A kind of coated aluminum powder and its preparation method and coating containing coated aluminum powder

A technology for coating aluminum and aluminum powder, which is applied to coating aluminum powder and its preparation, including the coating field of coating aluminum powder, which can solve the problem that it is difficult to be compatible with visible light camouflage and anti-infrared camouflage reconnaissance, low brightness camouflage color, low brightness, Can not meet the problems at the same time, to achieve the effect of good physical and mechanical properties and environmental adaptability, adjustable color and emissivity, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

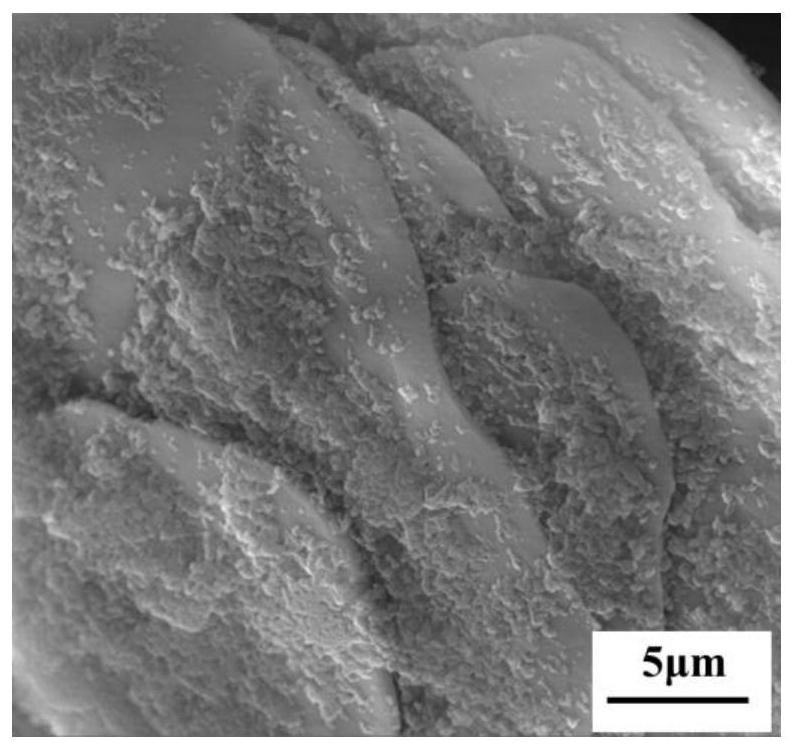

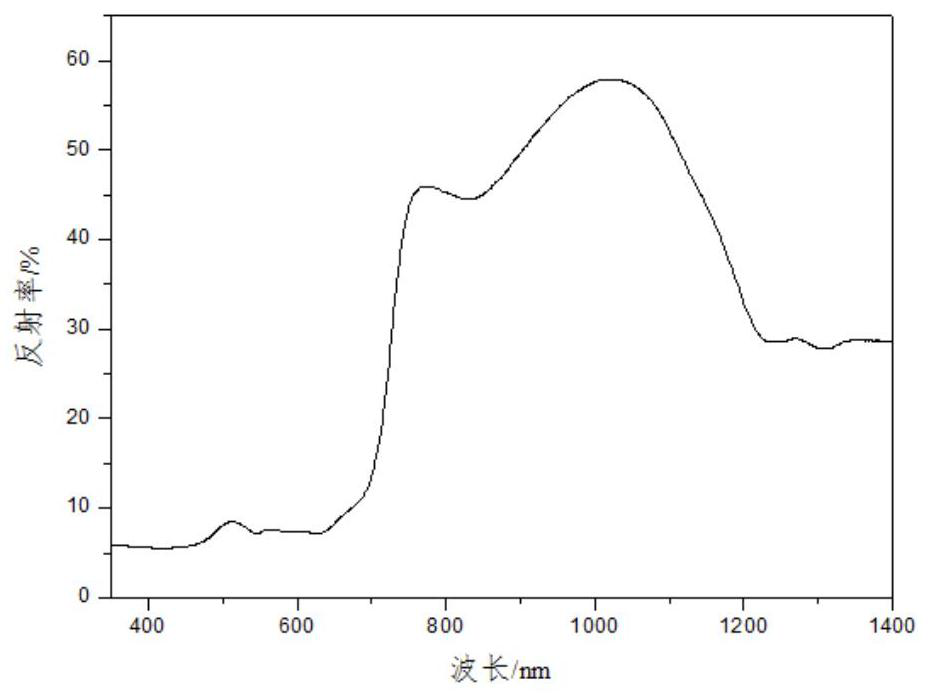

[0038] A kind of carbon black coated aluminum powder and green camouflage paint comprising carbon black coated aluminum powder

[0039] A carbon black-coated aluminum powder. The raw material composition of the carbon black-coated aluminum powder includes oily non-leafing aluminum powder, carbon black, xylene, and oleic acid in a mass ratio of 10:5:20:0.1:0.04. and a silane coupling agent; the raw materials are subjected to high-speed dispersion and grinding in a container with zirconia balls to obtain a coated aluminum powder slurry, and then use a cleaning agent to clean the surface of the coated aluminum powder to remove residual impurities on the surface to obtain Coated aluminum powder.

