A fully automatic and efficient autoclaved aerated concrete block demoulding device

A concrete block, autoclaved gas filling technology, applied in the direction of unloading devices, manufacturing tools, etc., can solve the problems of inaccurate positioning, increase the workload of staff, time-consuming and labor-intensive, etc., to improve productivity and reduce the need to find molds time, ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

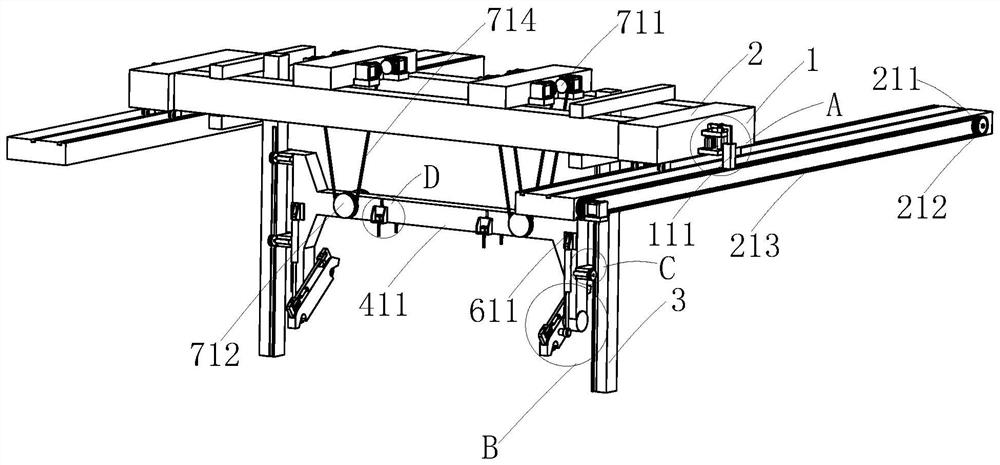

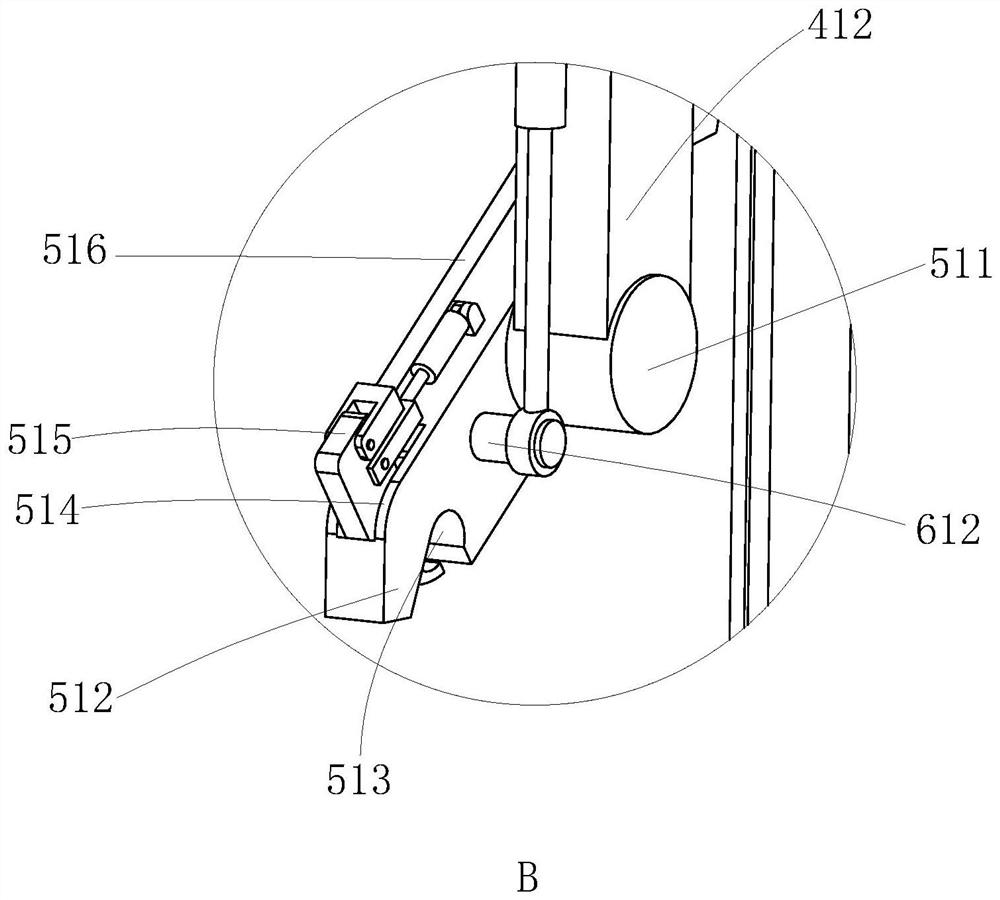

[0038] refer to figure 1 , is a fully automatic and efficient autoclaved aerated concrete block demoulding device disclosed in the present invention, comprising: a frame 1, a walking trolley 2 arranged on the top