Patents

Literature

33results about How to "Squeegee evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

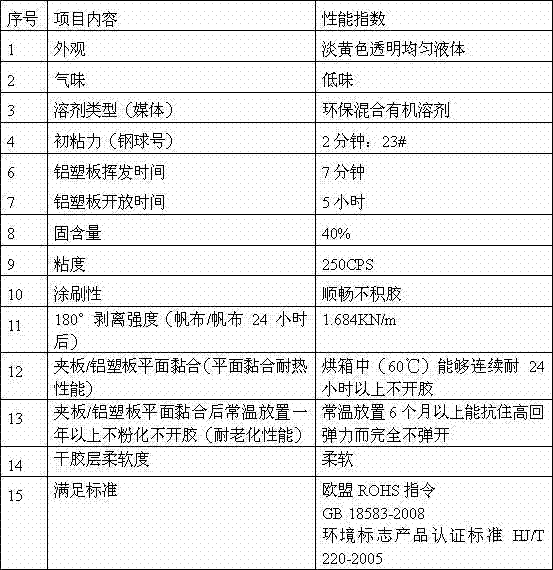

Environment-friendly solvent universal glue and preparation method thereof

InactiveCN102775938AGet rid of severe constraintsLow costMineral oil hydrocarbon copolymer adhesivesRosin adhesivesThermoplasticPolymer science

The invention discloses an environment-friendly solvent universal glue and a preparation method thereof. The best weight ratio of the universal glue is 9% of starburst SBS thermoplastic styrene-butadiene rubber, 2% of linear SBS thermoplastic styrene-butadiene rubber, 7% of rosin, 9.5% of hydrogenated rosin, 4% of C9 petroleum resin, 6% of a tackifying resin, 15% of No. 6 extraction solvent oil, 30% of methylal, 15% of methyl acetate, 0.2% of a wetting agent, 0.8% of an anti-aging agent, 0.5% of an antioxidant and 1.0% of a softening agent. The environment-friendly solvent universal glue has the comprehensive superiorities of low VOC, high solid content, no heavy metals, low smell, excellent initial adhesion, excellent cohesive strength, excellent permanent adhesion, excellent heat-resistant and ageing-resistant performance, short drying time, long opening time, large spraying area per weight (glue economization), and the like, has the advantages of reducing environment pollution, improving operation and construction environment, being low cost and low smell, and the like, is widely used in plate decoration industries of aluminum-plastic plates, clamping plates, density plates, paint-free plates, polymer plates, metal sheets, and the like, and is particularly suitable for applications in green high-grade decoration industries.

