Thermoelectric performance test workbench of thermoelectric generation single module

A technology for testing workbenches and thermoelectric power generation, which is applied in the direction of measuring electricity, measuring devices, and measuring electrical variables. It can solve problems such as difficult stability, large deviation of input thermal power, and heat leakage of input thermal power to reduce heat leakage. , improve the test accuracy, improve the effect of power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, an embodiment of the present invention will be specifically described below in conjunction with the accompanying drawings.

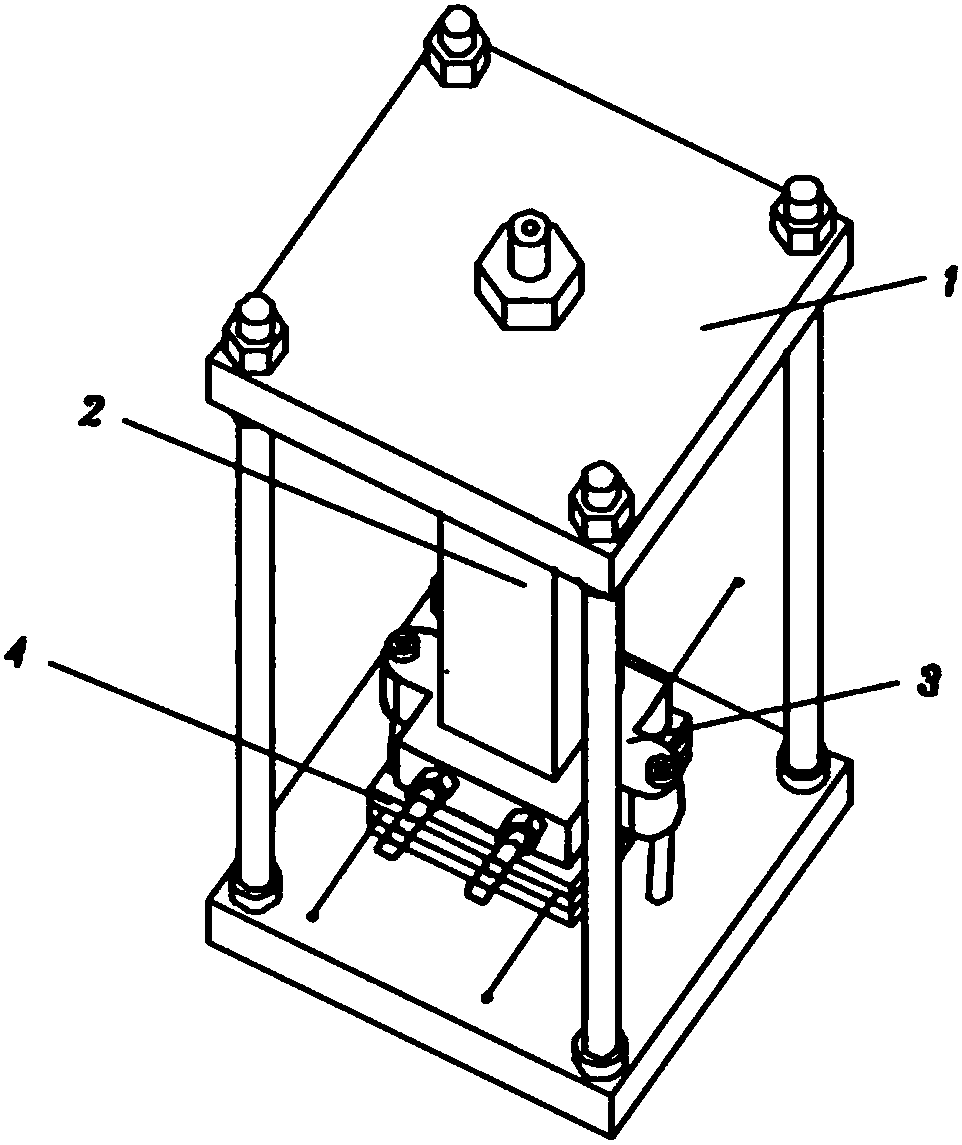

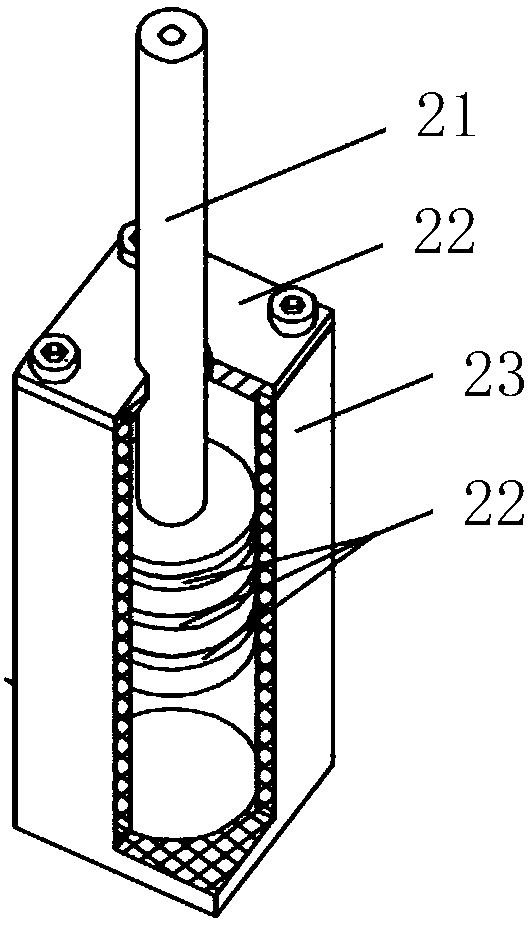

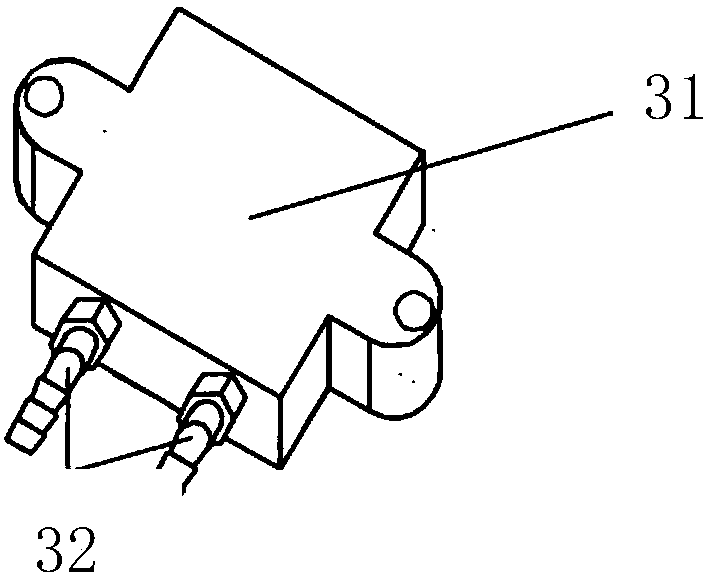

[0028] This embodiment includes a workbench 1 , a pneumatic system 2 , a cooling circulation system 3 , and an electric heating test system 4 . Workbench 1 adopts a structure in which the upper and lower working surfaces are screwed or clamped to four supporting columns. The lower working surface is equipped with an electric heating test system, a cooling circulation system, and an air pressure system in sequence from bottom to top. The cooling circulation system includes a cooling water jacket 31 and the cooling water nozzle 32, the two sides of the cooling water jacket are respectively provided with bosses, the bosses are provided with fixing holes, the cooling circulation system is connected to the lower working surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com