Fingerprint module conveying platform

A technology of conveying platform and fingerprint module, applied in the direction of conveyor, conveyor objects, transportation and packaging, etc., can solve the problems of affecting test efficiency and low positioning accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

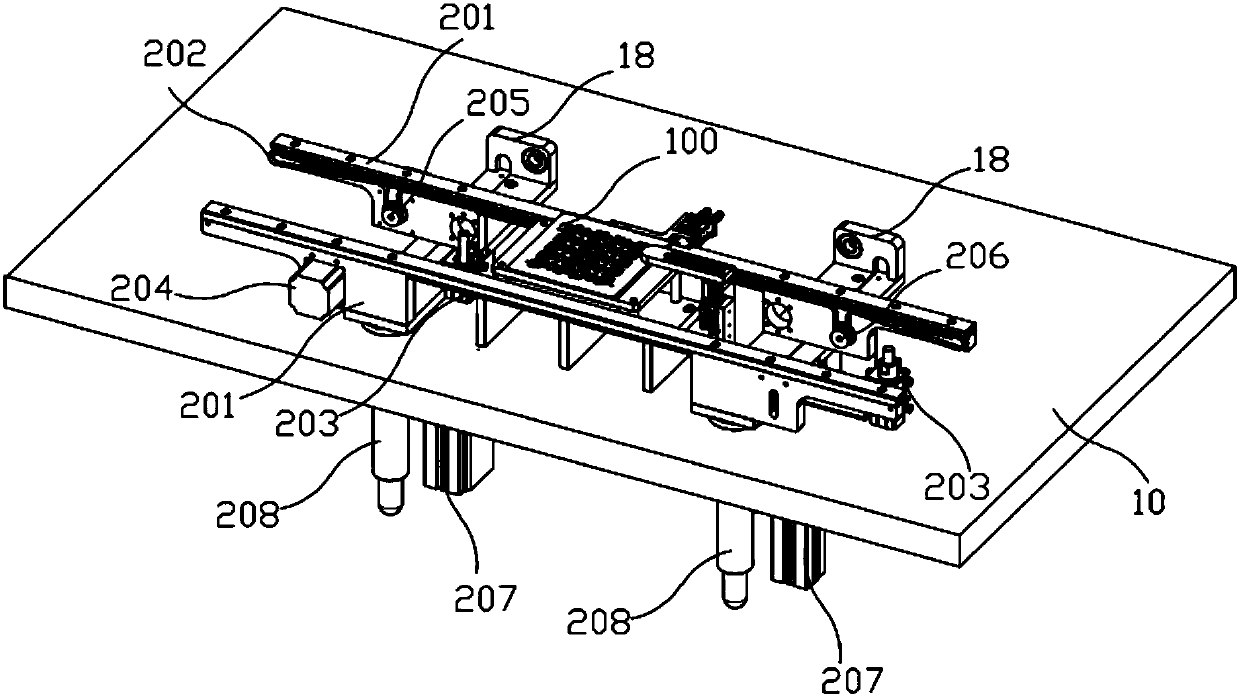

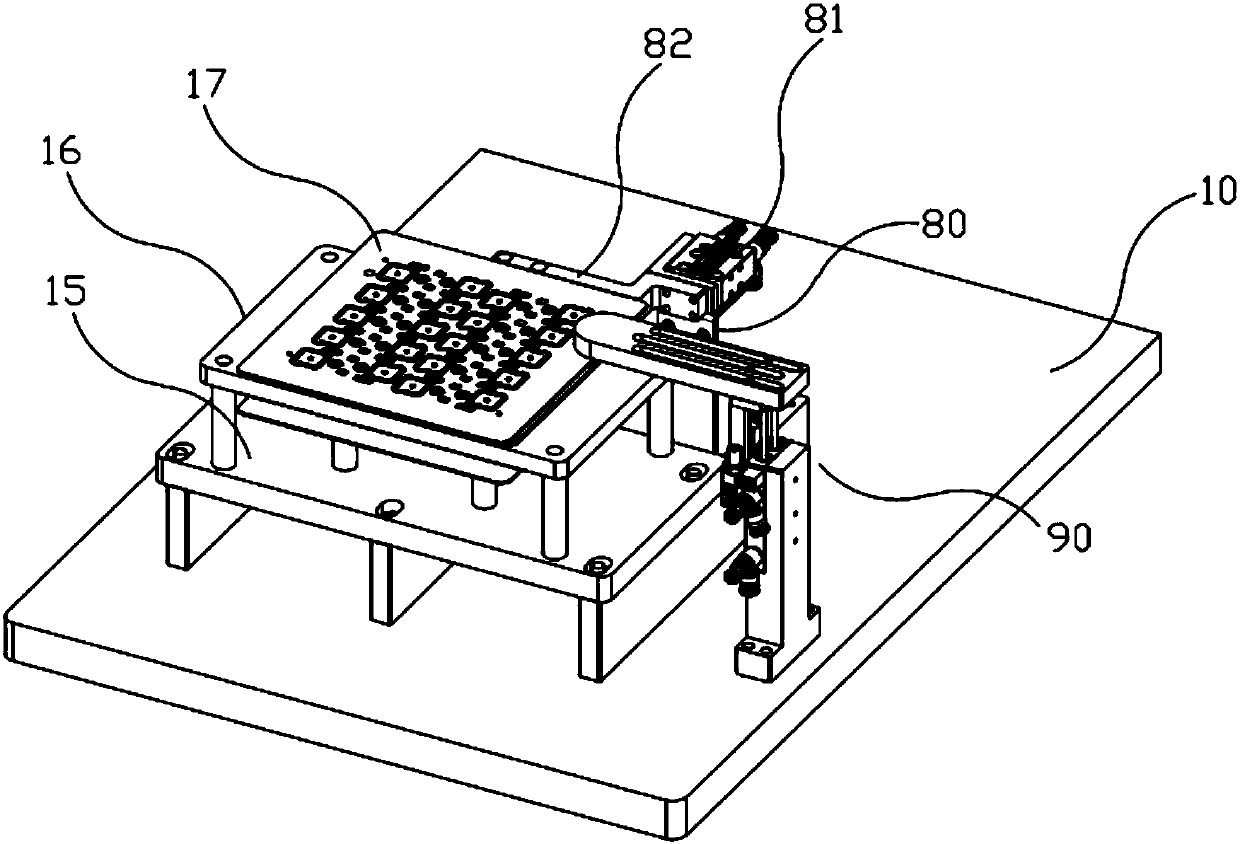

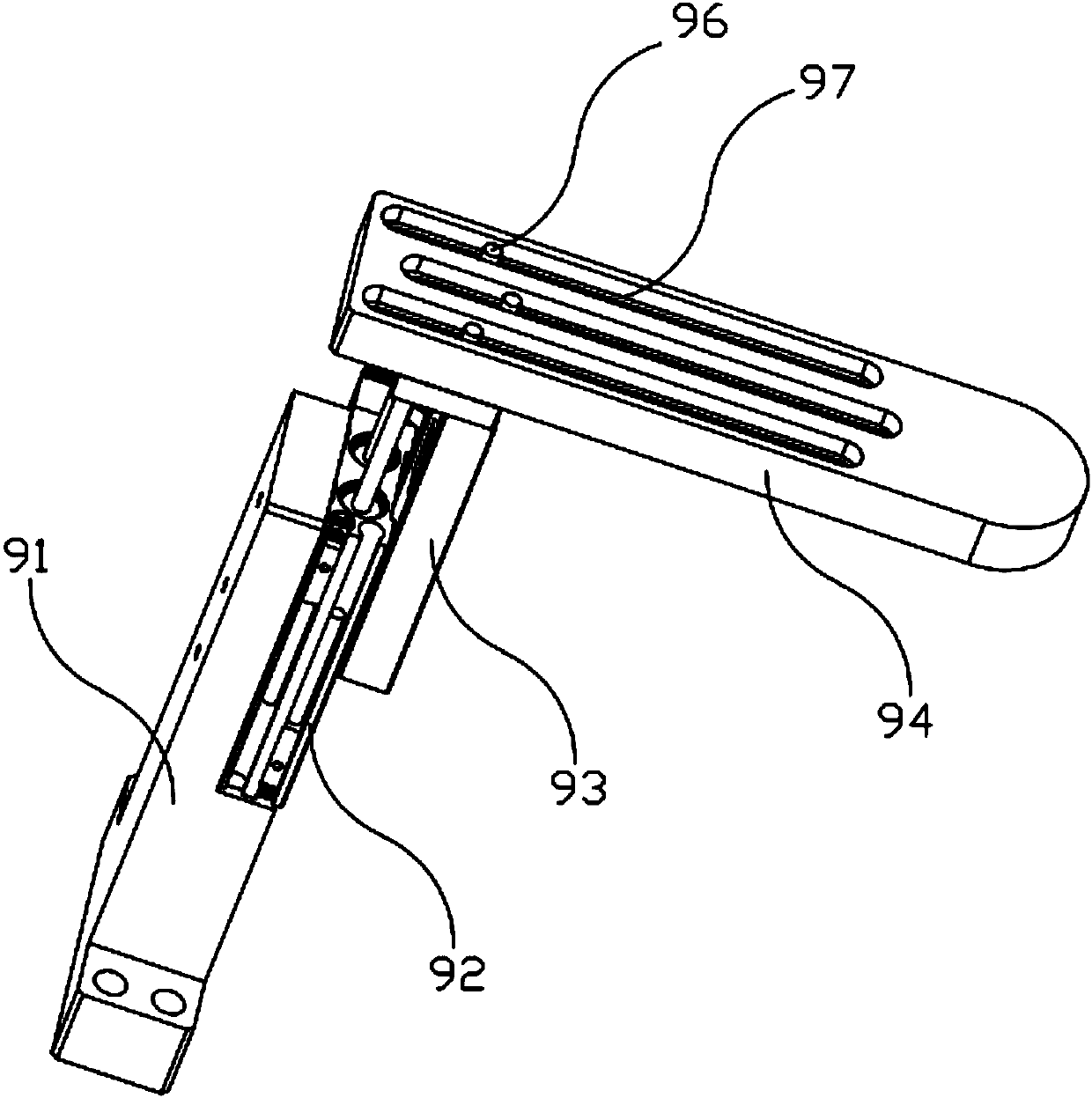

[0027] Such as Figures 1 to 4 As shown, the fingerprint module delivery platform of the present invention includes a fixed base 10 on which two opposite guide rail supports 18, a guide rail assembly, a positioning assembly 100, and a lifting cylinder 207 that drives the guide rail assembly to move up and down relative to the base 10 are provided. The guide rail assembly includes two guide rail support plates 201 installed on two guide rail support plates 18 parallel to each other, two opposite conveyor belts 202 arranged along the length direction of the two guide rail support plates 201, and a power to drive the conveyor belt 202 device; the guide rail support plate 201 is provided with a long slot along its length direction for the conveyor belt 202 to pass through; The driving motor 204 , the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com