Multi-point rotating clamping type picking device for wolfberry picking

A clamping and rotating clamp technology, applied in the direction of picking machines, applications, agricultural machinery and implements, etc., can solve the problems of reducing the output of wolfberry, damage, affecting the growth of wolfberry trees, etc., and achieves high picking efficiency, convenient operation and picking effect. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

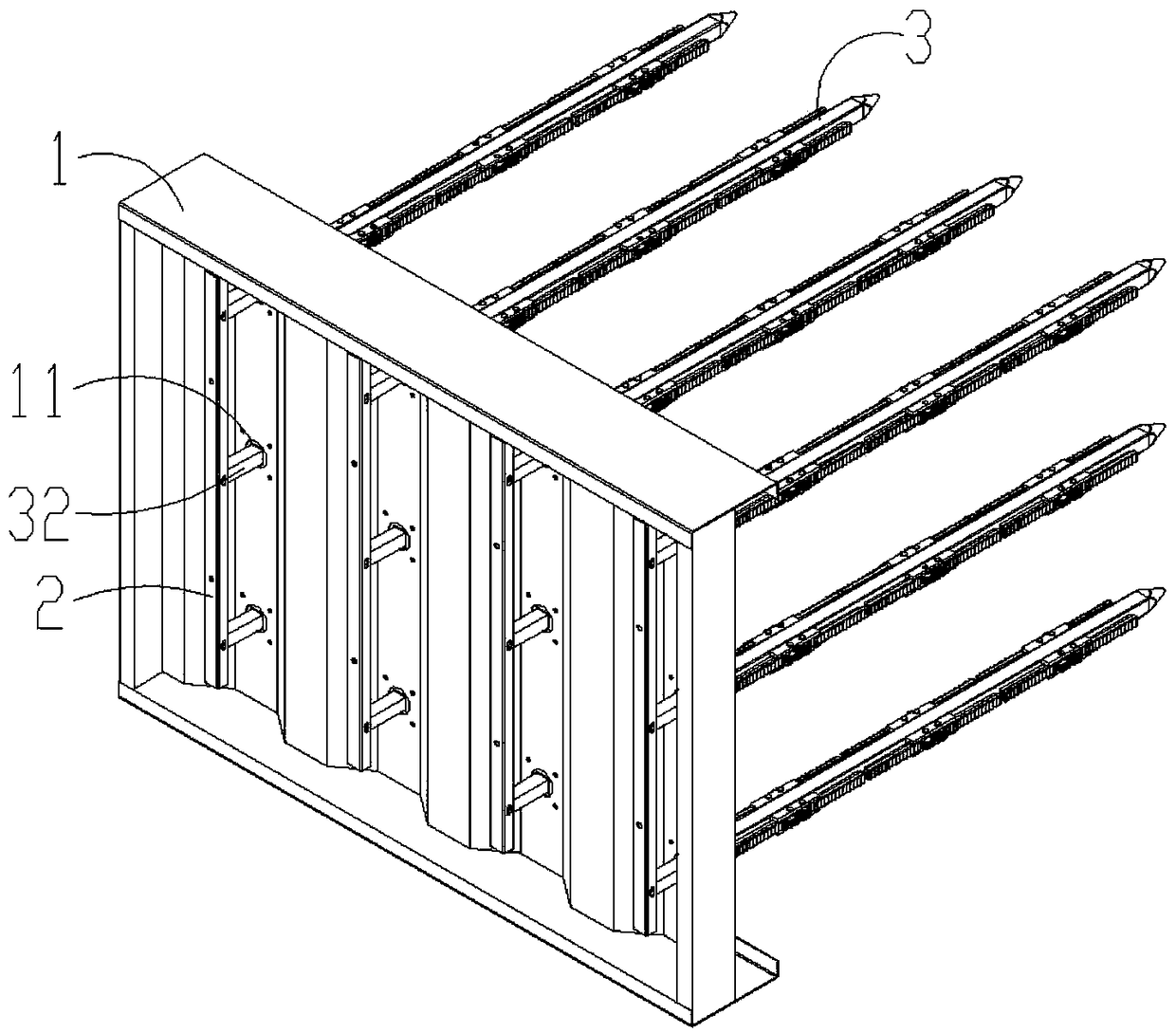

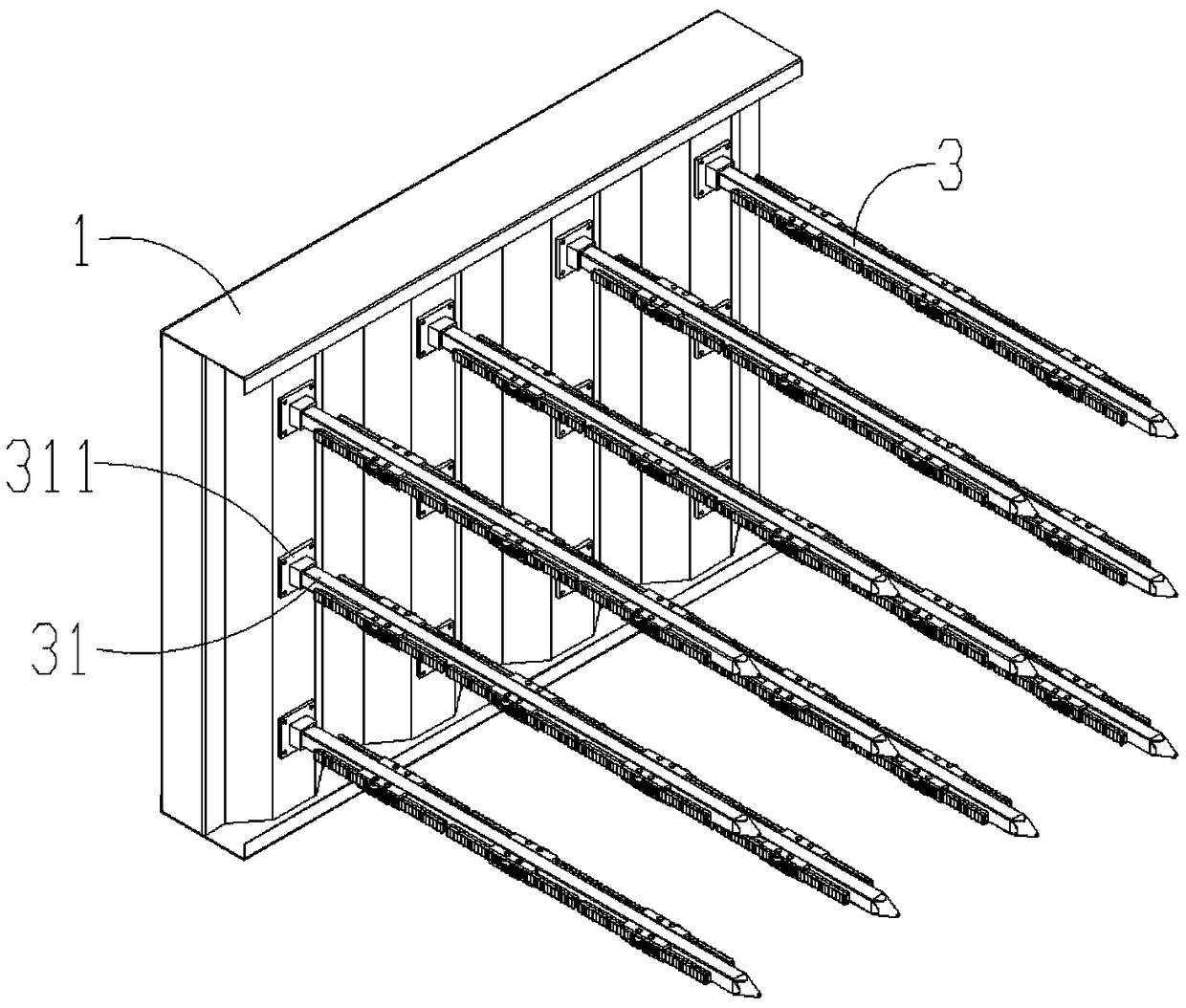

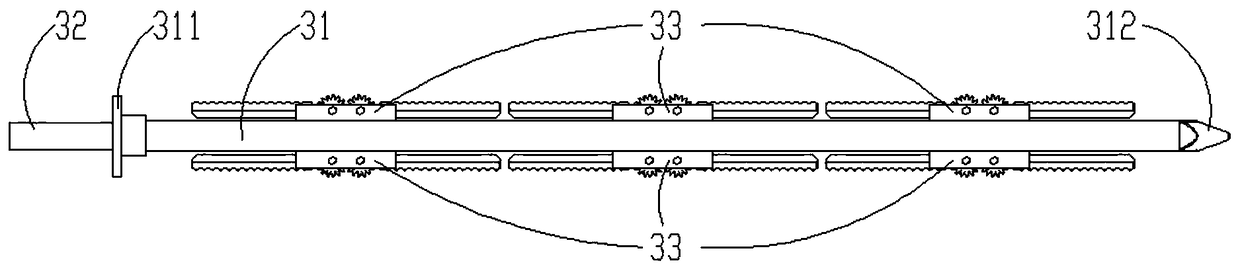

[0026] The working principle of the precise clamping and vibration of the multi-point rotating clamping picking device used for wolfberry picking in the present invention:

[0027] During work, the clamping hands 33 on each clamper 3 of the rotating and clamping fixed plate 1 are in an open state, that is, the two clamping hands 333 on the clamping hands 33 are separated; the equipment moves to For the position of the wolfberry tree, the rotating and clamping fixed plate 1 is evenly inserted into the canopy of the wolfberry tree along the array of holders 3, and the positioning square tube 31 relies on the square tube head 312 to enter between the branches and leaves without causing damage to the branches and leaves, and move to a suitable position , operate and pull the vertical groove frame 2 to move outward and drag the moving rod 32 out along the positioning square tube 31, the rack 321 on the moving rod 32 drives and clamps the full gear 336 on the gripping group 33 to rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com