Film ultraviolet detector and preparation method thereof

A UV detector and thin film technology, applied in semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of narrow band gap and limited application, and achieve the effect of mild conditions, simple steps and large area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

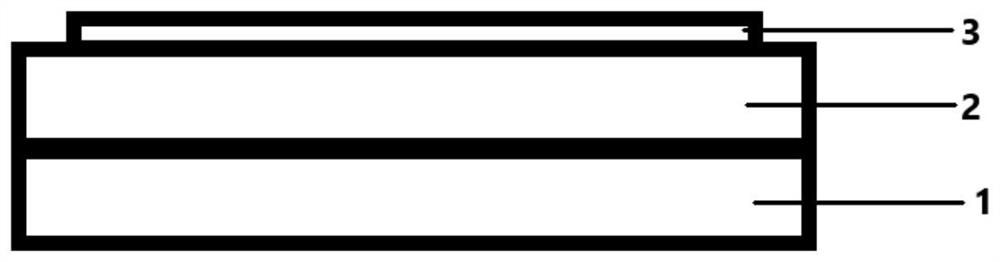

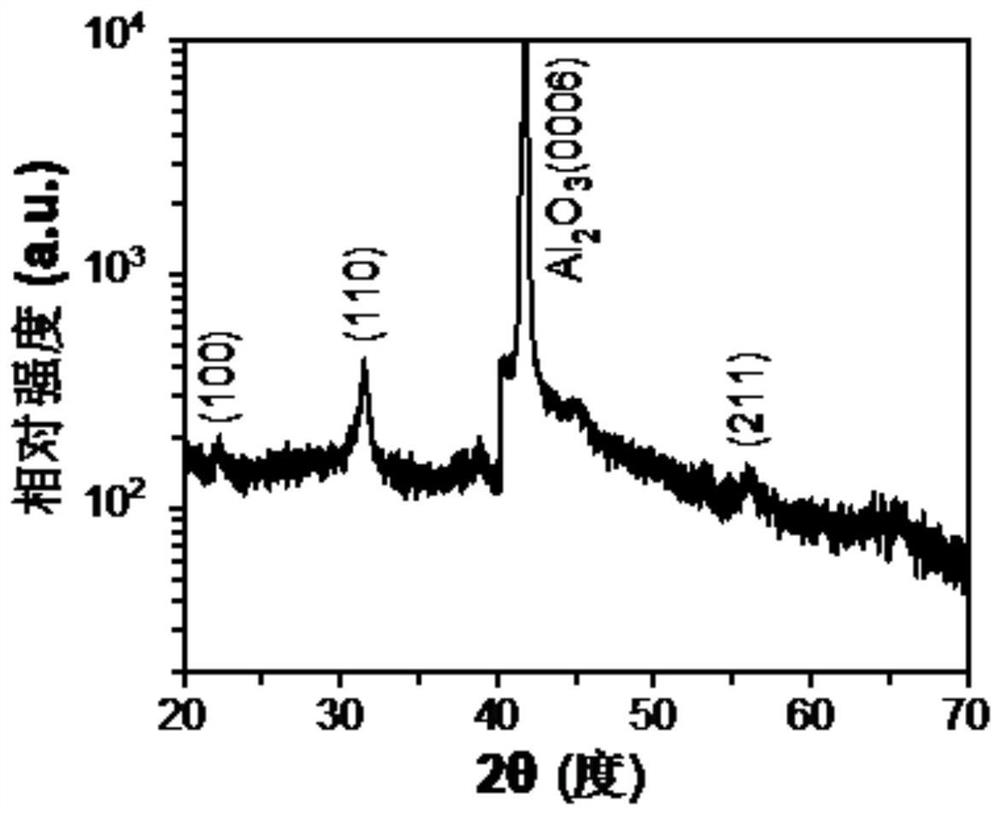

[0052] Figure 2-6 It is a kind of BaTiO provided by the present invention 3 BaTiO in Thin Film Ultraviolet Detector and Preparation Method Embodiment 1 3 Thin film test data.

[0053] Put the cleaned sapphire substrate into the magnetron sputtering growth chamber, adjust the growth temperature to 500°C, and the pressure to 1×10 -1 Pa. Use BaTiO with an elemental ratio of Ba and Ti of 1:1 3 Target material, sputtering RF power is 60W, grows for 2h, turns off the RF, lowers the substrate temperature to room temperature, and obtains BaTiO 3 film.

