Device and method for improving biological dephosphorizing and denitriding efficiency of low carbon source sewage

A sewage biological and carbon source technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, sludge treatment, etc. The effect of reducing and harmless, reducing the initial investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

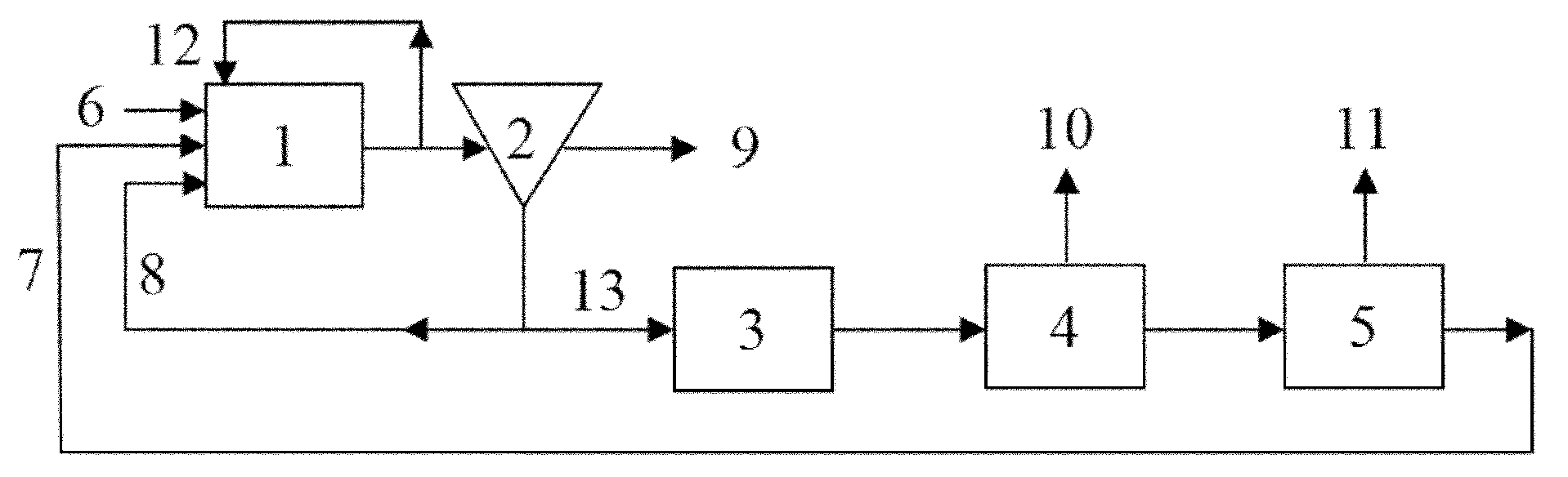

[0029] Such as figure 1 As shown, the system consists of anaerobic-anoxia-aerobic reaction tank A with the function of dephosphorization and denitrification 2 O biological reaction tank 1, sewage sedimentation tank 2, sludge mechanical thickening device 3, namely centrifugal thickener, pressure sludge microwave alkaline hydrolysis treatment device 4 and magnesium ammonium phosphate reaction sedimentation tank 5.

