Method for improving bonding performance of reconstituted bamboo

A technology for bamboo recombination and performance, applied in the directions of wood treatment, impregnated wood, wood impregnation, etc., can solve problems such as unsatisfactory damage degree of bamboo green, and achieve the effects of improving physical and mechanical strength, improving bamboo bonding performance and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

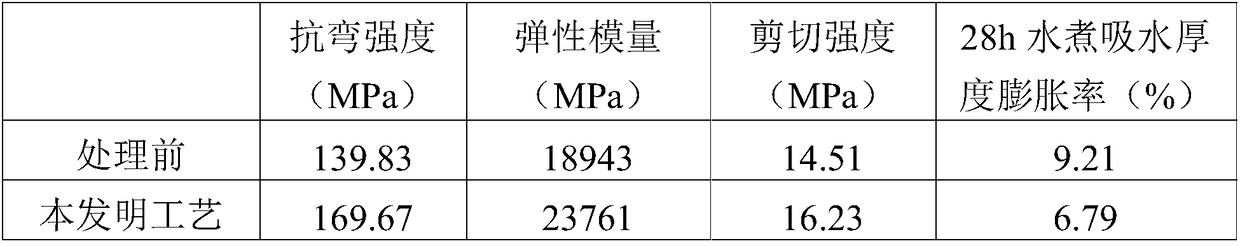

Embodiment 1

[0029] Choose the bamboo slices of hemp bamboo, and use a debulking machine to decompose into bamboo bundle units, and the diameter of the bamboo bundle is 6 to 10 cm; Put it into a carbonization tank for carbonization treatment, the carbonization treatment pressure is 0.35MPa, and the time is 120min. After the treatment, the bamboo bundles are dried to a moisture content of 5%. It is then immersed in the phenolic resin solution, and then the molar ratio of phenol in the phenolic resin: formaldehyde: NaOH is 1: 2.1: 0.1; the molecular weight distribution of the phenolic resin accounts for 96% between 200 and 400, The solid content is 20%, the dipping time is 15min, and the dipping amount is 15% of the mass fraction of bamboo bundles; the bamboo bundles after dipping are placed in a mesh belt dryer, and dried to a moisture content of 12%, and the drying temperature is 70 ℃; after the final bamboo bundles are assembled according to the grain, they are placed in a press and press...

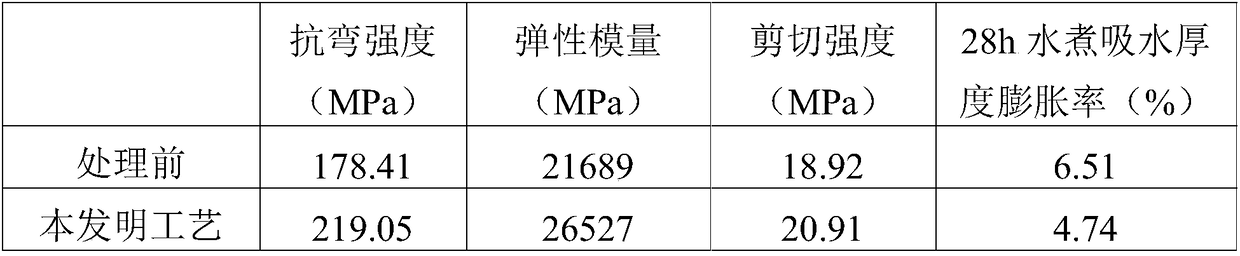

Embodiment 2

[0034] Choose powder single bamboo bamboo slices, and use a debonding machine to decompose into loose bundle units that are long, interlinked and keep the original arrangement of fibers. The diameter of the bamboo bundles is 5-8cm; 5% NaOH was used to treat the bamboo bundles, and the consumption was 20%. The treated bamboo bundles were put into a carbonization tank for carbonization treatment. The carbonization treatment pressure was 0.35MPa, and the time was 120min. After the treatment, the bamboo bundles were dried to a moisture content of 8%. It is then immersed in the phenolic resin solution, and then the molar ratio of phenol in the phenolic resin: formaldehyde: NaOH is 1: 2.1: 0.1; the molecular weight distribution of the phenolic resin accounts for 96% between 200 and 400, The solid content is 20%, the dipping time is 15min, and the dipping amount is 15% of the mass fraction of bamboo bundles; the bamboo bundles after dipping are placed in a mesh belt dryer, and dried t...

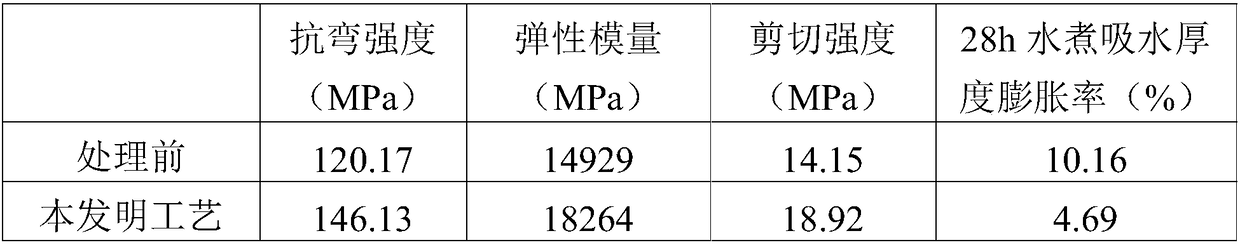

Embodiment 3

[0039] Select moso bamboo slices, and use a debonding machine to decompose into loose bundle units that are long, interlinked and keep the original arrangement of fibers. The diameter of the bamboo bundles is 5-8cm; NaOH is used to treat bamboo bundles in an amount of 15%. The treated bamboo bundles are put into a carbonization tank for carbonization treatment. The carbonization treatment pressure is 0.35MPa and the time is 120min. After the treatment, the bamboo bundles are dried to a moisture content of 8%. It is then immersed in the phenolic resin solution, and then the molar ratio of phenol in the phenolic resin: formaldehyde: NaOH is 1: 2.1: 0.1; the molecular weight distribution of the phenolic resin accounts for 96% between 200 and 400, The solid content is 20%, the dipping time is 15min, and the dipping amount is 15% of the mass fraction of bamboo bundles; the bamboo bundles after dipping are placed in a mesh belt dryer, and dried to a moisture content of 12%, and the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com