Exhaust particulate filter

A particle filter and filter technology, which is applied in the fields of dispersed particle filtration, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as limiting the selection of filter body materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

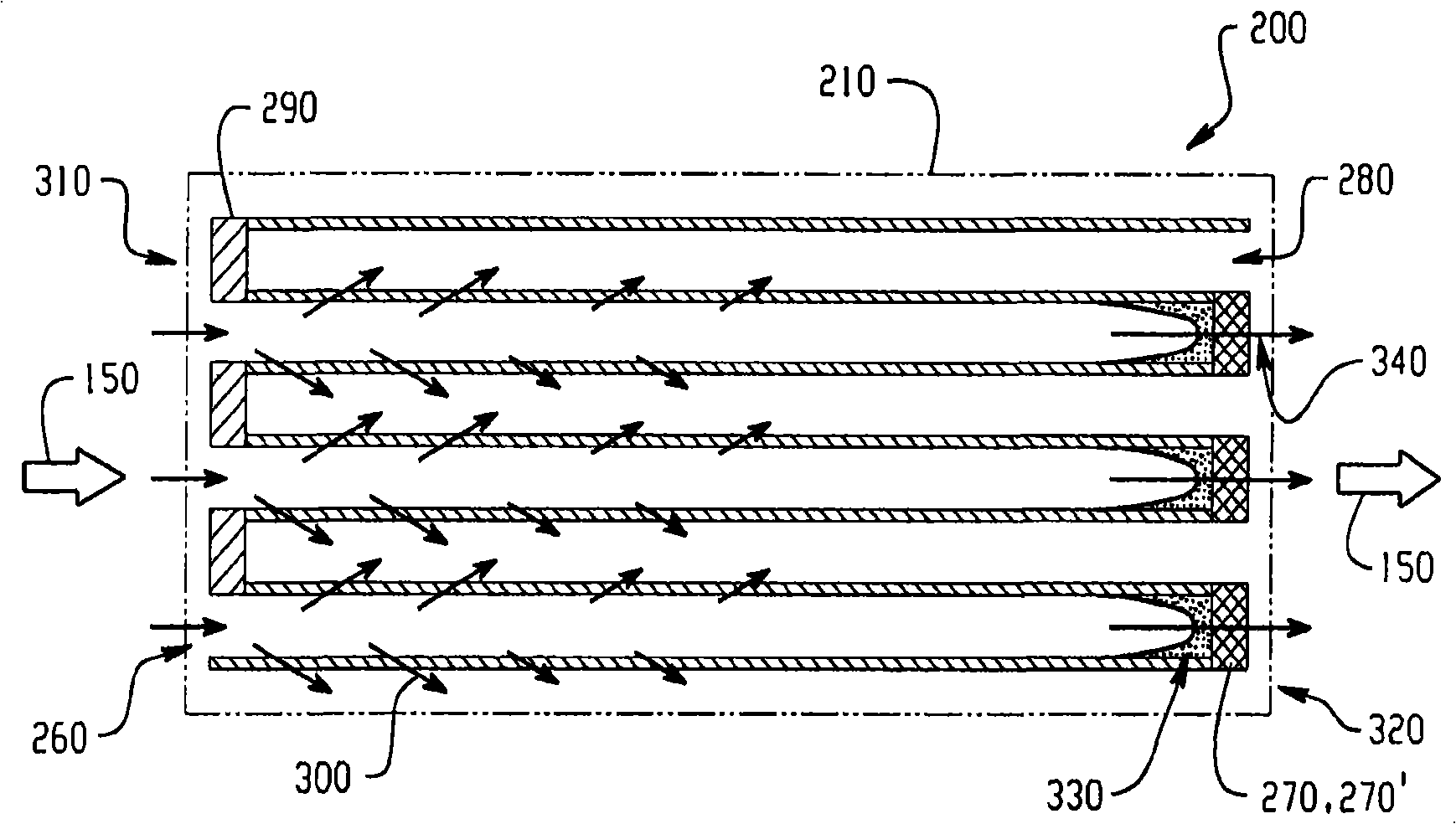

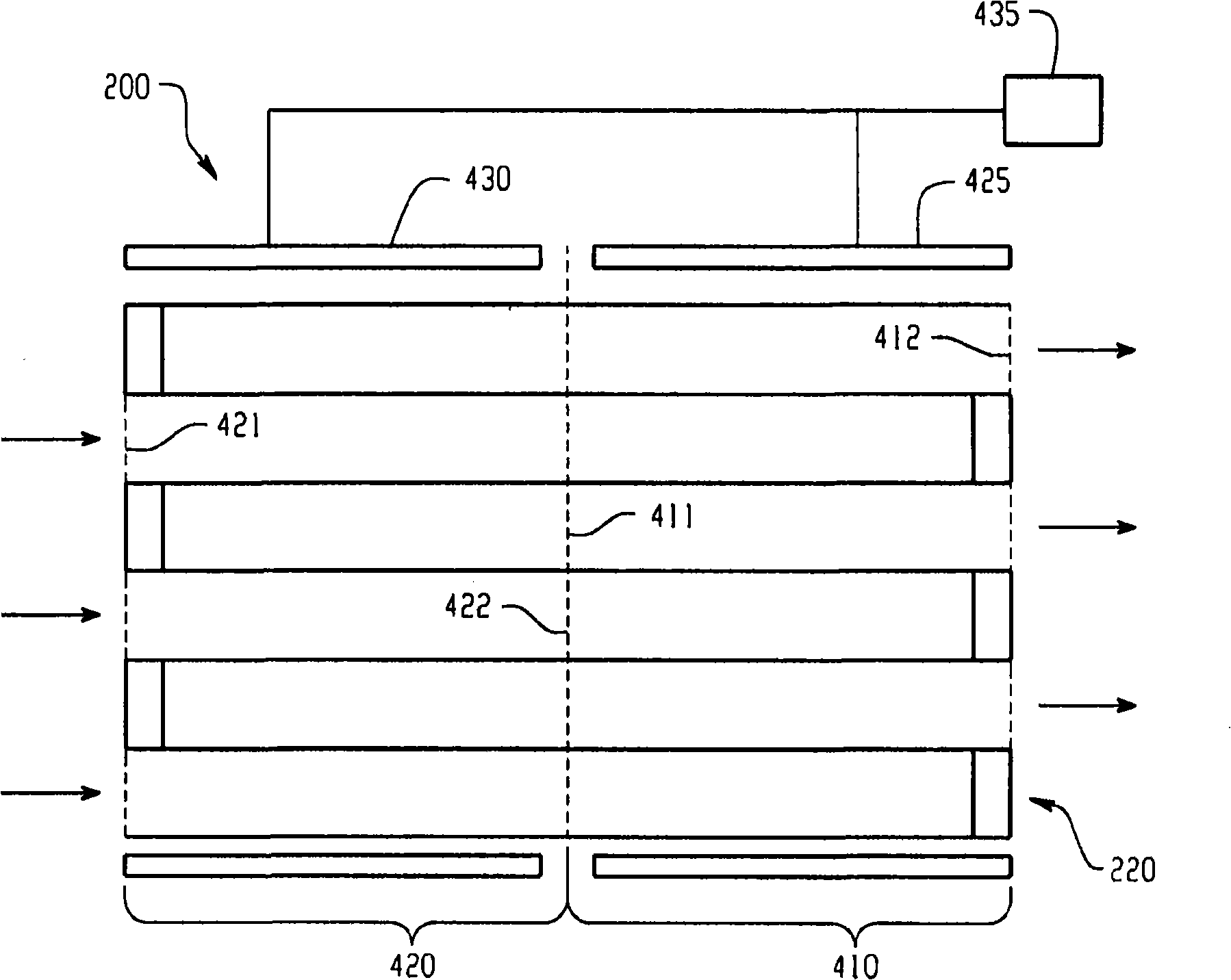

[0011] Embodiments of the present invention provide a particulate filter with improved regeneration characteristics for use in an exhaust system of an automotive diesel engine. While the embodiments described herein represent an automotive diesel engine as an exemplary diesel power plant using a particulate filter, it should be understood that the disclosed invention can also be applied to vehicles requiring the functionality of the particulate filter disclosed herein. Other diesel powered units, such as diesel generators. While the disclosed invention is well suited for filtering the by-products of combustion of diesel engines, it is also applicable to filtering the by-products of combustion of gasoline engines.

