Fingerprint module group testing platform

A test platform and fingerprint module technology, applied in the direction of measuring electricity, measuring device, registration/indication, etc., can solve the problems of affecting test efficiency, low positioning accuracy, and increase labor intensity, so as to improve detection efficiency and save labor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

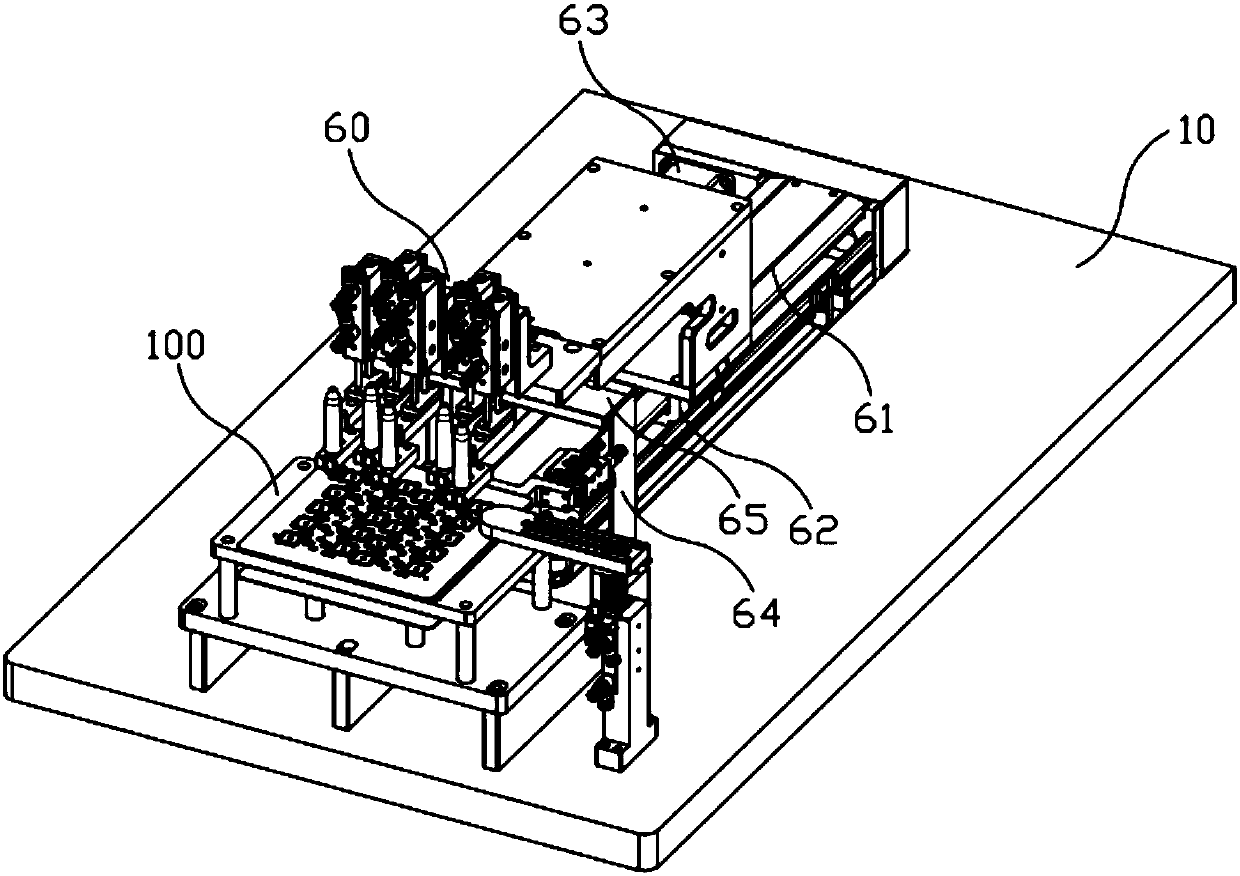

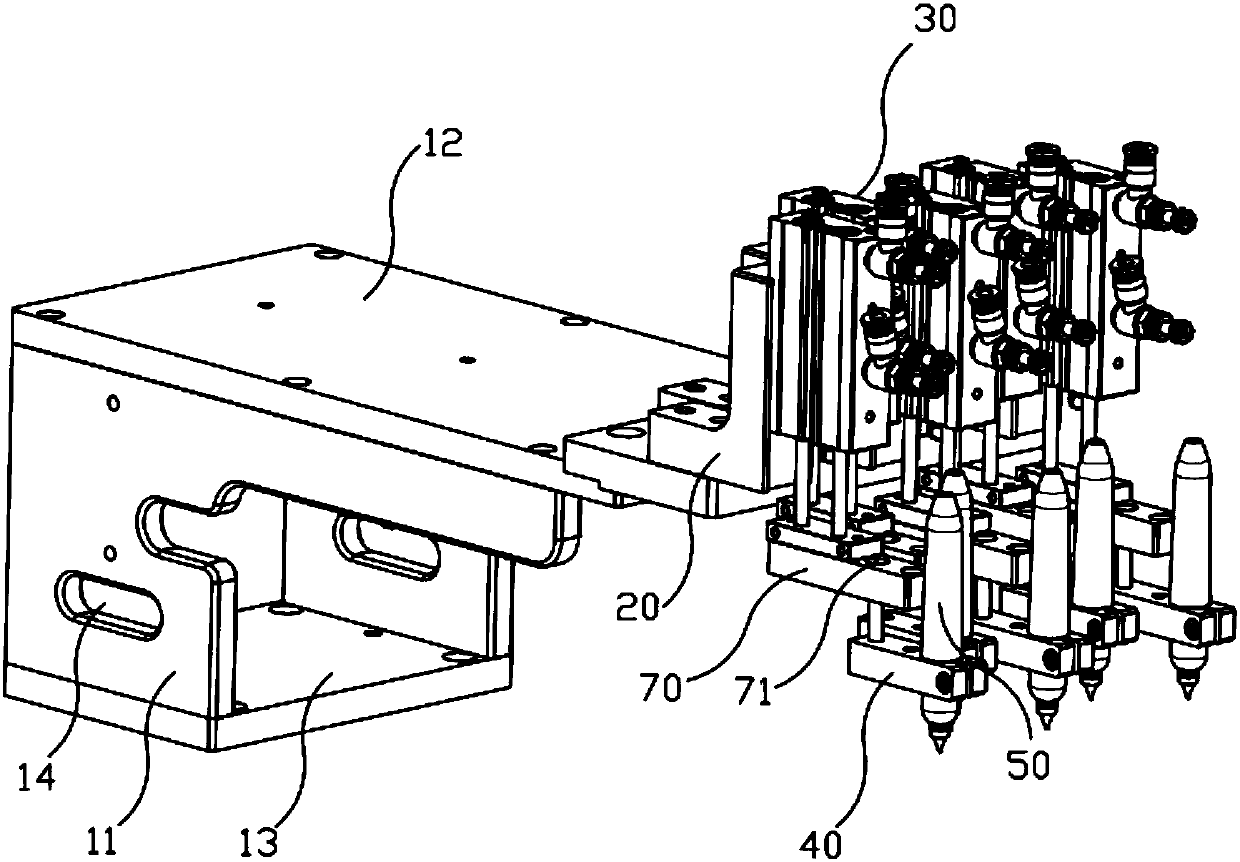

[0038] Such as figure 1 As shown, the fingerprint module testing platform of the present invention includes a base 10, on which a translation mechanism, an ink cartridge bracket 64 and a positioning assembly 100 are provided, on which the translation mechanism is provided with a dotting assembly 60, and the positioning assembly 100 is located in front of the translation mechanism, The translation mechanism is used to drive the dotting assembly 60 to move forward to directly above the positioning assembly 100 and backward to directly above the ink cartridge carriage 64 . The translation mechanism includes a slide rail 61, a slide block 62 slidably connected with the slide rail 61, a motor 63 that drives the slide block 62 to move along the slide rail 61; the ink cartridge carriage 64 is near the end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com