Phase synchronization measuring system and measuring method for double-shaft precision centrifugal machine

A precision centrifuge, phase synchronization technology, applied in the direction of measuring electrical variables, measuring devices, phase angle between voltage and current, etc. The error model coefficient is difficult to achieve high calibration accuracy and other problems, to achieve the effect of low hardware quantity and low hardware cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

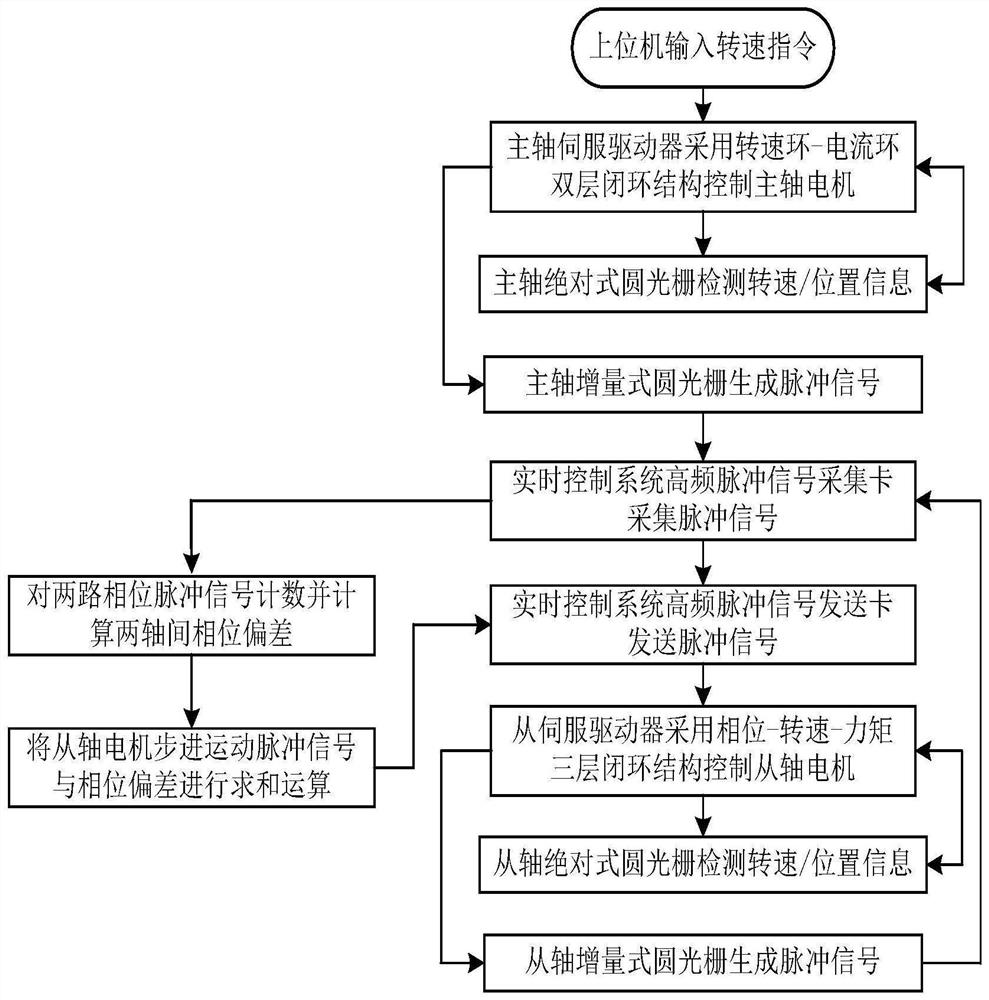

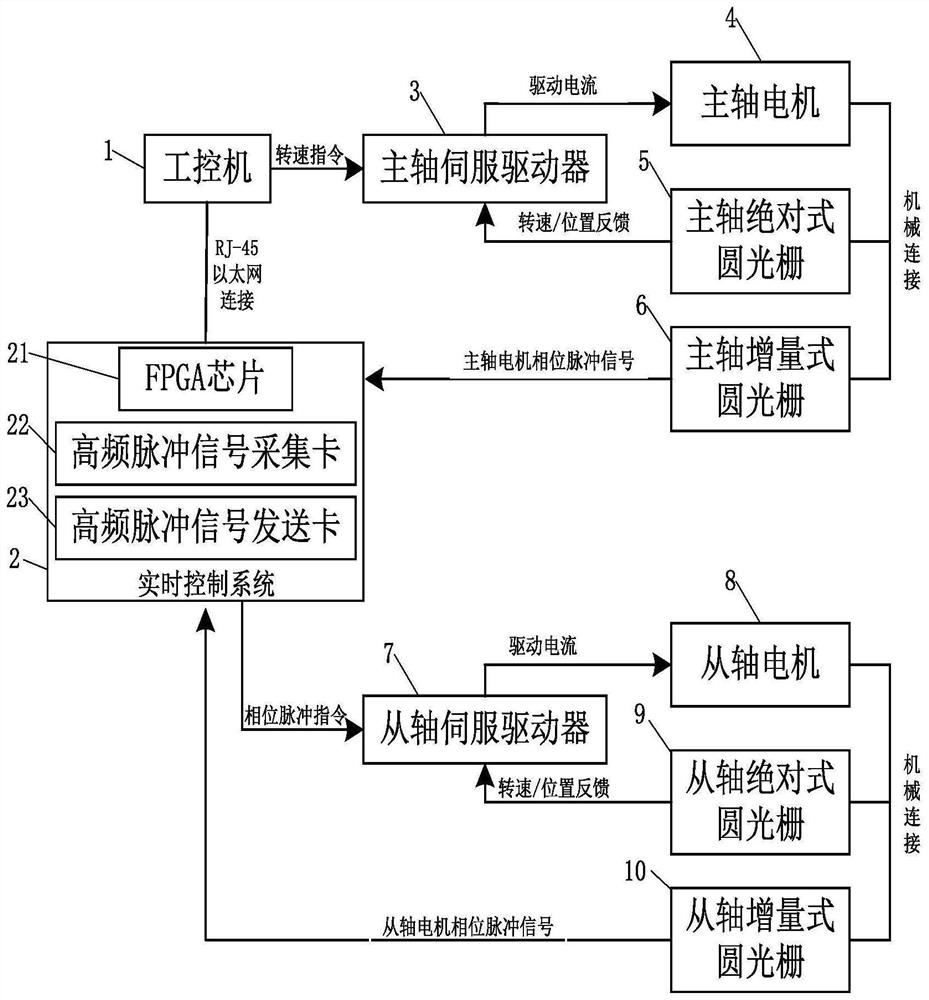

[0041] A two-axis precision centrifuge phase synchronization measurement system, including industrial computer, real-time control system, main shaft servo drive, main shaft motor, main shaft absolute circular grating, main shaft incremental type