Owner:深圳市顾康力化工有限公司

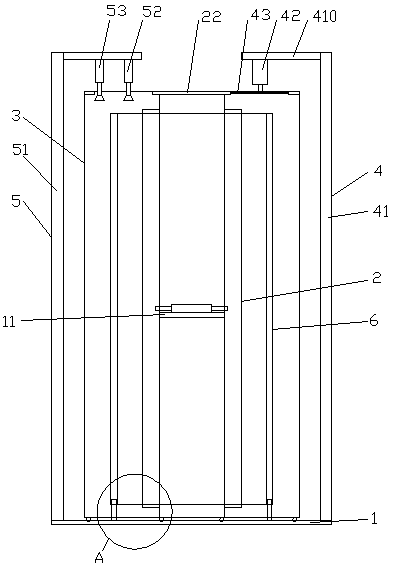

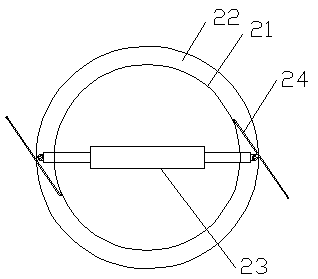

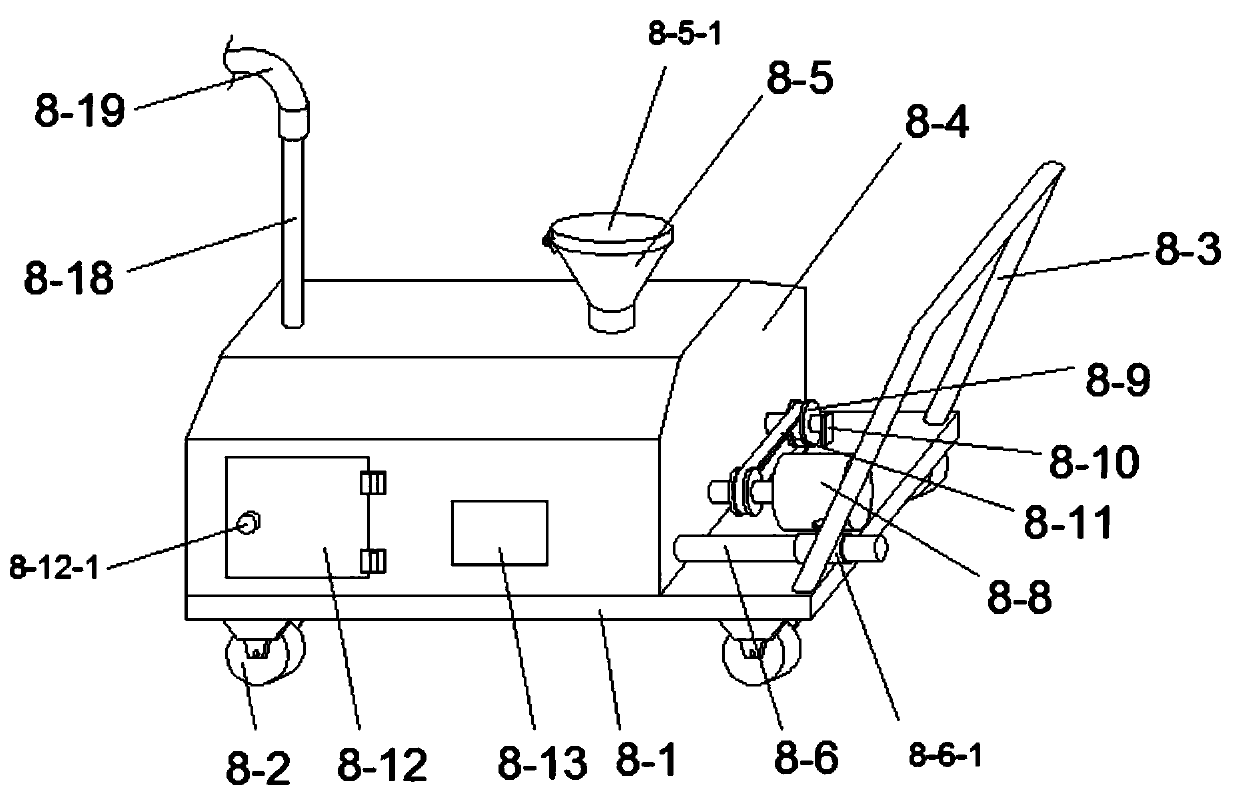

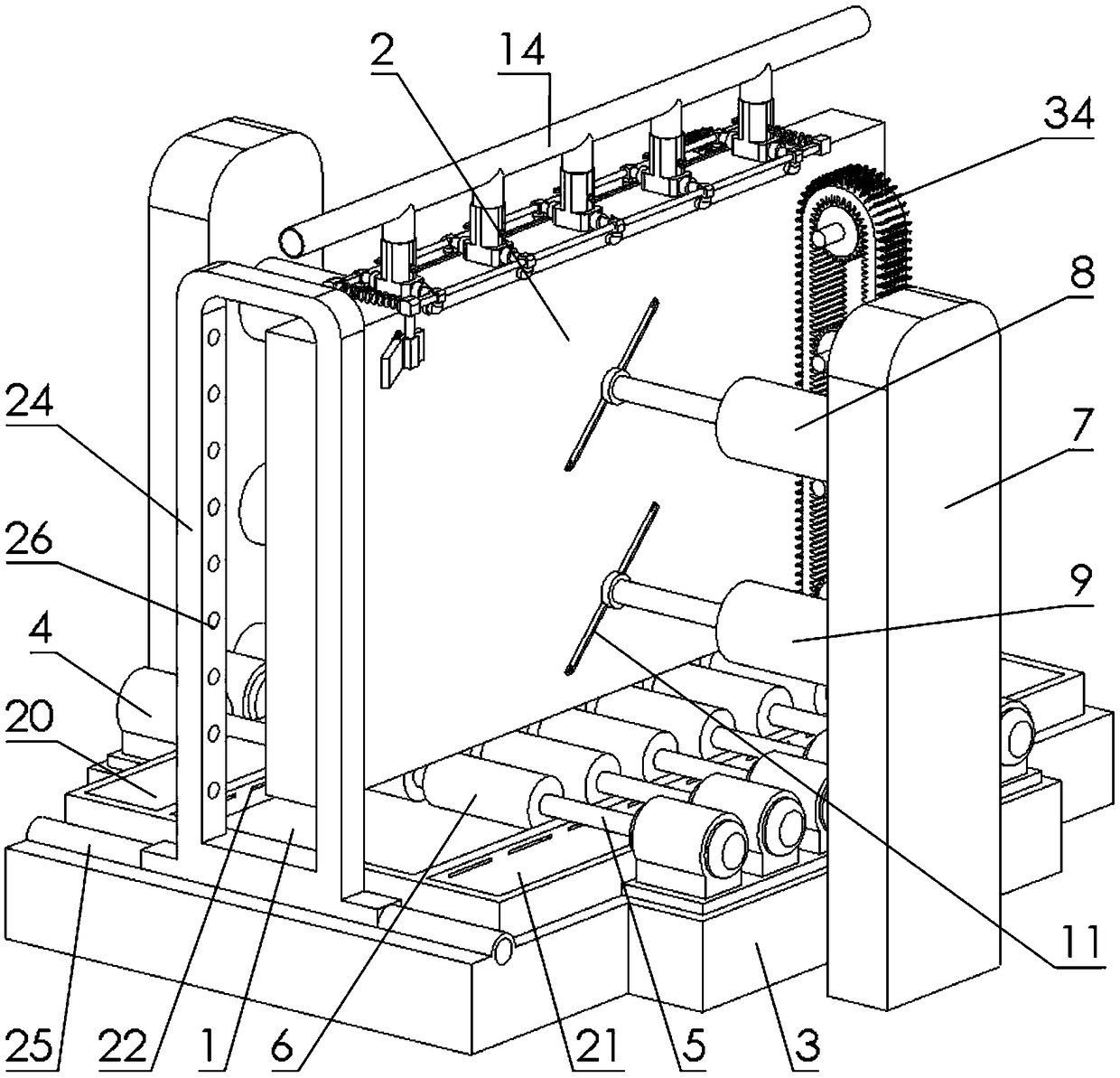

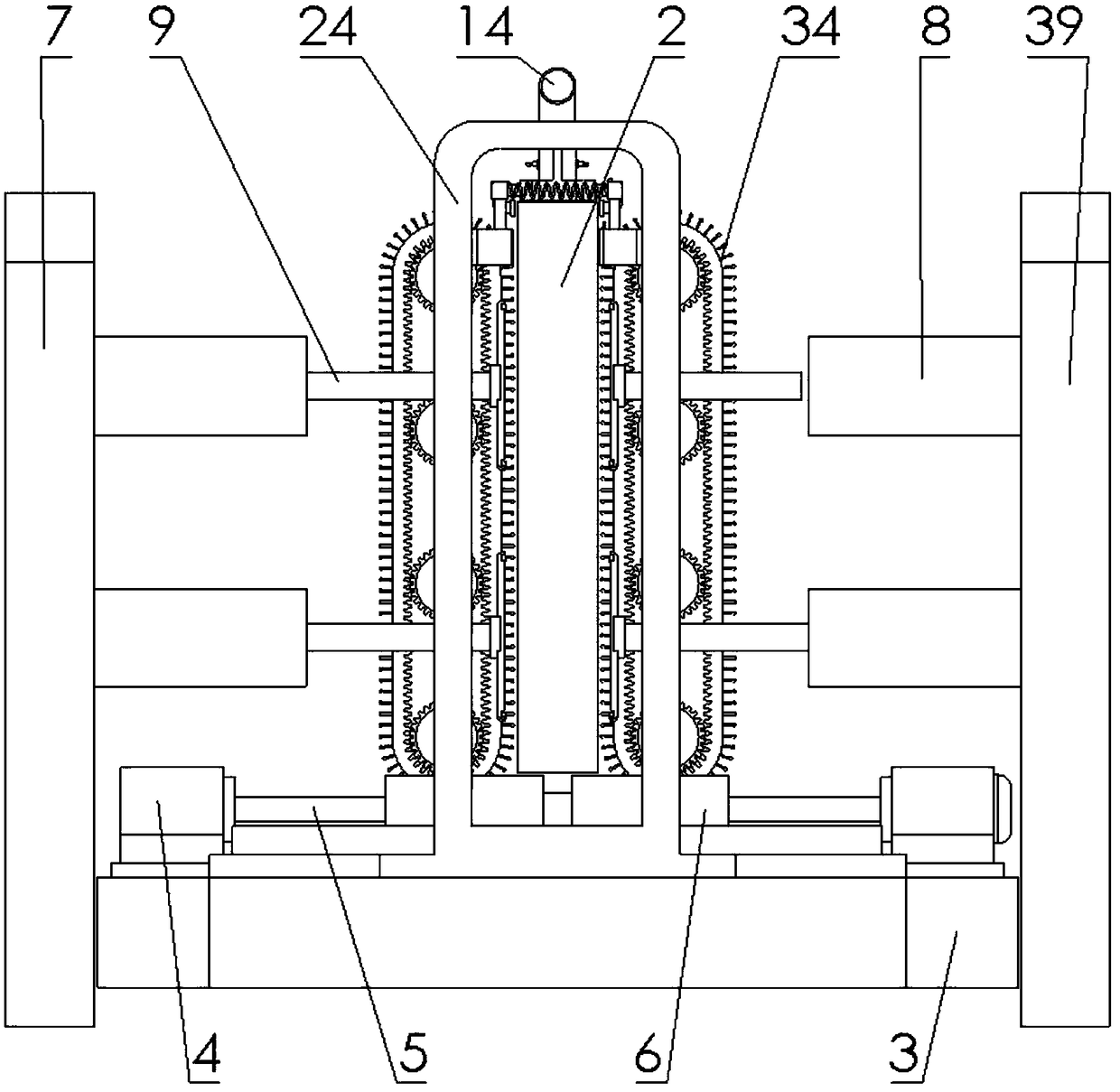

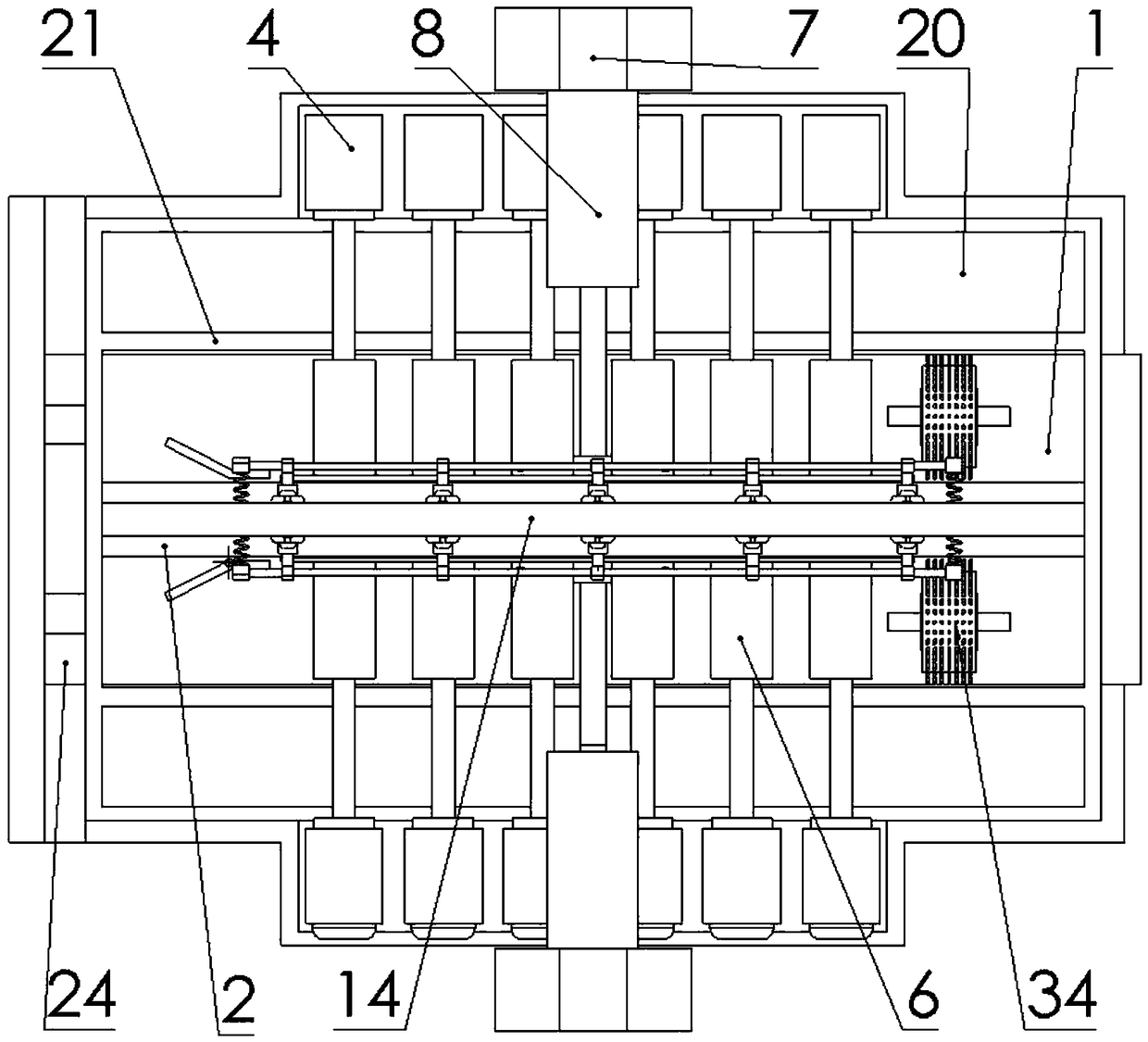

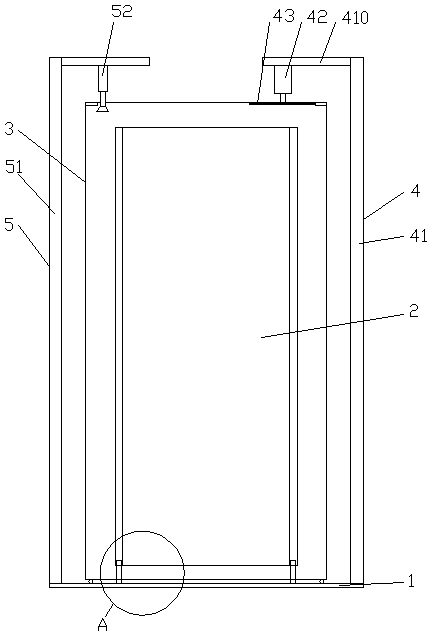

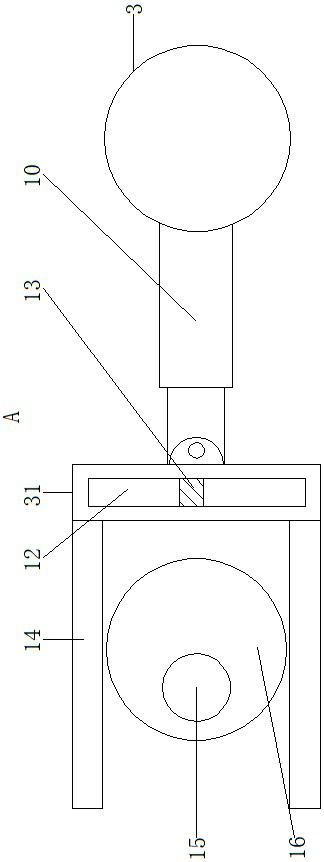

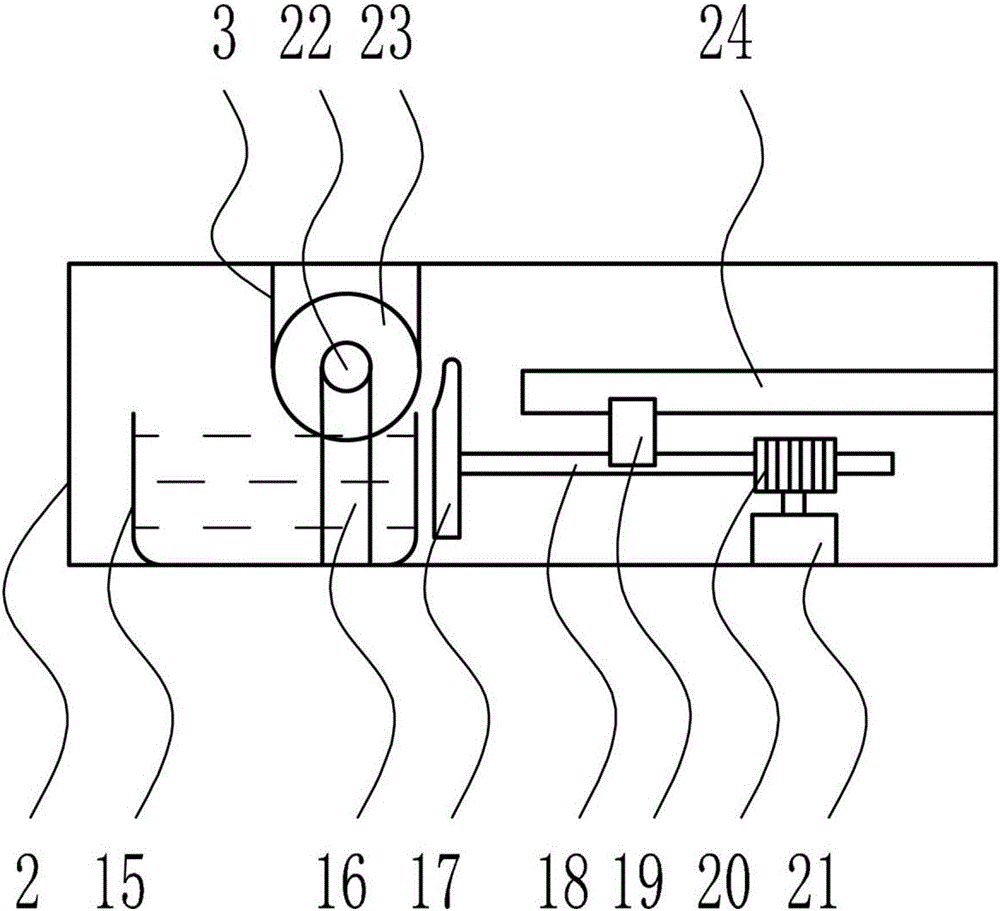