[0040] Its specific preparation method comprises the following steps:

[0041] S1: Weigh oily non-leafing aluminum powder, carbon black, xylene, oleic acid and silane coupling agent according to the mass ratio of raw materials, and carry out high-speed dispersion and grinding in a conta...

Embodiment 2

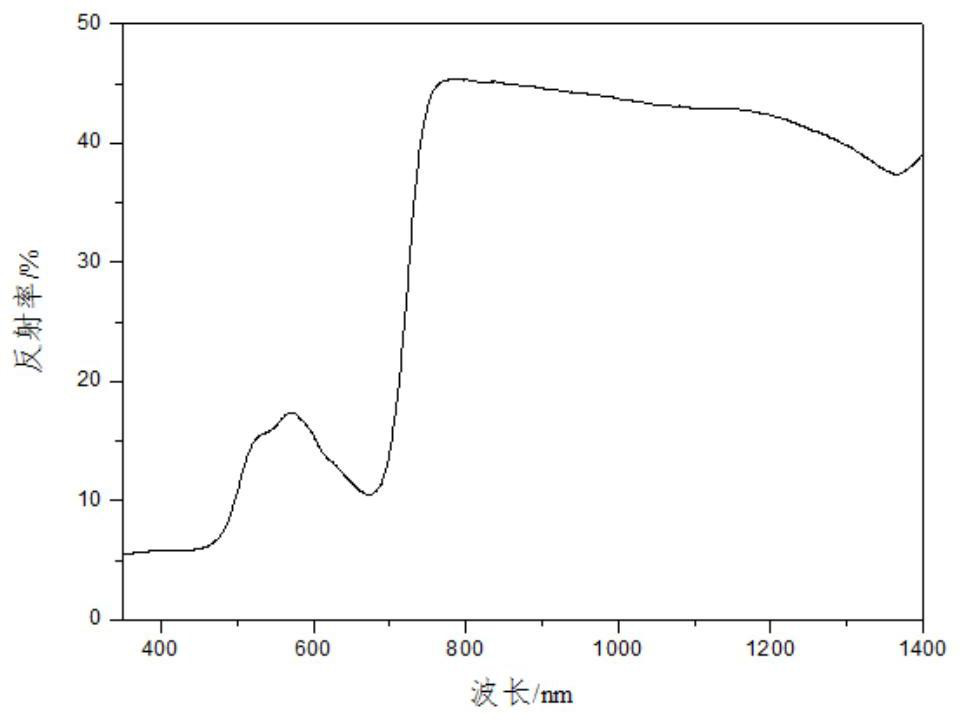

[0052] A kind of aluminum powder coated with medium chrome yellow and the yellow-green camouflage paint comprising said aluminum powder

[0053] A medium chrome yellow coated aluminum powder. The raw materials of the medium chrome yellow coated aluminum powder include oily non-leafing aluminum powder, medium chrome yellow, and 120# solvent oil in a mass ratio of 18:14:42:0.4:0.07 , oleic acid and silane coupling agent; the raw materials are dispersed and ground at a high speed in a container with zirconia balls to obtain coated aluminum powder slurry, and then the surface of the coated aluminum powder is cleaned with a cleaning agent to remove residual residues on the surface impurities to obtain the medium chrome yellow coated aluminum powder.

[0054] The preparation method of the above-mentioned medium chrome yellow coated aluminum powder comprises the following steps:

[0055] S1: Weigh the above raw materials, add an appropriate amount of zirconia balls with a diameter o...

Embodiment 3

[0066] A phthalocyanine blue-coated aluminum powder, the phthalocyanine blue-coated aluminum powder comprises raw material components including oily non-leafing aluminum powder, phthalocyanine blue, and xylene in a mass ratio of 26:14:50:1:0.1 Mix with 120# solvent oil 1:1, oleic acid and silane coupling agent, and carry out high-speed dispersion and grinding of the raw material components in a container with zirconia balls to obtain coated aluminum powder slurry, and then use a cleaning agent to coat the The surface of the aluminum-coated powder is cleaned to remove residual impurities on the surface to obtain the phthalocyanine blue-coated aluminum powder.

[0067] Its specific preparation method comprises the following steps:

[0068] S1: Weigh the above raw materials, add an appropriate amount of zirconia balls with a diameter of 1.2-1.6mm, and grind at a speed of 2000r / min for 5 hours at a high speed to obtain a coated aluminum powder slurry;

[0069] S2: The coated alum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com