Nanometer ceramic solar film

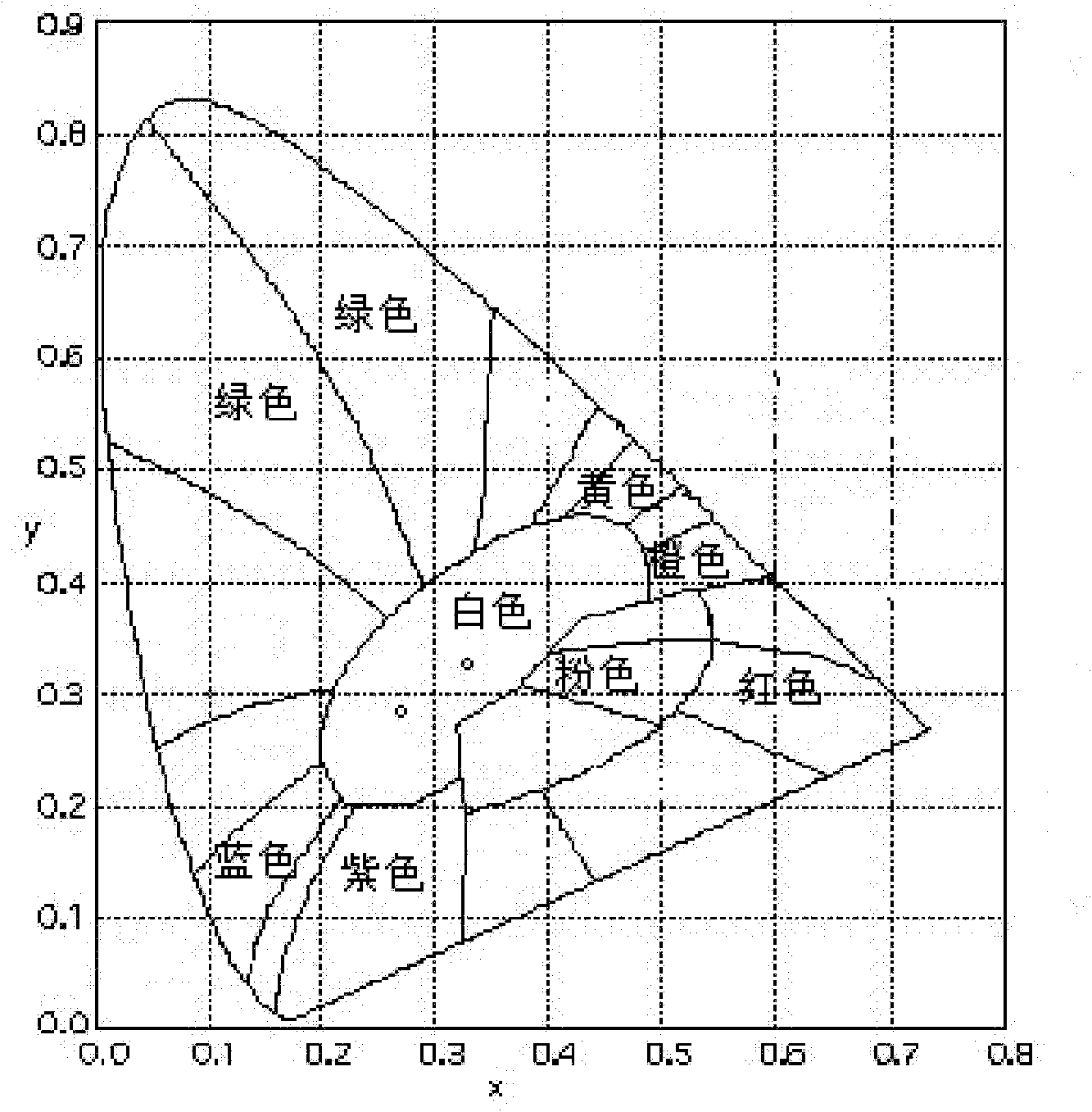

A nano-ceramic and solar film technology, applied in the direction of ion implantation plating, coating, layered products, etc., can solve the problems of easy oxidation of the metal layer, low visible light transmittance, low clarity and reflection, and achieve energy saving and Environmental protection, good spectral selectivity, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

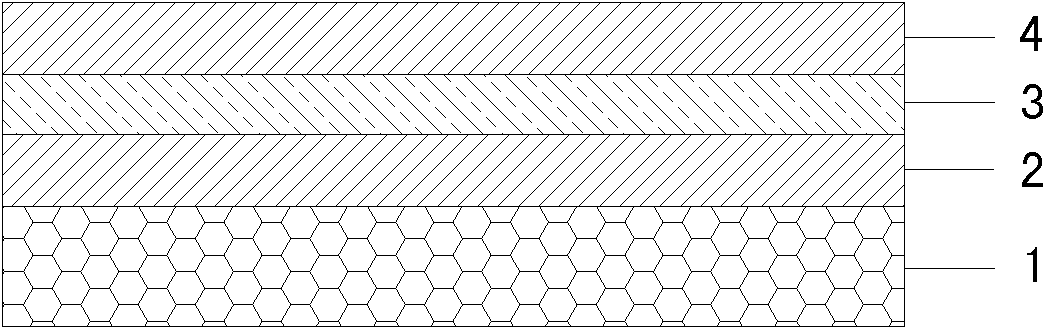

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0018] Substrate PET: polyethylene terephthalate, English name: polyethylene terephthalate. The thickness is 23μm~50μm, the transmittance is greater than 86%, and the heat resistance temperature is ≥150℃.

[0019] The first layer of titanium dioxide film: It is plated by intermediate frequency reactive magnetron sputtering twin targets, the target material is titanium target, the reaction gas is oxygen, and the film thickness is 26nm~38nm. Among them, the reactive sputtering state is monitored by the plasma emission spectrum monitoring and control device PEM, which avoids target poisoning and sparking, and improves the deposition rate and film quality.

[0020] The second layer of titanium nitride film: It is plated by twin targets of intermediate frequency reaction magnetron sputtering. The target material is titanium target, the reaction ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com