Heat accumulating type heating furnace with smoke backflow

A regenerative, heating furnace technology, applied in lighting and heating equipment, furnaces, furnace types, etc., can solve problems such as furnace pressure fluctuation, workpiece surface oxidation, unstable working conditions, etc., to extend service life, save energy, Emission reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

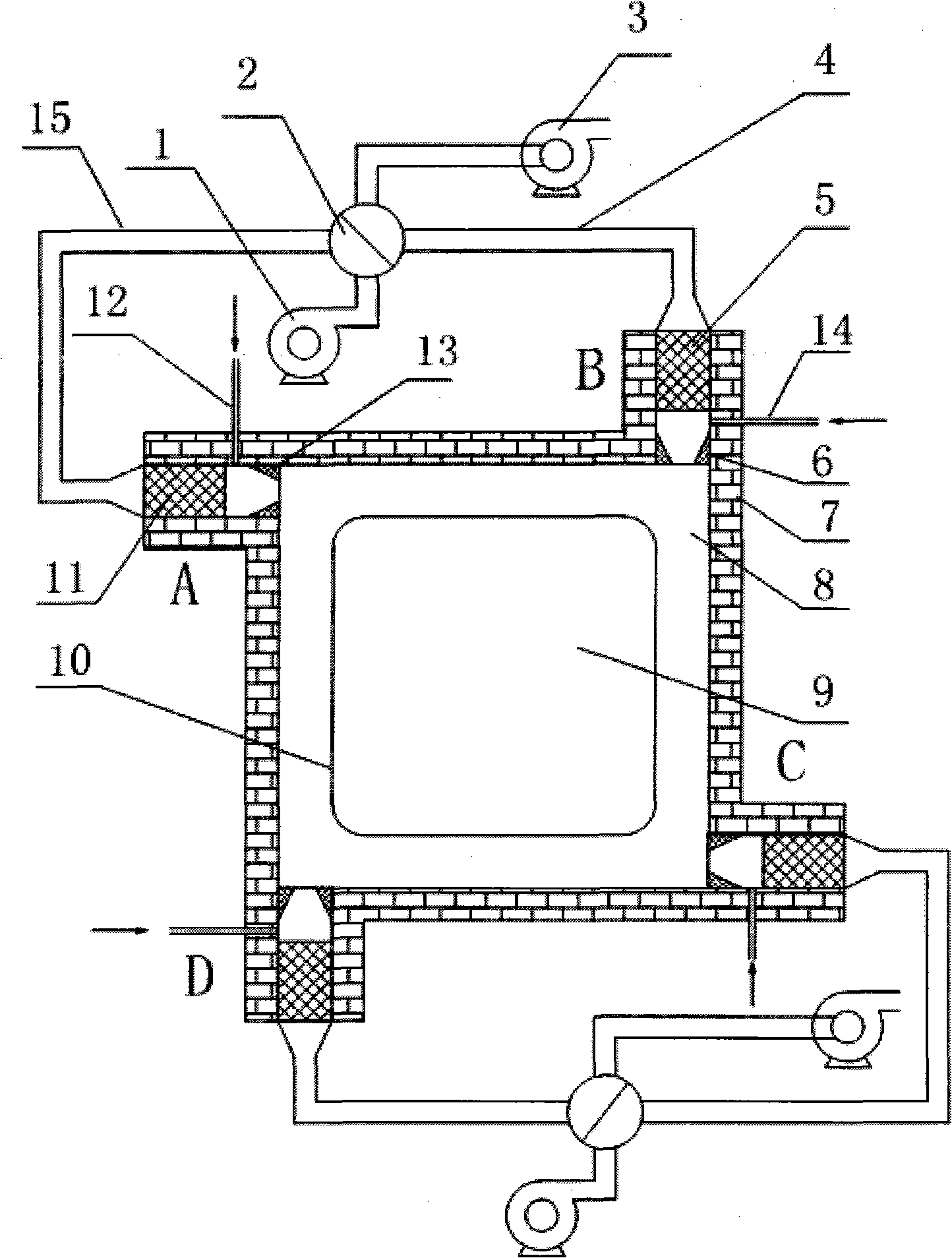

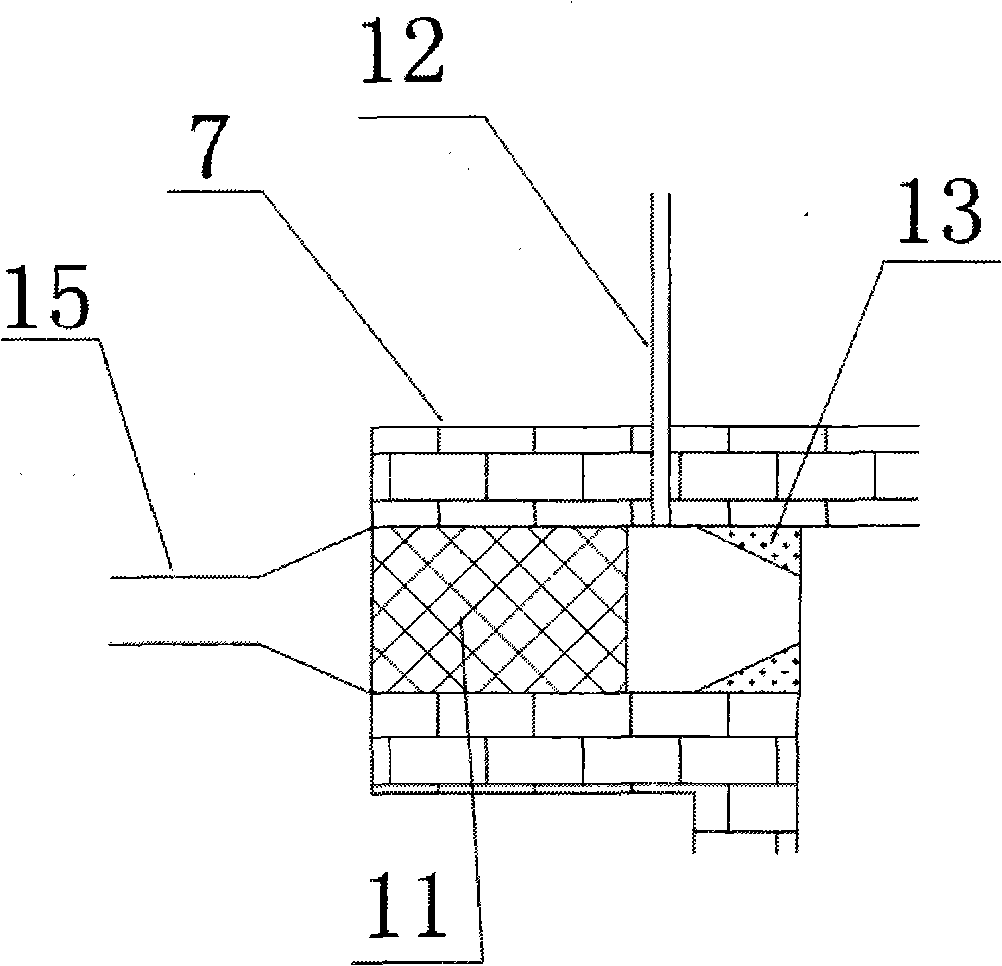

[0019] figure 1 A schematic diagram of the implementation structure of the regenerative heating furnace with flue gas reflow is given in this embodiment, including the furnace body 7, the blower 1, the induced draft fan 3 and the reversing mechanism 2, the furnace chamber 8 is rectangular or circular, and the circumferential The regenerators A, B, C, and D are arranged in the same direction. The four regenerators are divided into two groups. The two regenerators on the diagonal form a group, that is, A, C are a group, and B, D is a group of regenerators in which regenerators 11 are installed, the regenerators are spherical or honeycomb-shaped, fuel nozzles 12 are arranged downstream of the regenerators, fuel pipes are connected outside the fuel nozzles, and burner bricks are arranged on the furnace wall corresponding to the nozzles. It can be a wedge-shaped brick 13 or a special-shaped brick 16 with a guiding effect. The furnace cavity 8 and the heating chamber 9 are separated...

