Modified phenolic resin adhesive for chemical resistant laminate

A technology of phenolic resin glue and phenolic resin, which is applied in the field of physical and chemical boards, can solve the problems of poor heat resistance and oxidation resistance, warping and deformation of physical and chemical boards, and glue opening by drum guns, so as to improve the demoulding effect and reduce the cost of products , The effect of easy demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

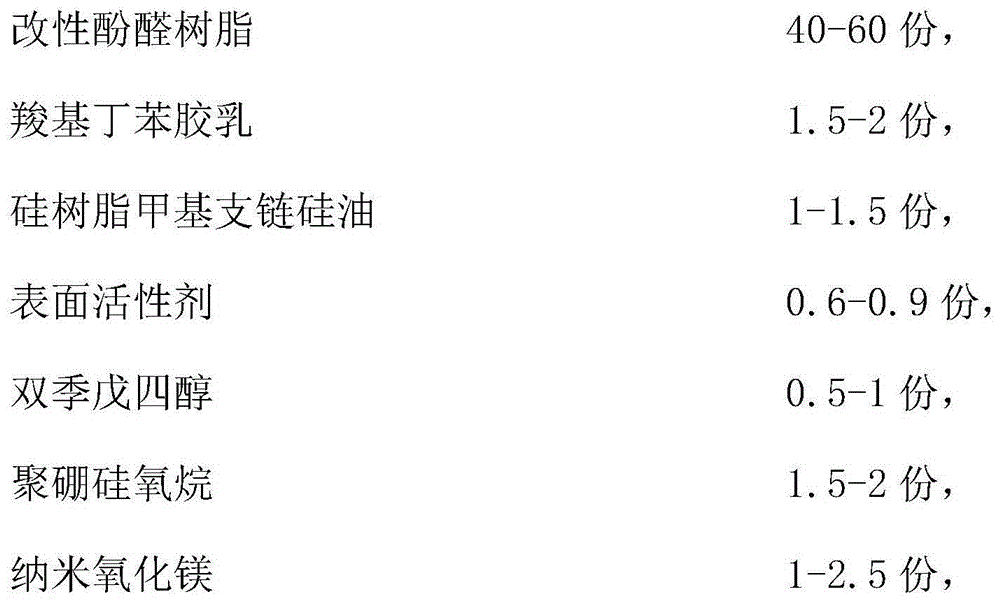

[0021] A kind of modified phenolic resin adhesive for physical and chemical board proposed by the present invention, its raw material comprises by weight:

[0022]

[0023]

[0024] In the preparation process of the modified phenolic resin, the cashew nut oil is sent to the distiller for vacuum distillation. The vacuum distillation temperature is 220°C, the vacuum distillation pressure is 1000Pa, and the preformed phenolic resin with a viscosity of 64mPa·s (25°C) is obtained. Material; Weigh 100 parts of phenol, 20 parts of prefabricated material, 20 parts of formaldehyde, 1 part of catalyst and 1.5 parts of additives in the reaction bottle by weight, add hydrochloric acid solution to adjust the pH value to 1.4, at a speed of 3 °C / min Raise the temperature to 100°C, keep it warm for 1.5h, and dehydrate under reduced pressure to obtain a modified phenolic resin.

Embodiment 2

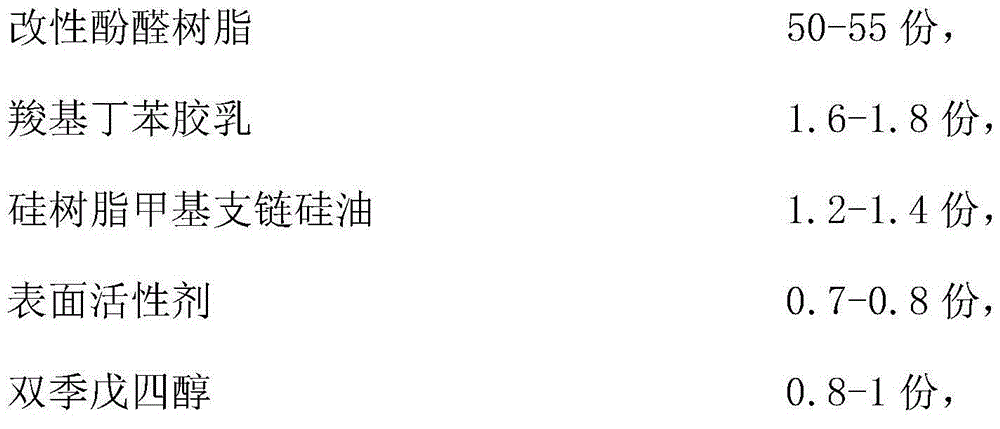

[0026] A kind of modified phenolic resin adhesive for physical and chemical board proposed by the present invention, its raw material comprises by weight:

[0027]

[0028] In the preparation process of the modified phenolic resin, the cashew nut oil is sent to a distiller for vacuum distillation. The vacuum distillation temperature is 220°C, and the vacuum distillation pressure is 1200Pa to obtain a preformed phenolic resin with a viscosity of 60mPa·s (25°C). Material; Weigh 100 parts of phenol, 40 parts of prefabricated material, 15 parts of formaldehyde, 2 parts of catalyst and 1 part of auxiliary agent into the reaction bottle by weight, add hydrochloric acid solution to adjust the pH value to 1.8, at a speed of 1 °C / min Raise the temperature to 100°C, keep it warm for 2 hours, and dehydrate under reduced pressure to obtain a modified phenolic resin.

Embodiment 3

[0030] A kind of modified phenolic resin adhesive for physical and chemical board proposed by the present invention, its raw material comprises by weight:

[0031]

[0032] In the preparation process of the modified phenolic resin, the cashew nut oil is sent to the distiller for vacuum distillation. The vacuum distillation temperature is 220°C, the vacuum distillation pressure is 1100Pa, and the preformed phenolic resin with a viscosity of 62mPa·s (25°C) is obtained. Material; Weigh 100 parts of phenol, 32 parts of prefabricated material, 17 parts of formaldehyde, 1.4 parts of catalyst and 1.3 parts of auxiliary agent into the reaction bottle by weight, add hydrochloric acid solution to adjust the pH value to 1.5, at a speed of 2 °C / min Raise the temperature to 100°C, keep it warm for 1.8h, and dehydrate under reduced pressure to obtain a modified phenolic resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com