Coal ash capable of adsorbing formaldehyde and preparation method of coal ash

A technology for adsorbing formaldehyde and fly ash, applied in separation methods, chemical instruments and methods, and other chemical processes, etc., can solve problems such as formaldehyde adsorption of fly ash without chemical modification treatment, and achieve human health protection, resource saving, The effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

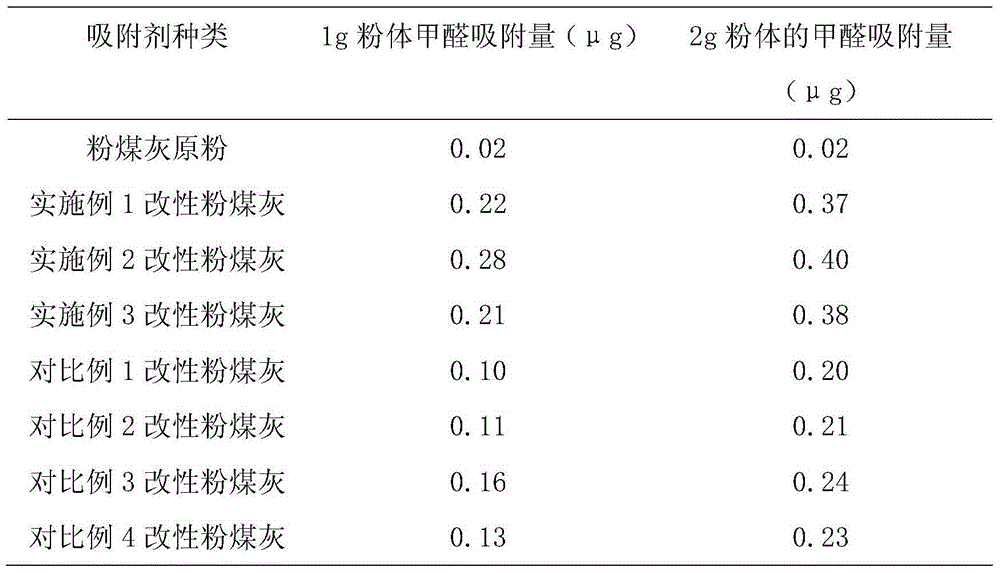

Examples

Embodiment 1

[0017] Get 100 grams of solid waste from power plants or coal-fired devices, and modify the raw materials by 5g surfactant N,N-dimethyldecylamide and bis-octyl alcohol succinic acid diester sulfonate, wherein N,N -The ratio of dimethyldecylamide and bis-octyl alcohol succinic acid diester sulfonate is 3:1; first stir and then soak for 0.5 hours, then use 7g formaldehyde capture agent 2-amino-2-methyl-1 - Carry out load treatment on the product obtained above with propanol, soak for 1.5 hours; dry at 20°C to remove most of the water so that the moisture content is lower than 30%, and then freeze-dry, the freeze-drying temperature is not higher than room temperature, and dry at room temperature for 5 hours , freeze-dried for 1 hour, and prepared fly ash capable of adsorbing formaldehyde.

Embodiment 2

[0019] Get 100 grams of solid waste from power plants or coal-fired devices, and modify the raw materials by 8g surfactant N,N-dimethyldecylamide and bis-octanol succinic acid diester sulfonate, wherein N,N -The ratio of dimethyldecylamide and bis-octyl alcohol succinic acid diester sulfonate is 3:1; first stir and then soak for 0.5 hours, then use 9g formaldehyde capture agent 2-amino-2-methyl-1 - Carry out load treatment on the product obtained above with propanol, soak for 1.5 hours; dry at 20°C to remove most of the water so that the moisture content is lower than 30%, and then freeze-dry, the freeze-drying temperature is not higher than room temperature, and dry at room temperature for 5 hours , freeze-dried for 1 hour, and prepared fly ash capable of adsorbing formaldehyde.

Embodiment 3

[0021] Get 100 grams of solid waste from power plants or coal-fired devices, and modify the raw materials through 10 g of surfactant N,N-dimethyldecylamide and bis-octyl alcohol succinic acid diester sulfonate, wherein N, N - The ratio of dimethylcaprylamide and bis-octyl alcohol succinic acid diester sulfonate is 3:1; first stir and then soak for 0.5 hours, then use 11g of formaldehyde capture agent 2-amino-2-methyl-1 - Carry out load treatment on the product obtained above with propanol, soak for 1.5 hours; dry at 20°C to remove most of the water so that the moisture content is lower than 30%, and then freeze-dry, the freeze-drying temperature is not higher than room temperature, and dry at room temperature for 5 hours , freeze-dried for 1 hour, and prepared fly ash capable of adsorbing formaldehyde.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com