Embodiment 2

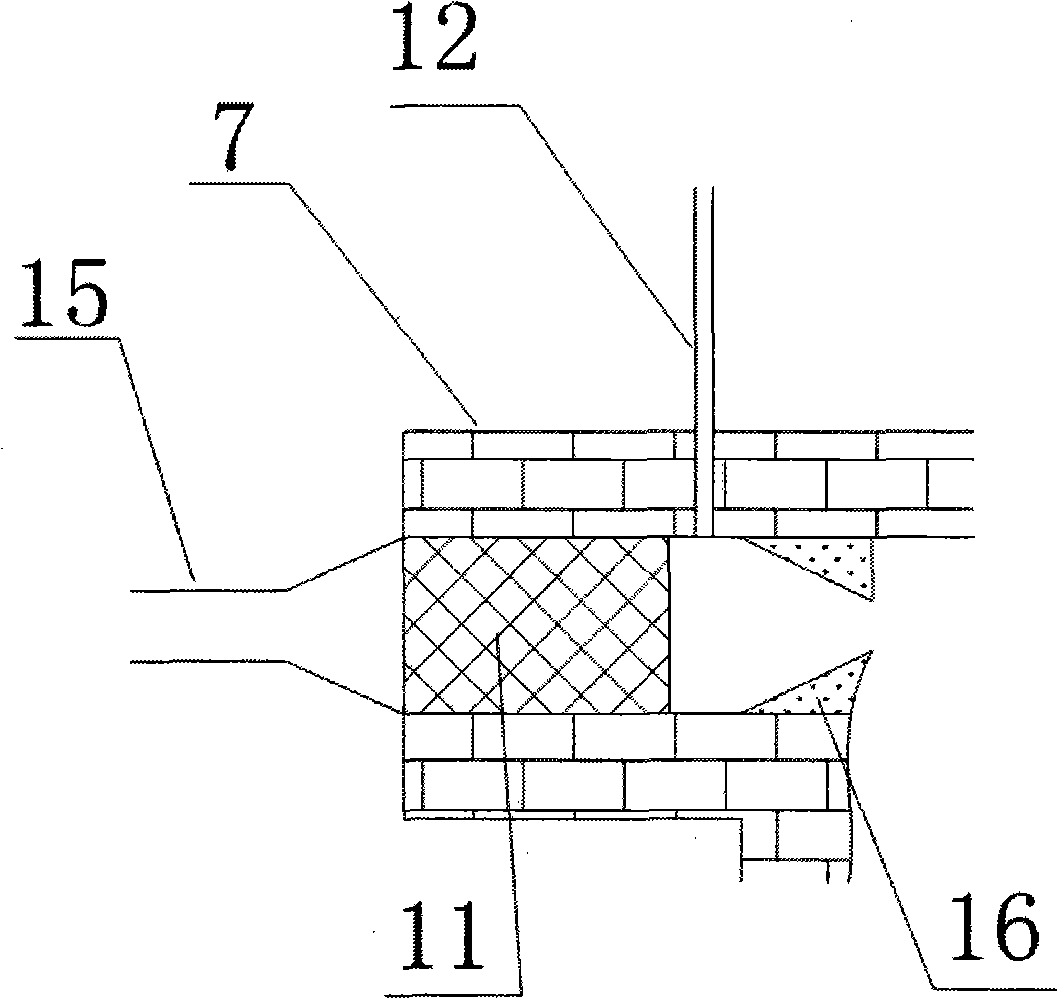

[0025] In this embodiment, the burner brick is a special-shaped brick with a guiding function.

[0026] Such as image 3 As shown, the burner brick at the nozzle of the regenerator is a special-shaped brick 16 with guiding function. Compared with ordinary wedge-shaped bricks, this special-shaped brick is more difficult to process, but it is conducive to the backflow of smoke and reduces the loss of air pressure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com