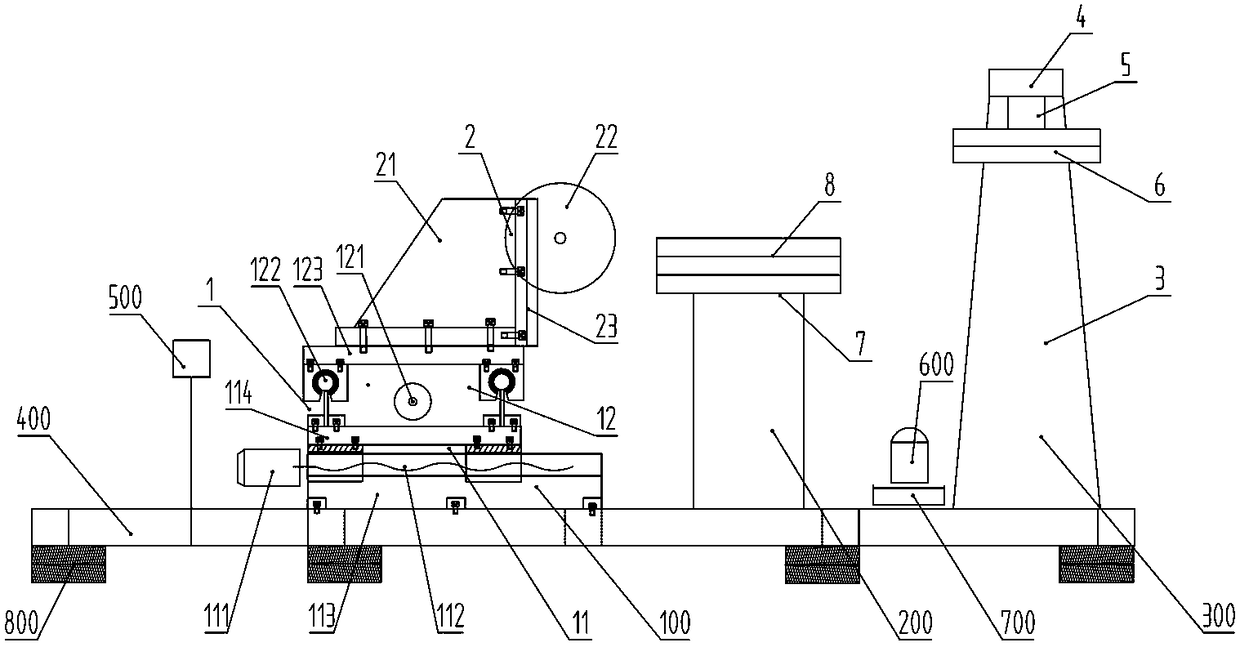

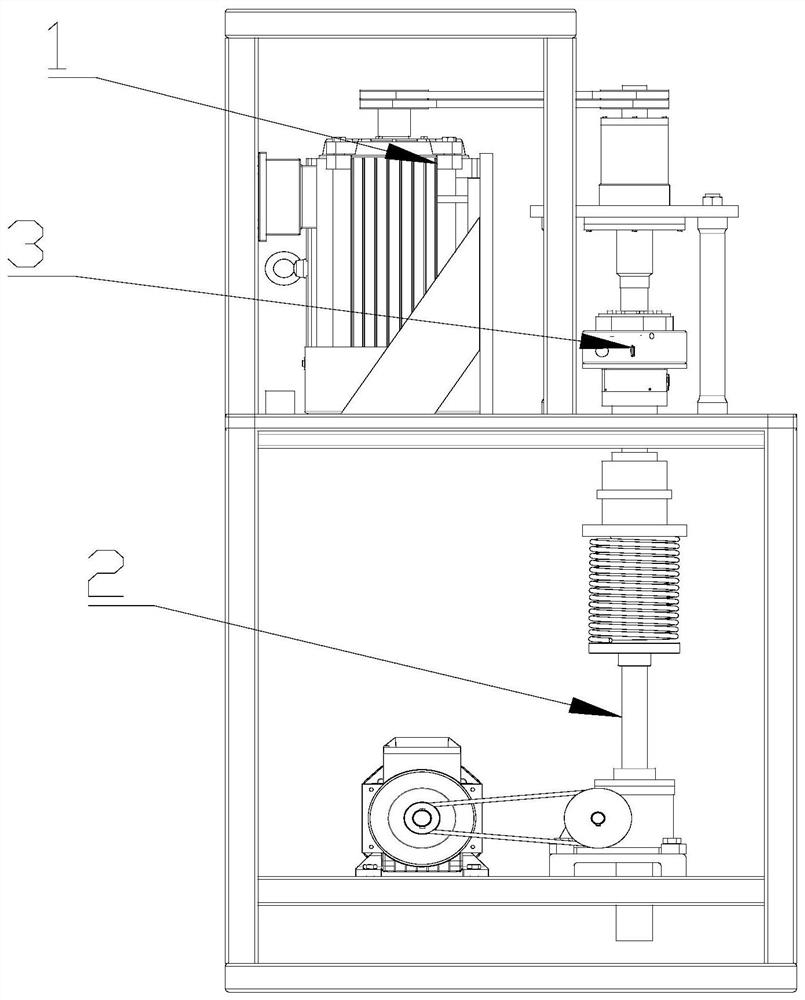

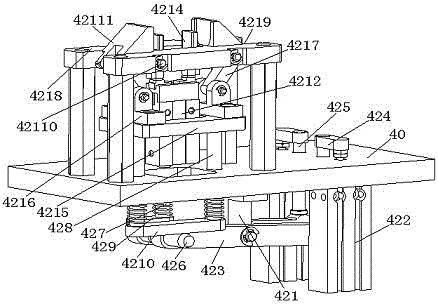

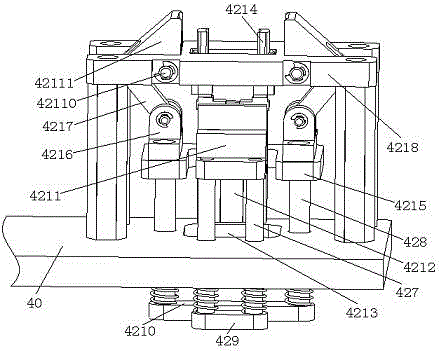

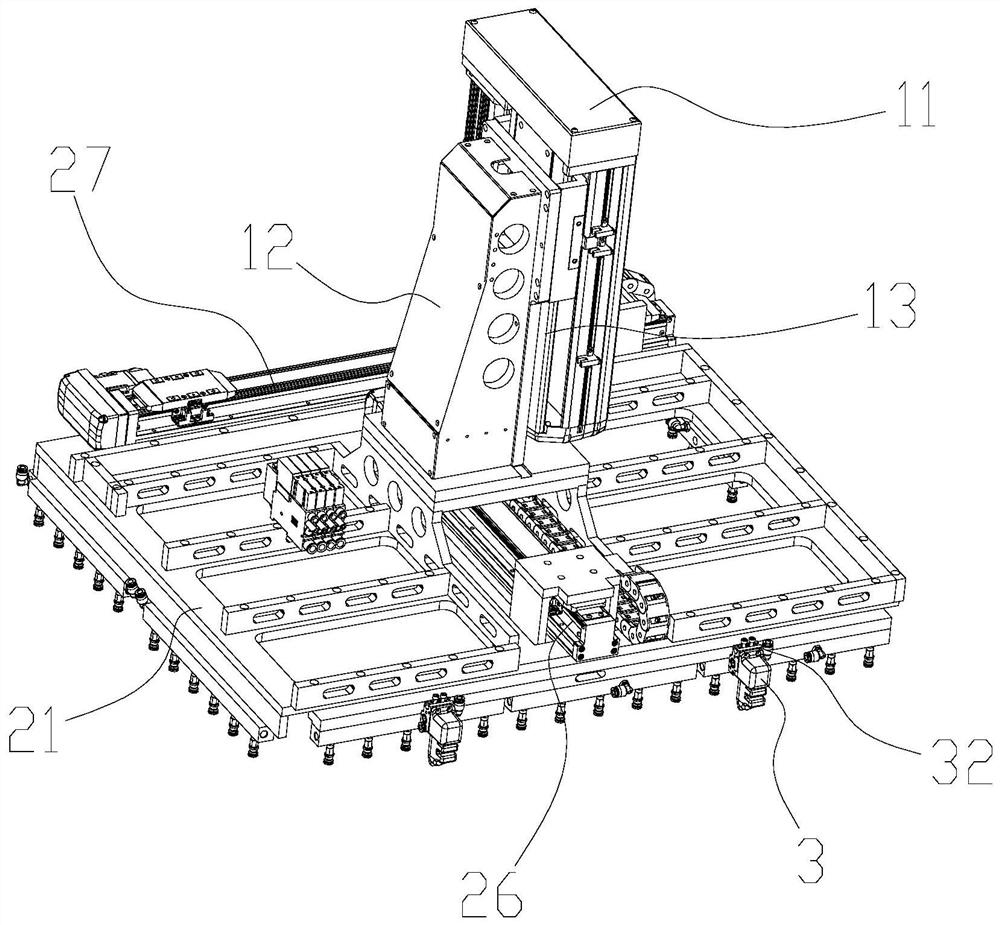

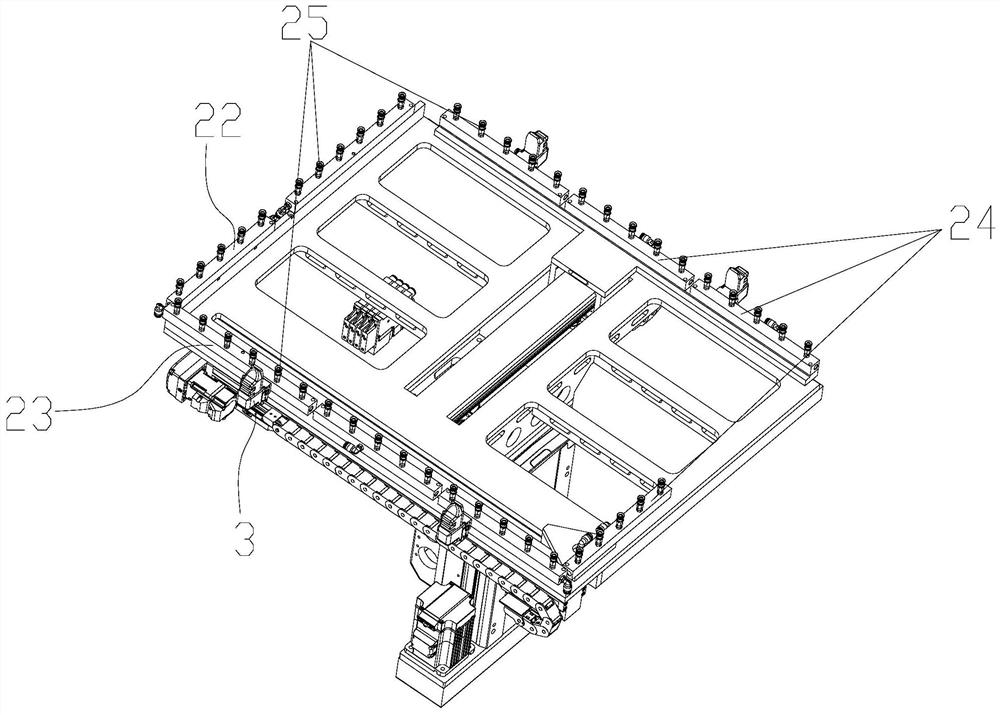

High-precision thrust ball bearing multi-parameter test platform capable of conveniently disassembling and assembling test sample

ActiveCN112557033ARealize simultaneous high-precision measurementAutomatic and accurate positioningMachine bearings testingProcess engineeringTest sample

The invention relates to the technical field of bearing performance tests, and discloses a high-precision thrust ball bearing multi-parameter test platform capable of conveniently disassembling and assembling a sample. The platform comprises a measurement and acquisition module, a power module and a loading module; the measurement and acquisition module comprises a sample cavity, a compatible fixture mechanism and a signal acquisition module; the compatible clamp mechanism and the signal acquisition system are installed in the sample cavity, the upper end of the sample cavity is connected withthe power module through a connecting shaft, and the lower end of the sample cavity is connected with the loading module through a loading base. According to the invention, a worm and gear adjustingmechanism is designed, so when different types of thrust ball bearings are tested, a clamp device does not need to be replaced and disassembled, and automatic and accurate positioning of the sensor isrealized; the synchronous high-precision measurement of normal loading and friction torque borne by the thrust ball bearing to be measured can be realized through the six-axis sensor; multi-parameteracquisition is realized, and the defect that the research parameters of the bearing experiment device are single is overcome.