circular grating, slave shaft servo drive, slave shaft motor, slave shaft Shaft absolute ring encoder, slave axis incremental ring encoder.

[0042] The industrial computer is used as a host computer to run a human-computer interaction interface, perform experimental operations and process management.

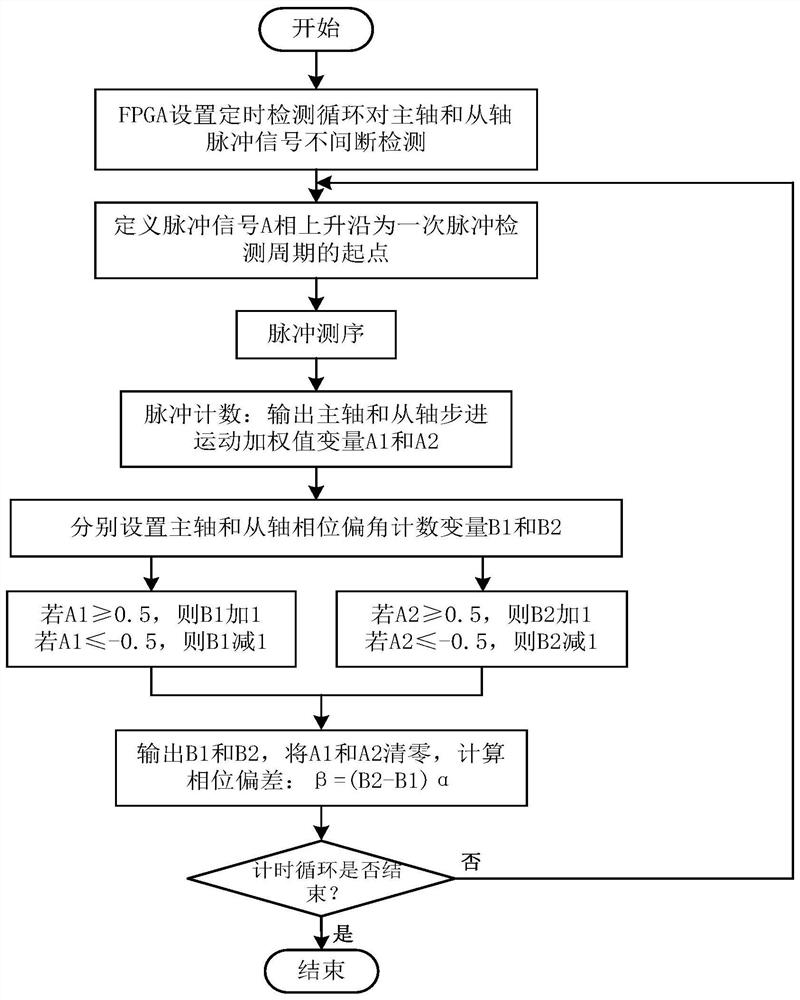

[0043] The real-time control system adopts the FPGA chip as the operation core, and cooperates with the high-frequency pulse signal acquisition card to realize the real-time acquisition of the precision centrifuge main shaft and slave shaft pulse signals, and the high-frequency pulse signal sending card 23 is used to generate the slave shaft motor motion control The desired stepping motion pulse signal.

[0044] The main shaft motor is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com