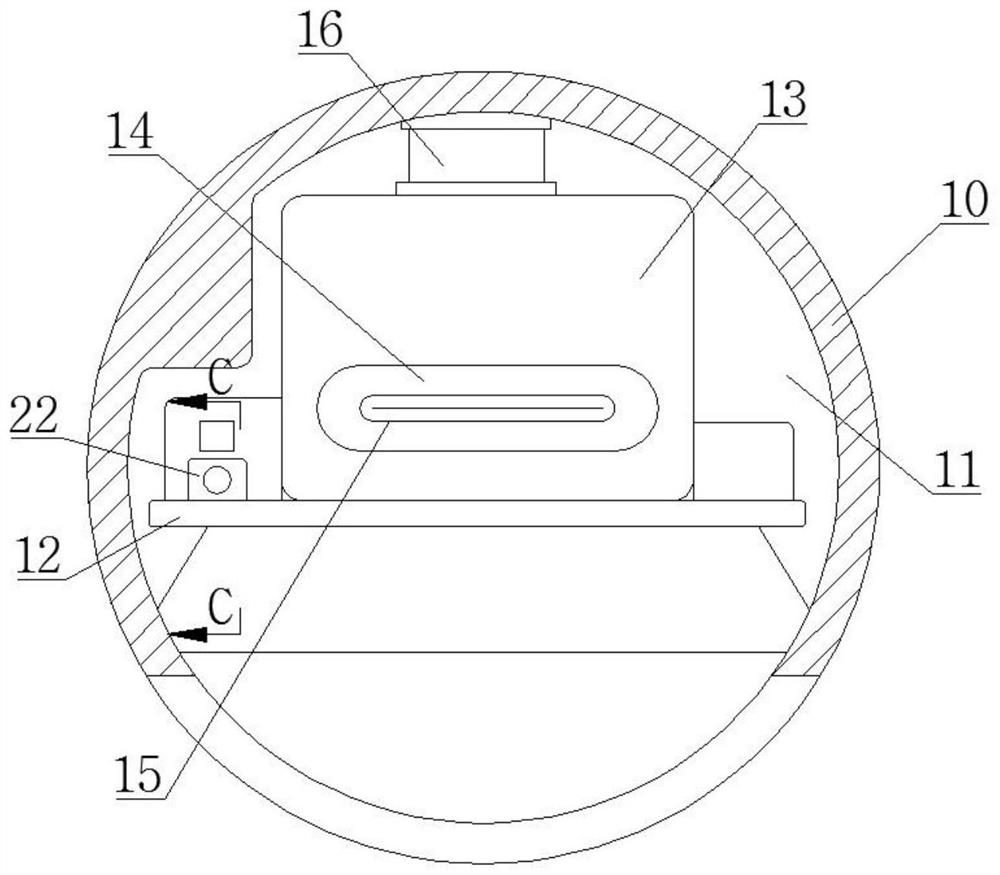

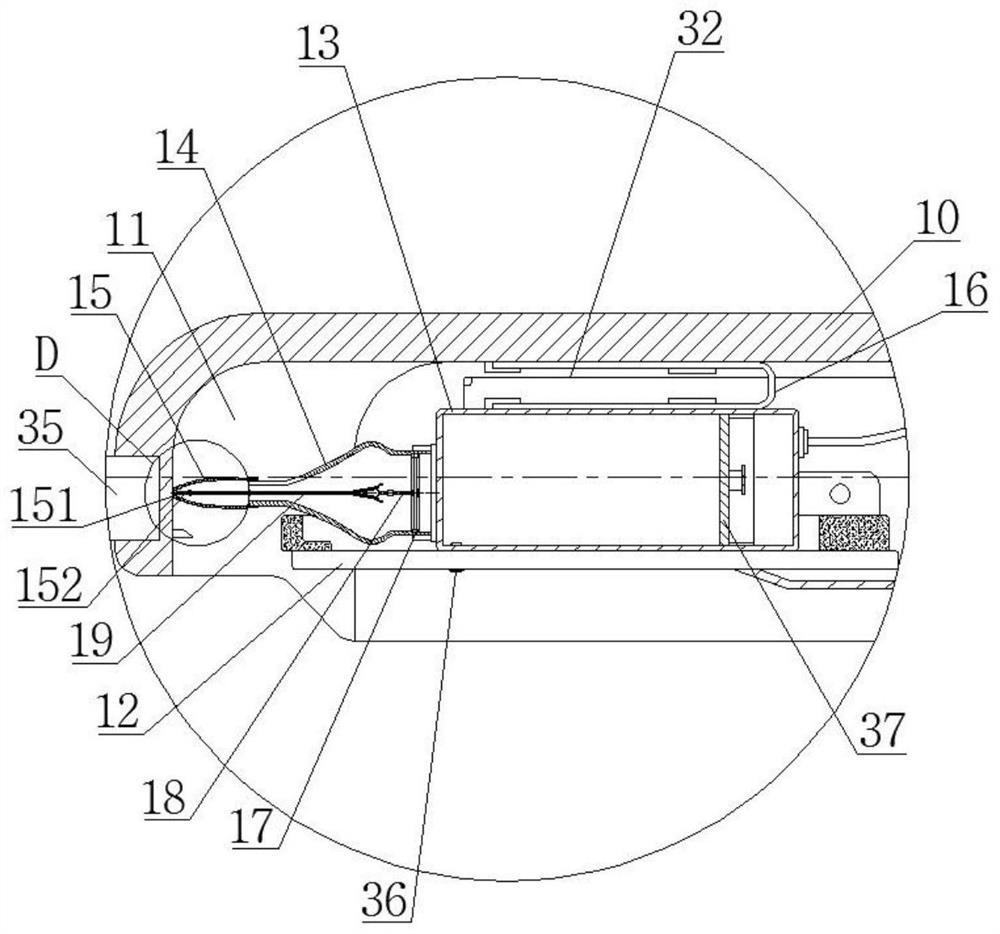

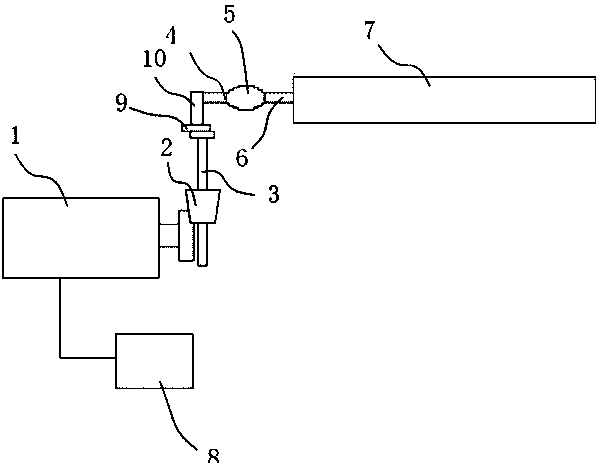

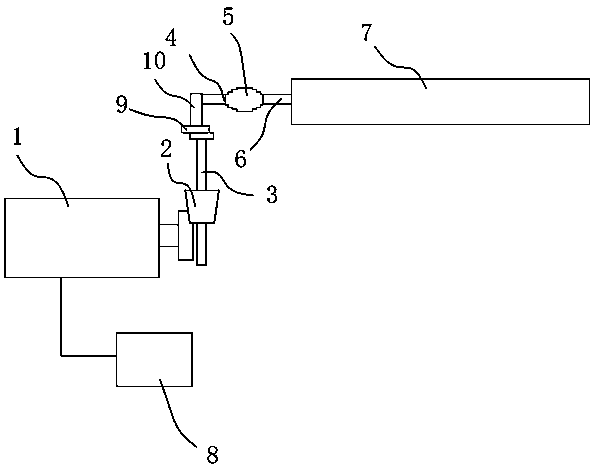

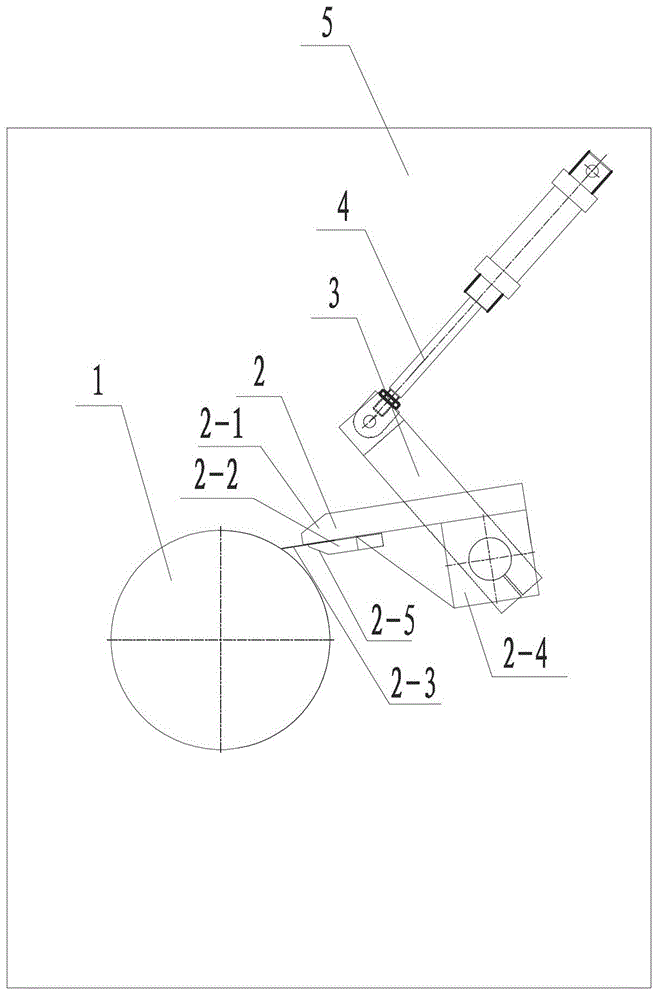

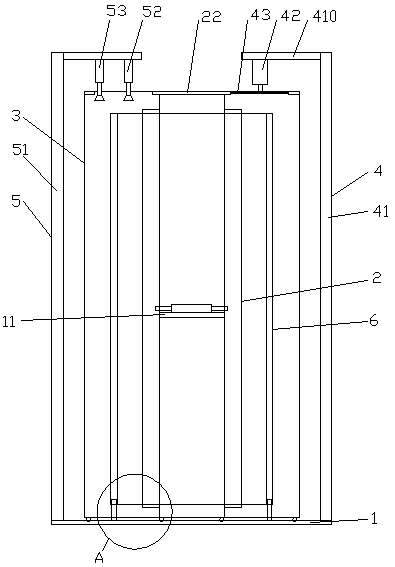

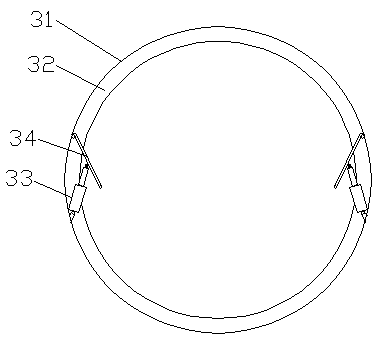

Rotary spraying device

InactiveCN108686858ASqueegee evenlyQuality improvementSpraying apparatusEngineeringMechanical engineering

