Hydraulic stop iron mechanism of cutting device

A cutting machine and hydraulic technology, applied in metal processing and other directions, can solve the problems of time-consuming and labor-intensive enterprises, large production volume, and even finding the correct position after trial cutting, and achieve the effect of improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

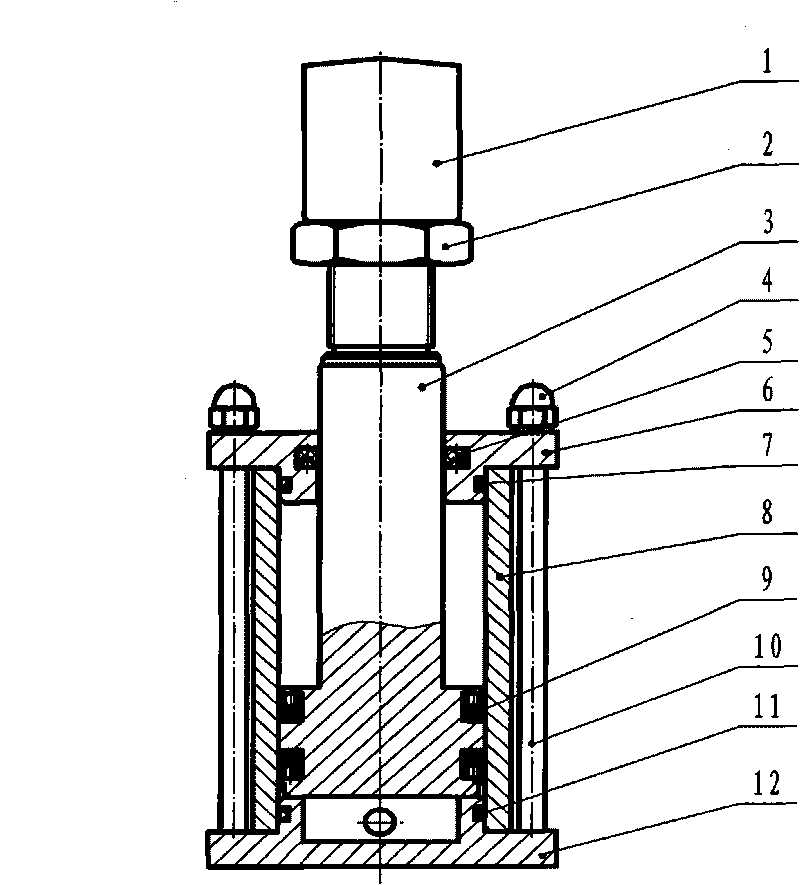

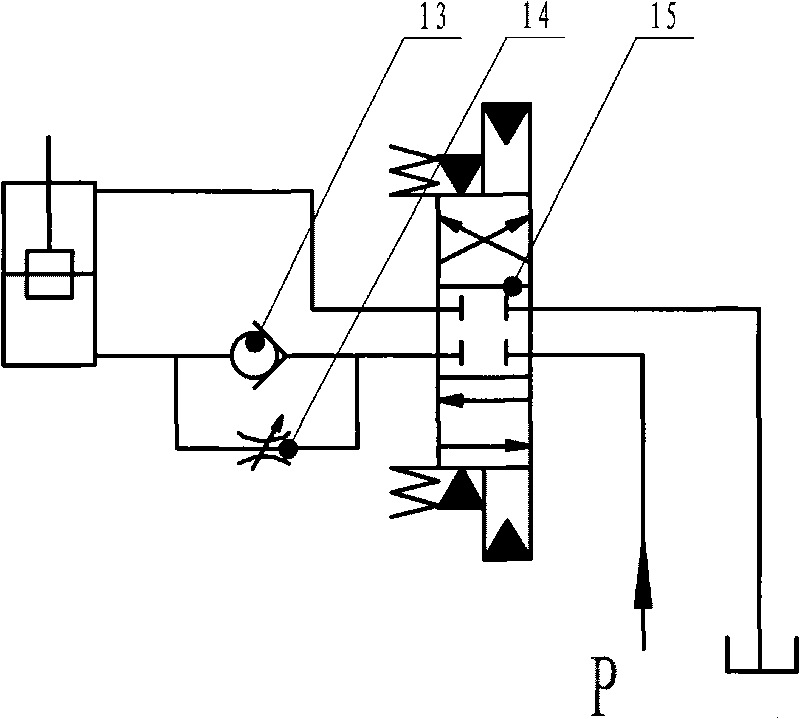

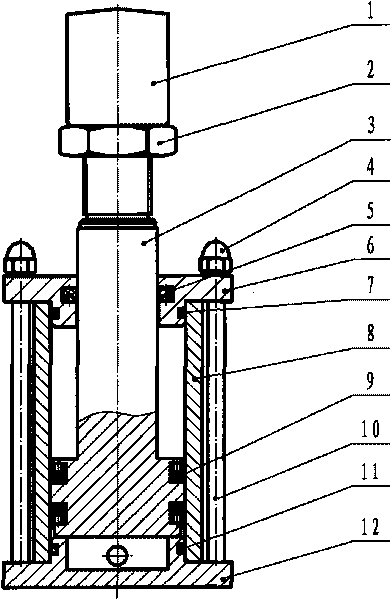

[0014] exist figure 1 Among them, the upper end cover 6, the cylinder barrel 8, and the lower end cover 12 are connected by a tie rod 10, the lower end of the tie rod 10 is threadedly connected with the lower end cover, the upper end of the tie rod 10 is fixed by the cap nut 4 and the upper end cover 6, and the cylinder barrel 8 and the upper end cover 6, the lower end O-rings 7 and 11 are respectively arranged between the covers 12 to play a sealing role. The piston rod 3 passes through the upper end cover 6 and is slidably fitted. The Y-shaped sealing ring 5 is in the groove of the upper end cover 6 to play a sealing role. The cylinder There is a sliding fit between the cylinder 8 and the piston rod 3, and two Y-shaped sealing rings 9 for the piston are installed in the groove of the piston rod 3, which act as a two-way seal. tight. figure 2 It is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com