[0030] 1. Excess sludge thickening

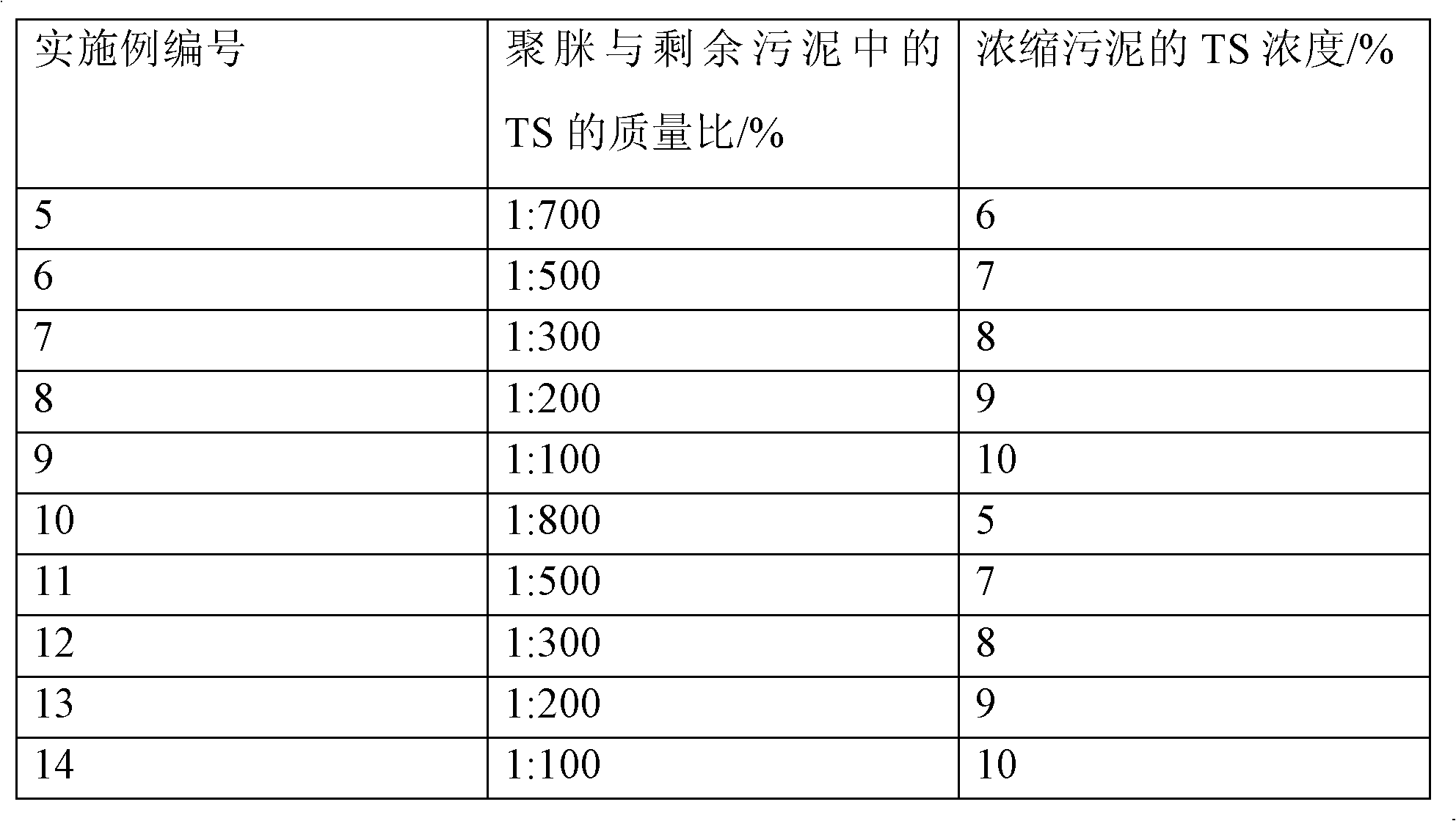

[0031] Add a liquid polymer flocculant—polyamidine to the remaining sludge with a solid content of 0.7% from the sewage sedimentation tank 2, and the mass ratio of the total solid TS in the flocculant to the remaining sludge is 1:1000 Under the conditions, the solid content of the remaining sludge becomes 4.5% after being concentrated by the centrifugal thickener, and the concentrated sludge enters the pressure-bearing sludge microwave alkaline hydrolysis treatment device 4.

[0032] 2. Microwave alkaline hydrolysis of concentrated sludg...

Embodiment 2

[0044] The composition of the low-carbon source sewage 6 is the same as in Example 1, that is, the COD in the low-carbon source sewage 6 is 200 mg / L, TN is 50 mg / L, TP is 6 mg / L, and BOD:TN2 O Treatment of biological reaction tank 1 and sewage sedimentation tank 2, A 2 The process parameters of the biological reaction tank 1 and the sewage sedimentation tank 2 are the same as those in Example 1. The water quality of the effluent 9 from the sewage sedimentation tank did not meet the first level B standard of the Pollutant Discharge Standard for Urban Sewage Treatment Plants (GB 18918-2002).

Embodiment 3

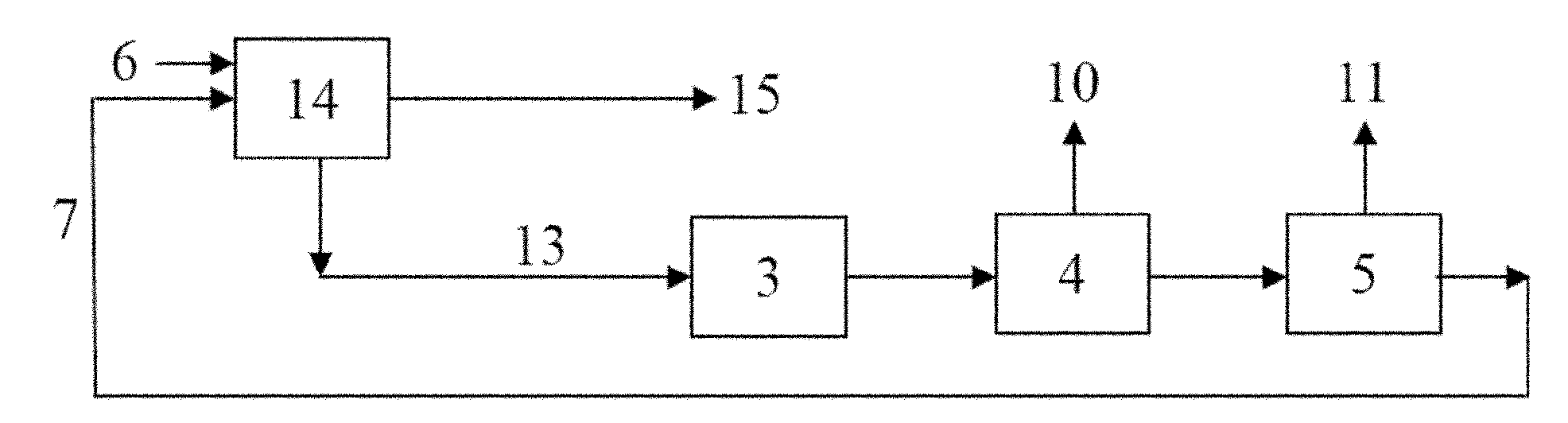

[0046] Such as figure 2 As shown, the system consists of an SBR tank 14, a sludge mechanical thickening device 3, that is, a centrifugal thickener, a pressure sludge microwave alkaline hydrolysis treatment device 4, and a magnesium ammonium phosphate reaction sedimentation tank 5.

[0047] 1. Excess sludge thickening

[0048] Add a liquid polymer flocculant—polyamidine to the remaining sludge with a solid content of 0.7% from the SBR biological reaction tank 14, and the mass ratio of the total solid TS in the flocculant to the remaining sludge is 1:1000 Under the conditions, the solid content of the remaining sludge becomes 4.5% after being concentrated by the centrifugal thickener, and the concentrated sludge enters the pressure sludge microwave alkaline hydrolysis treatment device 4.

[0049] 2. Microwave alkaline hydrolysis of concentrated sludge

[0050] Add 20M NaOH solution to the concentrated sludge with a solid content of 4.5% from the centrifugal thickener in the mixing tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com