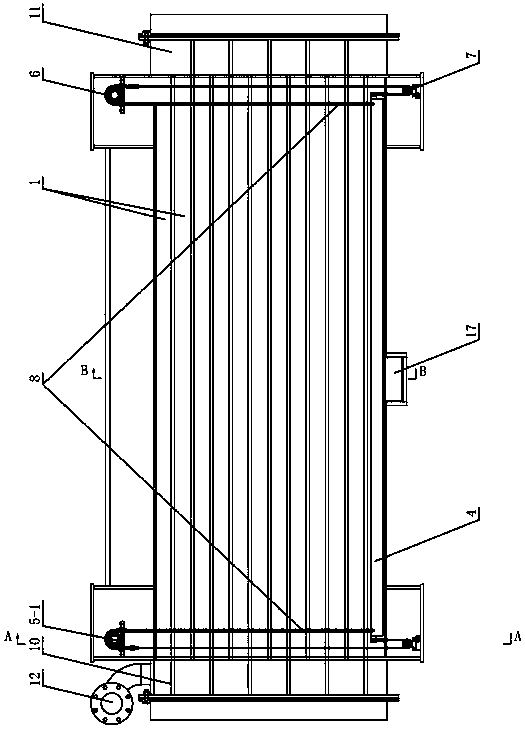

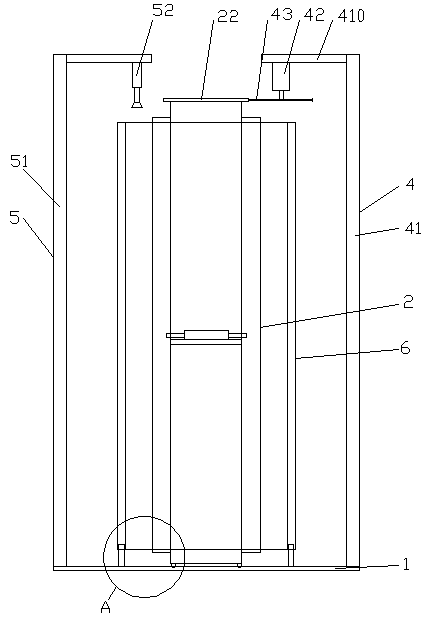

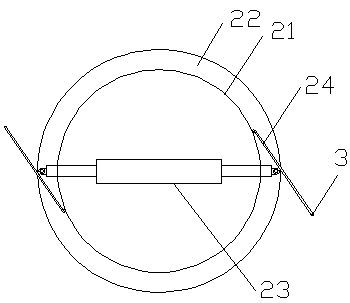

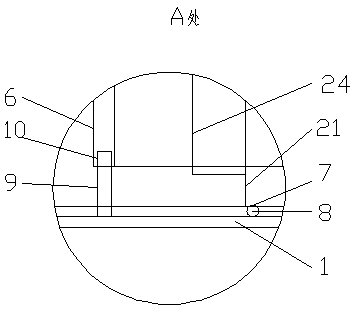

The invention discloses a rotary spraying device, relates to the field of spraying, and particularly relates to a rotary spraying device of a pipe body. The rotary spraying device is simple in structure and convenient to spray, and improves the working efficiency. The rotary spraying device comprises a base, an inner supporting mechanism, an outer supporting mechanism, a driving mechanism and a spraying mechanism. The inner supporting mechanism comprises an inner cylinder, the inner cylinder is rotatably and movably connected to the base, an outer annular rack is arranged on the surface of anupper cylinder opening of the inner cylinder, and an inner scraping smearing assembly is arranged on the inner cylinder. An inner spraying gun is located between the pipe body and the inner cylinder,and an outer spraying gun is located between the pipe body and an outer cylinder. The rotary spraying device improves the working efficiency and operates reliably.

Owner:YANGZHOU DONGFANG HANGER FRAME CO LTD

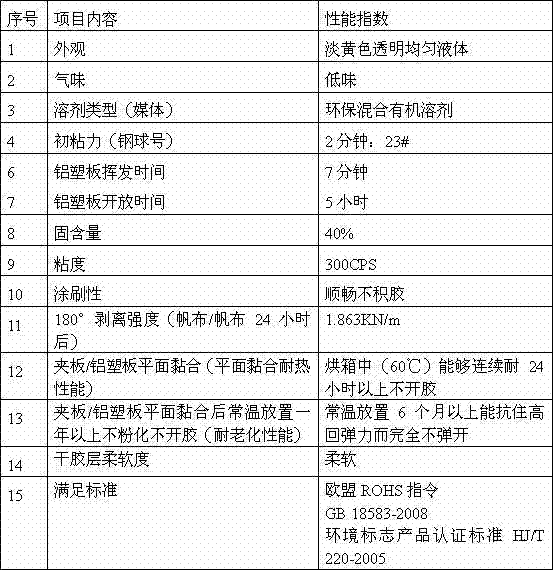

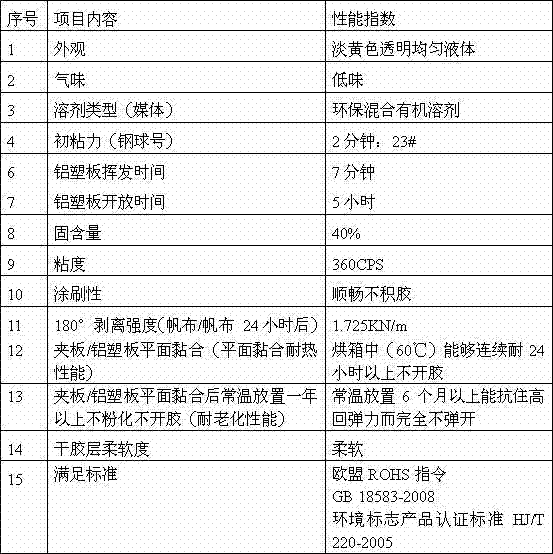

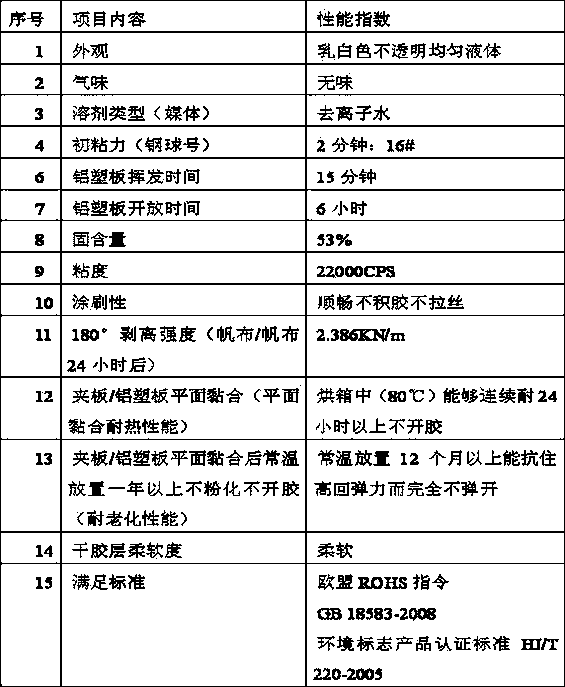

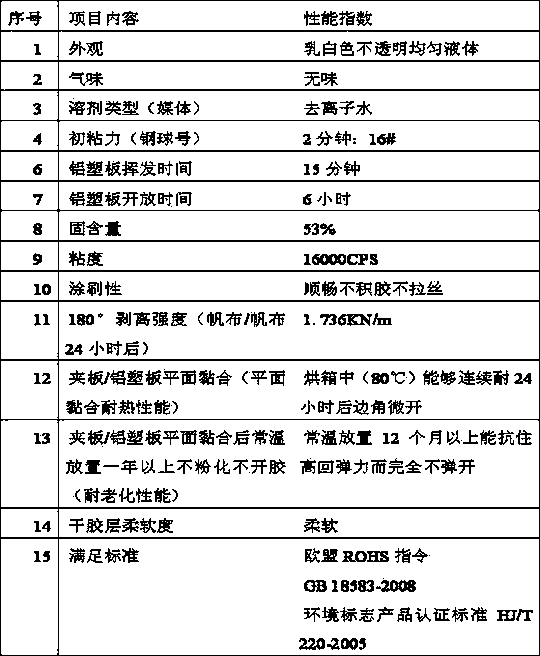

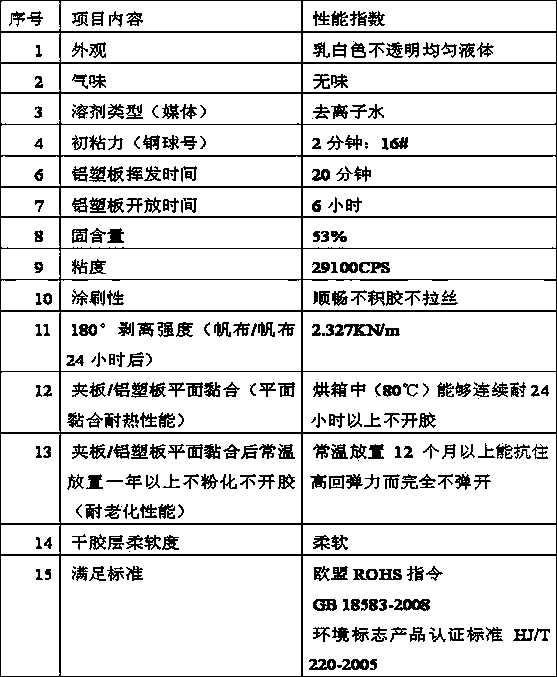

Environment-friendly water-based chloroprene universal rubber and preparation method thereof

InactiveCN103805097AGet rid of severe constraintsLow costMineral oil hydrocarbon copolymer adhesivesAldehyde/ketone condensation polymer adhesivesGlycerolMaterials science

The invention discloses environment-friendly water-based chloroprene universal rubber and a preparation method thereof. The universal rubber comprises the following main components in percentage by weight: 5% of a water-based rosin glycerol ester emulsion, 5.4% of a water-based pentalyn emulsion, 4% of a water-based petroleum resin emulsion, 8% of a water-based alkyl phenol emulsion, 11% of a water-based acrylic emulsion, 8% of a water-based EVA (Ethylene Vinyl-Acetate) emulsion, 42% of water-based anionic chloroprene latex and 6% of deionized water. The universal rubber disclosed by the invention has the comprehensive advantages of zero VOC (Volatile Organic Compounds), high solid content, no organic solvents, no heavy metals, no taste, excellent binding performance, heat-resistance and aging-resistance, shorter drying time, long open time, excellent leather grease resistance, rubber saving and the like, has the advantages of avoiding environmental pollution, improving the operation and construction environments, being low in cost, tasteless, fireproof and safe and the like, and can be widely applied to panel decorative industries such as aluminum-plastic panels, clamp boards, density boards, paint-free boards, macromolecular panels, screens and metal sheets. The environment-friendly water-based chloroprene universal rubber is especially suitable for being applied to green and environment-friendly top-grade decorative industries.