Owner:HEFEI UNIV OF TECH

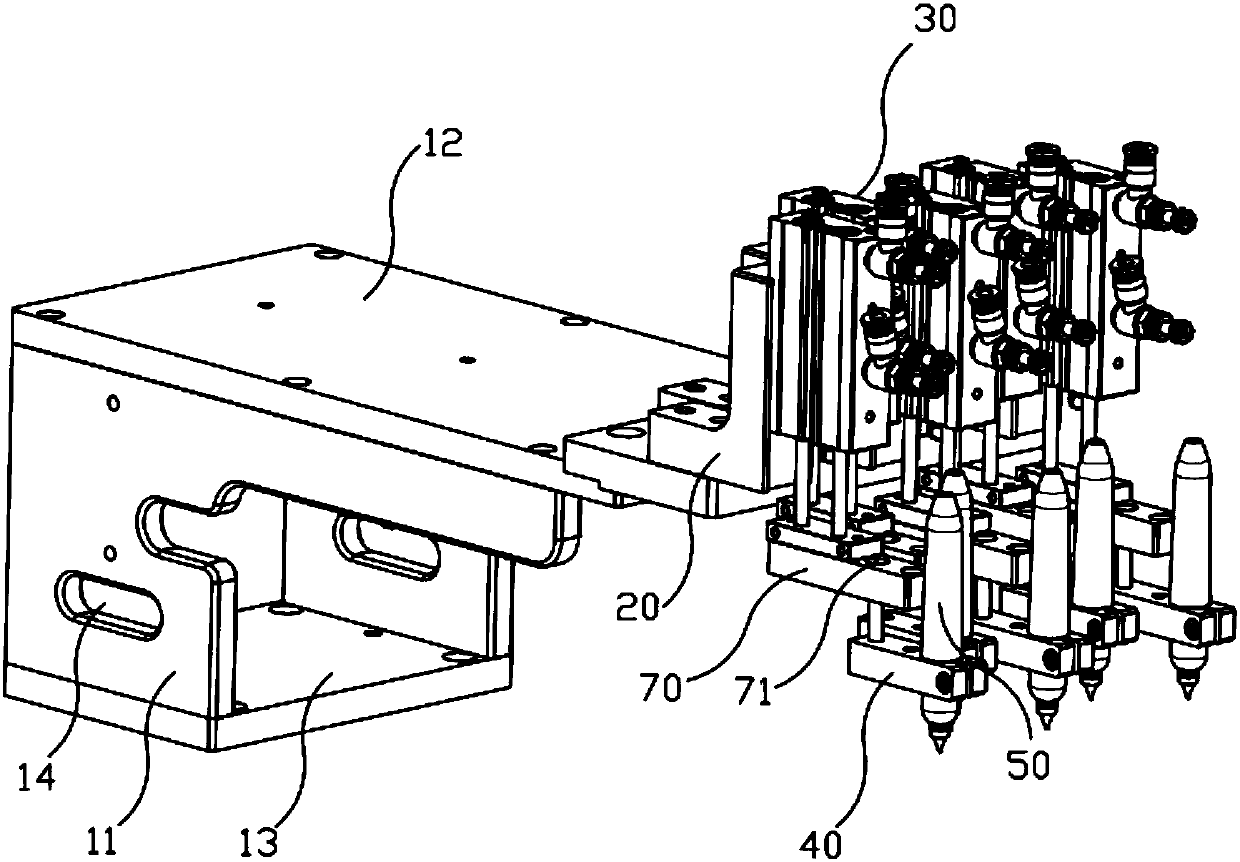

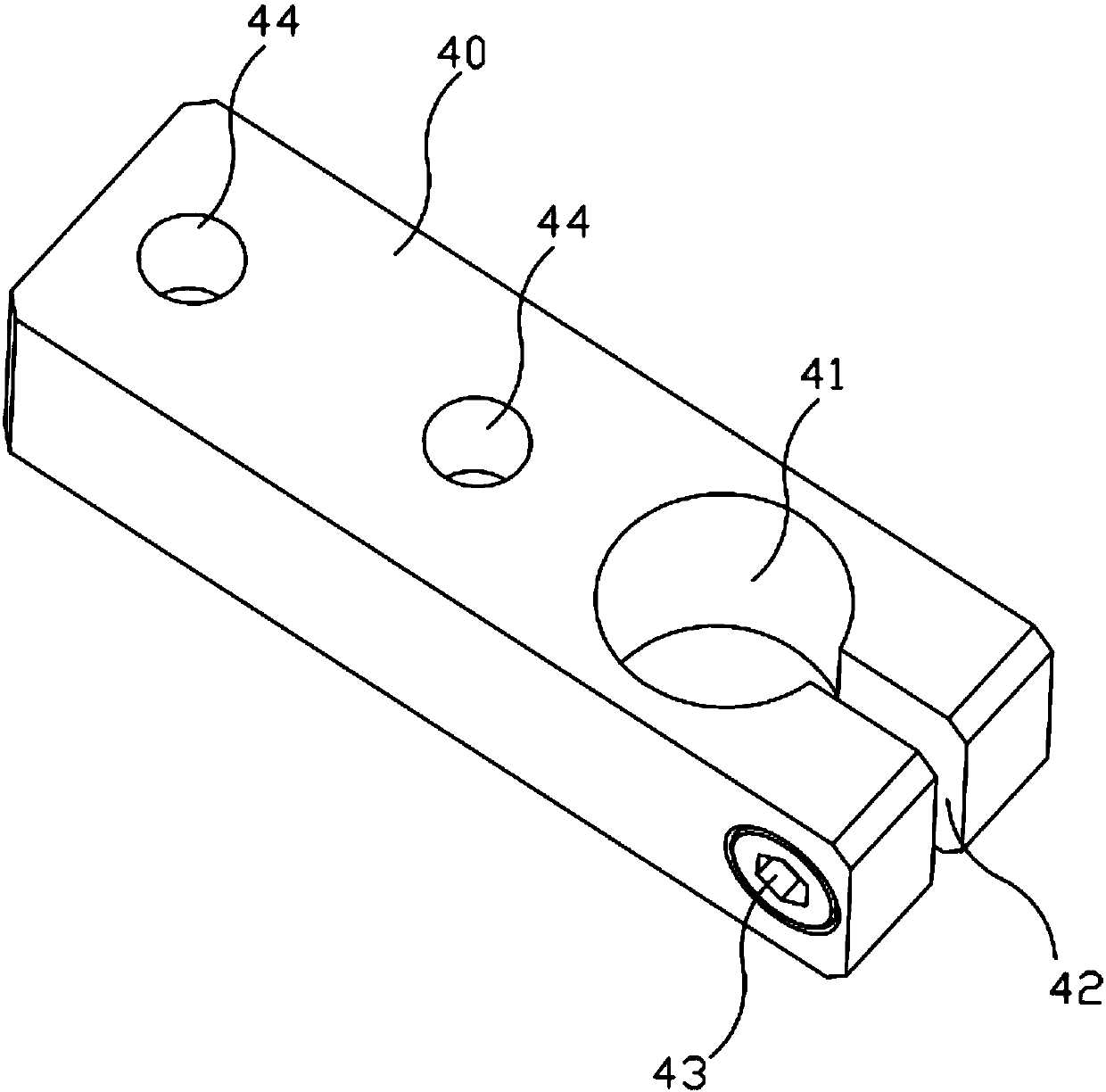

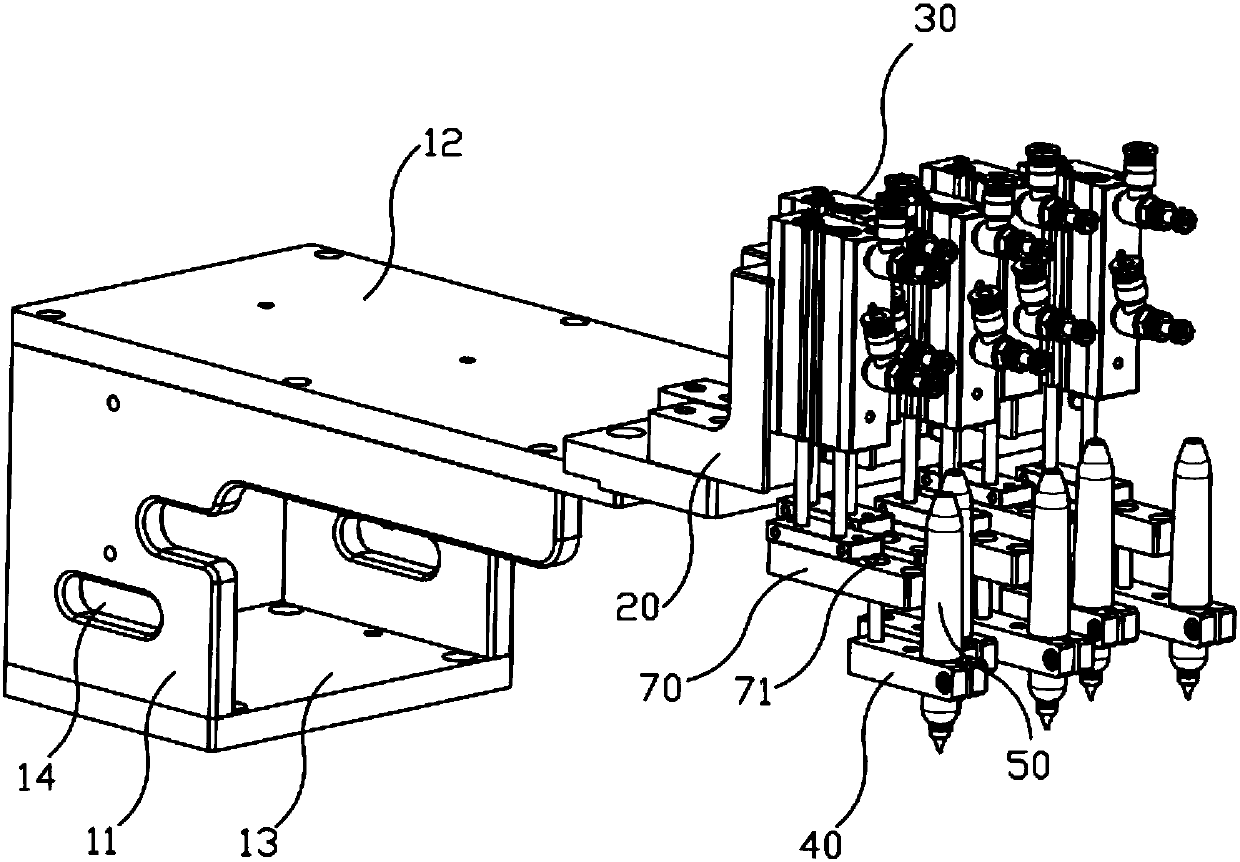

Positioning device of brake pump sealing ring feeding machine

InactiveCN106670769AAutomatic and accurate positioningNovel structureMetal working apparatusEngineeringMechanical engineering

