Open-end rotor spinning device

A rotor spinning, free-end technology, applied in the directions of free-end spinning machines, spinning machines, spinning machines with continuous winding, etc., can solve the problems of entry and insufficient sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

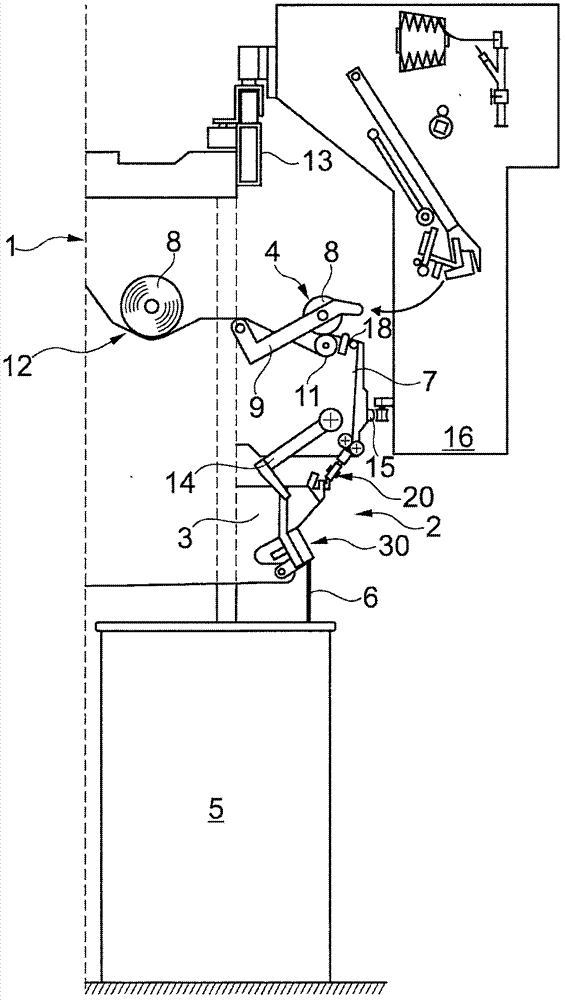

[0059] figure 1 Shown is a half side view of an open-end rotor spinning machine 1 . Such an open-end rotor spinning machine 1 generally has, as is known, a plurality of identical workstations 2 arranged side by side, expediently arranged on the front and rear of the textile machine.

[0060] Furthermore, these stations 2 are each equipped with an open-end rotor spinning device 3 and a winding device 4 .

[0061] During operation, in the open-end rotor spinning device 3, the fiber sliver 6 provided, for example, by the can 5 and prepared by the fiber sliver opening device 30 is spun into a yarn 7, and then the yarn is wound on the winding device 4 into a yarn 7. Cross-wind bobbin 8.

[0062] Such as figure 1 As shown, the winding device 4 is equipped with a creel 9 for rotating and holding an empty bobbin or a cross-wound bobbin 8, a bobbin drive roller 11 for frictionally driving the cross-wound bobbin 8, and a yarn reciprocating device 18 .