Owner:深圳市顾康力化工有限公司

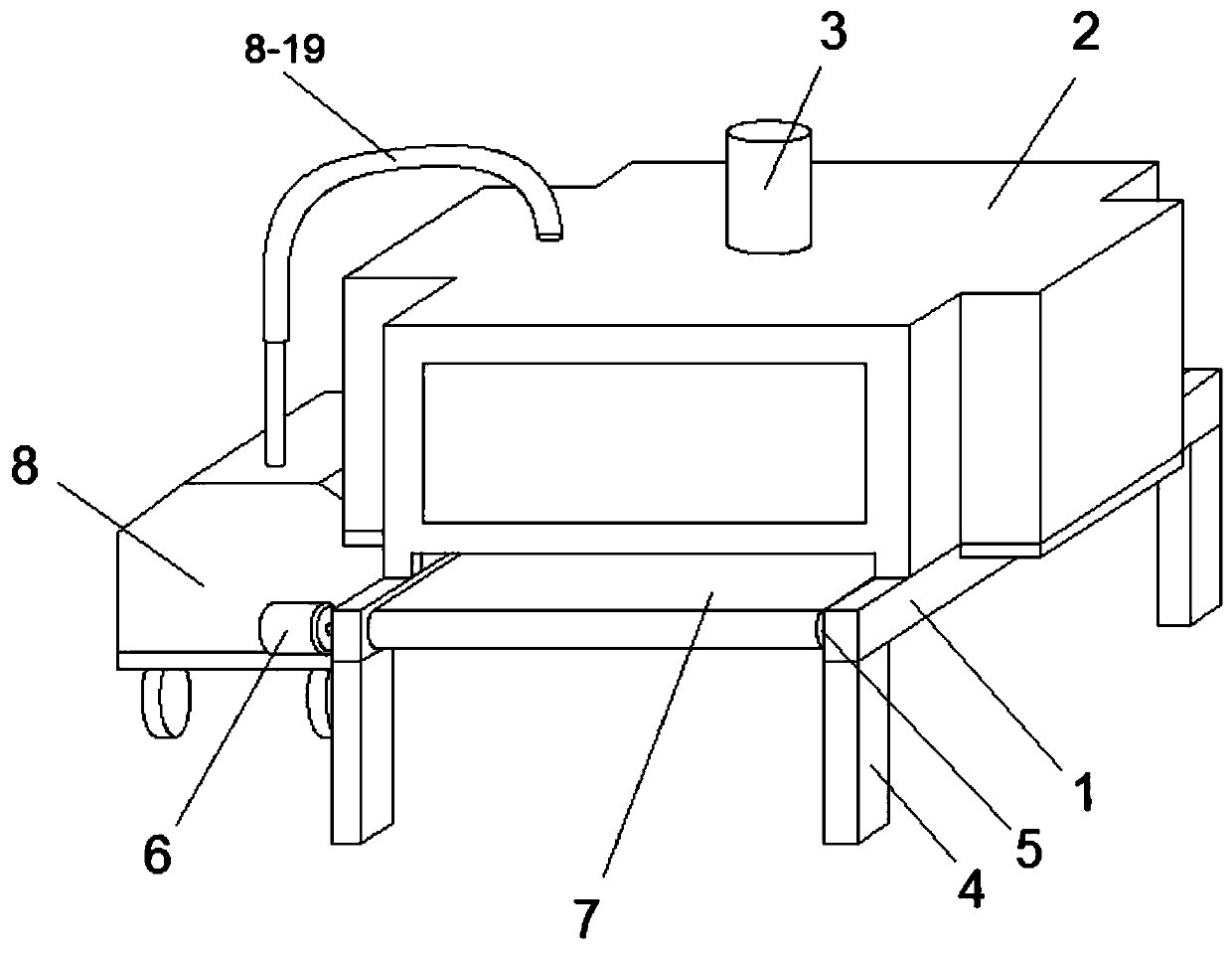

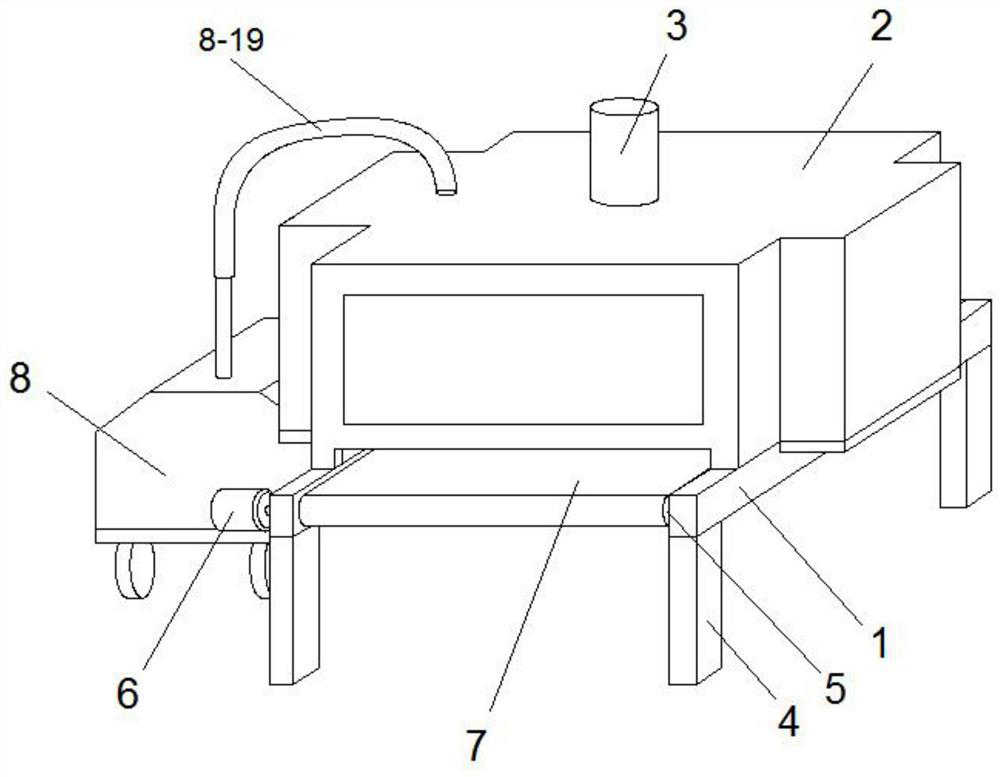

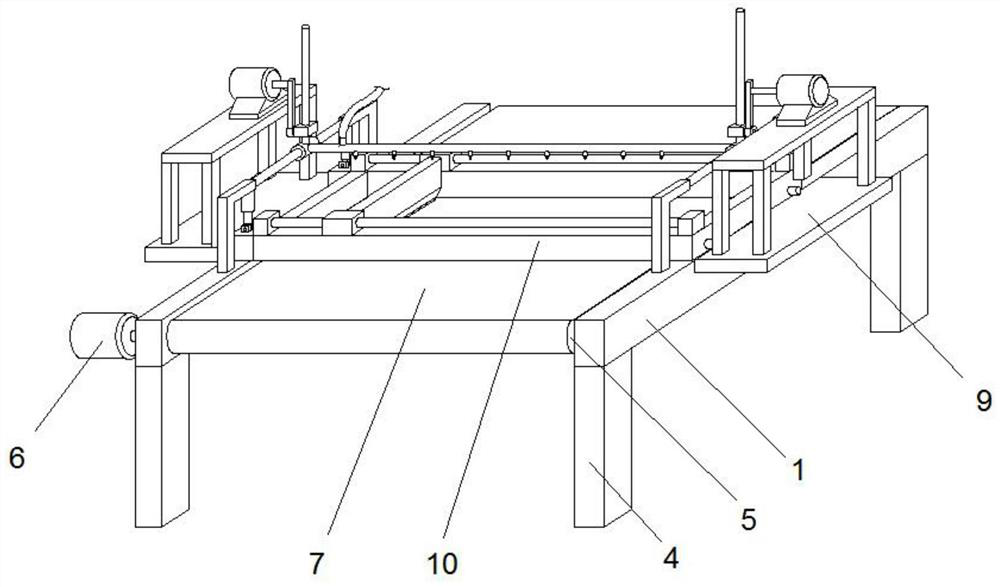

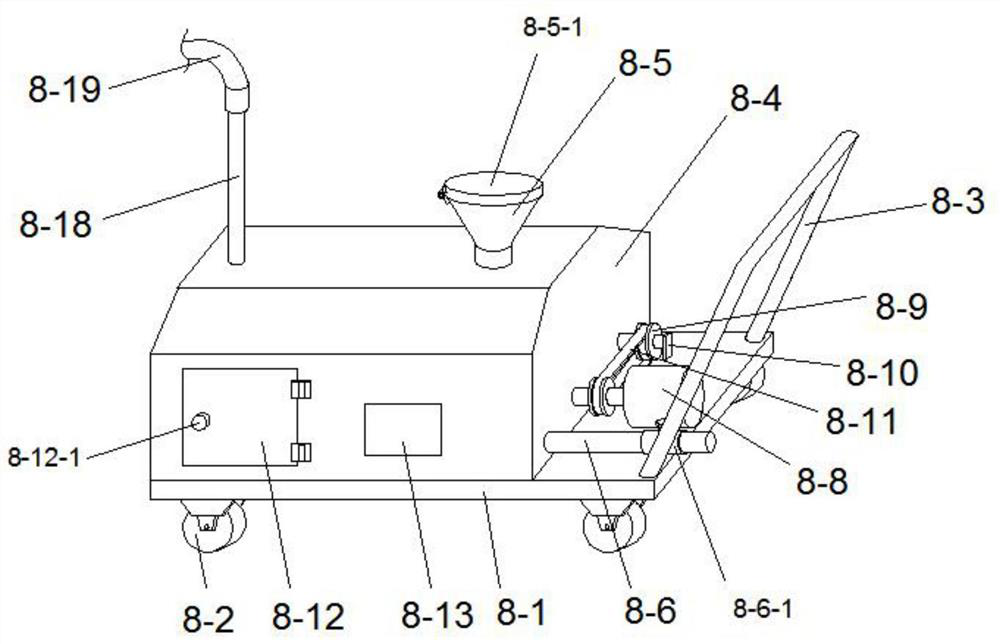

Coating device used for special coating glass fiber cloth preparation

ActiveCN110013930AImprove cleanlinessIncreased flexibility of useSpraying apparatusEngineeringCoating

A coating device used for special coating glass fiber cloth preparation comprises bottom frames, a shell, an exhaust pipe, column feet, a conveying roller, a transmission motor, a conveyor belt, a paint filling device, a spraying tool and a blade coating tool. The bottom frames are symmetrically arranged. The shell is arranged on the top faces of the bottom frames. Each column foot is arranged onthe lower surface of the bottom frame on the corresponding side. The conveying roller is arranged between the bottom frames on the two sides. The conveyor belt is arranged outside the conveying rollerin a wrapping manner. The paint filling device is arranged on one side of the bottom frames. The spraying tool is arranged above the bottom frames. The blade coating tool is arranged above the conveyor belt. The paint filling device is flexible to use and can clean the inner portion of a liquid storage cavity; and the device is stable in system operation, uniform in blade coating and high in coating efficiency.

Owner:镇江安之盾高温纤维制品有限公司

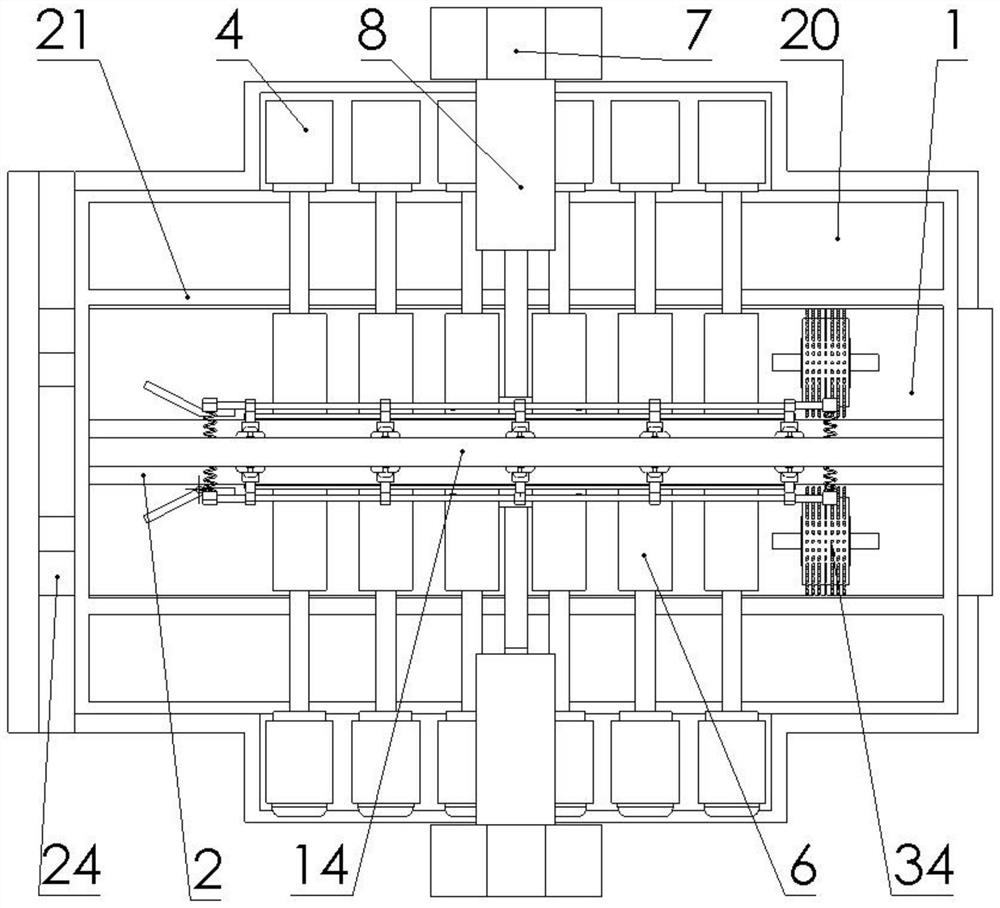

Wood processing equipment

The invention discloses wood processing equipment which comprises a wood-based panel to be processed. A glue collecting tank and glue standing tanks arranged on two sides of the glue collecting tank are arranged under the wood-based panel; a motor base is arranged on the outer sides of the glue standing tanks; motors are uniformly arranged on the motor base at intervals along the longitudinal direction; a glue discharging device is arranged above the wood-based panel; glue scraping devices are arranged on two sides of the wood-based panel; a glue coating device is arranged at the discharging end of the wood-based panel; and the wood-based panel is provided with a preheating frame in front of a feeding end. The wood processing equipment provided by the invention can be used for quickly preheating, gluing, scraping and coating the wood-based panel, is applicable to panels with different width sizes, and is comprehensive and uniform in coating; glues can be recycled; single-sided and two-sided glue coating is optional; the whole process is automatic and controllable; and the wood processing equipment is reliable to run and high-efficiency in operation.

