Mechanical arm based on pneumatic control surface and working method thereof

A working method and a technology of a robotic arm, applied to aircraft parts, electric controllers, controllers with specific characteristics, etc., can solve problems such as low precision, sub-machine attitude, and slow position response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific embodiments.

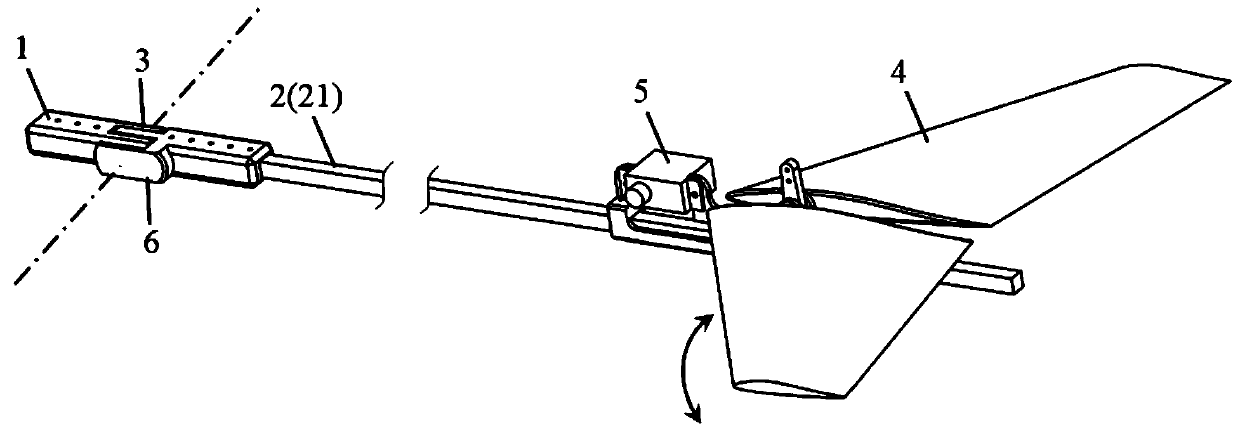

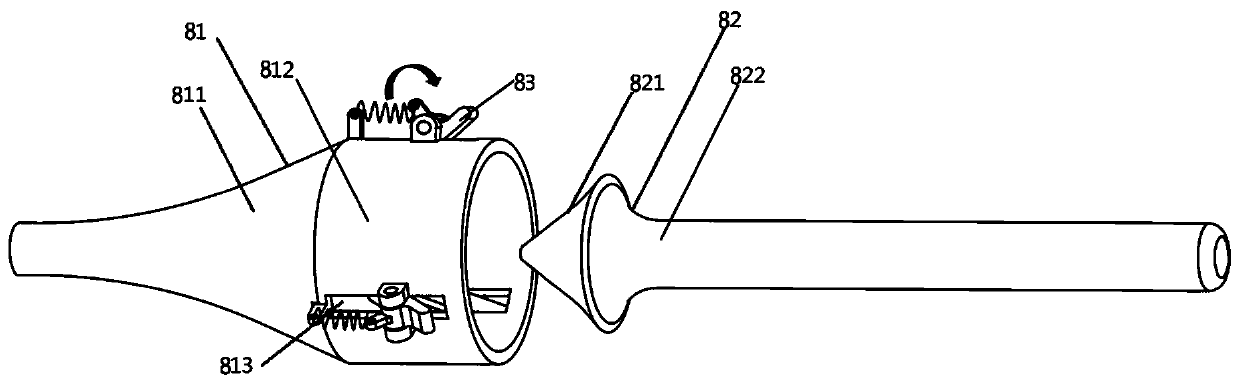

[0046] An embodiment of the present invention provides a mechanical arm based on an aerodynamic rudder surface, such as figure 1As shown, it includes: support 1, rigid pipe 2, ball hinge 3, rudder surface 4, servo motor 5, angle sensor 6, oil delivery pipe 7, docking lock 8, the mechanical arm based on the pneumatic rudder surface in this embodiment is used Air refueling scene.

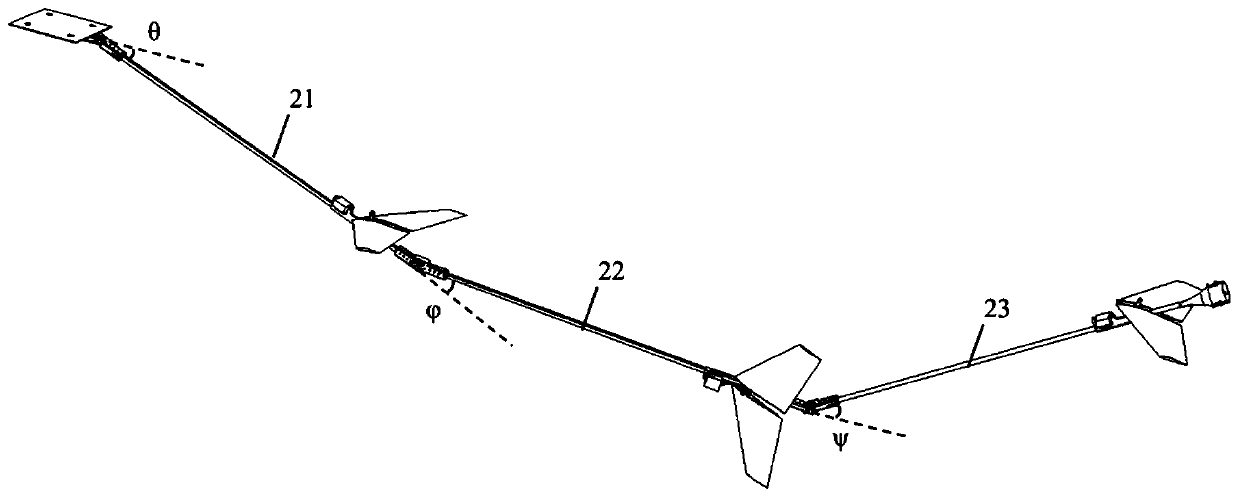

[0047] In this embodiment, there are three stages of rigid pipes, and the joints between the rigid pipes 2 are provided with supports 1 for connection. The third rigid pipe 23 is connected to the main machine, and the third rigid pipe 23 , the second rigid pipe 22 , and the first rigid pipe 21 are sequentially connected through a single-degree-of-freedom hinge 3 . An angle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com