Method for preparing ultrathin crystalline silicon double-sided solar cell

A technology of solar cells and crystalline silicon, applied in the field of solar cells, can solve problems such as poor uniformity of product diffusion junctions, difficulty in industrialization, and high damage rate of thin silicon wafers, to increase the duration of light stay, reduce the breakage rate, and improve light The effect of availability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

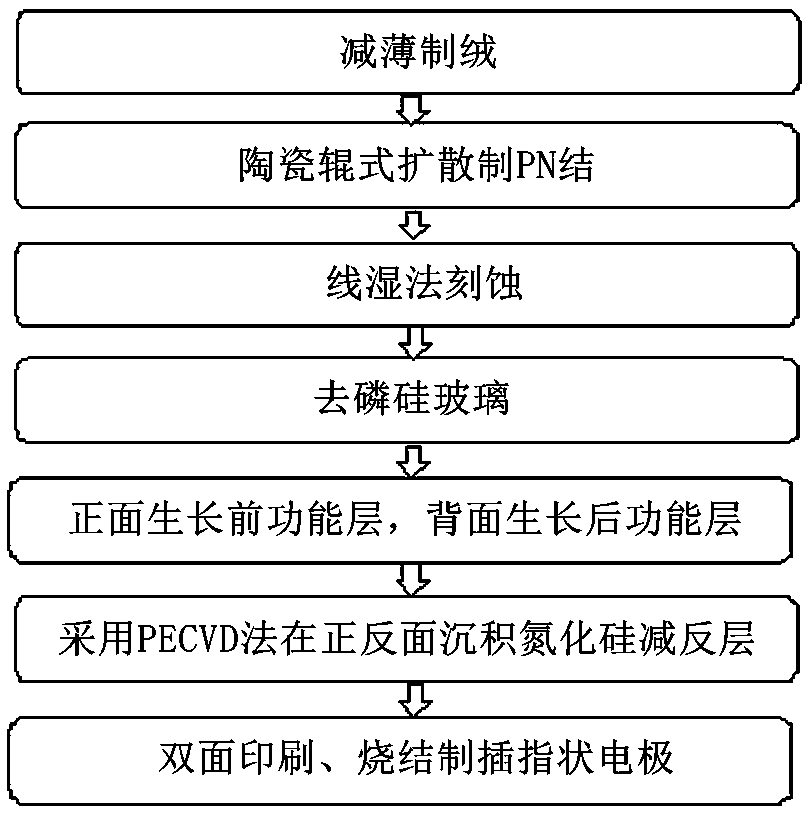

[0036] like figure 1 As shown, the preparation method of the ultra-thin crystalline silicon double-sided solar cell provided by the present embodiment is as follows: thinning and texturing - ceramic roll diffusion to make PN junction - line wet etching - dephosphorization silicon glass - growth functional layer - Double-sided deposition of silicon nitride antireflection layer - screen printing, sintering finger electrodes.

[0037] figure 1 Only the key steps in the present invention are shown, and some conventional processes such as cleaning are not listed here. The cleaning process includes cleaning before texturing and cleaning after texturing, etc. Before texturing, ultrasonic cleaning with acetone and alcohol is generally used to remove organic and inorganic impurities on the surface of polysilicon substrates, and then cleaned with deionized water; Rinse with deionized water and blow dry with nitrogen. These conventional processes will not be introduced too much in the...

Embodiment 2

[0046] Thinning and texturing: place a 200μm thick P-type polysilicon substrate in HF, H 2 O 2 , in the mixed solution of silver nitrate and copper nitrate, the mass fraction of HF is 35%, H 2 O 2 The mass fraction of 35%, the molar concentrations of silver nitrate and copper nitrate are 0.5mol / L and 0.3mol / L respectively, HF, H 2 O 2 The volume ratio of the additives (the additives here are silver nitrate and copper nitrate) is 3:2.5:1. Make polysilicon substrates in HF, H 2 O 2 The polysilicon substrate was thinned to 100 μm by soaking in a mixed solution of , silver nitrate and copper nitrate for 2200s at 25°C, and the surface of the polysilicon substrate was made into a textured structure.

[0047] Ceramic roll diffusion to make PN junction: prepare 4% phosphoric acid solution, and carry out ultrasonic atomization deposition on the thinned polysilicon substrate at 20 ℃ (ultrasonic frequency is 1.8MHz, atomization rate is 2mL / min, and the median fog particle is 4.0μm...

Embodiment 3

[0054] Thinning and texturing: place a 220μm thick P-type polysilicon substrate in HF, H 2 O 2 In the mixed solution with palladium nitrate, the mass fraction of HF is 30%, H 2 O 2 The mass fraction of 38%, the molar concentration of palladium nitrate is 1.2mol / L, HF, H 2 O 2 The volume ratio of palladium nitrate and palladium nitrate is 4.5:2:1. Make polysilicon substrates in HF, H 2 O 2 The polycrystalline silicon substrate is thinned to 110 μm by soaking in a mixed solution of palladium nitrate and 23° C. for 2000 s, and the surface of the polycrystalline silicon substrate is made into a textured structure.

[0055]Ceramic roll diffusion to make PN junction: prepare 6% phosphoric acid solution, and carry out ultrasonic atomization deposition on the thinned polysilicon substrate at 22°C (ultrasonic frequency is 1.75MHz, atomization rate is 3mL / min, and the median fog particle is The diameter of 3.8μm); then the polysilicon substrate is placed on the ceramic roller, he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com