The invention discloses a positioning device of a brake pump sealing ring feeding machine. The positioning device of the brake pump sealing ring feeding machine comprises a transposition installing plate. A positioning hinge base and two positioning guide rod air cylinders with upward piston rods are fixed to the lower plane of the transposition installing plate. A guiding connecting rod is in pin joint to each of the two sides of the positioning hinge base. The two positioning guide rod air cylinders are located on the two sides of the two guiding connecting rods correspondingly. The piston rods of the two positioning guide rod air cylinders penetrate the transposition installing plate and then are each fixedly provided with a positioning guiding block through an air cylinder connecting device. A longitudinal positioning guiding shaft is fixed to the lower plane of each of the two positioning guiding blocks. The lower ends of the two positioning guiding shafts penetrate the transposition installing plate and then are attached to the upper planes of one ends of the two guiding connecting rods correspondingly, and a positioning pin shaft is fixed to the other end of each of the two guiding connecting rods. By means of the above manner, the positioning device is simple and novel in structure, easy and convenient to operate, capable of automatically and accurately positioning workpieces and free of manual assistance, and mechanical automatic work is achieved.

Owner:苏州迈邻物业管理有限公司

Automatic zoning plate falling prevention suction cup device and control method thereof

PendingCN112794075AAutomatic and accurate positioningImprove the efficiency of automatic connectionCharge manipulationPackagingPrinted circuit boardMechanical engineering

The invention discloses an automatic zoning plate falling prevention suction cup device. The device comprises a transmission mechanism and a suction cup module; the suction cup module comprises a base plate, a transverse suction set, a longitudinal suction set and movable suction sets, and the transverse suction set and the longitudinal suction set are fixed to the base plate; the base plate is provided with a transverse guide rail and a longitudinal guide rail, the transverse guide rail and the longitudinal guide rail are in sliding connection with sliding blocks respectively, the movable suction sets are installed on the sliding connection blocks of the transverse guide rail and the sliding connection blocks of the longitudinal guide rail respectively, and a suction cup area is formed through mutual cooperation of the transverse suction set, the longitudinal suction set, the movable suction set of the transverse guide rail and the movable suction set of the longitudinal guide rail. The invention relates to a control method of the automatic zoning plate falling prevention suction cup device. According to the control method, accurate grabbing is achieved by inputting the size of a printed circuit board through an upper computer, the interval can be adjusted in a stepless mode, the device adapts to the specifications of most printed circuit boards, human intervention is reduced, and the automatic wiring efficiency of an exposure machine is improved.

