Gluing method for wood veneer

A technology of wood veneer and veneer, which is applied in the direction of bonding of wood veneer, chemical instruments and methods, wood laminate products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

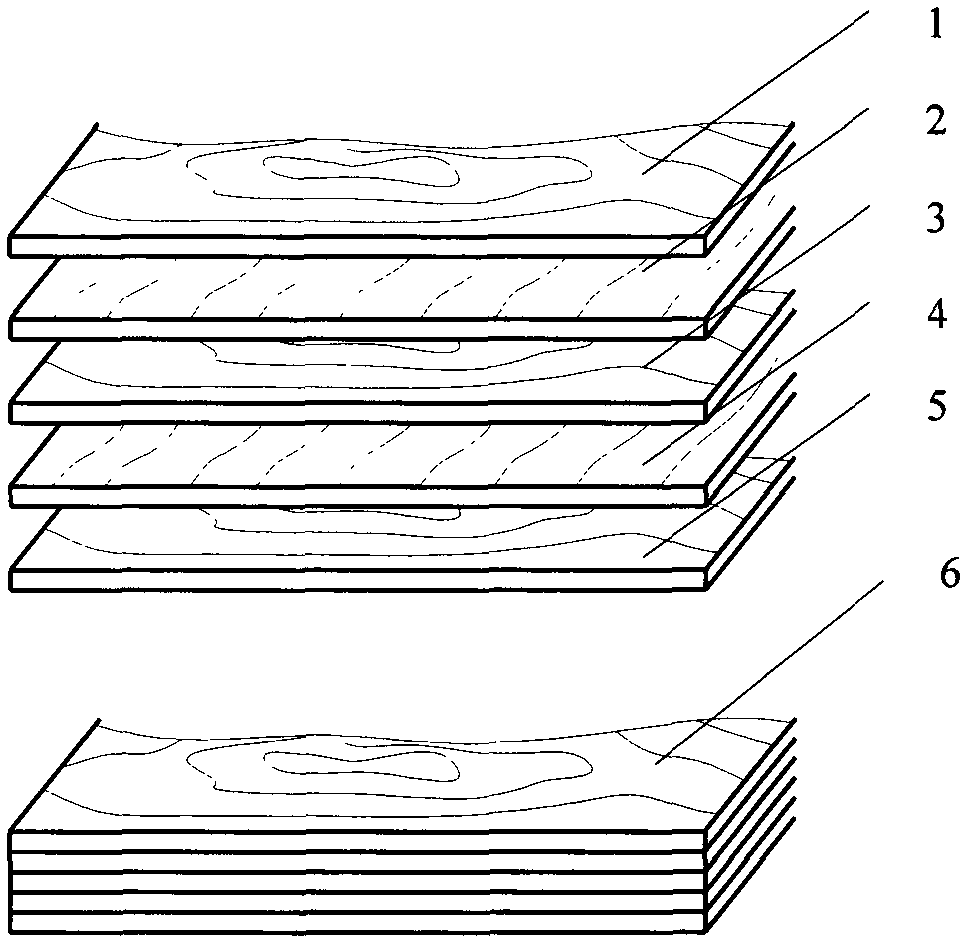

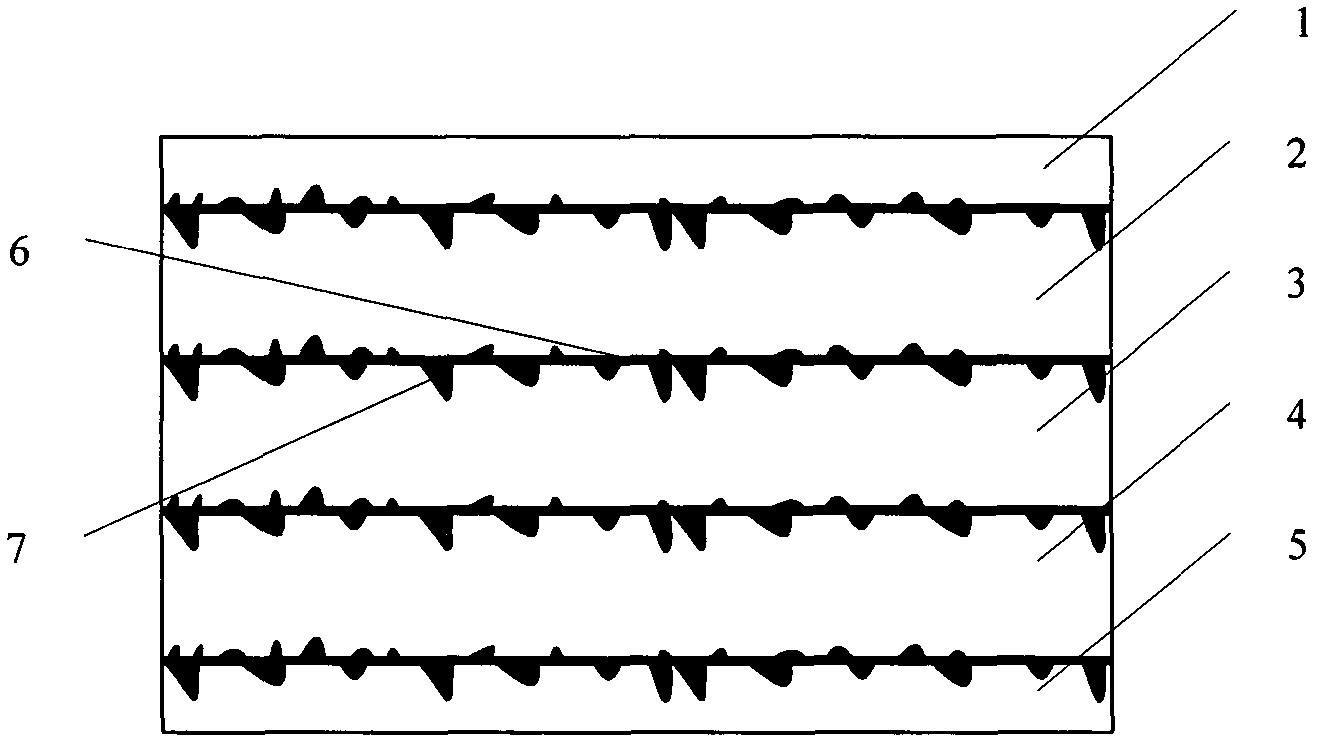

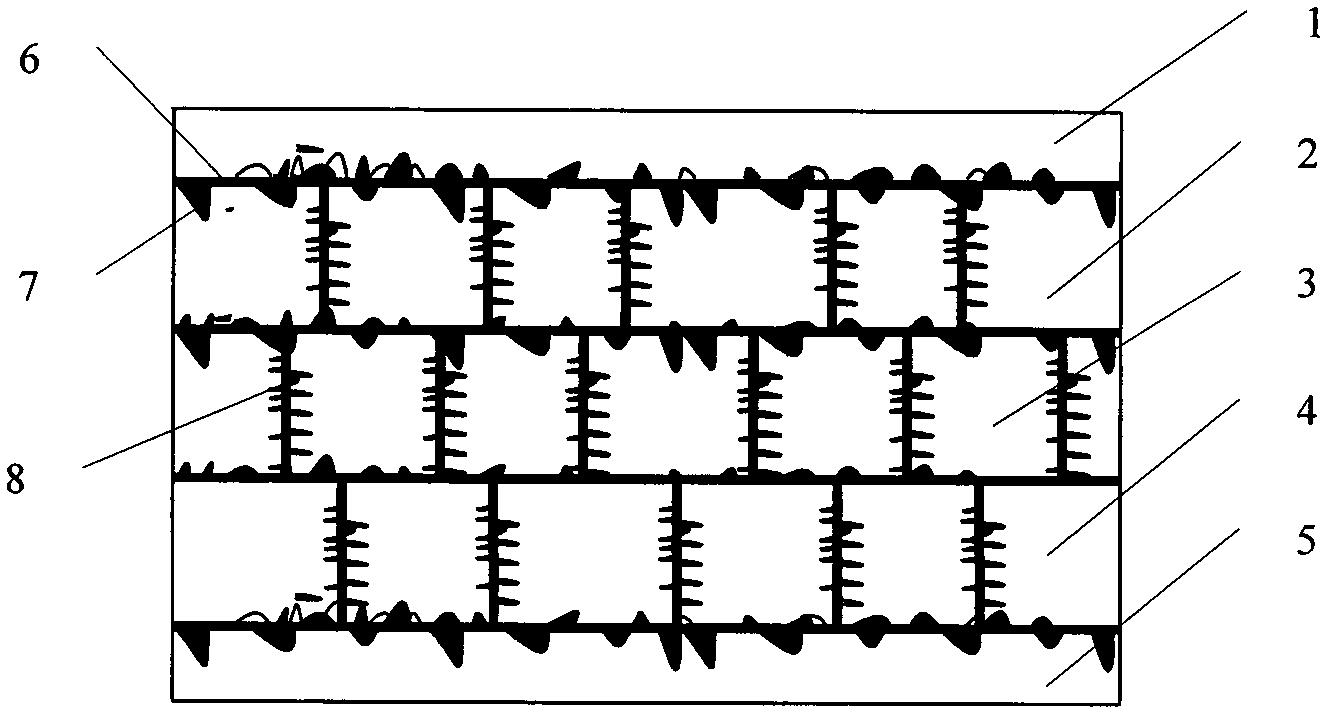

[0016] The present invention will be further described below in conjunction with accompanying drawing and case.

[0017] A wood veneer gluing method of the present invention includes the following basic steps: (1) veneer manufacturing: sawing the log into wood sections of a certain specification length, and then using a rotary cutter or a planer to cut the wood sections with or without softening treatment. Cutting machine and other processing into veneer, veneer thickness ranging from 1 mm to 6 mm; (2) Punching uses physical or mechanical methods to punch holes in the core board, the hole diameter is 0.1 mm to 1 mm, and the holes can be randomly The distribution can also be distributed according to certain rules. The holes are hollow or semi-permeable holes, and the shape of the holes is round, square, etc.; (3) Dry the veneer to a certain moisture content of 5% to 20%; (4) Glue coating According to the process requirements, the dried core board is glued, the glue amount is 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com