High-temperature-resistant screw conveyor

A screw conveyor, high temperature resistant technology, applied in the direction of packaging, etc., to achieve the effect of lowering the temperature, convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

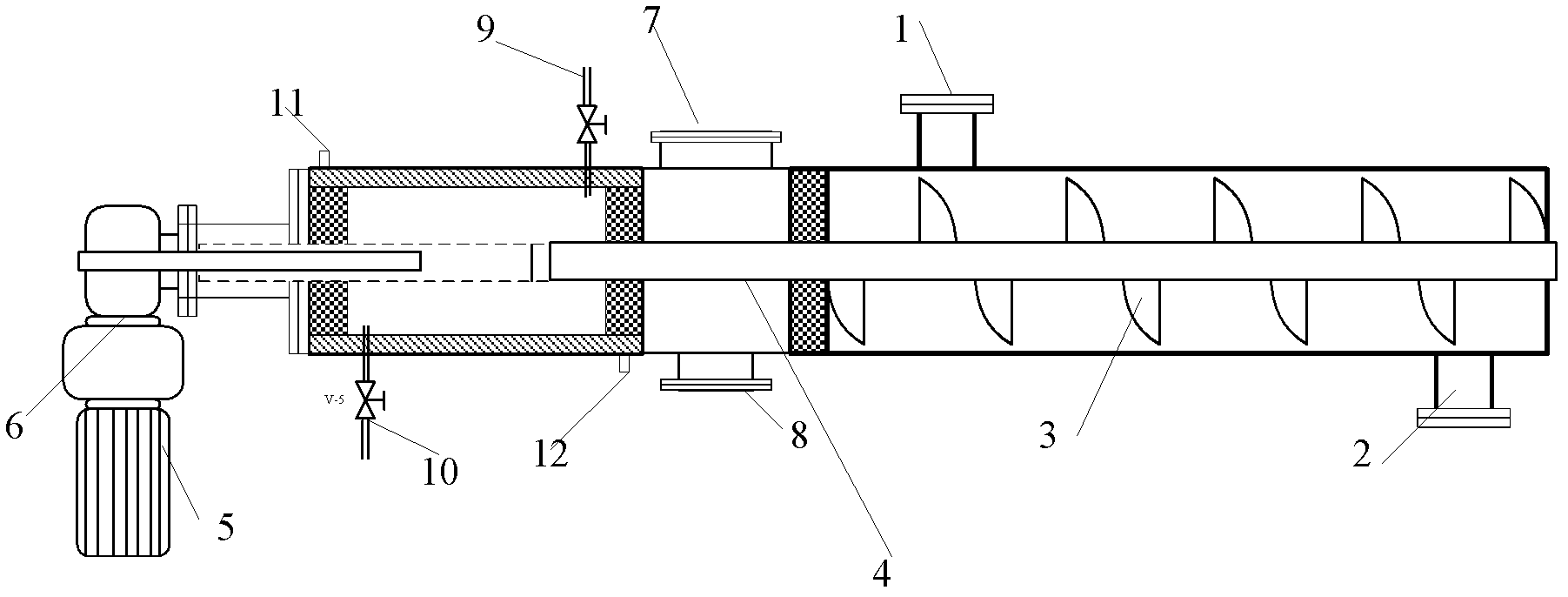

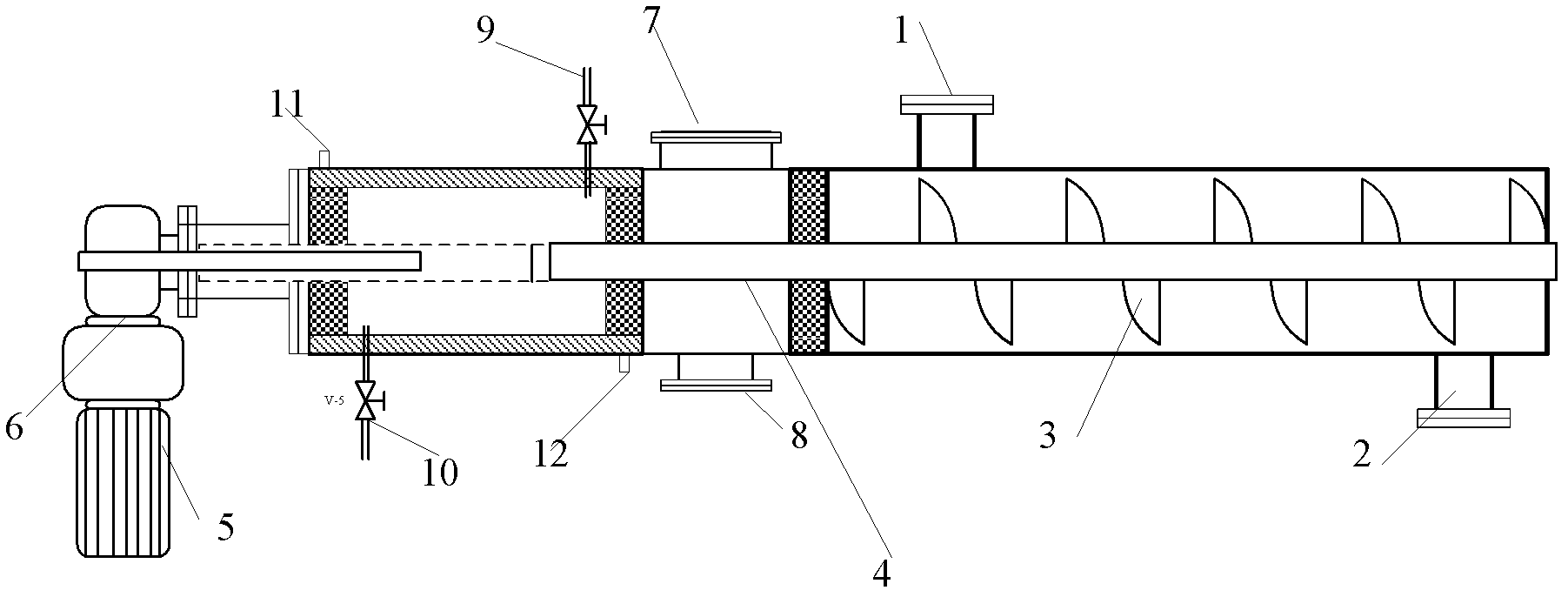

[0033] 700°C high-temperature bituminous coal particles are sent into the main body of the screw conveyor from the material inlet, and the screw shaft is controlled by the motor to drive the screw blades, and the conveyed coal particles are discharged from the outlet; at a temperature of 700°C, coal particles may undergo thermal decomposition. Volatile matter, the pyrolysis gas and tar produced enter the solid heat insulation sealing device through the interface of the screw shaft, and the pyrolysis gas and tar are taken out by sand washing, and part of the heat is brought out, which reduces the temperature; cooling by circulating air The temperature of the screw axis is reduced; through the cooling effect of circulating water, the temperature of the shell of the screw conveyor is further reduced.

Embodiment 2

[0035] The high-temperature lignite particles at 750°C are sent into the main body of the screw conveyor from the material inlet, the screw shaft is controlled by the motor and the screw blades are driven, and the coal particles are discharged from the outlet; at 750°C, the coal particles undergo thermal decomposition to release volatile matter, and the generated gas and The tar enters the solid heat insulation sealing device through the interface of the screw shaft, and the pyrolysis gas and tar are taken out by the scouring of coal ash, and part of the heat is taken out; the cooling of the circulating gas reduces the temperature of the screw shaft; through the cooling of the circulating oil The cooling effect further reduces the temperature of the screw conveyor shell.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com