Method for producing particle board through anti-insect and anti-mold composite urea formaldehyde resin

The technology of urea-formaldehyde resin and urea-formaldehyde resin glue is applied in the field of particleboard production by using the compound urea-formaldehyde resin for insect and mildew prevention, which can solve the problems that the urea-formaldehyde resin adhesive has no insect-proof and mildew-proof effect, and the adhesive has no insect-proof and mildew-proof effect. Reduce free formaldehyde content, white color, good freeze-thaw resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

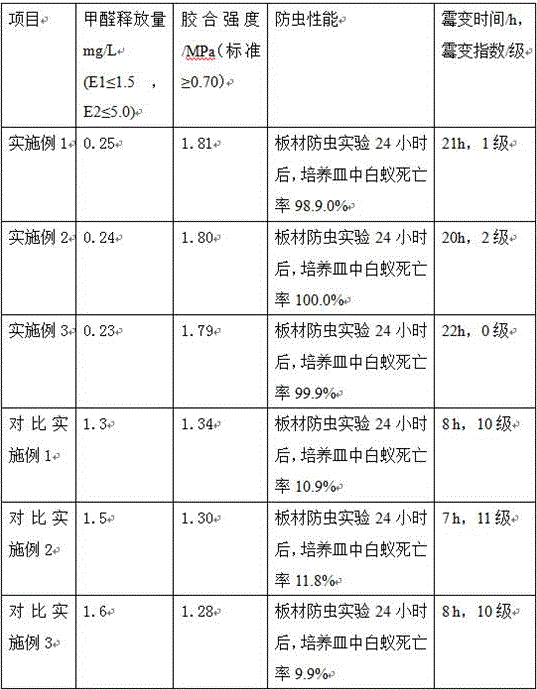

Examples

Embodiment 1

[0061] The method for producing particleboard by adopting an insect-proof and mildew-proof composite urea-formaldehyde resin comprises the following steps:

[0062] 1) After simple screening, the waste materials that cannot be used in the process of making multi-layer eucalyptus boards after rotary cutting eucalyptus boards are sent to the planer by the conveyor for shavings, and then sent by the conveyor to the wet shavings silo for transitional storage; The moisture content of wood shavings should be kept below 20% by weight;

[0063] 2) The wet shavings are sent to the drum dryer by the conveyor for drying, so that the moisture content of the shavings is below 10% by weight;

[0064] 3) Separate the dried shavings to separate the veneer; separate metal and sand;

[0065] 4) After the dried shavings are screened and sorted, the dry shavings of the surface core layer with a length of less than 2 cm are sent to the dry shaving material transition warehouse of the surface core...

Embodiment 2

[0084] The method for producing particleboard by adopting an insect-proof and mildew-proof composite urea-formaldehyde resin comprises the following steps:

[0085] 1) After simple screening, the waste materials that cannot be used in the process of making multi-layer eucalyptus boards after rotary cutting eucalyptus boards are sent to the planer by the conveyor for shavings, and then sent by the conveyor to the wet shavings silo for transitional storage; The moisture content of wood shavings should be kept below 20% by weight;

[0086] 2) The wet shavings are sent to the drum dryer by the conveyor for drying, so that the moisture content of the shavings is below 10% by weight;

[0087] 3) Separate the dried shavings to separate the veneer; separate metal and sand;

[0088] 4) After the dried shavings are screened and sorted, the dry shavings of the surface core layer with a length of less than 2 cm are sent to the dry shaving material transition warehouse of the surface core...

Embodiment 3

[0107] The method for producing particleboard by adopting an insect-proof and mildew-proof composite urea-formaldehyde resin comprises the following steps:

[0108] 1) After simple screening, the waste materials that cannot be used in the process of making multi-layer eucalyptus boards after rotary cutting eucalyptus boards are sent to the planer by the conveyor for shavings, and then sent by the conveyor to the wet shavings silo for transitional storage; The moisture content of wood shavings should be kept below 20% by weight;

[0109] 2) The wet shavings are sent to the drum dryer by the conveyor for drying, so that the moisture content of the shavings is below 10% by weight;

[0110] 3) Separate the dried shavings to separate the veneer; separate metal and sand;

[0111] 4) After the dried shavings are screened and sorted, the dry shavings of the surface core layer with a length of less than 2 cm are sent to the dry shaving material transition warehouse of the surface core...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com