Measurement condition reproducing device and method based on body's surface texture characteristic and contact pressure

A technology of surface texture and contact pressure, which is applied in the direction of color/spectral characteristic measurement, diagnostic recording/measurement, and instruments for radiological diagnosis, etc., can only be solved at the pixel level, measurement errors cannot be considered and resolved, no Consider the contact pressure of the measurement site and other issues to achieve the effect of ensuring correctness, simplifying acquisition, and reducing image distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be discussed in further detail below in conjunction with the accompanying drawings and specific embodiments.

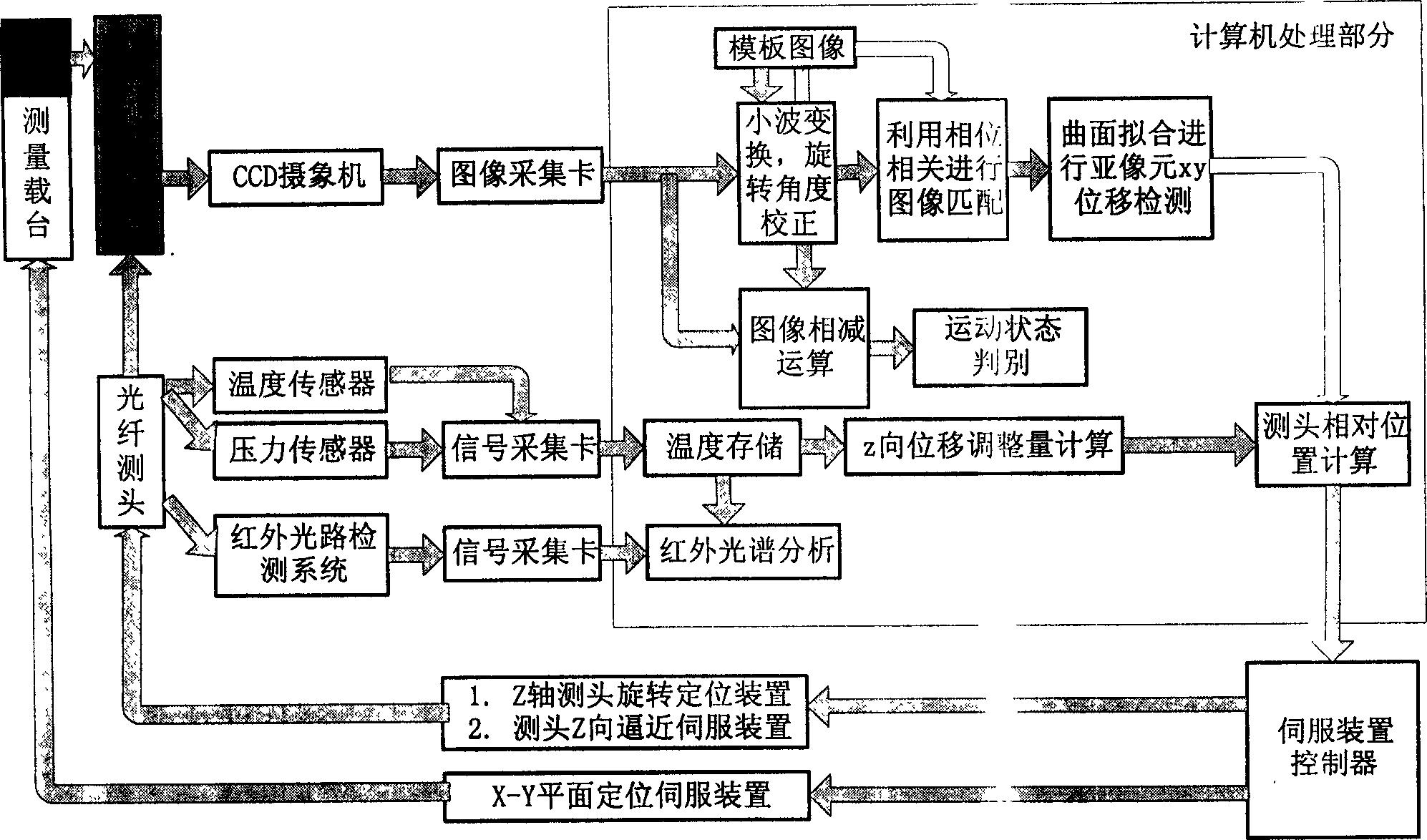

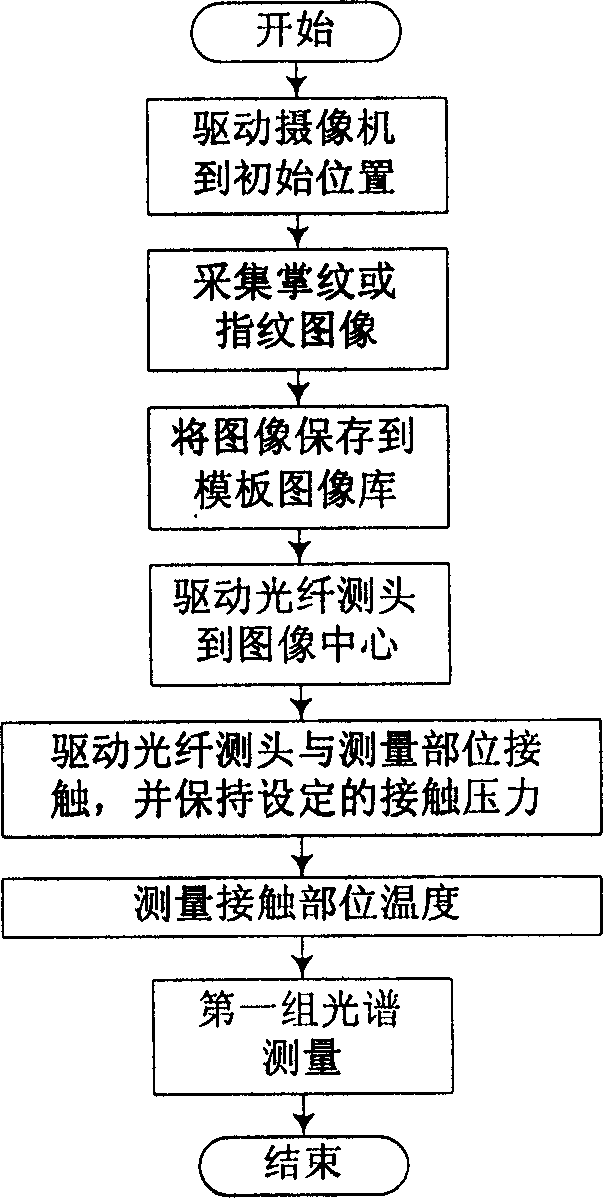

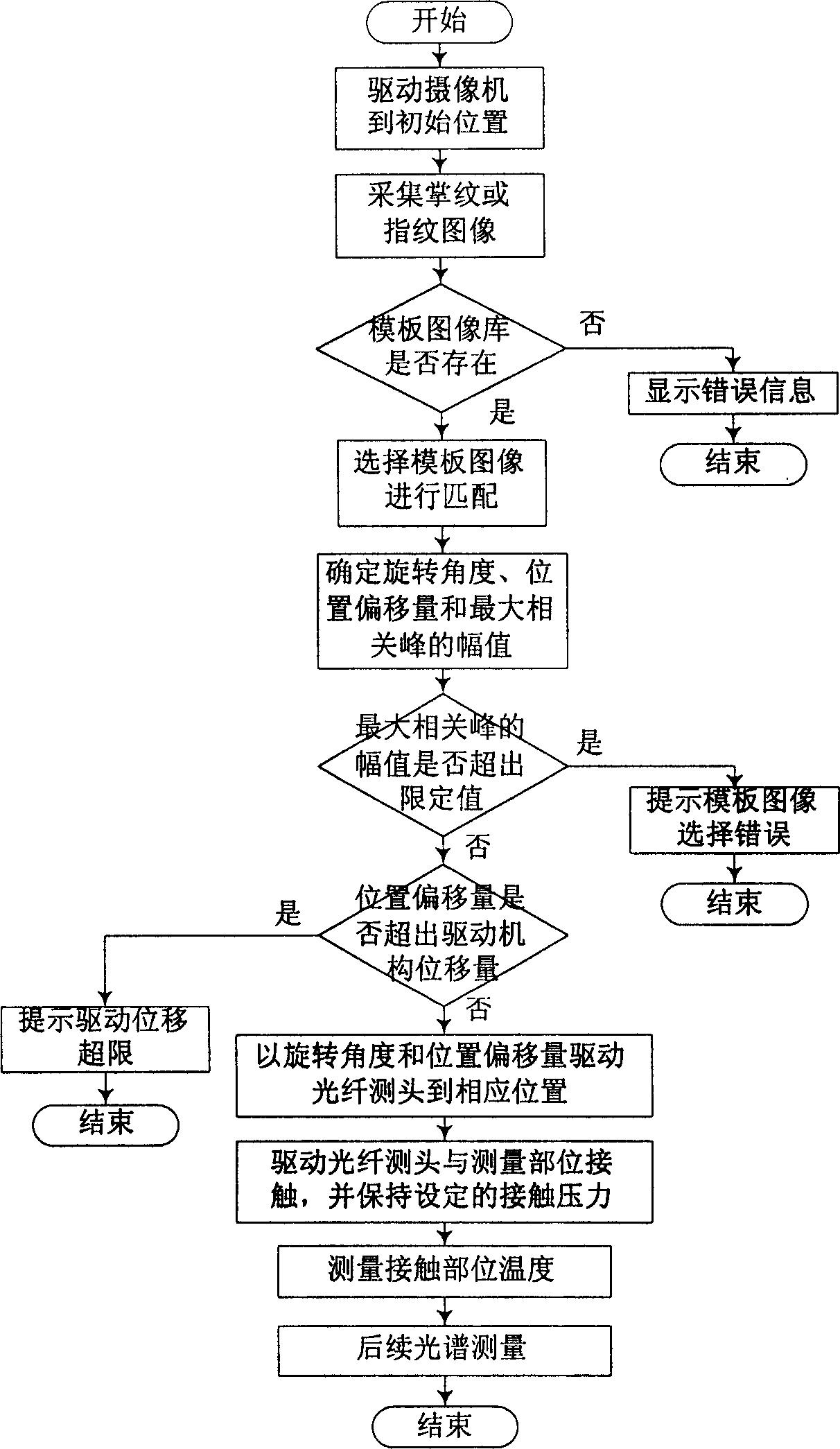

[0064] 1. The structure of the measurement condition reproduction system

[0065] The lighting device is installed under the stage with holes, the device is provided with a hole attached to the stage, and the axes coincide; the servo positioning device is composed of four parts: x-axis servo positioning device, y-axis servo positioning device, z-axis servo positioning device, z-axis rotation servo positioning device; the z-axis rotation servo positioning device is installed on the z-axis servo positioning device; the optical fiber probe is installed on the z-axis rotation servo positioning device, and the central axis coincides with its rotation axis; the servo The displacement mechanism in the positioning device is driven by a stepping motor and controlled by a servo controller, which is controlled by a computer.

[0066] Among the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com