Owner:湖南省杨林木业有限公司

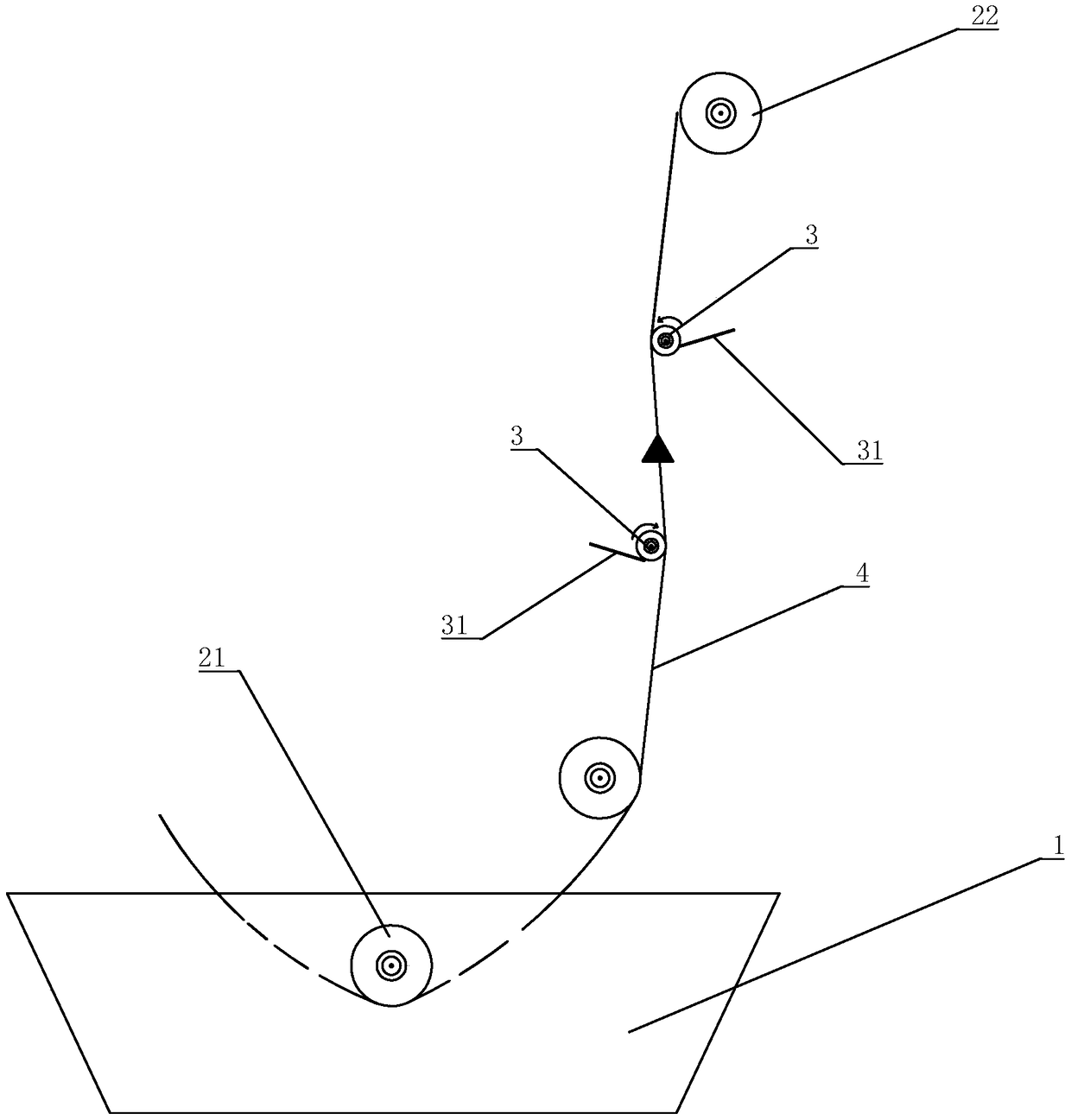

Novel prepreg presoaking device

PendingCN109127276ASqueegee evenlyLiquid surface applicatorsCoatingsForeign matterPulp and paper industry

The invention discloses a novel prepreg presoaking device. The novel prepreg presoaking device comprises a glue tank and a conveying roller, wherein the conveying roller comprises a presoaking rollerarranged inside the glue tank and a first transmission roller arranged above the glue tank; at least two glue scraping rollers are arranged between the first transmission roller and the presoaking roller, and the glue scraping rollers are arranged on two sides of the transmission direction respectively so as to scrape glue on positive and negative surfaces; a scraper blade is arranged on each gluescraping roller, each glue scraping roller is connected with a driving device so as to drive the corresponding glue scraping roller to rotate actively; and simultaneously, the rotation directions ofthe glue scraping rollers are opposite to the transmissions of the glue scraping rollers. In the device, glass fabric is conveyed by a conveying roller, the glass fabric is guided into the glue tank for glue soaking by the presoaking roller, after glue soaking of the glass fabric, the glue scraping rollers rotate actively, the scraper blades are driven to scrape a glue solution on the glass fabric, simultaneously, the glue scraping is more uniform due to the arrangement of the scraper blades, and simultaneously, foreign matters such as broken filaments on the glass fabric can be scraped.

Owner:KAIPING PACIFIC INSULATION MATERIAL

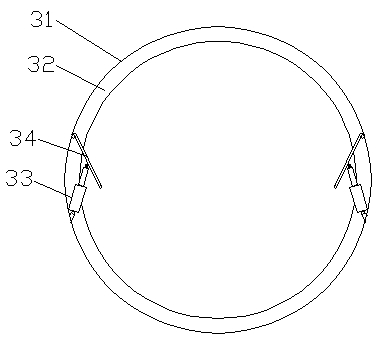

Steel pipe surface spraying equipment

InactiveCN110639729AImprove work efficiencyEasy to operateLiquid surface applicatorsSpraying apparatusMechanical engineeringSteel tube

The invention discloses steel pipe surface spraying equipment, and relates to the field of spraying, in particular to the steel pipe surface spraying equipment. The invention provides the steel pipe surface spraying equipment which is simple in structure, convenient to spray and capable of improving the working efficiency. The steel pipe surface spraying equipment comprises a base, an outer supporting mechanism, a driving mechanism and a spraying mechanism, wherein the outer support mechanism comprises an outer cylinder, the outer cylinder is rotationally and movably connected to the base, aninner annular rack is arranged on the inner wall of the upper cylinder opening of the outer cylinder, a pair of outer scraping coating assemblies which are symmetrically arranged are arranged on the inner wall of the outer cylinder, a pipe body is arranged in the outer cylinder, the pipe body is rotationally and movably connected to the base, and an outer spray gun is positioned between the pipe body and the outer cylinder. According to the steel pipe surface spraying equipment, the working efficiency is improved, and the operation is reliable.

