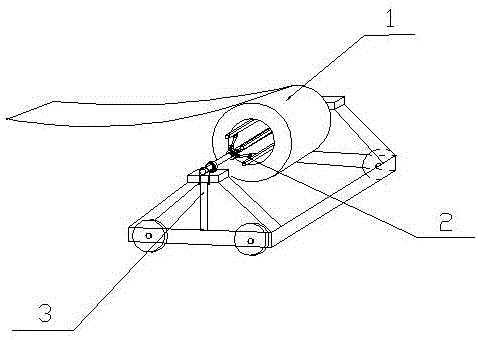

Automatic releasing device and method of color steel tile coil on construction site

A construction site, automatic release technology, applied in the direction of roof engineering tools, roofing, construction, etc., can solve problems affecting construction progress and quality, operator crush injury, damage and scrap, etc., to improve labor efficiency and product quality. , reduce security risks, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

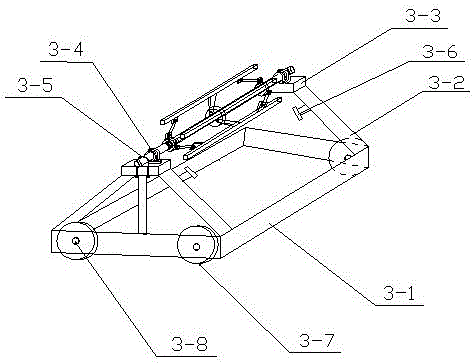

[0032] In the technical transformation project of a steel factory in Shandong, the color steel tile was produced on site, and the automatic release device and method of the color steel tile coil on the construction site were adopted. The specific technical steps are:

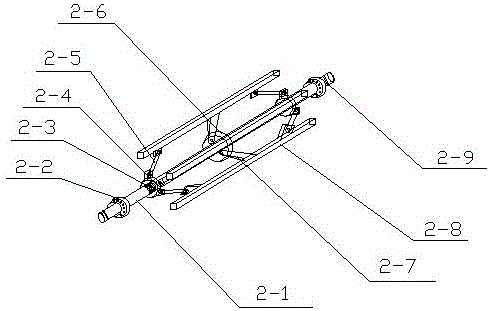

[0033] Step 1: Stow in the supporting roll rod, set the roll material:

[0034] Use a cylindrical crowbar with a diameter of 25mm to 28mm, insert it into the pry shaft holes 2-9 on the front end and rear end of the shaft, and pry the shaft 2-1 to rotate counterclockwise, so that each support roll rod 2-8 At the same time, the volume of the releaser 2 is reduced to the center hole of the coiled material 1 of the color steel tile, and the coiled material with a weight of 3t and a total area of 1100 square meters is set on each supporting roll rod 2-8. superior;

[0035] Step 2: Stretch out the supporting roll rod to support the coiled material:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com