Multifunctional push-support guide manipulator on drilling floor

A drilling floor, multi-functional technology, applied in the field of multi-functional drilling floor pushing, supporting and guiding manipulators, can solve the problems of limited installation, low precision, single function, etc., and achieve a large-scale effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

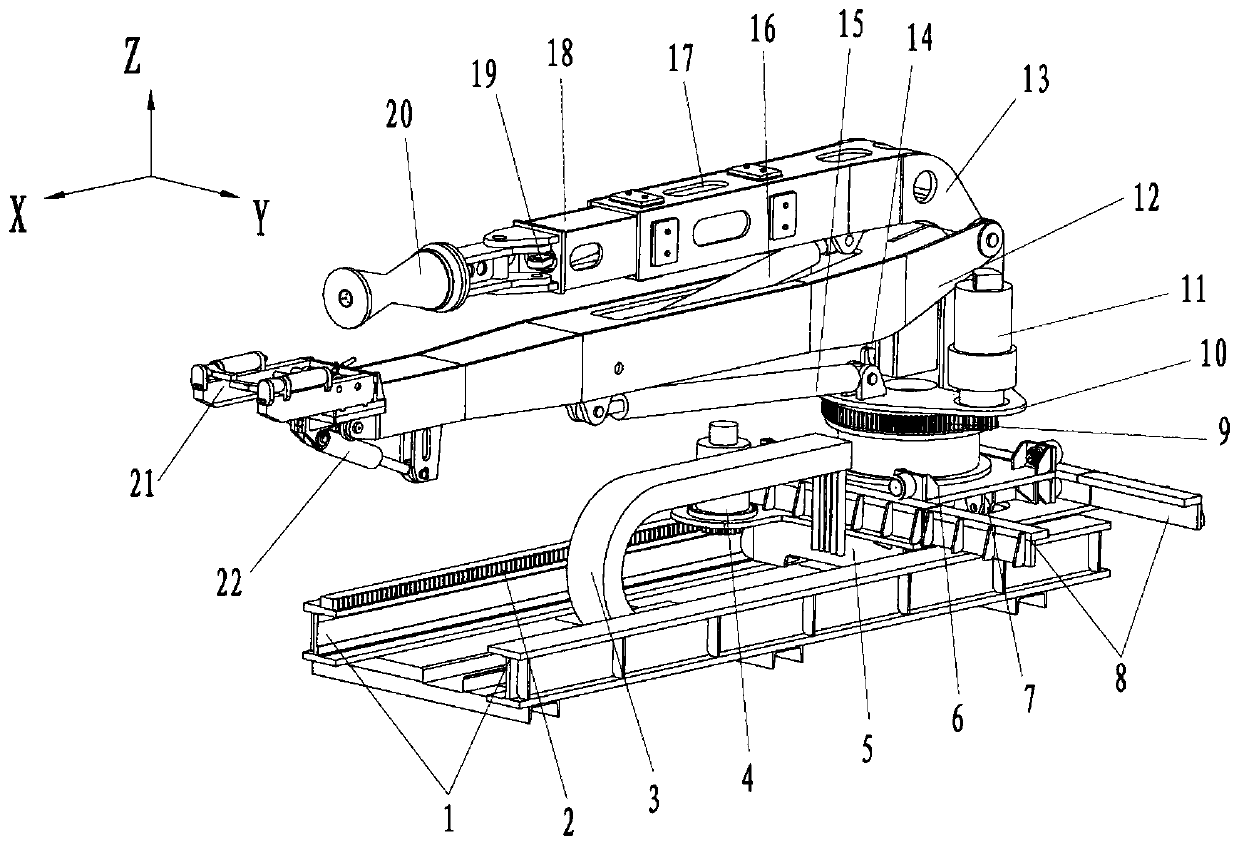

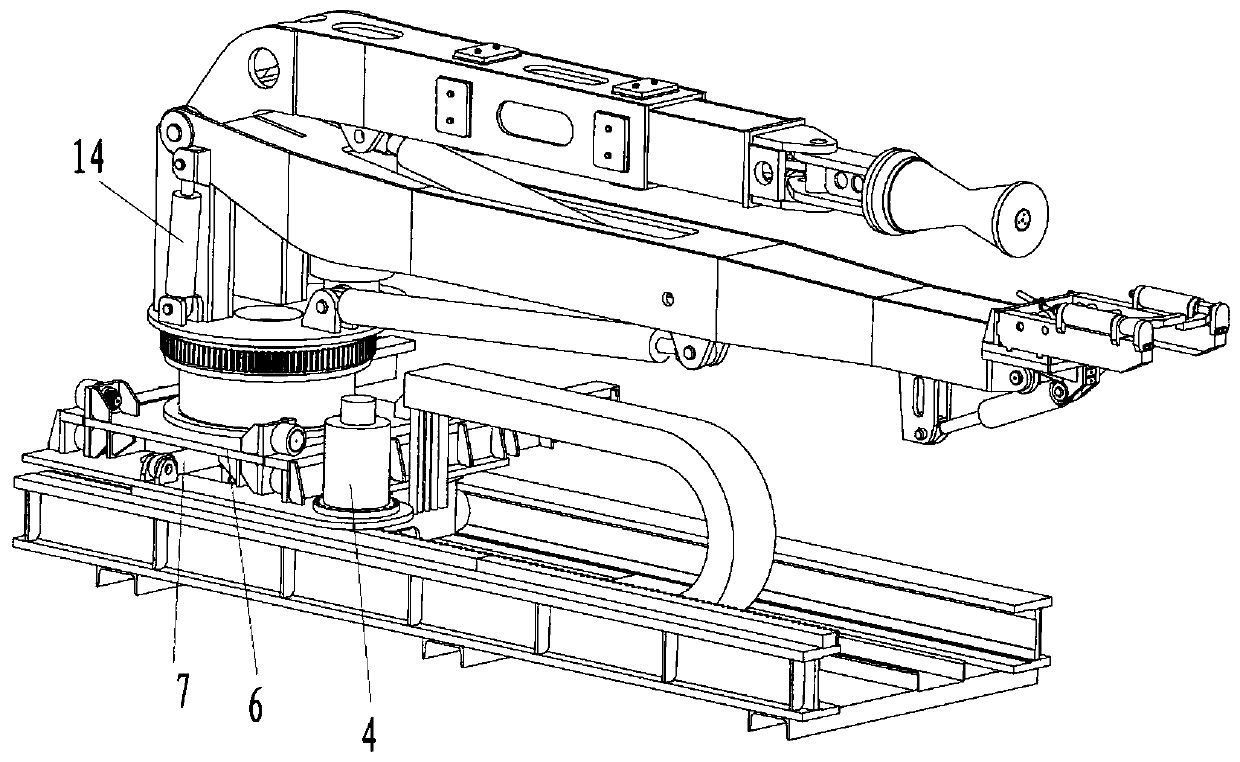

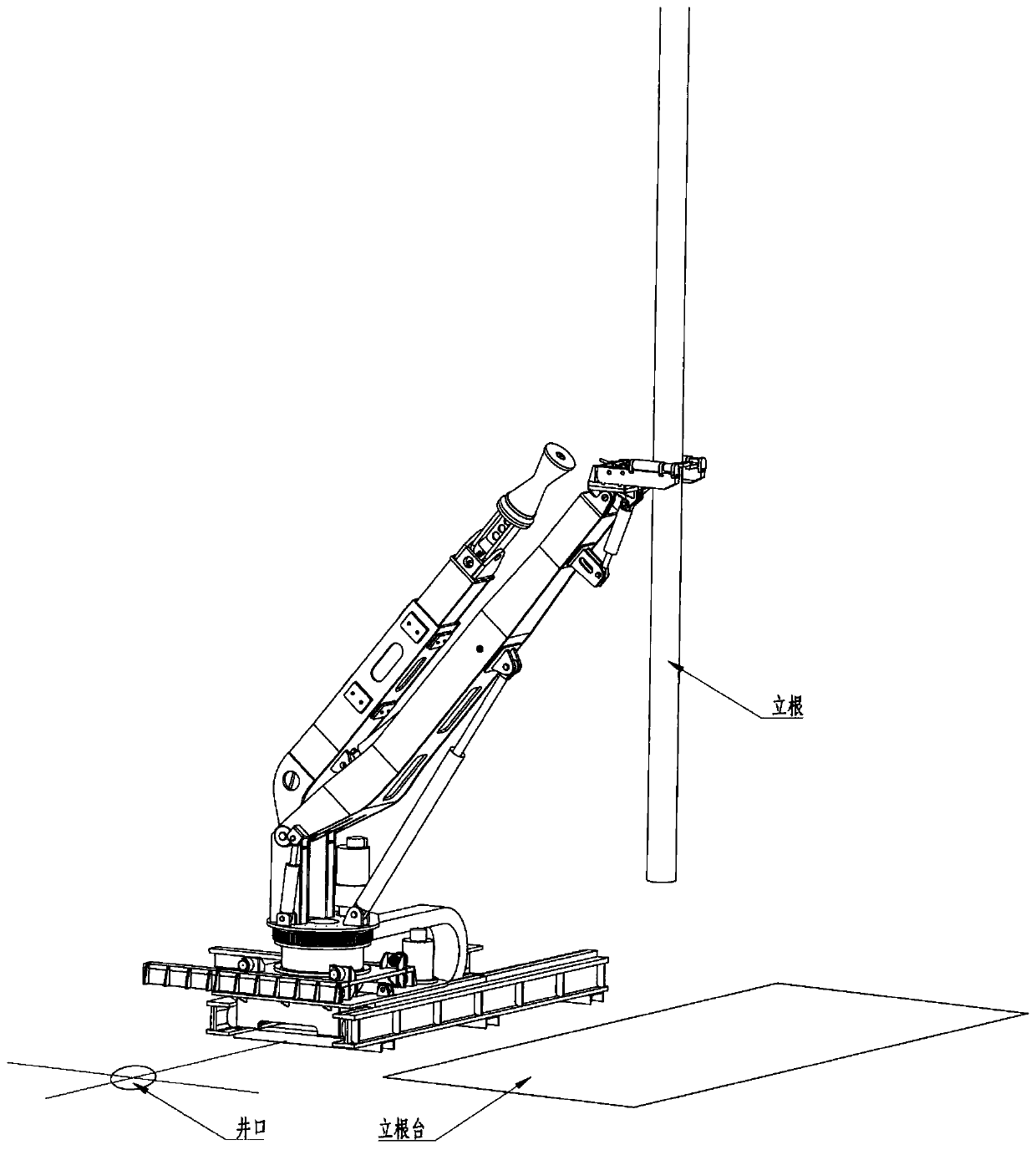

[0031] The present invention provides a multi-functional drill floor pushing and guiding manipulator, such as figure 1 and figure 2 As shown, it includes the X-direction running track 1, which is installed in the middle of the stand on the drill floor, and the X-direction running track 1 includes two X-direction track bodies fixed side by side on the drill floor, one of the two X-direction track bodies is The inner side is provided with a rack 2, and the X-direction traveling track 1 is equipped with an X-direction traveling trolley 5 that can slide horizontally and reciprocatingly. There is a translation gear, the translation gear and the rack 2 mesh with each other, there is also a roller wheel under the X-direction walking block 5, and a drag chain 3 is arranged between the two X-direction track bodies, and the fixed end of the drag chai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com