Owner:ZHONGSHAN AISCENT TECH

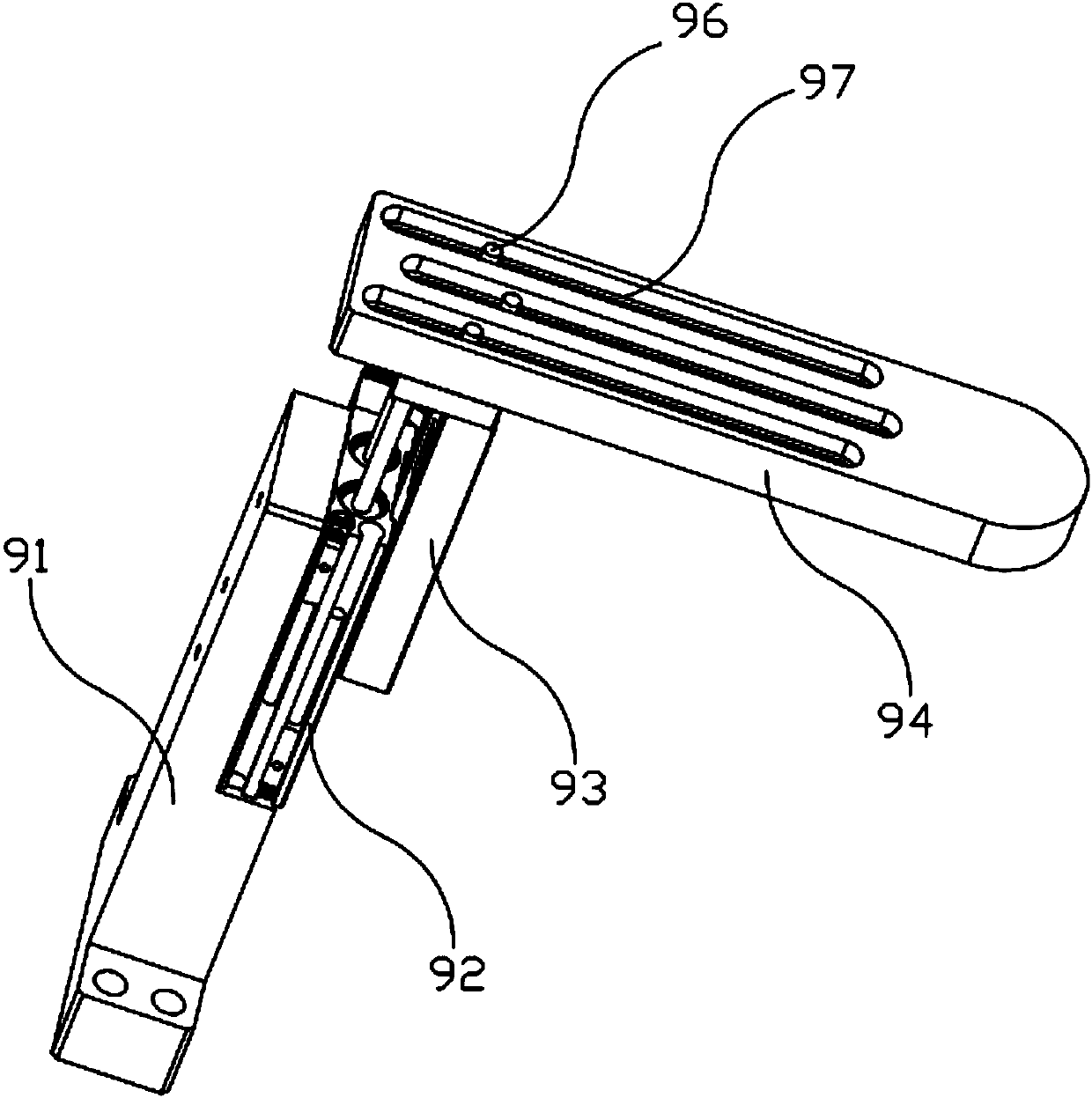

Automatic marking device for fingerprint modules

PendingCN107694958AAutomatic and accurate positioningTypewritersSortingEngineeringMechanical engineering

The invention discloses an automatic marking device for fingerprint modules. The automatic marking device comprises a fixed base. A conveying assembly, a positioning assembly, a horizontal moving mechanism and a cartridge bracket are arranged on the base. A dotting assembly is arranged on the horizontal moving mechanism. The conveying assembly is used for conveying fingerprint modules. The positioning assembly is located in front of the horizontal moving mechanism and used for positioning the fingerprint modules conveyed by the conveying assembly. The horizontal moving mechanism comprises a sliding rail arranged on the base, a sliding block slidably connected with the sliding rail, and a motor driving the sliding block to move along the sliding rail. The dotting assembly is used for marking the fingerprint modules on the positioning assembly. According to the automatic marking device for fingerprint modules, automatic feeding and discharging can be achieved, and when a defective fingerprint module is detected, the automatic marking device can automatically move to the position above the defective fingerprint module and automatically mark the defective fingerprint module.

Owner:JIANGSU A KERR BIOLOGICAL RECOGNITION TECH CO LTD

A fully automatic and efficient autoclaved aerated concrete block demoulding device

The invention relates to a fully automatic and efficient autoclaved aerated concrete block demoulding device, which belongs to the technical field of aerated brick production equipment. It includes: a frame, a walking trolley arranged on the top of the frame, and a support frame arranged at the bottom of the frame and parallel to each other, the top of the frame is provided with a positioning mechanism for automatically positioning the walking trolley, and the support frame A clamping mechanism for clamping the mold is arranged between them, and a drive mechanism for driving the clamping mechanism to slide vertically is provided on the top of the frame. The invention can realize automatic and accurate positioning, so that the clamping mechanism can accurately locate the position of the mold, and greatly reduces the time for the clamping mechanism to find and pick up the mold.

Owner:惠州市鑫业建材有限公司

Anchor net positioning and edge holding device and working method thereof

PendingCN108326204AAutomatic and accurate positioningHigh degree of automationWire networkWorking setAutomation

The invention discloses an anchor net positioning and edge holding device. The device comprises a base, a workbench, a positioning device, a edge holding mechanism, a pressing device and a hydraulic device; the workbench is arranged on the base, and the positioning device is arranged on the workbench, and is used for enabling the anchor net to be subjected to the edge holding to be positioned at acorrect holding position; the edge holding mechanism is rotationally arranged at the end of the workbench, is used for carrying out edge holding for the anchor net, and the pressing device is arranged above the workbench, and is used for pressing the anchor net after the edge holding; and the hydraulic device is arranged on the side part of the workbench, and the edge holding mechanism and the pressing device are driven. The invention further discloses a working method of the anchor net positioning and edge holding device. The device can be used for automatically and accurately positioning, holding edges and pressing, and is high in automation degree, and is suitable for different anchor nets; the anchor net can be effectively subjected to the edge holding, so that the quality of the edgeholding is guaranteed, and the production efficiency is improved; and the structure is simple, the operation is simple and convenient, and the universality is high.

