Plastics composite wall brick

A technology of composite wall bricks and plastics, applied in the field of building materials, can solve the problems of limited size, inconvenient maintenance, poor recyclability of bricks, etc., and achieve the effect of high dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

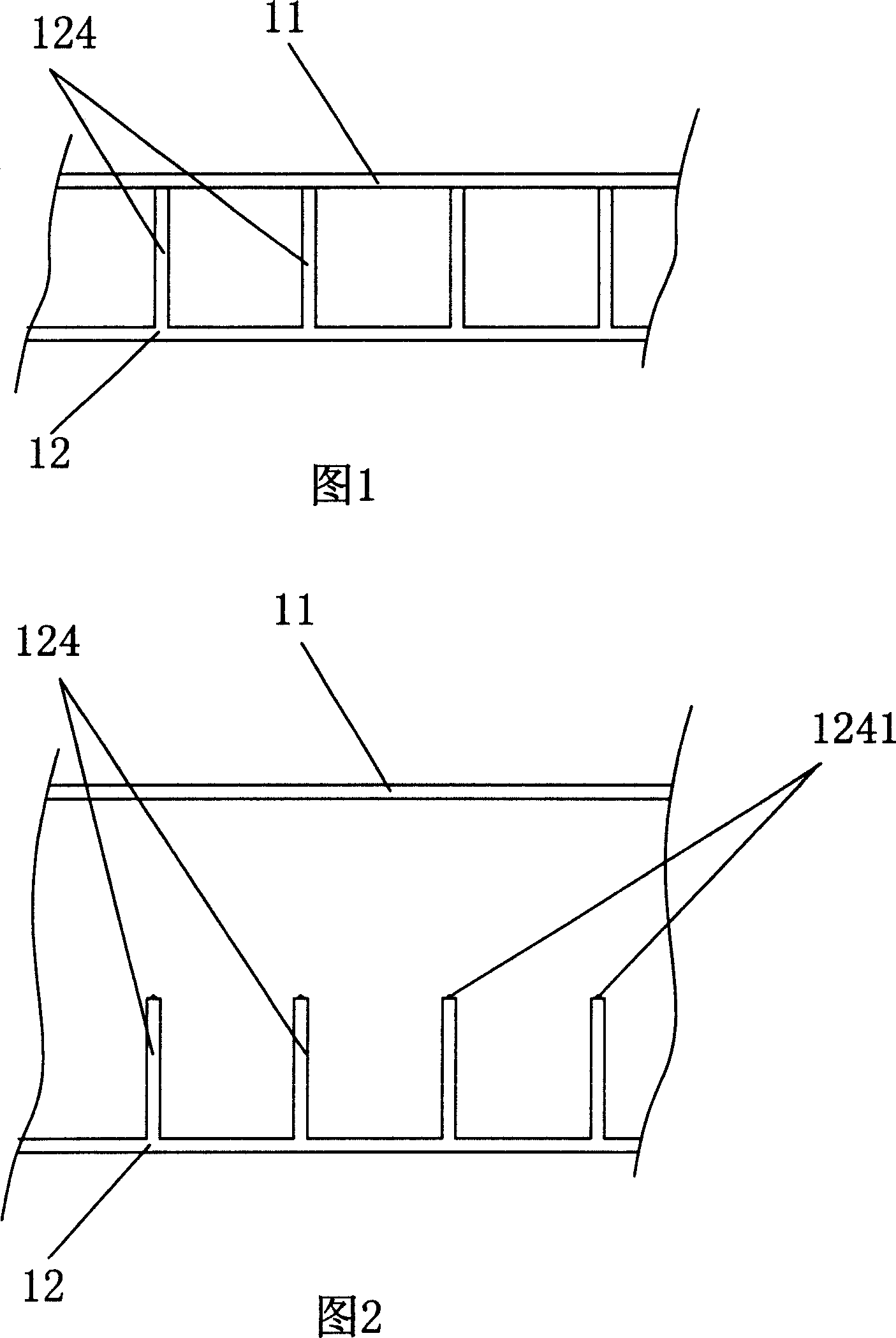

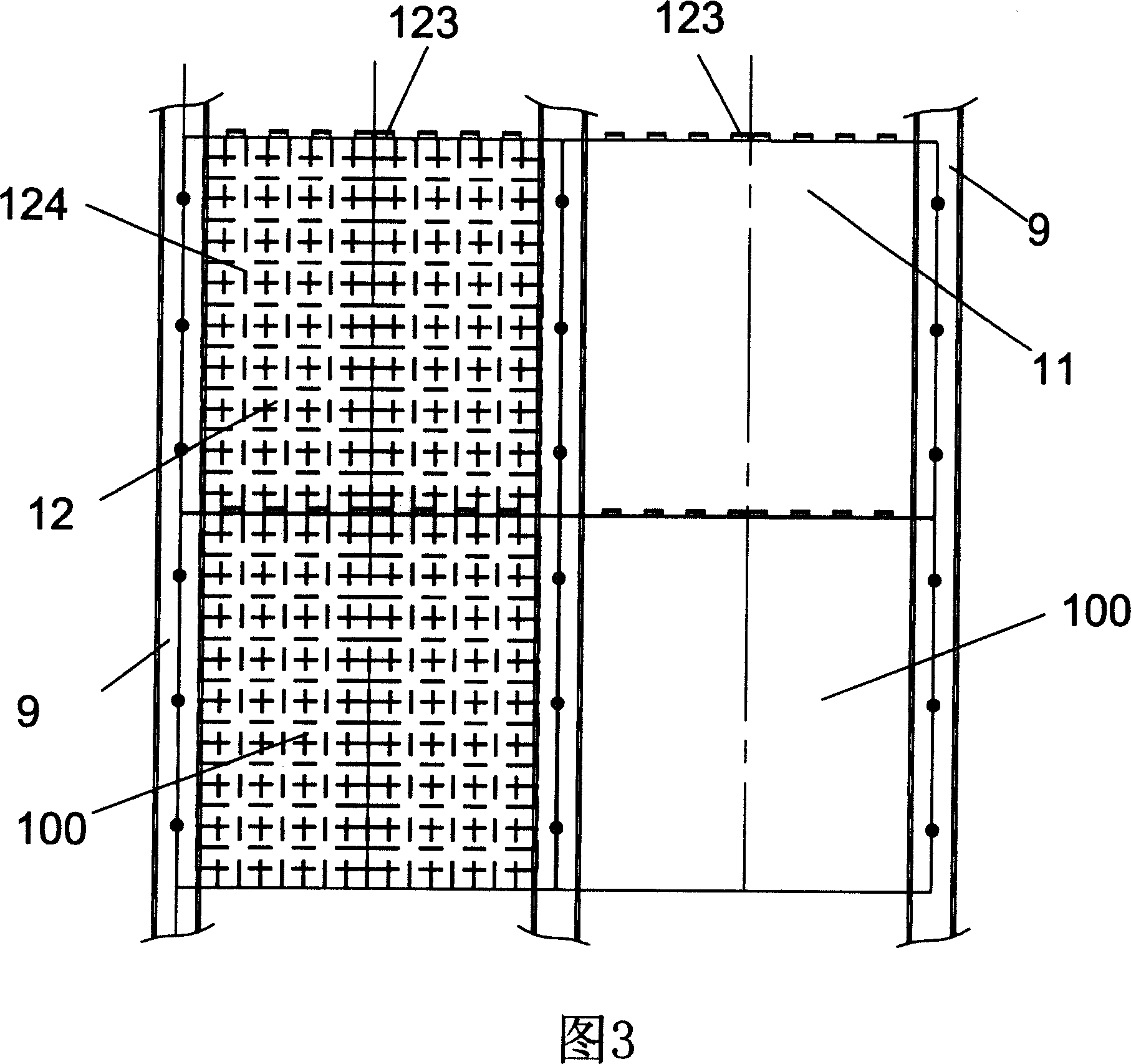

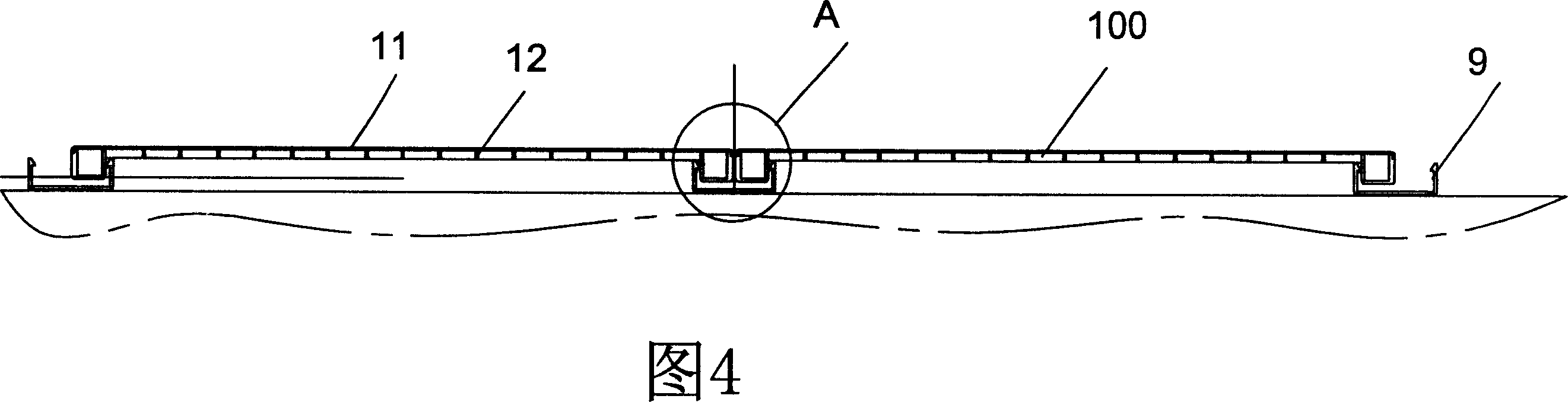

[0049] Embodiment 1, referring to Fig. 1 to Fig. 7, a plastic composite wall tile 100 of the present invention includes:

[0050] The plastic panel 11 is a monomer structure with a certain shape made by direct extrusion molding or extrusion molding, and has an upper surface and a lower surface;

[0051] The injection molded part 12 is a single structure made by direct injection molding and matched to the shape of the plastic panel. The contact between its upper part and