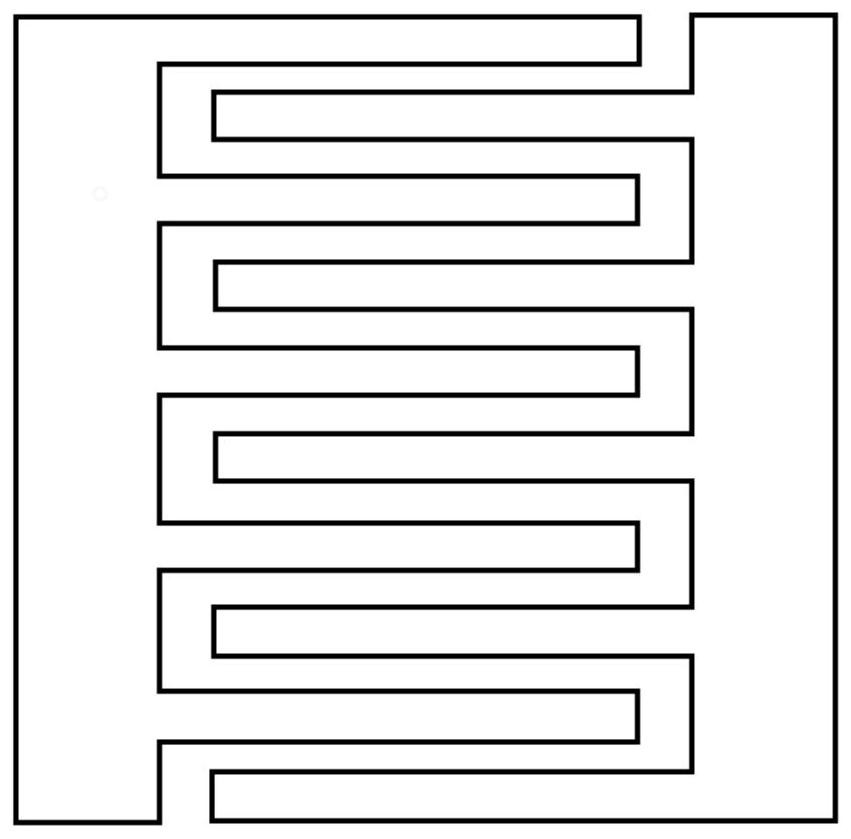

[0054] In BaTiO 3 Use negative photolithography to form 20 pairs of interdigitated electrode masks with a spacing of 5 μm and a length of 500 μm on the thin film material: put the obtained sample into a small coating machine, and under the condition of a pressure of 6 Pa and a current of 9 mA, sputter Then, the colloidal mask was removed by ultrasound for 3 minutes to form a platinum interdigitated electrode layer, and BaTiO wi...

Embodiment 2

[0061] Figure 7-10 It is a kind of BaTiO provided by the present invention 3 BaTiO in Thin Film Ultraviolet Detector and Preparation Method Embodiment 2 3 Thin film test data.

[0062] Put the cleaned sapphire substrate into the magnetron sputtering growth chamber, adjust the growth temperature to 20°C, and the pressure to 1×10 -2 Pa. Use BaTiO with an elemental ratio of Ba and Ti of 1:1 3 For the target material, the sputtering RF power is 40W, grow for 1h, turn off the RF, lower the substrate temperature to room temperature, and obtain BaTiO 3 film.

[0063] In BaTiO 3 On the film material, 20 pairs of interdigitated electrode masks with a pitch of 5 μm and a length of 500 μm were formed using negative resist lithography. The obtained sample was put into a small coating machine, and metal platinum was sputtered under the condition of a pressure of 6 Pa and a current of 9 mA. Then the colloidal mask was removed by ultrasonication for 3min to obtain BaTiO with MSM str...

Embodiment 3

[0070] Figure 11-14 It is a kind of BaTiO provided by the present invention 3 BaTiO in Thin Film Ultraviolet Detector and Preparation Method Embodiment 3 3 Thin film test data.

[0071] Put the cleaned sapphire substrate into the magnetron sputtering growth chamber, adjust the growth temperature to 500°C, and the pressure to 1×10Pa. Use BaTiO with an elemental ratio of Ba and Ti of 1:1 3 For the target material, the sputtering RF power is 180W, grow for 2h, turn off the RF, lower the substrate temperature to room temperature, and obtain BaTiO 3 film.

[0072] In BaTiO 3 On the film material, 20 pairs of interdigitated electrode masks with a pitch of 5 μm and a length of 500 μm were formed using negative resist lithography. The obtained sample was put into a small coating machine, and metal platinum was sputtered under the condition of a pressure of 6 Pa and a current of 9 mA. Then the colloidal mask was removed by ultrasonication for 3min to obtain BaTiO with MSM struc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com