Preparation method of high-flame-retardant artificial plate

A high flame-retardant, man-made technology, applied in the field of architectural decorative boards, can solve the problems of particle boards not being mildew-proof and anti-bacterial, affecting indoor environmental quality, particle board odor, etc., achieving excellent flame-retardant and anti-bacterial anti-corrosion performance, good flatness, and not easy to change color Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

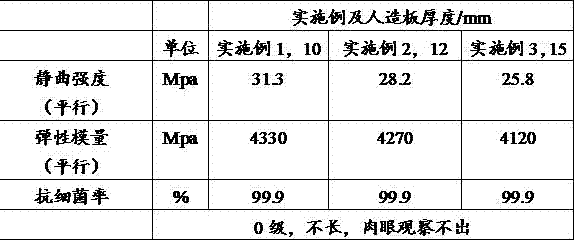

Embodiment 1

[0025] A method for preparing a high flame-retardant artificial board, said preparation method comprising the following steps: firstly, selecting sawdust and shavings, removing impurities such as sand, dust and iron filings by screening and magnetic absorption, crushing, and then steaming at 110°C 15min, then dry until the moisture content is lower than 5.0%, the obtained dried raw material and high flame-retardant rubber powder are mixed evenly in the mixer, and the core layer is obtained by loading the billet, hot pressing once, and cooling; secondly, prepare the upper surface layer and The lower surface layer, the upper and lower surface layers are all made of veneer with a thickness of 1.0mm, and the upper and lower surface layers and the core layer are evenly coated with an appropriate amount of molten high flame-retardant rubber powder, and then combined with the core layer, after two times Hot pressing, cooling, trimming and grinding process to produce highly flame retar...

Embodiment 2

[0035] A method for preparing high flame-retardant artificial boards. The preparation method includes the following steps: first, select sawdust and shavings, remove impurities such as sediment, dust and iron filings by screening and magnetic absorption, crush them, and then steam them at 120 ° C. 15min, then dry until the moisture content is lower than 5.0%, the obtained dried raw material and high flame-retardant rubber powder are mixed evenly in the mixer, and the core layer is obtained by loading the billet, hot pressing once, and cooling; secondly, prepare the upper surface layer and The lower surface layer, the upper and lower surface layers are all made of veneer with a thickness of 1.2mm, and the upper and lower surface layers and the core layer are evenly coated with an appropriate amount of molten high flame-retardant rubber powder, and then combined with the core layer, after two times Hot pressing, cooling, trimming and grinding process to produce high flame retarda...

Embodiment 3

[0045] A method for preparing high flame-retardant artificial boards. The preparation method includes the following steps: first, select sawdust and shavings, remove impurities such as sand, dust and iron filings by screening and magnetic absorption, crush them, and then steam them at 115 ° C. 20min, then dry until the moisture content is lower than 5.0%, the obtained dried raw material and high flame-retardant rubber powder are mixed evenly in the mixer, and the core layer is obtained by loading the billet, hot pressing once, and cooling; secondly, prepare the upper surface layer and The lower surface layer, the upper and lower surface layers are all made of veneer with a thickness of 1.1mm, and the upper and lower surface layers and the core layer are evenly coated with an appropriate amount of melted high flame-retardant rubber powder, and then combined with the core layer, after two times Hot pressing, cooling, trimming and grinding process to produce highly flame retardant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com