Test point automatic positioning method and copper thickness automatic detection method and system

A technology of automatic positioning and testing points, applied in measurement devices, image data processing, instruments, etc., can solve the problems of cumbersome process and low efficiency, and achieve the effect of improving production efficiency, accurate and stable measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

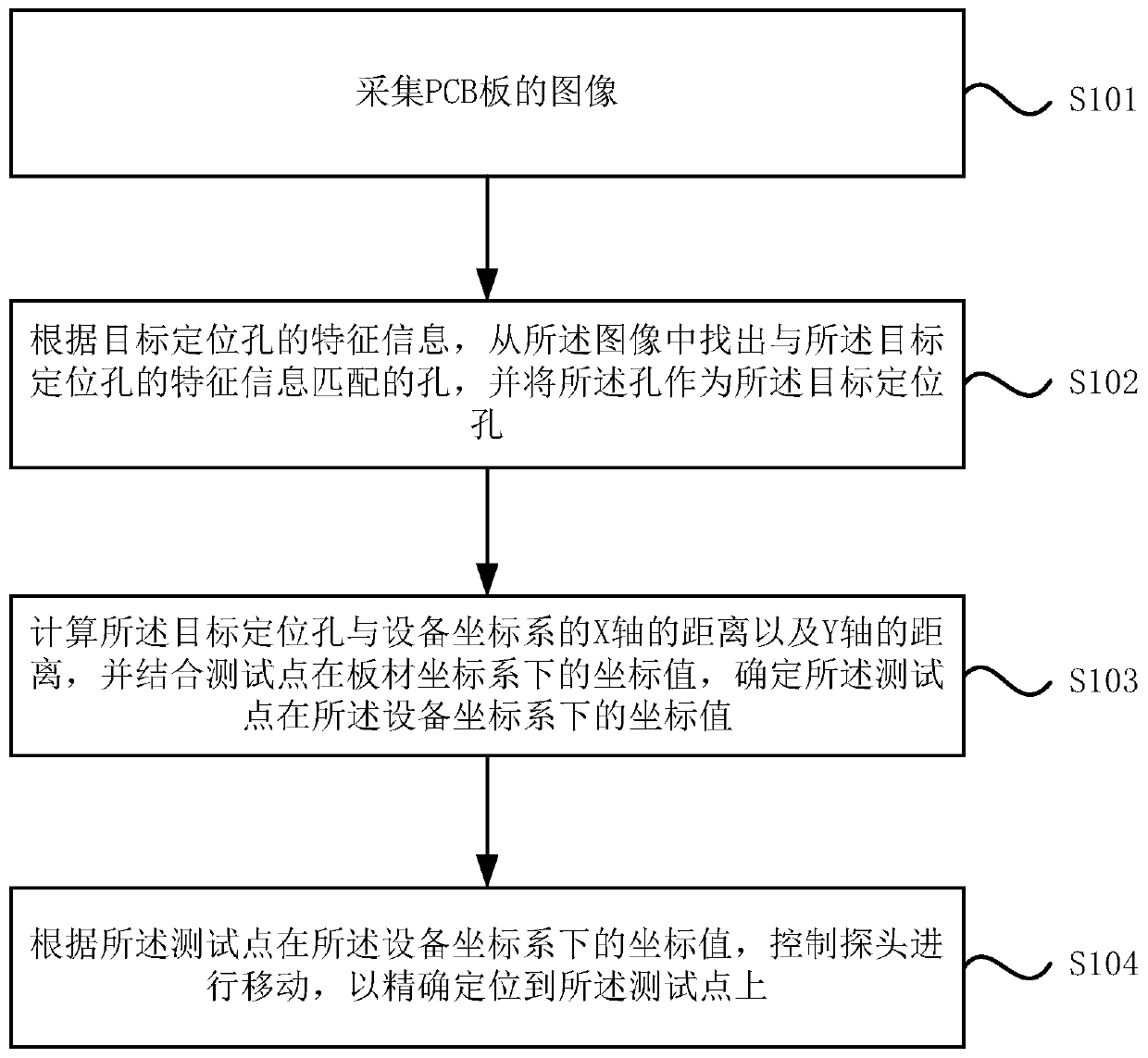

[0052] Please refer to figure 1 , figure 1 It is a schematic flow chart of a test point automatic positioning method provided in Embodiment 1 of the present invention. The method is suitable for the scene of automatic detection of PCB copper thickness. The method is executed by the test point automatic positioning system. The system can be controlled by software and / or Hardware implementation, integrated inside the automation equipment.

[0053] The method specifically includes the following steps:

[0054] S101. Collect images of the PCB board.

[0055] It should be noted that the image of the PCB board is collected by a CCD camera installed above the detection platform.