of the frame 1, and the walking trolley 2 can move along the Sliding in the direction of extension; and there are two supporting frames 3 installed at the bottom of the frame 1, and the adjacent supporting frames 3 are parallel to each other.

[0039] A positioning mechanism is arranged on the top of the frame 1, and the positioning mechanism can realize automatic and accurate positioning of the walking trolley 2.

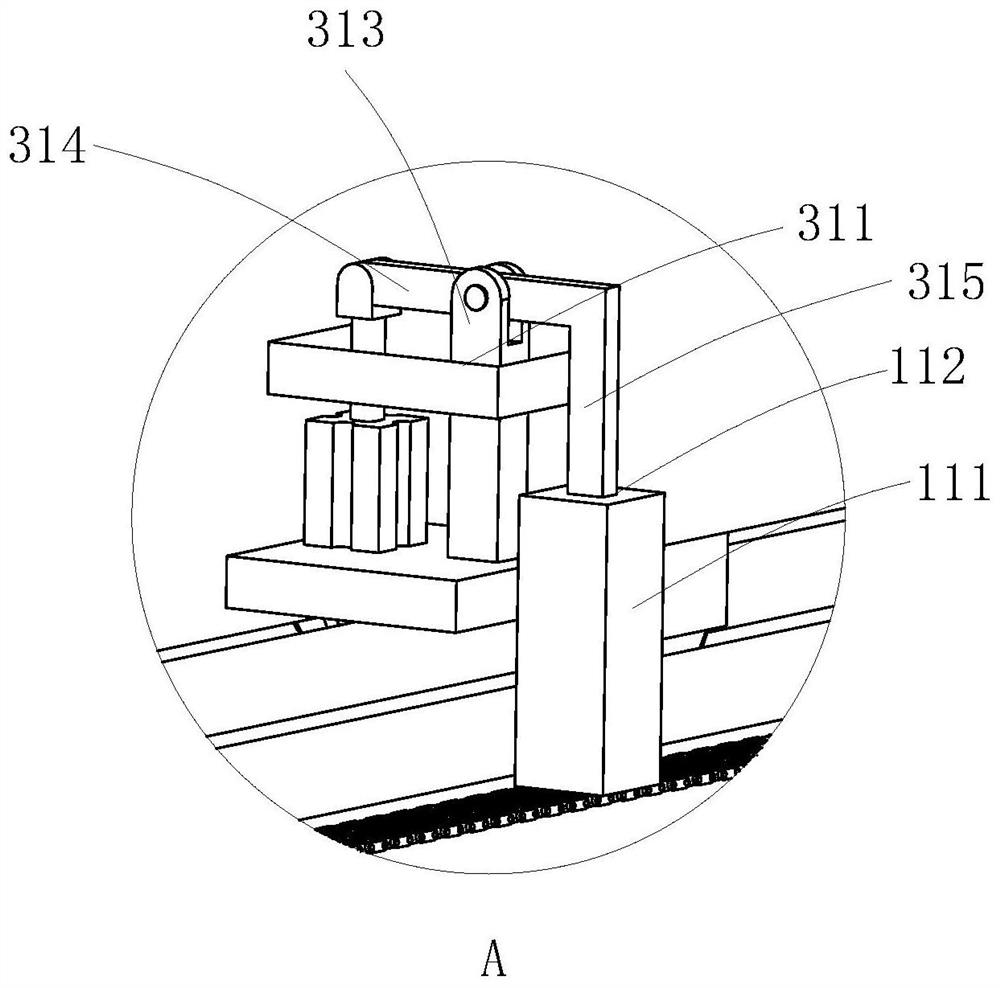

[0040] In this embodiment, the positioning assembly includes: a positioning block 111 slidingly connected to the outer side of the frame 1, the positioning block 111 can slide along the extension direction of the frame 1, and the number of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com