Automatic overedging machine and working method thereof

A working method and anchor netting technology, applied in the field of online netting, wire processing, and other household appliances, can solve the problems of low work efficiency, potential safety hazards, production and processing of anchor nets that cannot meet production needs, and no mechanized operation, etc., so as to be easy to quickly master , Easy to hold the edge of the anchor net, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

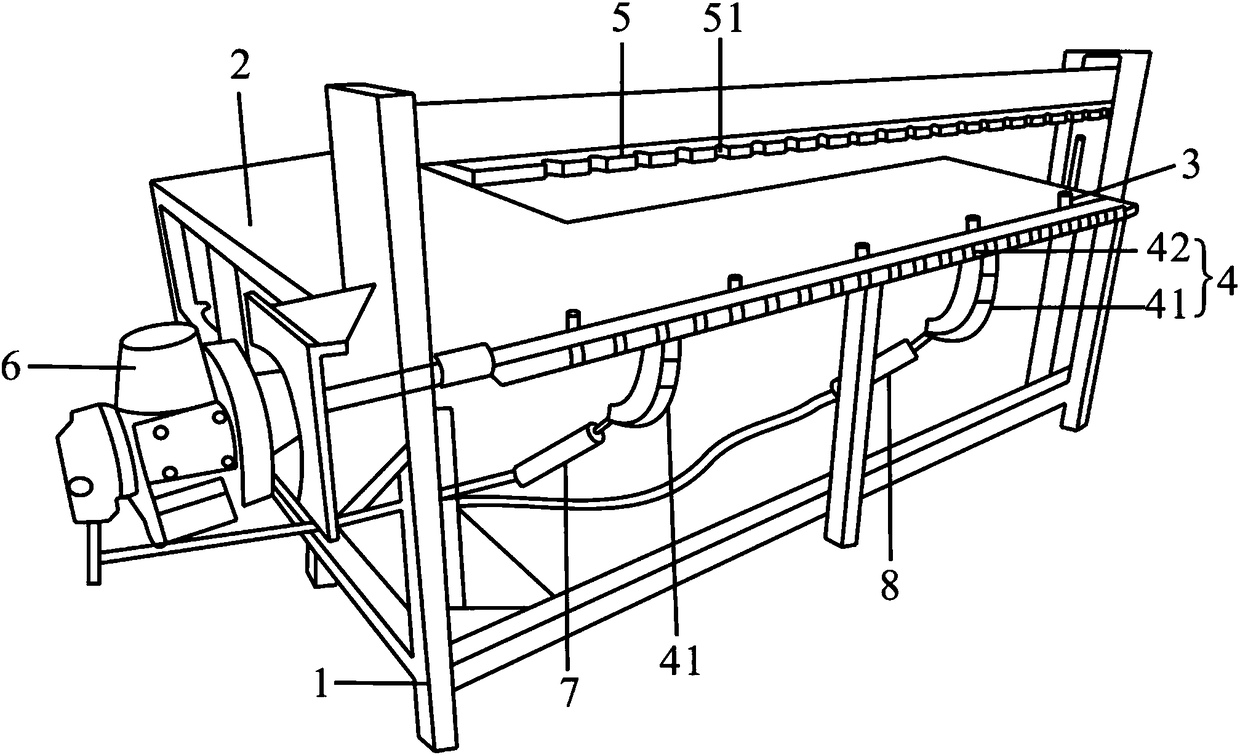

[0032] Such as figure 1 As shown, this embodiment discloses an automatic edge-holding machine for anchor netting, including a base 1, a workbench 2, a limit device 3, an edge-holding mechanism 4, a pressing device 5 and a hydraulic device 6, and the workbench 2 is set On the base 1, the workbench 2 is L-shaped, and the workbench 2 is adapted to the anchor net of the edge to be grasped. The limiting device 3 is fixedly arranged on the end of the workbench 2, and is used to place the anchor net to be held in the correct edge-holding position, and the edge-holding mechanism 4 is rotated and arranged on the limiting device 3 for use in For holding the edge of the anchor net, the pressing device 5 is arranged above the workbench 2, and is used to compress the anchor net after the edge is grasped, and the hydraulic device 6 is fixedly arranged on the workbench 2 The side of the side, driving the gripping mechanism 4 and pressing device 5.

[0033] The edge grip mechanism 4 include...

Embodiment 2

[0038] This embodiment discloses an automatic edge-holding machine for anchor nets, which includes a base 1, a workbench 2, a limit device 3, an edge-holding mechanism 4, a pressing device 5 and a hydraulic device 6, and the workbench 2 is set on the On the base 1, the workbench 2 is an L-shaped workbench, and the workbench 2 can be adapted to the shape and size of the anchor net to be held. The limiting device 3 is fixedly arranged on the end of the workbench 2, and is used to place the anchor net to be held in the correct edge-holding position, and the edge-holding mechanism 4 is rotated and arranged on the limiting device 3 for use in When holding the edge of the anchor net, the pressing device 5 is arranged on the top of the workbench 2, and is used to compress the anchor net after holding the edge to prevent warping. The hydraulic device 6 is fixedly arranged on the The side part of the workbench 2, drives the edge-holding mechanism 4 and the pressing device 5, can automa...

Embodiment 3

[0044] This embodiment discloses a working method of an automatic edge-holding machine for anchor nets, including the following steps:

[0045] S1. Put the anchor net on the workbench, and the limit device will limit the anchor net so that it is in the correct edge holding position;

[0046] S2. Turn on the automatic edge gripping machine for the anchor net, the hydraulic motor, the first auxiliary oil cylinder and the second auxiliary oil cylinder drive the push rod to rotate, and the edge grip groove rotates under the drive of the push rod to grip the anchor net;

[0047] S3. The pressing device moves down to the workbench and presses against the grip edge;

[0048] S4. The pressing device moves upwards to leave the workbench;

[0049] S5. Remove the compressed anchor net from the workbench.

[0050] Implement the present invention, have following beneficial effect:

[0051] (1) The anchor net automatic edge-holding machine of the present invention can automatically and acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com