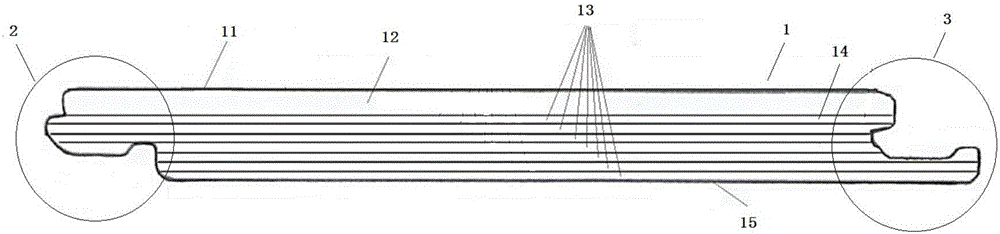

Locking multi-layer solid wood composite floor and preparation method thereof

A solid wood composite flooring and locking technology, which is applied in the field of building materials, can solve the problems of large height difference in assembly, glue opening, delamination, and large pavement gaps, etc., and achieve good water resistance, increased stability, and uniform thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

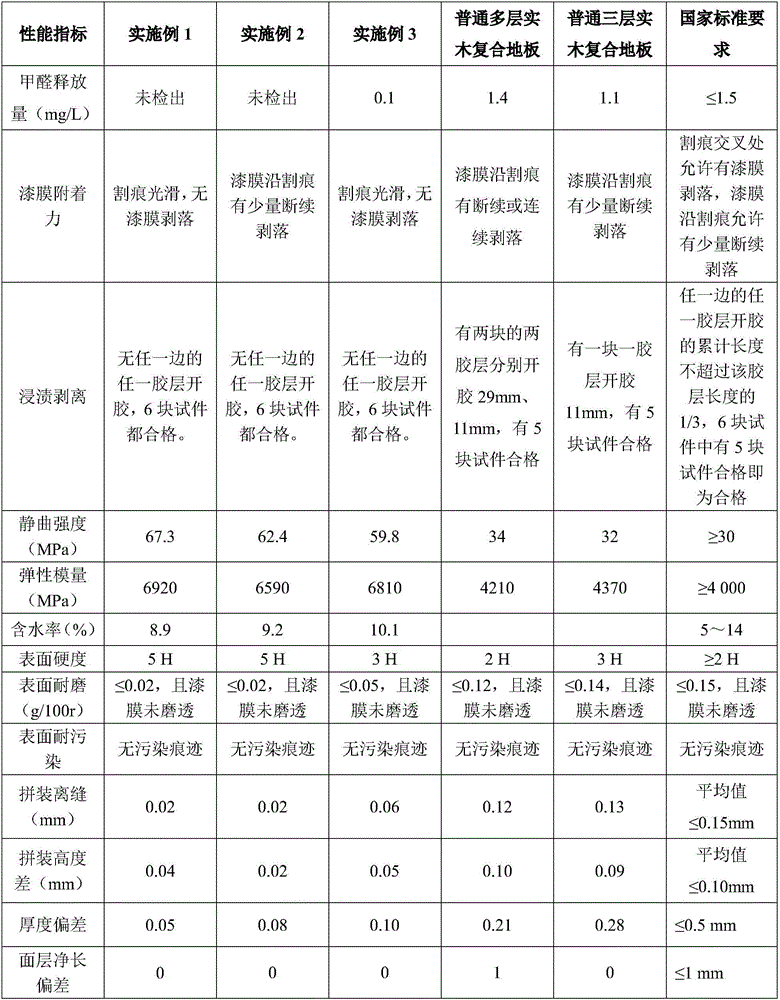

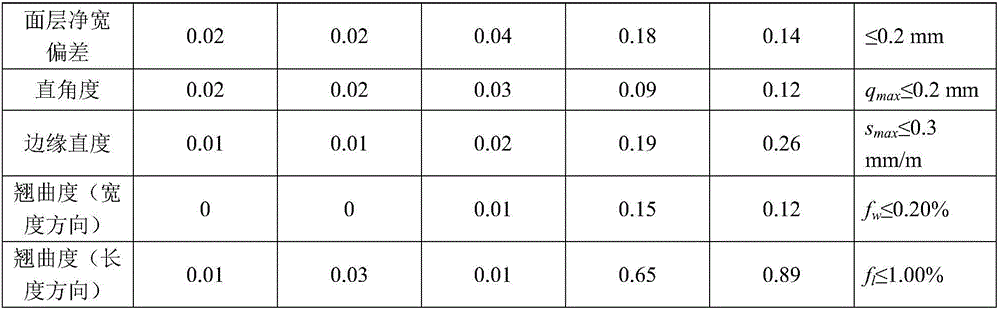

Examples

Embodiment 1

[0043] 1) American red oak wood veneer was selected as the surface veneer. First, red oak logs were cooked and softened, then sliced into veneers with a thickness of 2.3mm, and then naturally air-dried to a moisture content of 7%. Among the high-quality red oak veneers, choose the veneer without decay, insect eyes, cracks, dead knots and other defects, and with small color deviation as the floor surface veneer;

[0044] 2) Selecting Eucalyptus urophylla veneer wood as the base material, steaming and softening the logs of Eucalyptus urophylla, and then rotary-cutting the Eucalyptus urophylla veneer, and drying to a moisture content of 7%;

[0045] 3) Double-sided sanding of the dried Eucalyptus urophylla veneer, according to the vertical formation method of the veneer texture of the adjacent layer, using an environmentally friendly high water resistance formaldehyde-free adhesive without adding formaldehyde, and the amount of glue applied is 280g / m 2 , under the gluing proc...

Embodiment 2

[0052] 1) Merbau wood veneer is selected as the surface veneer for multi-layer solid wood composite flooring. First, the wood section of merbau log is steamed and softened, and then sliced into veneers with a thickness of 3.3mm, and then air-dried to moisture 7%; from the dried merbau veneer, select the veneer without decay, insect eyes, cracks, dead knots and other defects, and with small color deviation as the floor surface veneer;

[0053] 2) Selecting Eucalyptus urophylla veneer wood as the base material, steaming and softening the logs of Eucalyptus urophylla, and then rotary-cutting the Eucalyptus urophylla veneer, and drying to a moisture content of 7%;

[0054] 3) Double-sided sanding of the dried Eucalyptus urophylla veneer, according to the vertical formation method of the veneer texture of the adjacent layer, using an environmentally friendly high water resistance formaldehyde-free adhesive without adding formaldehyde, and the amount of glue applied is 280g / m2, u...

Embodiment 3

[0061] 1) The jatoba wood veneer is selected as the surface veneer for multi-layer solid wood composite flooring. Firstly, the jatoba log segments are steamed and softened, then sliced into veneers with a thickness of 2.3mm, and then air-dried to a moisture content of 7 %; From the dried jatoba veneer, select a veneer without decay, insect eyes, cracks, dead knots and other defects, and with less color deviation as the floor surface veneer;

[0062] 2) Eucalyptus urophylla was selected as the base material veneer wood, and the logs of Eucalyptus urophylla were cooked and softened, and then the veneer of Eucalyptus urophylla was peeled and dried to a moisture content of 7%;

[0063] 3) Double-sided sanding is carried out on the dried giant eucalyptus veneer. According to the vertical formation method of the veneer texture of the adjacent layer, the formaldehyde-free environmentally friendly and high water-resistant formaldehyde-free adhesive is used. The amount of glue applied...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com