Novel halogenide-resistant and fireproof plate

A fire-proof board and anti-return technology, which is applied in the field of fire-proof boards, can solve problems such as returning halogen and moisture absorption fundamentally, so as to improve the application range and safety, good flame retardancy and smoke elimination, and prevent moisture absorption and return to halogen Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

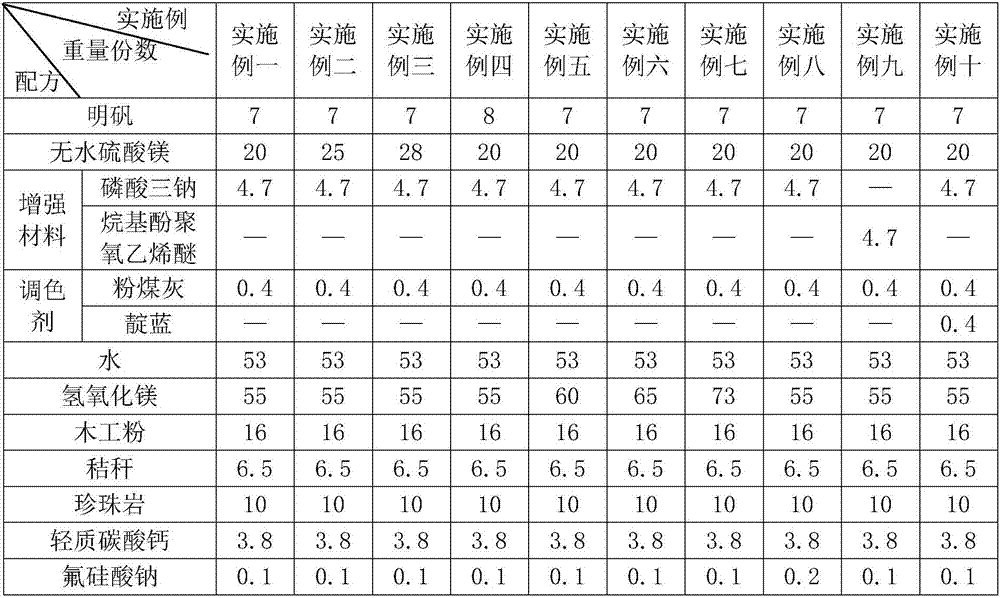

Embodiment 1

[0065] For the new anti-return halogen fireproof board, first mix the following raw materials by weight to obtain the fluid:

[0066] 7 parts of alum;

[0067] 20 parts of anhydrous magnesium sulfate;

[0068] 4.7 parts of trisodium phosphate;

[0069] 0.4 parts of fly ash;

[0070] 53 parts of water;

[0071] The obtained fluid is sequentially added to the following raw materials to form a slurry:

[0072] 55 parts of magnesium hydroxide, its magnesium content ≥ 85%, active magnesium > 65%;

[0073] 16 parts of woodworking powder, which is made by drying and refining pine wood;

[0074] 6.5 parts of straw;

[0075] Perlite 10 parts, fineness ≤ 45 mesh;

[0076] 3.8 parts of light calcium carbonate, fineness ≥ 400 mesh, whiteness ≥ 85;

[0077] Finally add 0.1 part of sodium fluorosilicate;

[0078] The obtained slurry and two layers of glass fiber mesh cloth are mechanically rolled, cut, and cured to obtain a finished product of 2440×1220×9 (mm). The specification of...

Embodiment 2

[0089] The difference between Embodiment 2 and Embodiment 1 of the new anti-halogen fireproof board is that the weight fraction of anhydrous magnesium sulfate is increased from 20 parts to 25 parts.

[0090] The prepared product is sent to the National Building Materials Industry Wall Roofing Material Quality Supervision, Inspection and Testing Center for testing, and the results are as follows:

[0091] Anti-halogenation: no water drops, no moisture return, in line with JC688-2006 standard;

[0092] Factory moisture content: 5%, better than the highest standard value of JC688-2006 8%;

[0093] The screw holding force is 30N / m, which is better than the minimum standard value of 20N / m in JC688-2006;

[0094] Chloride ion content 0%, better than the highest standard value of JC688-2006;

[0095] Non-flammability: meet the requirements of Class A in GB8624-1997.

Embodiment 3

[0097] The difference between the third embodiment and the first embodiment of the new anti-halogen fireproof board is that the weight fraction of anhydrous magnesium sulfate is increased from 20 parts to 28 parts.

[0098] The prepared product is sent to the National Building Materials Industry Wall Roofing Material Quality Supervision, Inspection and Testing Center for testing, and the results are as follows:

[0099] Anti-halogenation: no water drops, no moisture return, in line with JC688-2006 standard;

[0100] Factory moisture content: 5%, better than the highest standard value of JC688-2006 8%;

[0101] The screw holding force is 30N / m, which is better than the minimum standard value of 20N / m in JC688-2006;

[0102] Chloride ion content 0%, better than the highest standard value of JC688-2006;

[0103] Non-flammability: meet the requirements of Class A in GB8624-1997.

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com