Manufacturing method of multi-layer bending structure

A manufacturing method and bending technology, applied in the field of mechanical processing, can solve the problems of difficulty in realizing the bending and forming of composite structures of multi-layer materials, low production efficiency, narrow application range, etc., and achieve enhanced mechanical properties, high production efficiency, and reduced forming processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

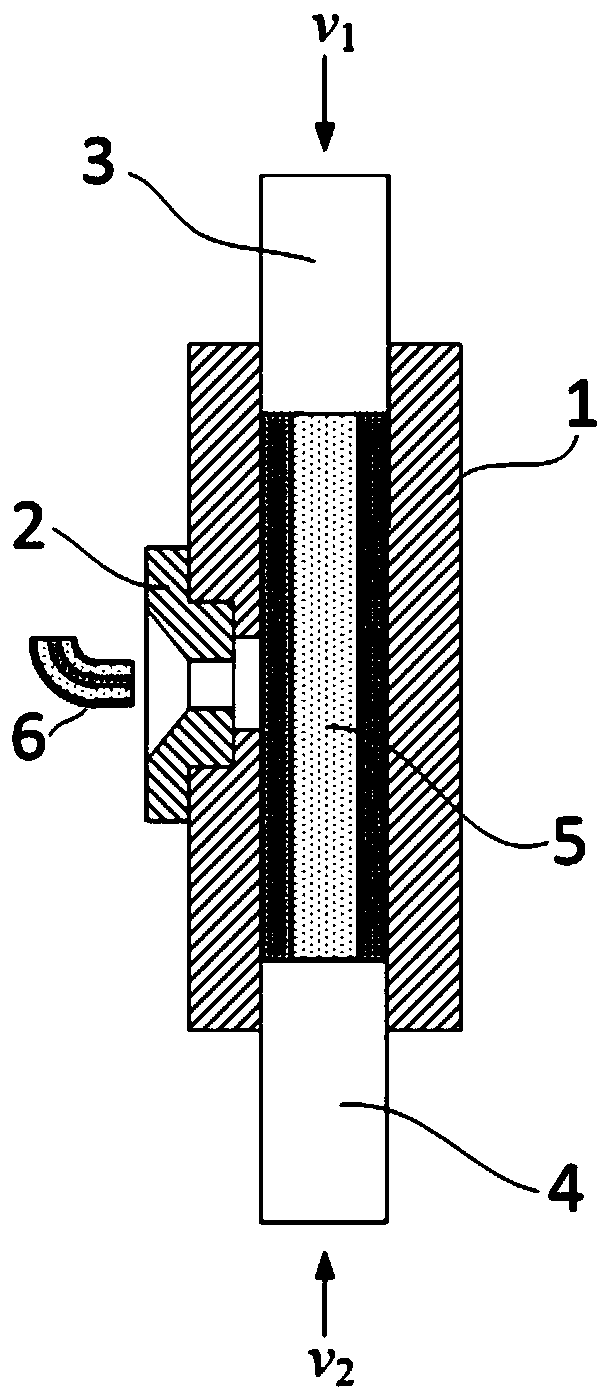

[0038] This embodiment provides a method for manufacturing a multi-layer bending structure, which is used for the manufacture of a closed multi-layer metal bending structure. figure 1 The differential lateral extrusion device shown includes an extrusion cylinder 1, a forming die 2, a first extrusion push rod 3 and a second extrusion push rod 4, the first extrusion push rod 3 and the second extrusion push rod The rods 4 are arranged along the axis of the extrusion cylinder 1 and are symmetrically distributed on both sides of the extrusion cylinder 1; the forming die 2 is installed on the side perpendicular to the axis of the extrusion cylinder 1.

[0039] The specific steps are:

[0040] Step (1) Prepare a composite type original blank 5, the composite type original blank 5 adopts a nested structure, including an inner layer of bar material and an outer layer of cylindrical structure surrounding the cylindrical surface of the bar. Among them, the inner layer is material two, and the...

Embodiment 2

[0052] This embodiment provides a manufacturing method of a multilayer bending structure, which is used for the manufacture of an open multilayer metal bending structure. The difference from the first embodiment is that the structure of the composite original blank 5 is different. Specifically:

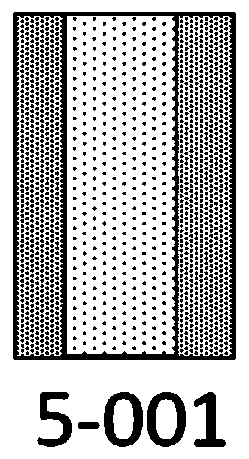

[0053] Step (1) adopts a multi-layer stacked structure. The longitudinal cross-sectional shape of the composite original blank 5 adopts the first longitudinal section 5-001 of the blank as shown in Fig. 2(a), and the cross section adopts the shape shown in Fig. 2(e). The third cross-section 5-005 of the blank, or the longitudinal cross-sectional shape of the composite original blank 5 adopts the third longitudinal section 5-008 of the blank as shown in Fig. 2(g), and the cross-section adopts the blank as shown in Fig. 2(f) The fourth cross section 5-006. Among them, the third cross section 5-005 of the blank is a three-layer plate stack structure, the middle layer is material two, and th...

Embodiment 3

[0061] This embodiment provides a method for manufacturing a multilayer bending structure, which is used for the manufacture of a closed multilayer metal / metal matrix composite bending structure. The difference from the first embodiment is that the inner layer in the composite original blank 5 The materials are made differently.

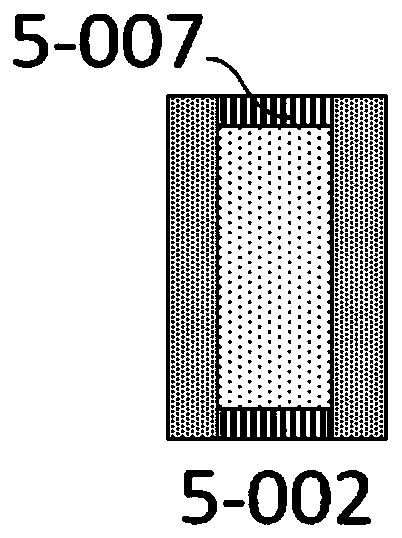

[0062] Step (1) The inner layer material in the composite original blank 5 adopts a form in which metal powder and a reinforcing phase are mixed with each other. Specifically, such as Figure 5 As shown, first weigh the metal powder and the reinforcing phase, then mix them in a vacuum environment and fill the mixed powder into the metal pipe sleeve in the vacuum environment; then perform the mixing of the powder in the pipe sleeve Compact and seal both ends of the sleeve to obtain the second longitudinal section 5-002 of the original blank shown in Figure 2(b), which has a head 5-007; the inner layer material is guaranteed by the head 5-007 In a vacuum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com