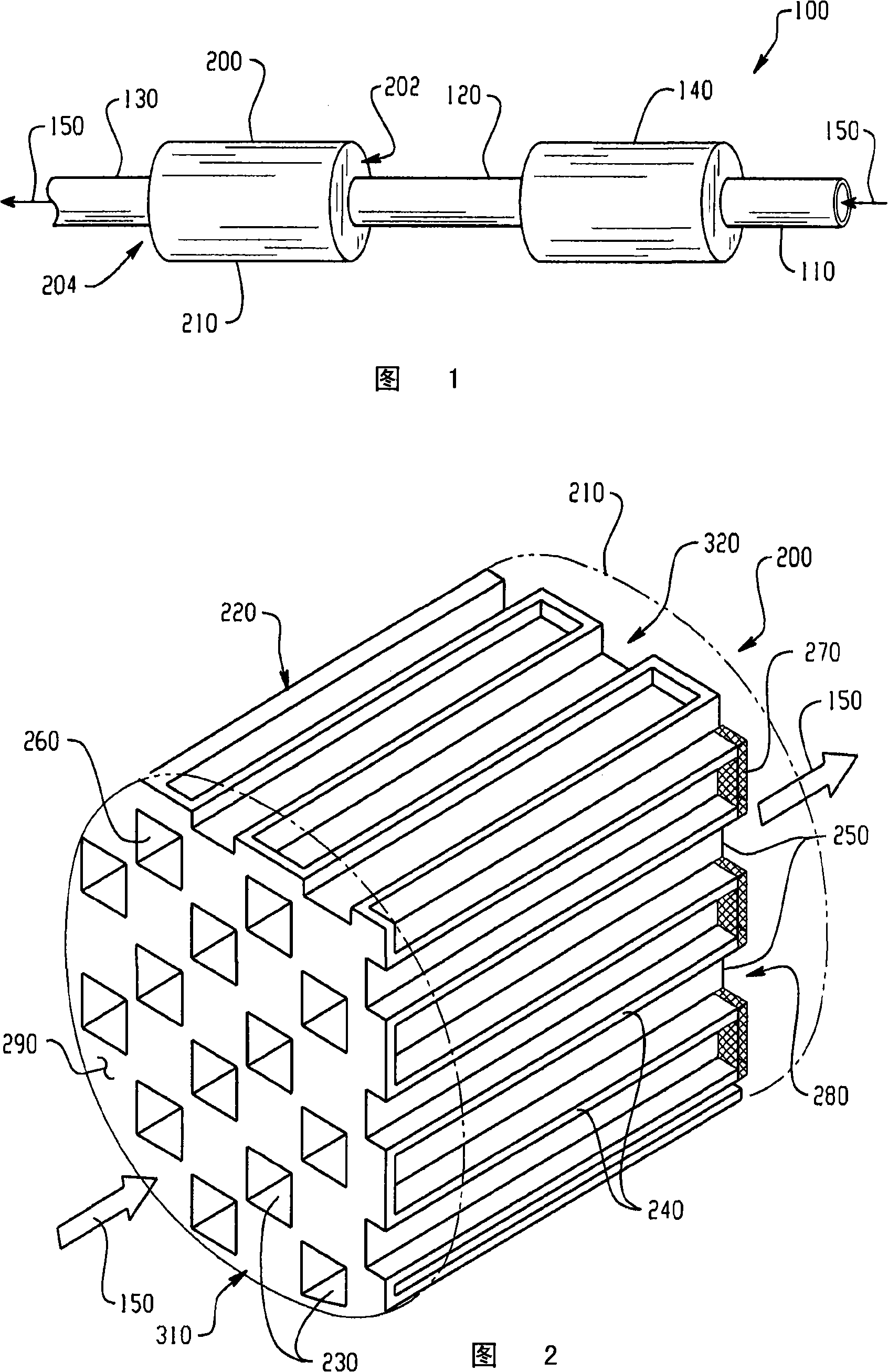

[0012] An exemplary exhaust system 100 for an automotive diesel engine (not shown) is shown in FIG. 1, the exhaust system 100 having a manifold exhaust pipe 110 suitably connected at one end to An exhaust manifold (not shown) of a diesel engine (not shown) to recei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com