High-precision thrust ball bearing multi-parameter test platform capable of conveniently disassembling and assembling test sample

A technology of thrust ball bearings and test platforms, which is applied in the direction of mechanical bearing testing, measuring devices, testing of mechanical components, etc., can solve the problem of inability to achieve synchronization, direct and accurate measurement of the normal pressure and friction torque of experimental bearings, low efficiency, and bearing problems. The research on the performance parameters of the sample is single and other problems, to achieve the effect of synchronous high-precision measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

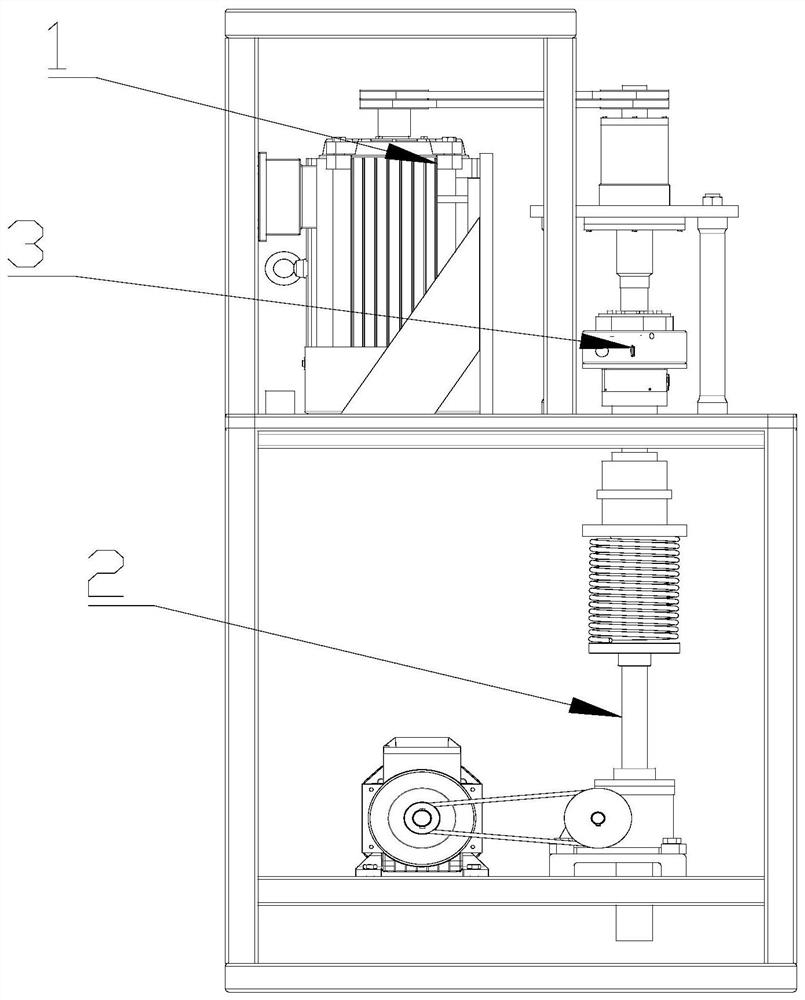

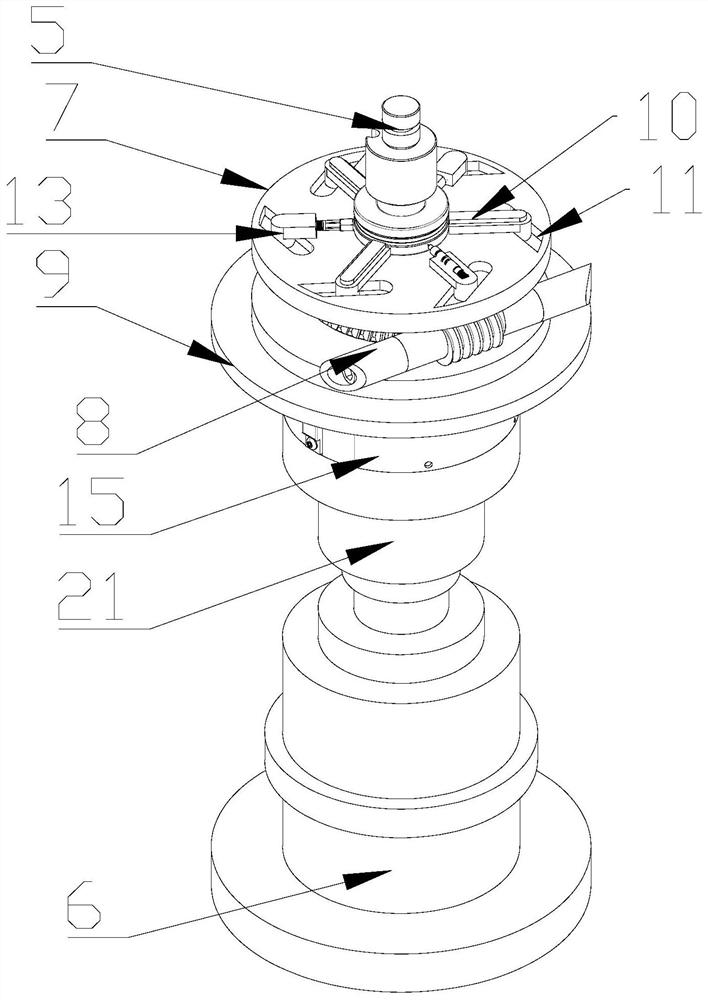

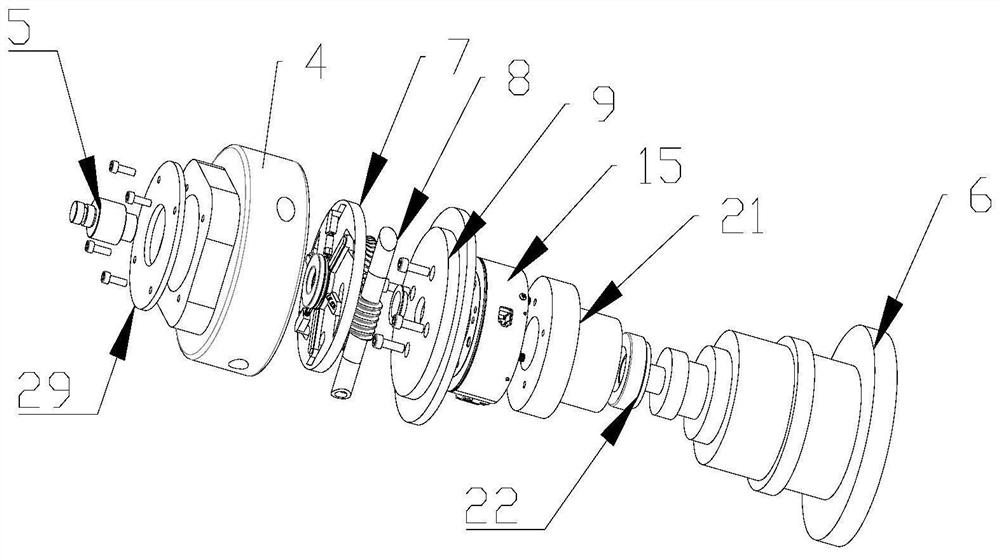

[0032] A high-precision thrust ball bearing multi-parameter test platform that can easily disassemble and assemble samples, including a measurement and acquisition module 3, a power module 1, and a loading module 2. The measurement and acquisition module 3 includes a sample cavity 4, a compatible fixture mechanism, The signal acquisition module, compatible with the fixture mechanism, and the signal acquisition system are installed in the sample cavity 4. The upper end of the sample cavity 4 is connected to the power module 1 through the connecting shaft 5, and the lower end of the sample cavity 4 is connected to the loading base 6. Module 2 is connected.

[0033] Further, the compatible fixture mechanism includes a worm wheel 7, an adjusting worm 8, and a lower baffle 9. The bottom of the worm wheel 7 meshes with the adjusting worm 8. Six centering brackets 10 are evenly distributed on the worm wheel 7. There are six limit grooves 11 corresponding to the centering bracket 10, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com