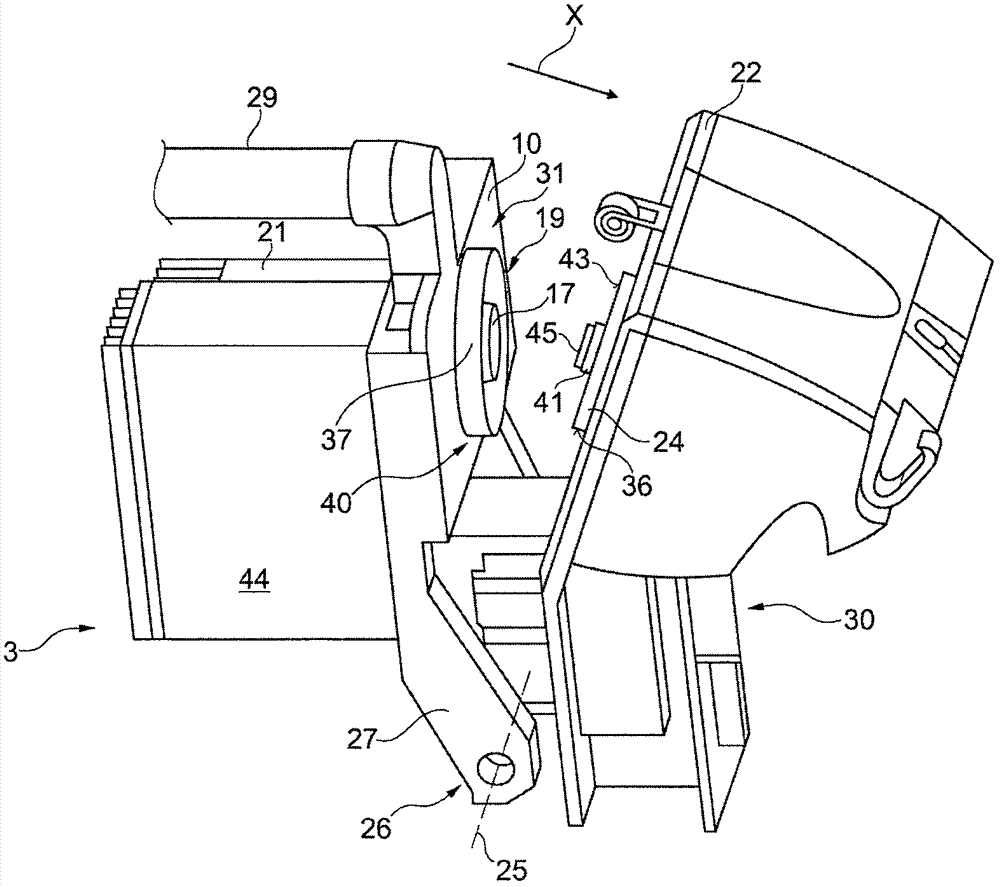

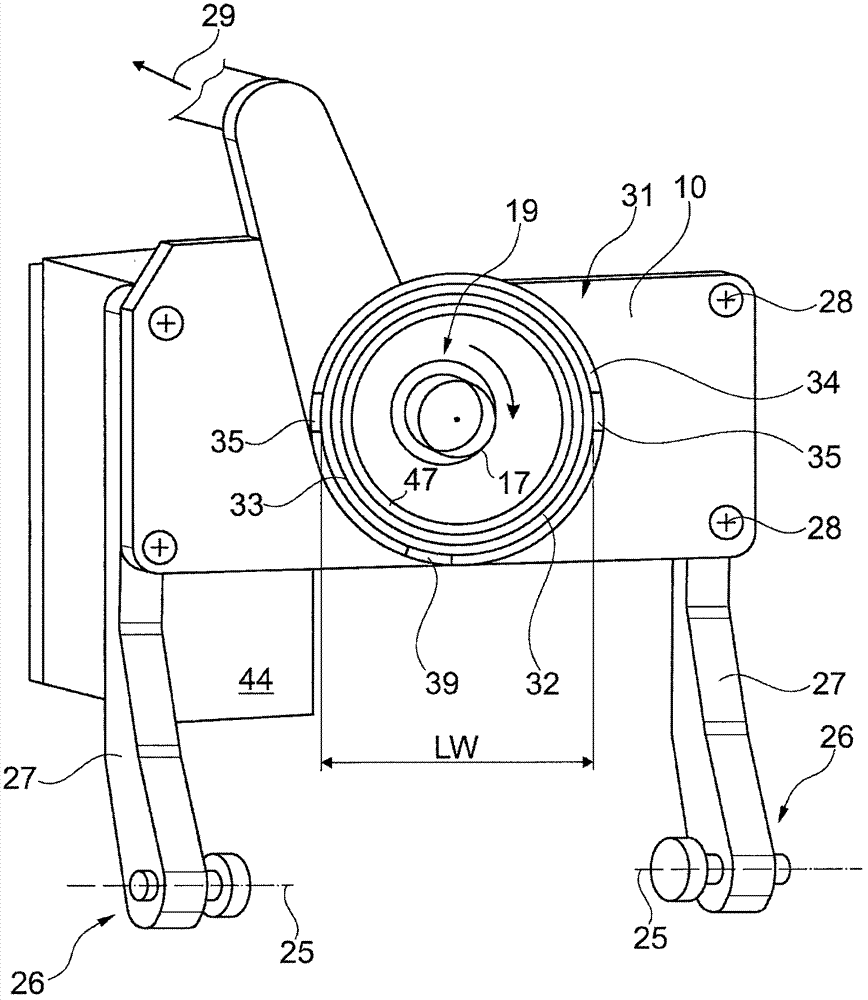

[0063] In this embodiment, e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com