Reactive powder concrete material manhole cover and manufacturing method thereof

An active powder and material inspection technology, which is applied in the direction of manufacturing tools, artificial islands, underwater structures, etc., can solve the problems of poor impact performance, high cost, and low strength of inspection manhole covers, so as to reduce weight, solve damage, and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

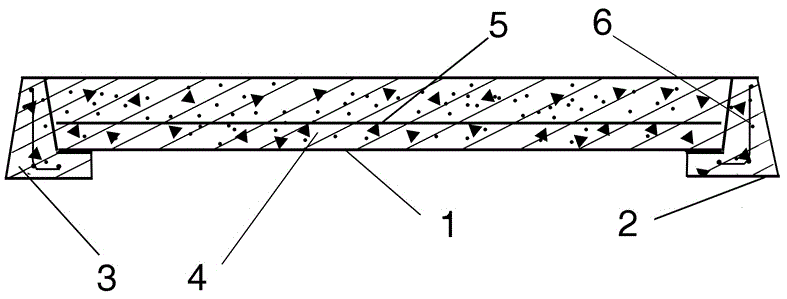

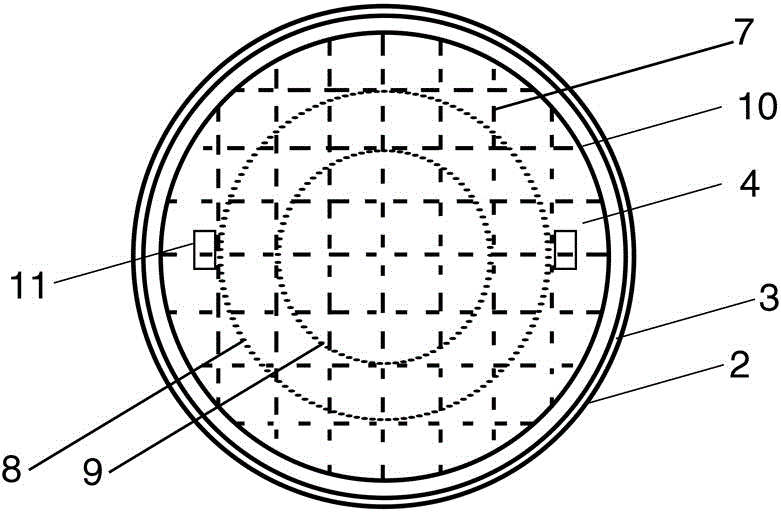

[0035] Embodiment 1: see each accompanying drawing:

[0036] A method for manufacturing an active powder concrete material inspection well cover, comprising the following steps:

[0037]a. Prepare steel skeleton:

[0038] Get steel bar, cut off, make the steel bar 6 that is arranged in the well block 2, standby;

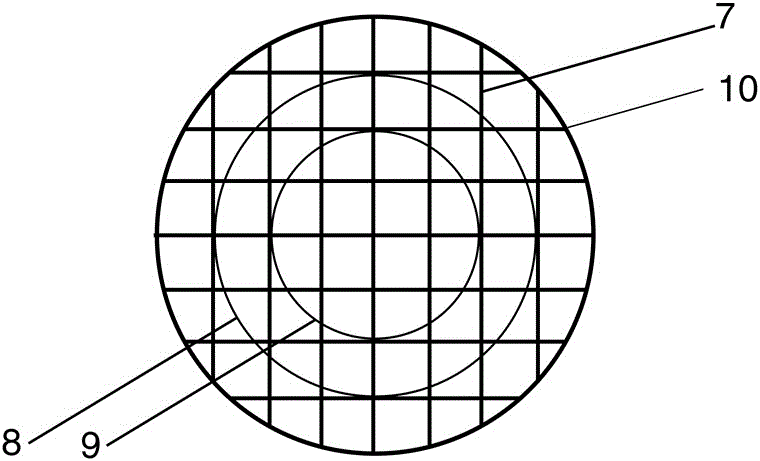

[0039] Get flat steel or angle steel, make circular steel hoop 10; Get reinforcing bar, make well-shaped steel bar (or claim grid shape steel bar) 7, inner circular steel bar 9 and outer circular steel bar 8, make well-shaped steel bar (or claim grid shape steel bar) The two ends of each steel bar in grid shape steel bars) 7 are fixedly welded with circular steel hoops 10, and the inner circular steel bars 9 and outer circular steel bars 8 are fixedly welded with the well-shaped steel bars 7 to obtain the steel bar support body of well cover 1 5. Spare;

[0040] b. Preparation of active powder concrete mixture:

[0041] Get 720 parts by weight of P.O42.5 cement, ...

Embodiment 2

[0045] Embodiment 2: see each accompanying drawing:

[0046] A method for manufacturing an active powder concrete material inspection well cover, comprising the following steps:

[0047] a. Prepare steel skeleton:

[0048] Get steel bar, cut off, make the steel bar 6 that is arranged in the well block 2, standby;

[0049] Get flat steel or angle steel, make circular steel hoop 10; Get reinforcing bar, make well-shaped steel bar (or claim grid shape steel bar) 7, inner circular steel bar 9 and outer circular steel bar 8, make well-shaped steel bar (or claim grid shape steel bar) The two ends of each steel bar in grid shape steel bars) 7 are fixedly welded with circular steel hoops 10, and the inner circular steel bars 9 and outer circular steel bars 8 are fixedly welded with the well-shaped steel bars 7 to obtain the steel bar support body of well cover 1 5. Spare;

[0050] b. Preparation of active powder concrete mixture:

[0051] Get 700 parts by weight of P.O42.5 cement,...

Embodiment 3

[0055] Embodiment 3: see each accompanying drawing:

[0056] A method for manufacturing an active powder concrete material inspection well cover, comprising the following steps:

[0057] a. Prepare steel skeleton:

[0058] Get steel bar, cut off, make the steel bar 6 that is arranged in the well block 2, standby;

[0059] Get flat steel or angle steel, make circular steel hoop 10; Get reinforcing bar, make well-shaped steel bar (or claim grid shape steel bar) 7, inner circular steel bar 9 and outer circular steel bar 8, make well-shaped steel bar (or claim grid shape steel bar) The two ends of each steel bar in grid shape steel bars) 7 are fixedly welded with circular steel hoops 10, and the inner circular steel bars 9 and outer circular steel bars 8 are fixedly welded with the well-shaped steel bars 7 to obtain the steel bar support body of well cover 1 5. Spare;

[0060] b. Preparation of active powder concrete mixture:

[0061] Get 700 parts by weight of P.C42.5 cement,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com