Sheet automatic glue coating machine

A fully automatic, gluing machine technology, applied in the direction of conveyor objects, object supply, sending objects, etc., can solve the problems of easy gluing, low degree of automation, uneven gluing and squeegeeing, etc., to achieve uniform squeegeeing and coating The effect of uniform amount of glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

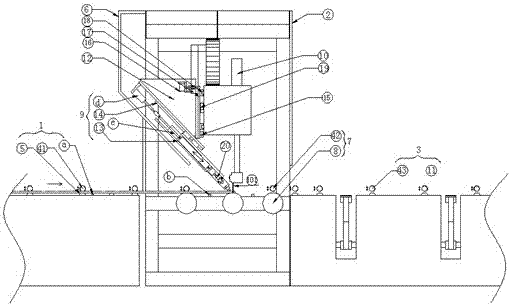

[0013] Specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0014] like figure 1 As shown, the fully automatic gluing machine for plates includes a feeder 1, a host machine 2, a discharge flap device 3, and a computer control system. The feeder includes a feeder pressure wheel 41, a conveying wheel 5 and an induction element a, Its main engine is made up of frame 6, conveying part 7, and conveying part is made up of main conveying wheel 8 and pressure wheel 42, is connected with the multi-degree-of-freedom glue spray assembly 9 that can laterally move and fixed-axis rotation and is connected on the frame The vertically movable scraping assembly 10 is composed of a rod member slidably connected on the frame and driven by a lifting motor, and the lower end of the scraping assembly is a detachable scraper 101 of non-stick material. Its multi-degree-of-freedom glue spray assembly consists of a sports car 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com