Owner:内蒙古上海庙矿业有限责任公司

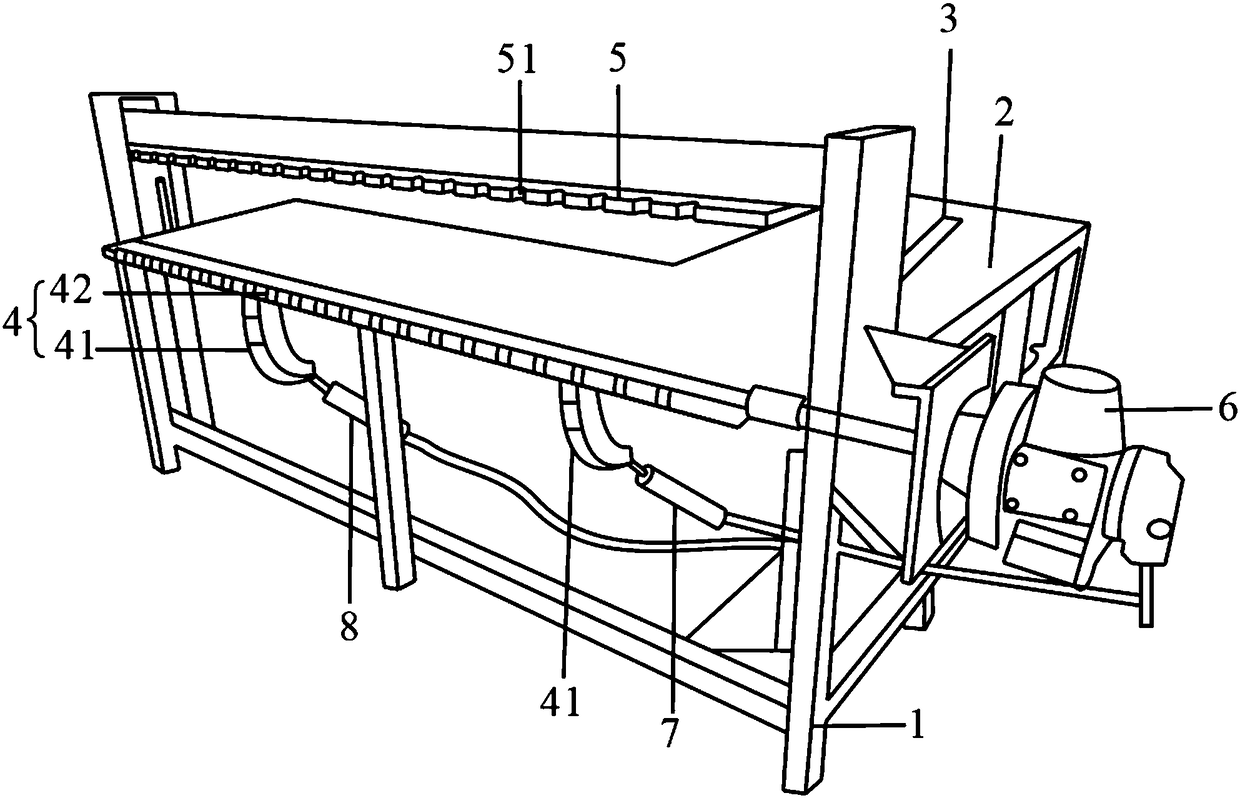

Fingerprint module conveying platform

The invention discloses a fingerprint module conveying platform. The fingerprint module conveying platform comprises a fixed base. The base is provided with two opposite guide rail supports, a guide rail assembly, a positioning assembly and a lifting air cylinder driving the guide rail assembly to ascend and descend relative to the base. The guide rail assembly comprises two parallel guide rail supporting plates arranged on the two guide rail supports, two opposite conveying belts arranged in the length direction of the two guide rail supporting plates, and a power device driving the conveyingbelt. The guide rail supporting plates are provided with long grooves for the conveying belts to penetrate in the length direction of the guide rail supporting plates. The two power devices are arranged and arranged on the two guide rail supporting plates correspondingly. Each power device comprises a drive motor arranged on the corresponding guide rail supporting plate, a driving gear and a driven gear. The conveying belts are wound around the driving wheels and the driven wheels, and the driving wheels are in transmission connection with output shafts of the drive motors. The positioning assembly is located between the two guide rail supporting plates and used for positioning whole-plate fingerprint modules conveyed through the guide rail assemblies.

Owner:JIANGSU A KERR BIOLOGICAL RECOGNITION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com