Owner:谈骏

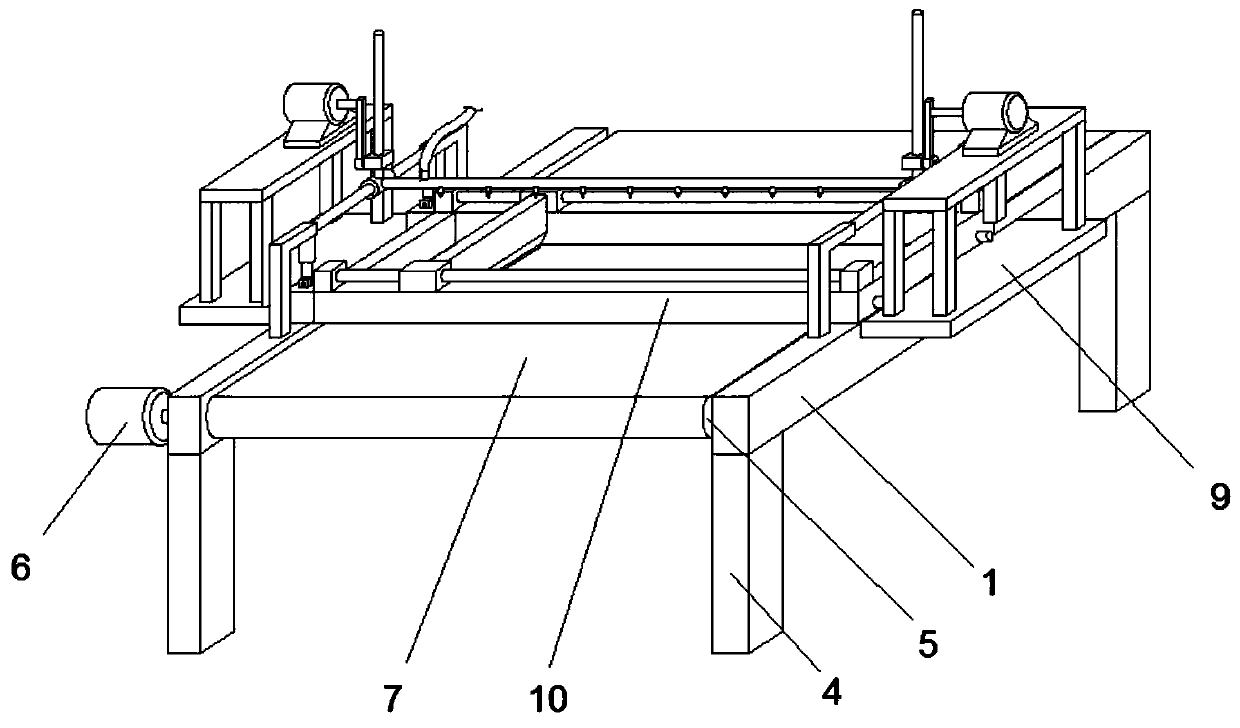

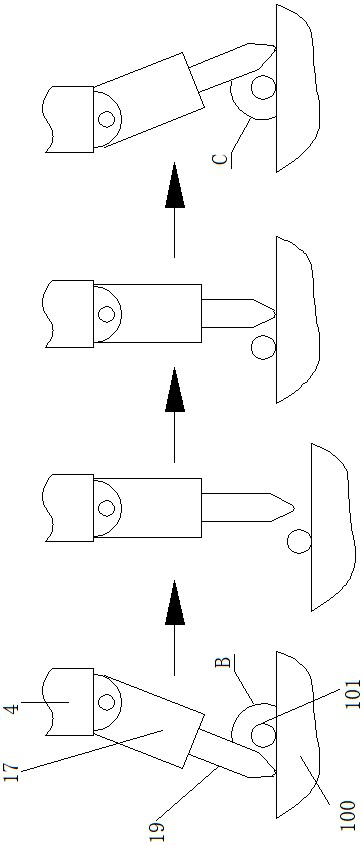

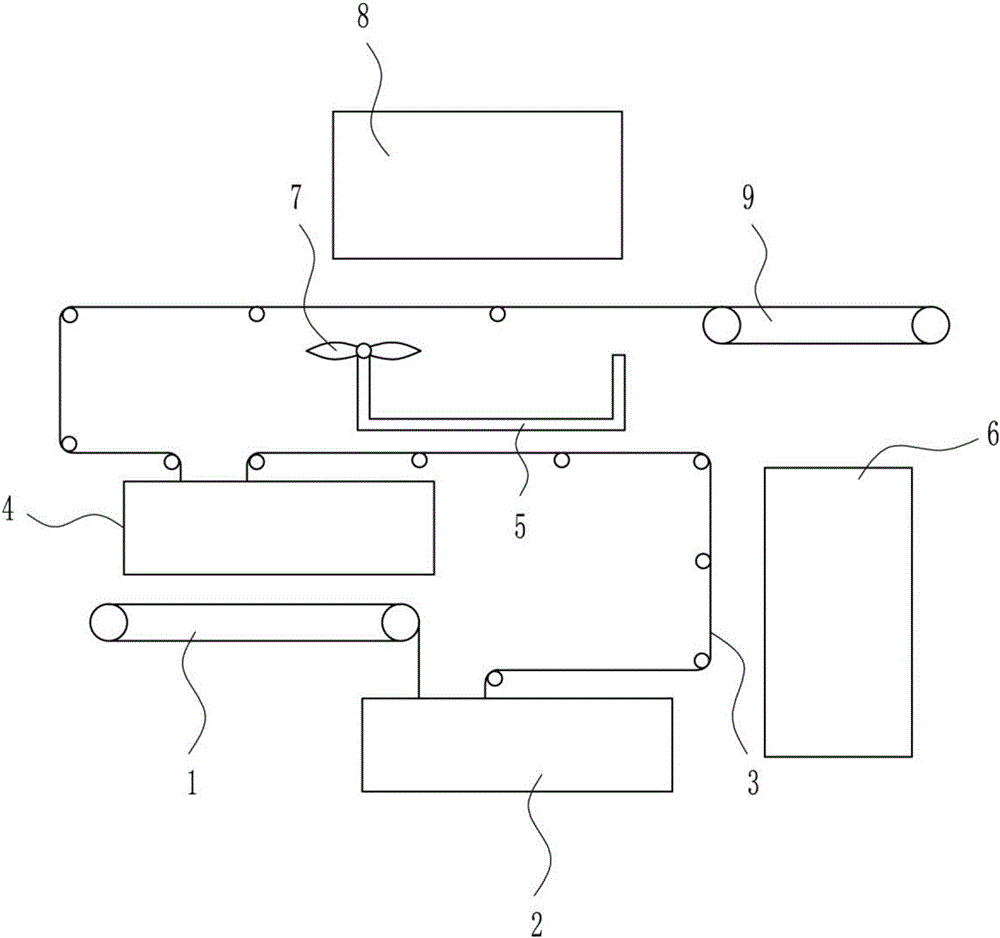

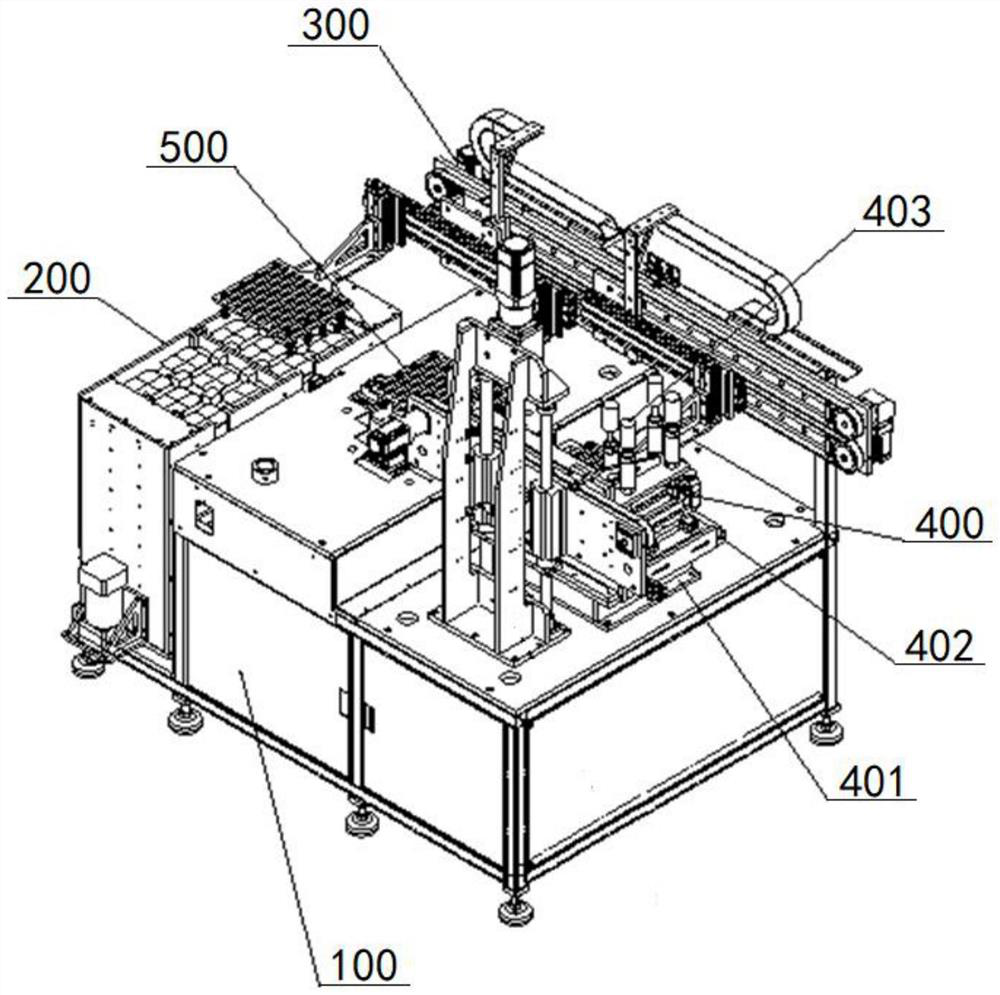

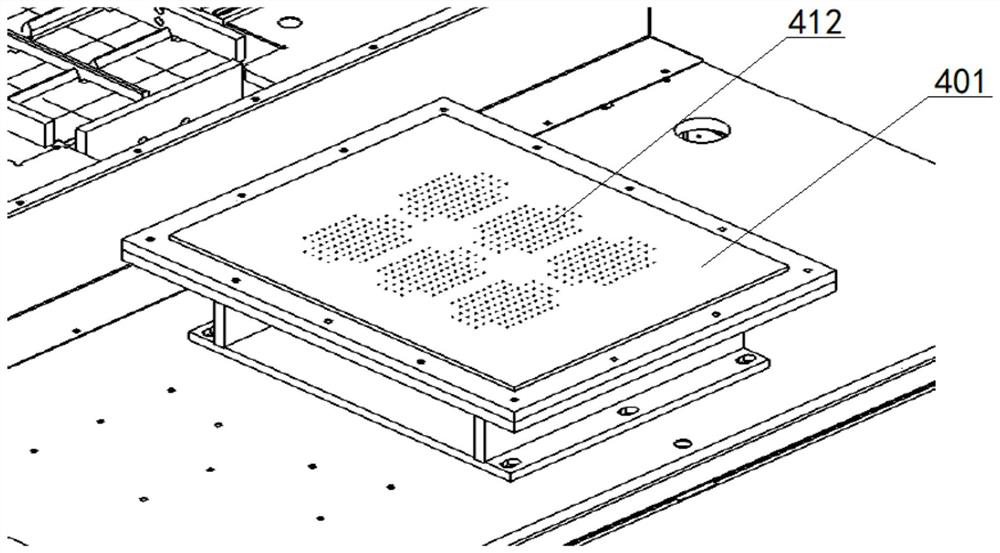

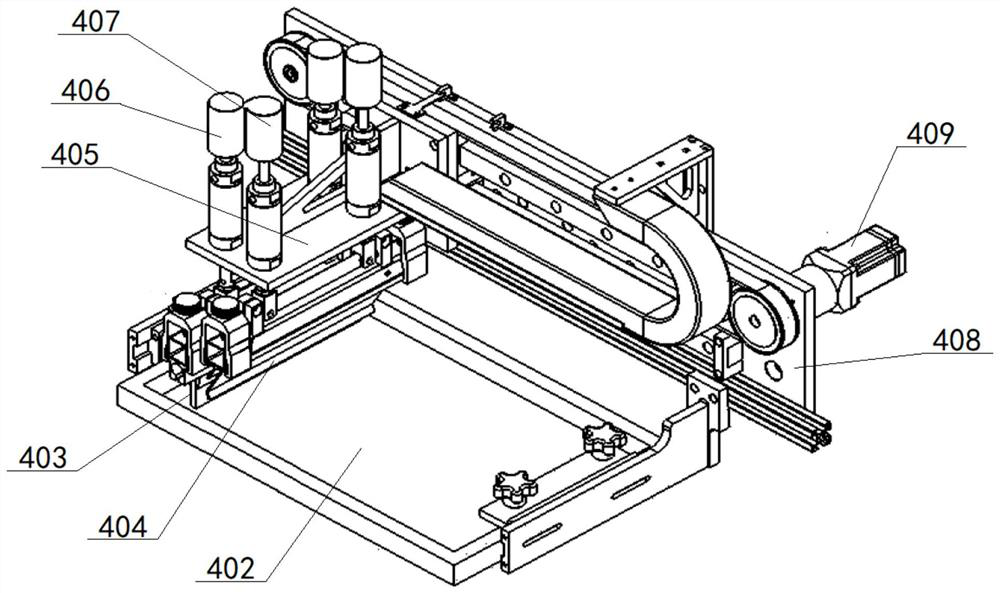

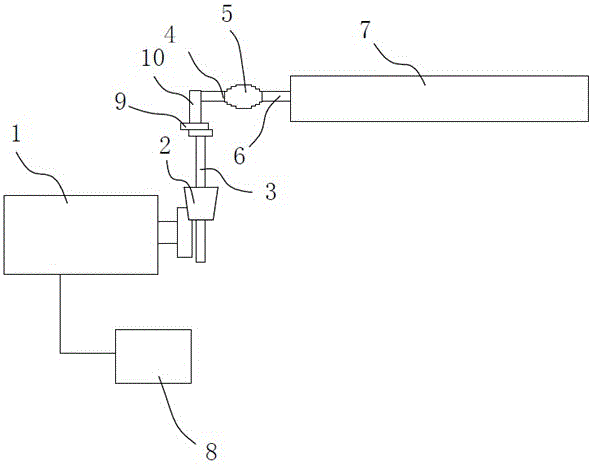

Sheet automatic glue coating machine

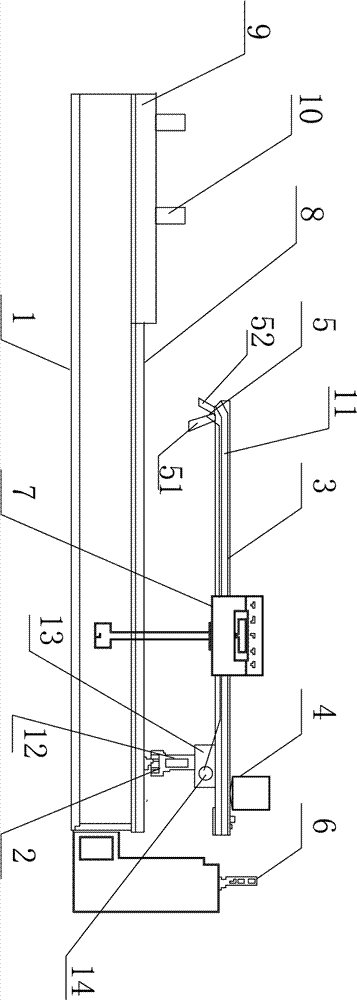

ActiveCN105197590BUniform amount of glueSqueegee evenlyArticle feedersConveyor partsComputer control systemElectricity

Fully automatic gluing machine for sheet materials, including a feeder, a host, a discharge turning device, and a computer control system. The feeder includes a conveying wheel and a pressure wheel placed above the conveying wheel. It is characterized in that the host The frame, the conveying part, also includes a multi-degree-of-freedom glue spraying assembly connected to the frame that can move laterally and rotate with a fixed axis, and a squeegee assembly that can move vertically on the frame. The host part is also equipped with sensor The sensing element b of the plate position, the discharge turning device is connected with the conveying part, and the computer control system is electrically connected with the feeder, the host and the discharging turning device for motion detection and control. The present invention can complete the board gluing process without manual operation, fully automatic feed gluing, scraping, and automatic plate turning, and can ensure that the amount of glue applied to each batch of boards is uniform and appropriate while completing the gluing work quickly and automatically , squeegee evenly; and the equipment can be applied to a variety of boards of different sizes.