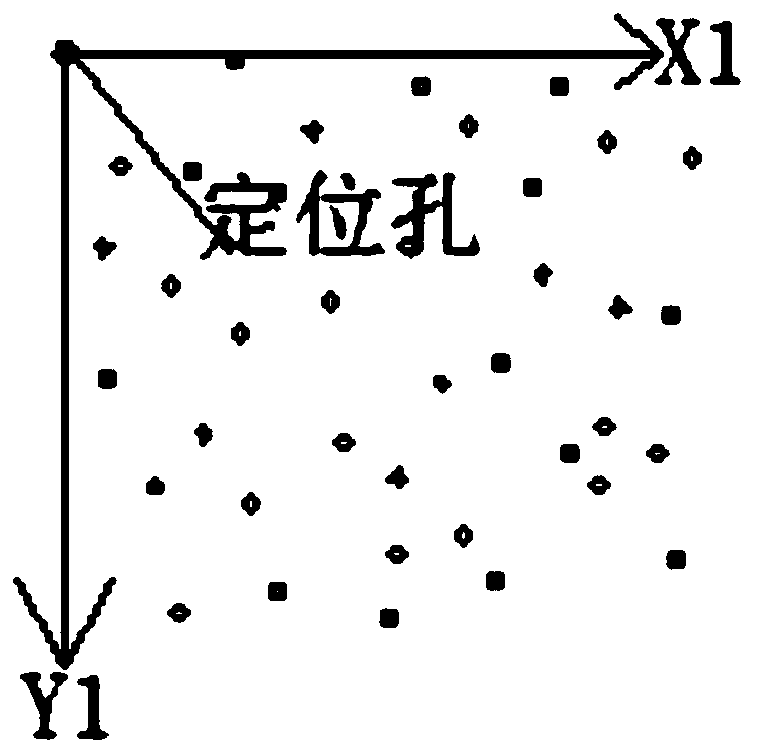

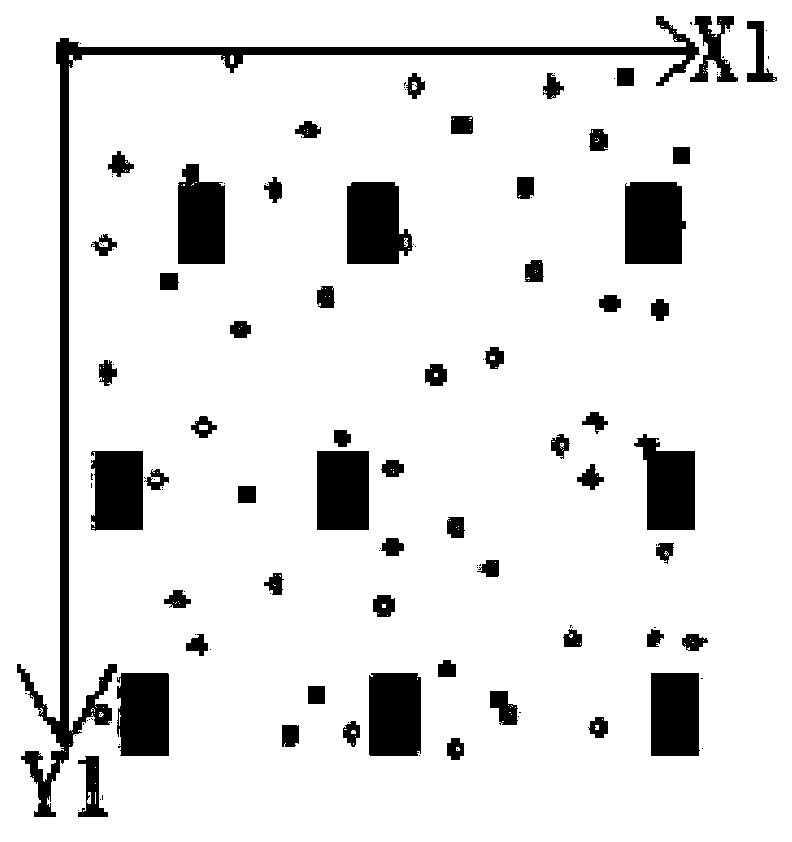

[0056] S102. According to the characteristic information of the target positioning hole, find a hole matching the characteristic information of the target positioning hole from the image, and use the hole as the target positioning hole.

[0057] It should be noted that the feature information may includ...

Embodiment 2

[0074] Please refer to Image 6 , an embodiment of the present invention provides a method for automatic detection of copper thickness, the method comprising:

[0075] S201. Position the probe on the test point of the PCB board.

[0076] Specifically, in this step, the positioning of the probe on the test point of the PCB is realized based on the automatic positioning method of the test point provided by the present invention. If the coordinate value of each test point in the device coordinate system is obtained, then it is only necessary to control the probe to move according to the coordinate value corresponding to each test point.

[0077] S202. Using the probe to measure the copper thickness data at the location of the test point.

[0078] An automatic copper thickness detection method provided by an embodiment of the present invention can determine the coordinate value of each test point on the PCB on the equipment coordinate system by converting the plate coordinate sy...

Embodiment 3

[0080] Please refer to Figure 7 , the embodiment of the present invention provides a test point automatic positioning system, the system includes:

[0081] Acquisition module 31, for collecting the image of PCB board;

[0082] The matching module 32 is configured to find a hole from the image that matches the feature information of the target positioning hole according to the feature information of the target positioning hole, and use the hole as the target positioning hole;

[0083] The calculation module 33 is used to calculate the distance between the target positioning hole and the X-axis and the Y-axis of the equipment coordinate system, and combine the coordinate values of the test point in the plate coordinate system to determine the distance between the test point and the equipment coordinate system. The coordinate value under the system;

[0084] The control module is used to control the movement of the probe according to the coordinate value of the test point in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com