Preparation method of solar selective absorbing coating with double-texture surface and coating

A technology for absorbing coatings and solar energy, applied in coatings, metal material coating processes, vacuum evaporation plating, etc., can solve problems such as inability to make further breakthroughs, achieve novel structures, prevent diffusion and fusion, and improve thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

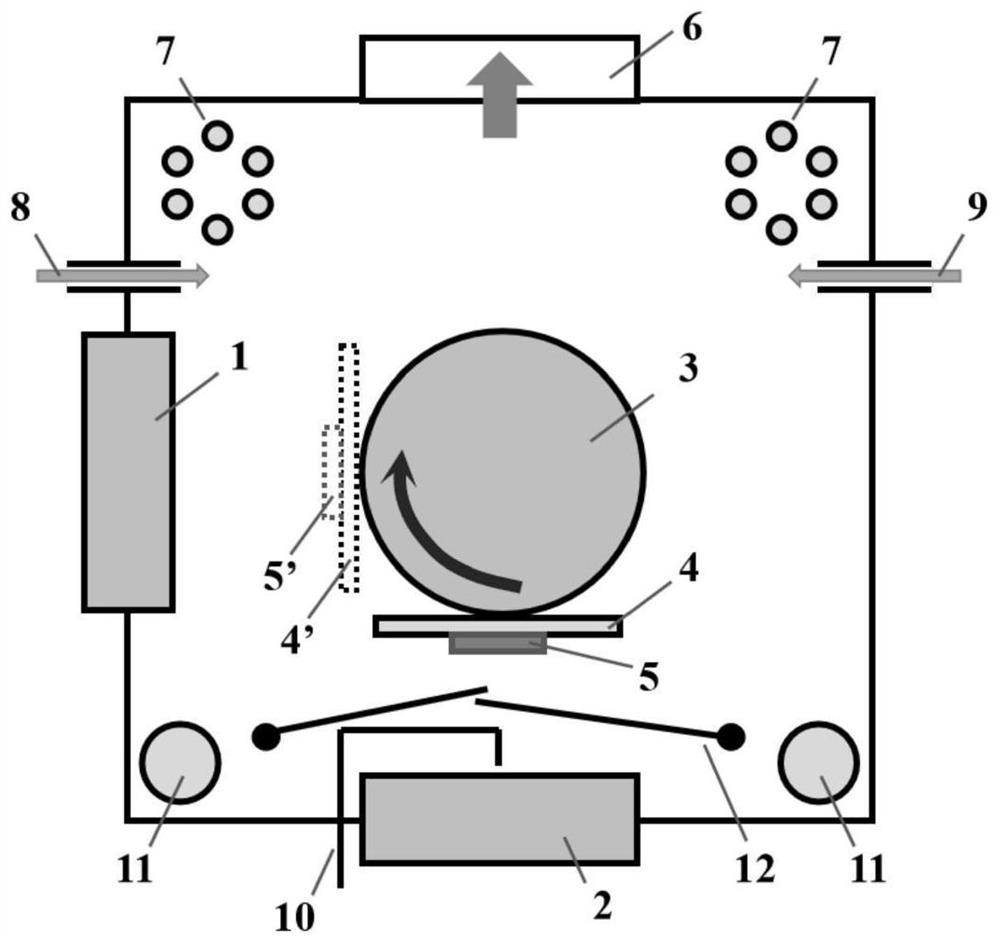

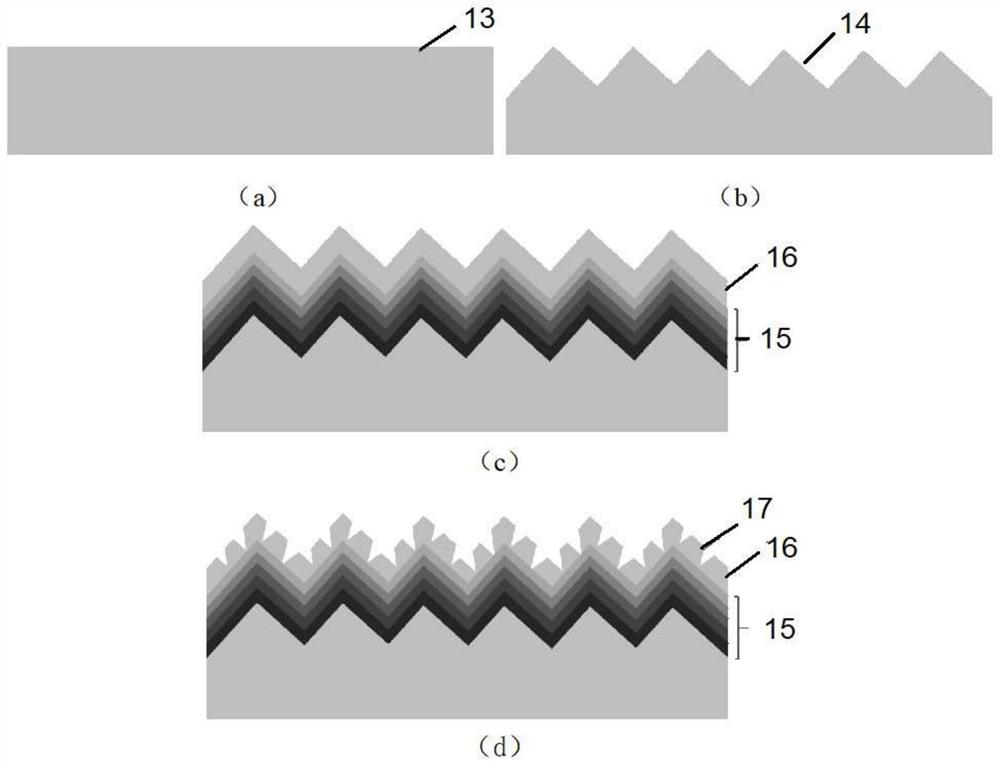

[0055] Combined equipment diagram figure 1 , Schematic diagram of substrate coating morphology change figure 2 , the present invention provides a double-textured surface solar energy selective absorption coating and a preparation method thereof comprising the following steps:

[0056] (1) Preparing the experimental environment: on the radio frequency magnetron sputtering PVD equipment, press figure 1 Place sputtering target 1, arc power target 2, turntable 3, sample holder 4, and substrate 5 at the positions shown. At this time, substrate 5 is parallel to arc power target 2, and the surface of substrate 5 is flat (see figure 2 13) in (a), vacuumize by mechanical pump, molecular pump group 6, open heating tube 7 simultaneously, when vacuum degree reaches ideal value, when temperature reaches target value; Vacuum degree is generally 10 -3 Pa level, the temperature in the cavity is determined by the application and performance of the coating, generally between 100-300°C;

[...

example 1

[0075] The present invention provides a method for preparing a double-textured surface solar energy selective absorption coating. The prepared textured surface morphology can be adjusted by adjusting the substrate bias, etching time, distance between the arc power target 2 and the substrate 5, Arc power parameters, air pressure, etc., can obtain surface textures with different shapes;

