Automatic marking device for fingerprint modules

A fingerprint module and automatic marking technology, which is applied in printing, sorting, typewriters, etc., can solve the problems of low positioning accuracy, increased manual labor intensity, and affecting test efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

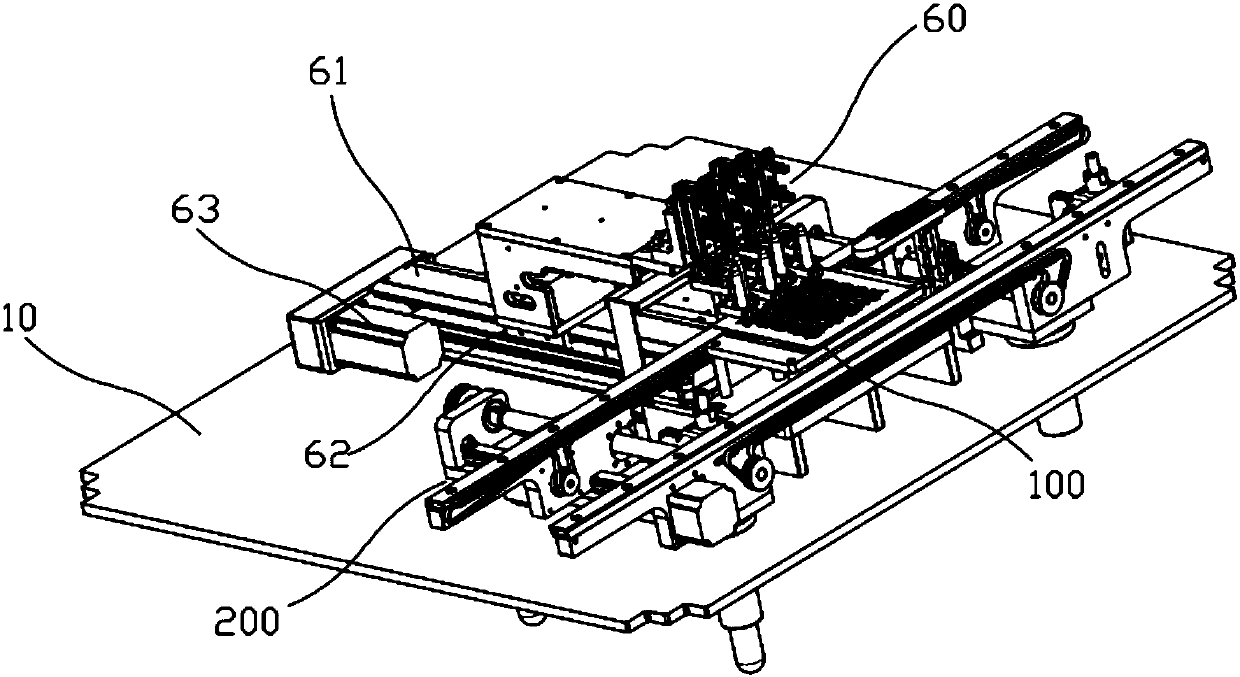

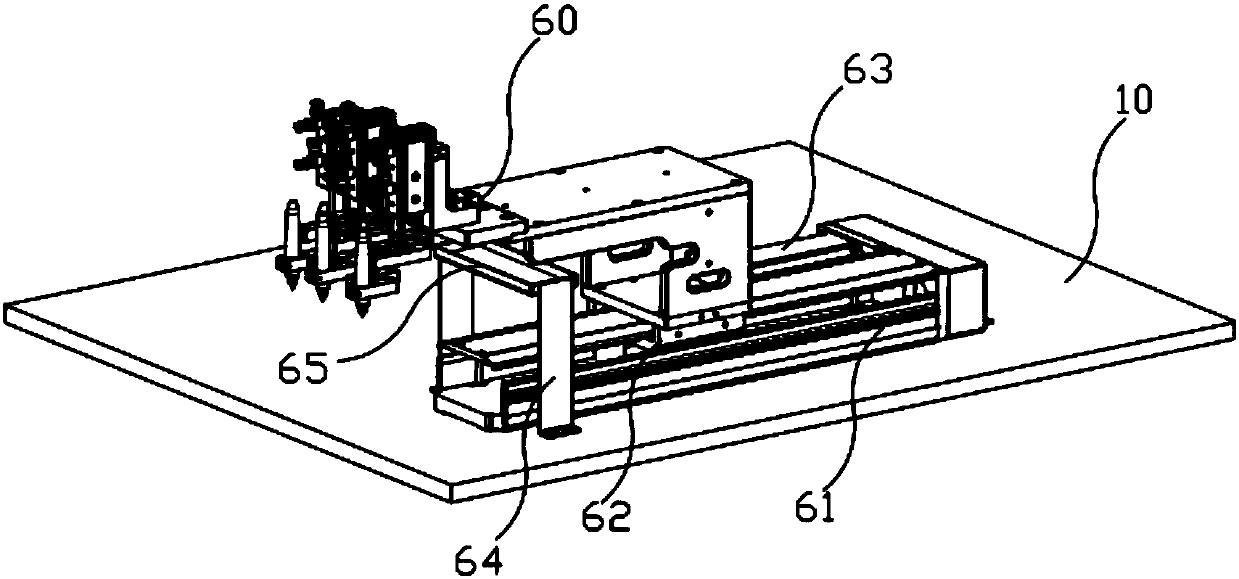

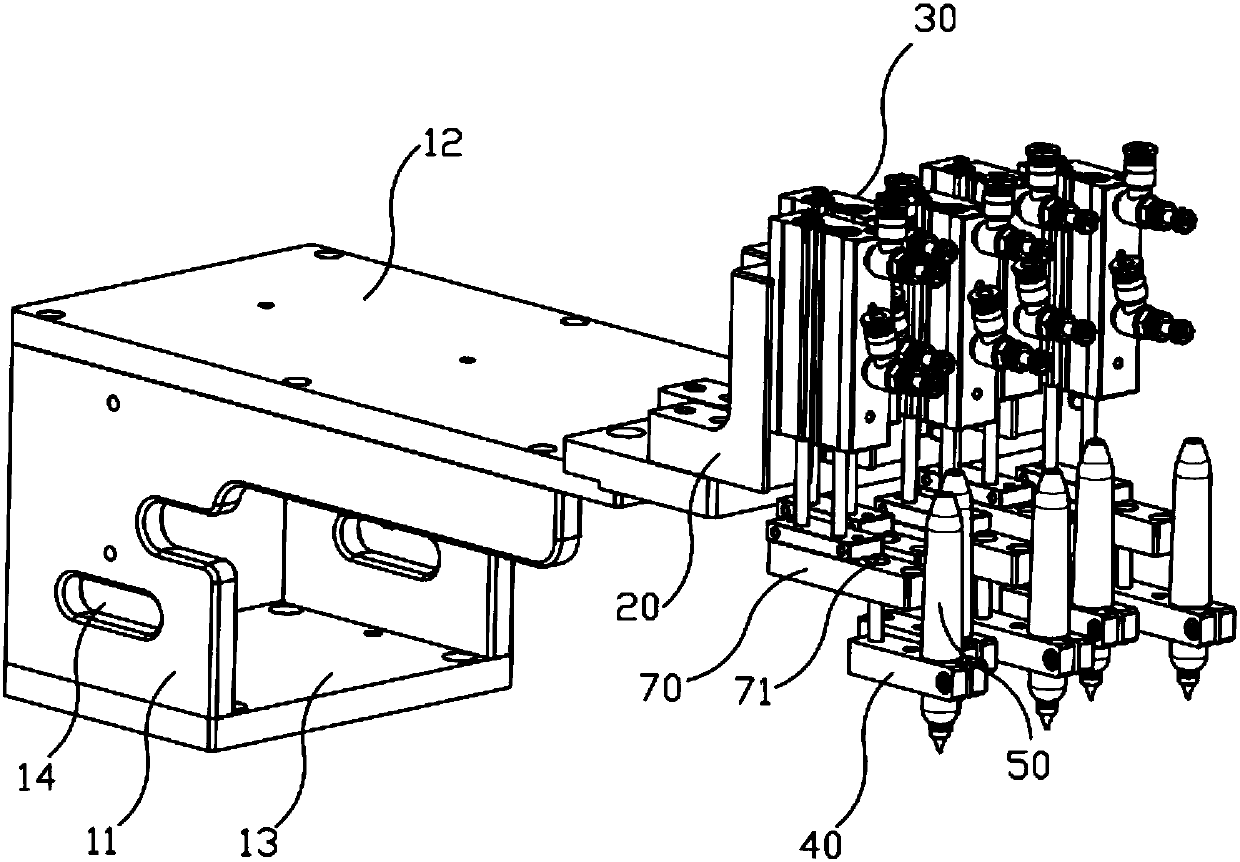

[0046] Such as figure 1 As shown, the fingerprint module automatic marking device of the present invention comprises a fixed base 10, the base 10 is provided with a transport assembly 200, a positioning assembly 100, a translation mechanism and an ink cartridge bracket 64, and the translation mechanism is provided with a dotting assembly 60. The assembly 200 is used to transport the fingerprint module; the positioning assembly 100 is located in front of the translation mechanism, and is used to position the fingerprint module delivered by the transportation assembly 200; the translation mechanism includes a slide rail 61 arranged on the base 10, and a slide rail 61 The sliding block 62 is slidably connected, and the motor 63 that drives the sliding block 62 to move along the slide rail 61 ; the dott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com