Method and system thereof for oxygen-enriched flameless combustion of coal powder

A flameless combustion and oxygen-enriched combustion technology, which is applied in the field of coal-fired boiler combustion, can solve the problems of complex facilities and operating procedures and the difficulty of using solid fuels, so as to improve stability and burnout rate, avoid high-temperature preheating process, The effect of radiative heat transfer enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

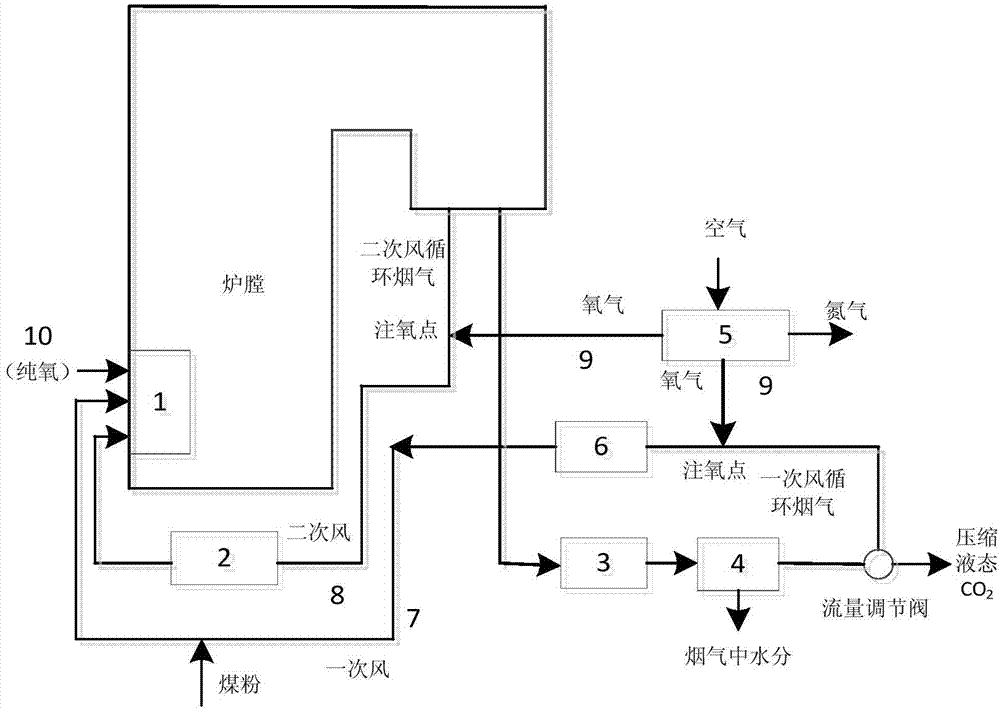

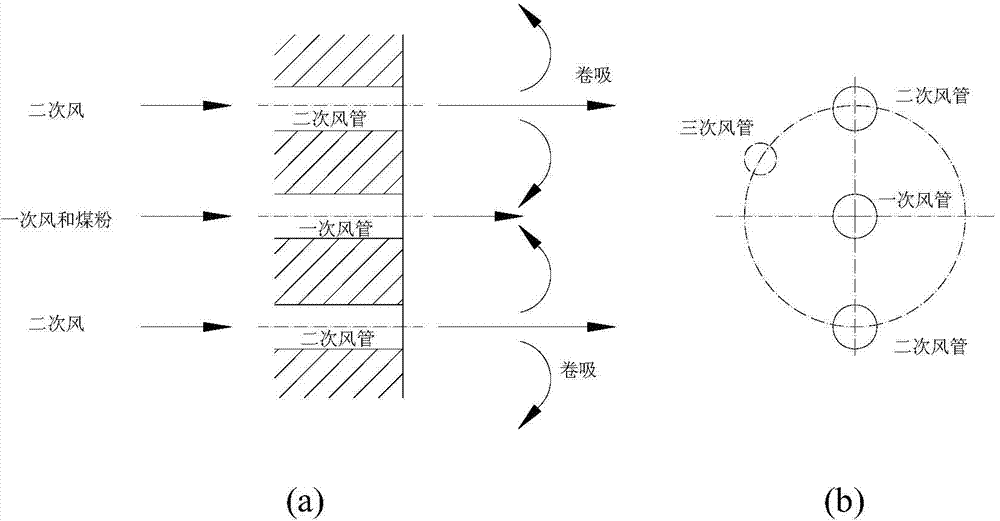

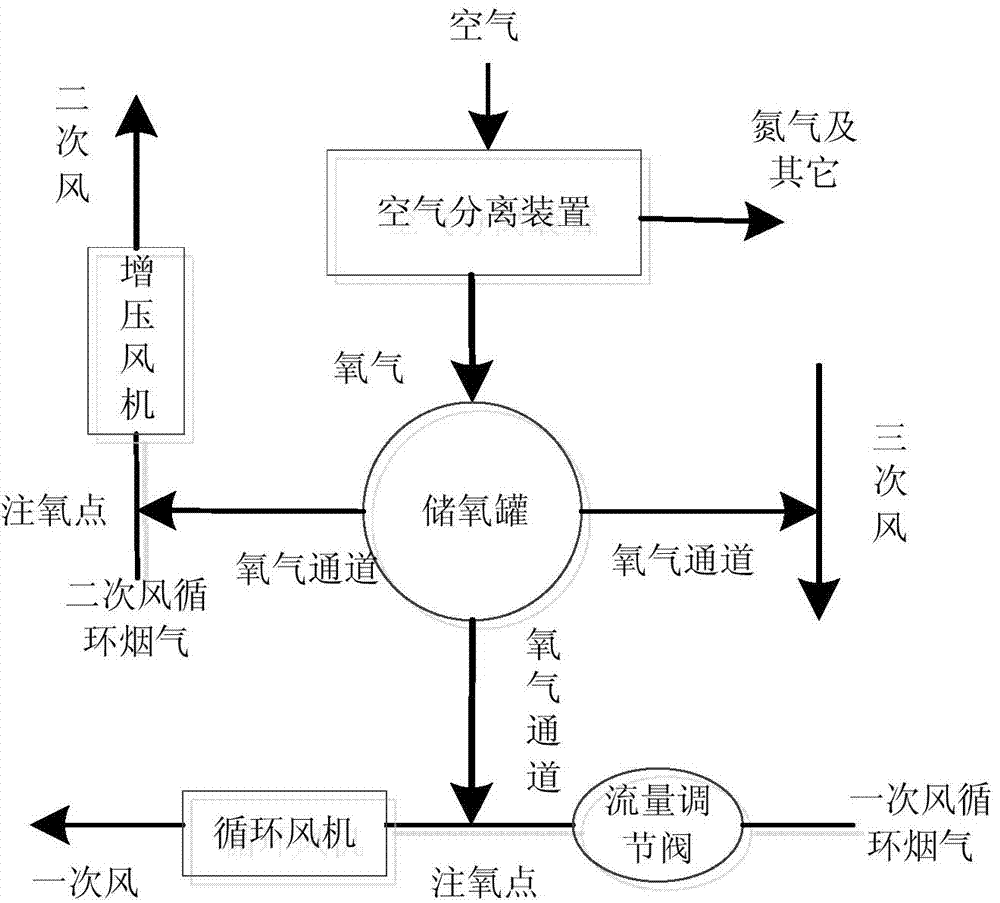

[0029] After the flue gas is discharged from the furnace, the primary air circulation flue gas is purified by the flue gas purifier 3 and condensed and dehydrated by the condenser 4, and a part of it is discharged from the circulation system and compressed into liquid CO 2 , and the other part forms primary air after oxygen injection, which is pressurized by the circulating fan 6 and enters the primary air channel, and circulates into the furnace through the flameless burner 1 in the form of direct current; The ratio can be controlled by the flow regulating valve; the primary air temperature is 100-250°C, and the outlet wind speed of the flameless burner is 10-25m / s. Secondary air circulating flue gas is injected with oxygen to form secondary air, which is pressurized by the booster fan and enters the secondary air duct, and circulates into the furnace through the flameless burner 1 in the form of high-speed jet flow; the temperature of the secondary air is 300-500 ℃, the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com