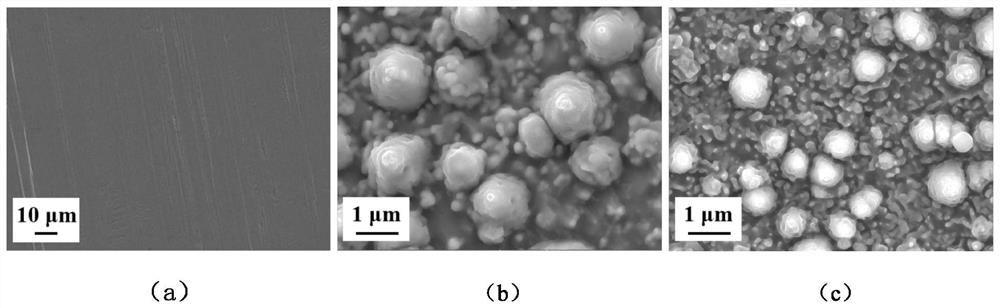

[0076] combine figure 1 , image 3 , Figure 4 , taking the surface textured surface in the form of particles, stainless steel as the substrate, high-entropy alloy as the absorbing layer, and high-entropy alloy oxide as the anti-reflection layer as an example to illustrate, and verify the comparison The stainless steel substrate with only textured surface, no absorbing layer and oxide anti-reflection layer, coating with absorbing layer, anti-reflective layer on textured surface, and secondary textured surface have better spectral selectivity.

[0077] (1) Preparing the experimental environme...

example 2

[0088] combine Figure 5 , on the basis of Example 1, it was further verified that the high temperature of the solar selective absorption coating on the surface of the particle morphology double-textured surface with stainless steel as the substrate, high-entropy alloy as the absorption layer, high-entropy alloy oxide as the protective layer, and anti-reflection layer stable performance.

[0089] (1) Preparing the experimental environment: as in Example 1;

[0090] (2) The textured surface is etched on the flat stainless steel substrate: as in Example 1;

[0091] (3) Deposition of multilayer absorption coating: as in Example 1;

[0092] (4) Deposition of pure high-entropy alloy oxide anti-reflection layer: as in Example 1;

[0093] (5) The secondary textured surface is etched on the anti-reflection layer: as in Example 1;

[0094] (6) Test the properties before annealing: measure the surface morphology, reflection spectrum, such as Figure 4 , the results are analyzed as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thermal stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com