the lower surface of the plastic panel is connected together by welding; Fixed undercuts 121, undercuts 121 are respectively located on the left and right sides; the opposite sides are provided with positioning and water-retaining structures that can be spliced with each other; The lower side is provided with a lip 122, and the upper side is provided with a groove-type stopper 123 which can realize water blocking;

[0052] The overlapping parts of the periphery of the plastic panel 11 and the corresponding p...

Embodiment 2

[0065] Embodiment 2, as shown in FIG. 16, a plastic composite wall tile 100 of the present invention is different from Embodiment 1 in that the opposite sides of the injection molded part 12 are provided with positioning and splicing. Water-retaining structure; not only includes the upper and lower sides of the plastic composite wall tile 100, that is, the lower side of the plastic composite wall tile 100 is provided with a lip 122, and the upper side is provided with a groove-type stopper 123 that can realize water-retaining; and , the left and right sides of the plastic composite wall tile 100 are also provided with such a positioning and water retaining structure, that is, a side lip 126 is provided on the convex edge 125 on the left, and a groove type stopper 127 is provided on the convex edge 125 on the right, so that , between the left and right of the plastic composite wall tile 100 is not only fixed by the buckle groove 9, but also the splicing of the side lip 126 and t...

Embodiment 3

[0066] Embodiment 3, as shown in Figure 17, a plastic composite wall tile 100 of the present invention differs from Embodiment 1 in that the groove-type block 123 is a strip-shaped continuous block, but there are multiple Open your mouth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com