Owner:苏州市锲镒机械科技有限公司

Cold water phase change machine and heat pump system

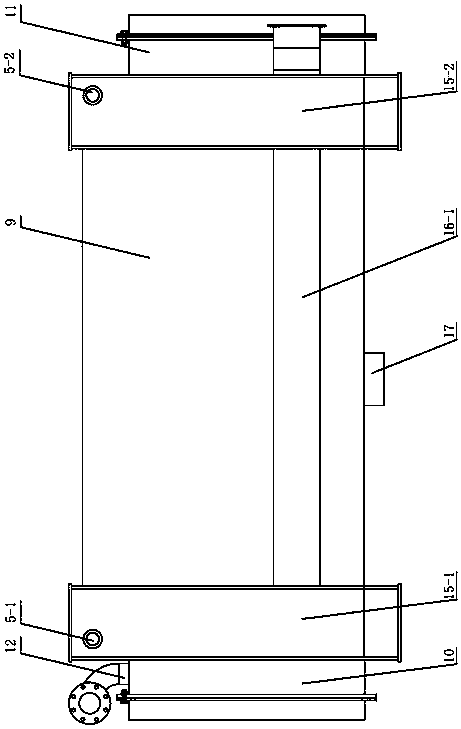

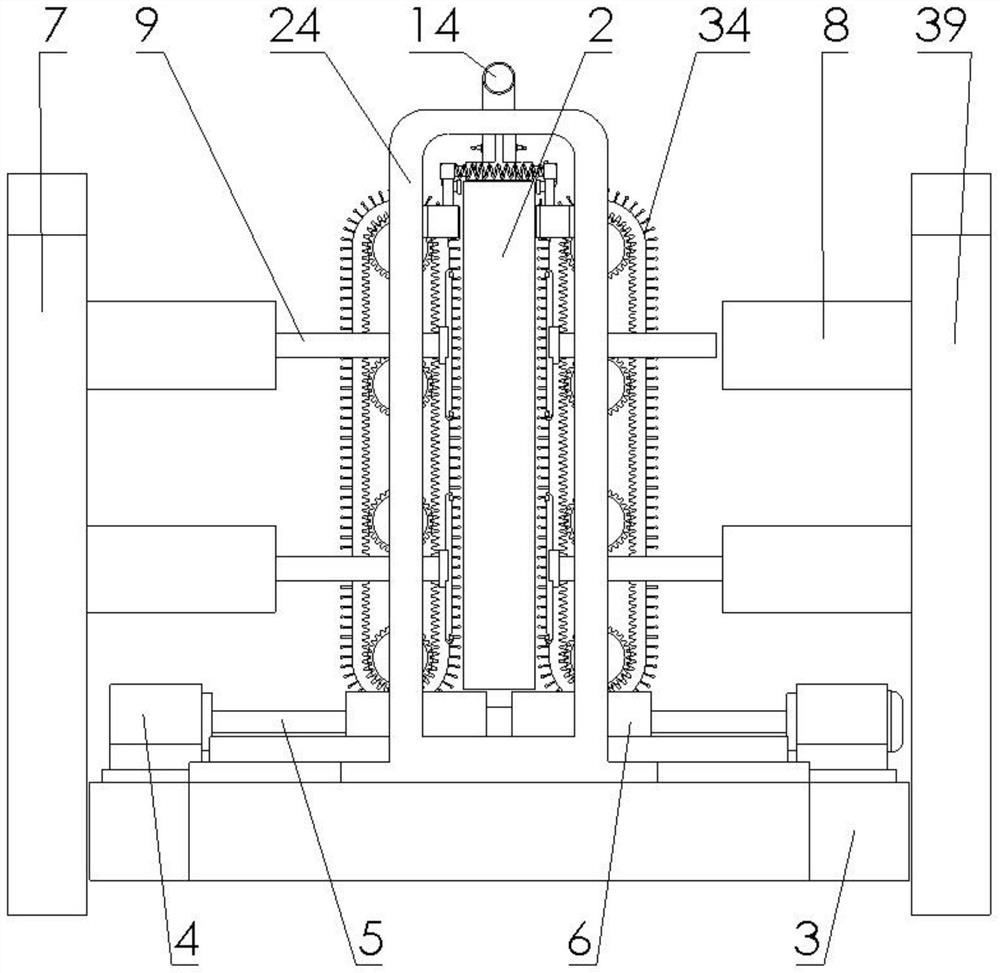

InactiveCN108626927ASqueegee evenlyImprove heat transfer efficiencyCentral heating with accumulated heatHeat recovery systemsAnti freezingReciprocating motion

The invention discloses a cold water phase change machine and a heat pump system, and belongs to the technical field of energy sources. According to the cold water phase change machine and the heat pump system, phase change latent heat released when water is changed to ice is extracted from the cold water. The device comprises heat exchange pipes, pipe rows, cold water flow channels, a scraper, atransmission chain, main shafts, transmission wheels, a transmission motor, a transmission motor reducer, an ice breaking propeller, an external observable travel control device, a shell, a left flowguide box, a right flow guide box, an anti-freezing water solution inlet, an anti-freezing water solution outlet, a cold water inlet, ice discharging openings, a cold water inlet cavity and cold waterinlets. According to the cold water phase change machine and the heat pump system, an ice layer is scraped by the vertical reciprocating motion of the scraper, the ice layer is crushed and pushed tothe ice discharging openings, so that efficient ice removing and ice discharging of the cold water phase change machine are realized; and the machine and the system are suitable for heat pump heat supply and air conditioner ice cold accumulation systems capable of extracting the cold water phase change energy.

Owner:青岛瑞焓清洁能源供热研究院

Drawing and color palette integrated processing device based on Internet of Things control

ActiveCN113231269APrevent horizontal movementGuaranteed coating integrityLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention discloses a drawing and color palette integrated processing device based on Internet of Things control. The drawing and color palette integrated processing device comprises a shell, an electric rotating base is arranged at the bottom in the shell, an electric lifting device is arranged on the electric rotating base, a circular plate is arranged on a fixing assembly, a vertical shaft is arranged at the top in the shell, a driving assembly is arranged at the top in the shell, a connecting base is arranged at the bottom of the vertical shaft, an elastic telescopic scraper device is arranged at the bottom of the connecting base, a second electric telescopic rod is arranged at the lower end, facing the circular plate, of an L-shaped rod, an arc-shaped plate is arranged on the second electric telescopic rod, and a discharging device is arranged on one side of the connecting base. According to the drawing and color palette integrated processing device based on Internet of Things control, the driving assembly drives the vertical shaft to rotate in a reciprocating mode to conduct fan-shaped reciprocating smearing on paint, the paint centrifugally thrown out when a scraping plate scrapes the paint can be collected and then evenly smeared to the outer side of the circular plate, paint waste is avoided, a product is more attractive and practical, the processing efficiency of a color palette is improved, and meanwhile, the arc-shaped plate not only has the function of scraping the paint, but also has the function of clamping the circular plate, so that the circular plate is prevented from moving due to the horizontal thrust of the scraping plate.

Owner:CHONGQING THREE GORGES UNIV

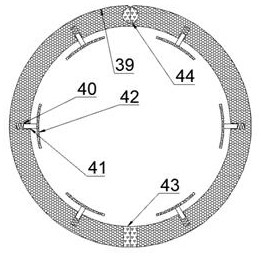

Automatic blade-coating method for solid propellant cladding lining layer of rocket engine

InactiveCN107537749ASqueegee evenlyGuaranteed uniformityLiquid surface applicatorsCoatingsNumerical controlSlurry

The invention discloses an automatic blade coating method for a solid propellant cladding lining layer of a rocket engine. The automatic blade-coating method comprises the steps of preparation beforecoating, distributing of material slurry, blade coating of the material slurry and beforehand solidification; during distributing of the material slurry, the quantitative material slurry of the cladding lining layer is distributed on a cladding face, and the material slurry is distributed in a strip shape; and during blade coating of the material slurry, an automatic blade-coating program is started, even blade coating is achieved by constant-speed moving of a brush blade on the cladding face. During mechanical blade coating, the rotating speed of a blade-coating piece, the displacement speedand the displacement amount of a brush rod in the radial and axial directions are controlled through a program by utilizing a numerical control machine tool, and even coating and adjusting and controlling of the blade-coating speed are achieved; and the brush blade on the rigid brush rod is made of ox-tendon imitating plate composite materials with the certain strength and toughness, the brush rodand the brush blade are firmly positioned, so that angle offset is not generated between the brush rod and the brush blade. The automatic blade coating method for the solid propellant cladding lininglayer of the rocket engine can be widely applied to automatic blade coating of the cladding lining layer between solid rocket engine heat insulation materials and a solid propellant and has the advantages that the structure is simple, the process is controllable, the quality is reliable, and safety and effectivity are achieved.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

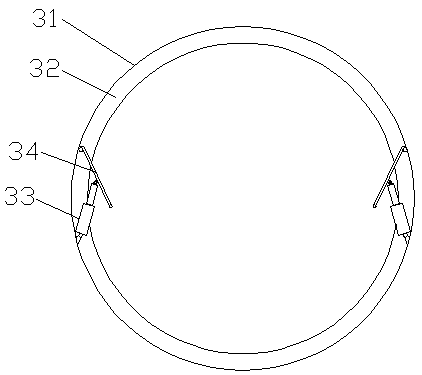

Paint spraying equipment for cylindrical surface

InactiveCN111659573ARealize fully automatic paintingClean and comprehensiveCleaning using toolsSpray boothsBilateral symmetryFully automated

The invention relates to the field of paint spraying machines, in particular to paint spraying equipment for a cylindrical surface. The paint spraying equipment comprises a rack, a hinge for being hinged to the rack, and a switch for locking the rack, the rack is composed of two semicircular ring columns which are hinged and closed into a circular ring column through the hinge, a working cavity isformed by an inner ring of the rack in a surrounded mode, a track groove is formed in the top of the rack, a ring sleeve with the same height as the track groove is rotationally arranged in the working cavity, and two supporting shafts are fixedly arranged on the outer ring surface of the ring sleeve in a bilateral symmetry mode. The paint spraying equipment for the cylindrical surface provided by the invention can spray paint to the cylindrical surface fully automatically, meanwhile, the working surface can be completely cleaned before paint spraying so as to ensure the subsequent paint spraying quantity, after paint is sprayed on the working surface, the sprayed paint can be scraped evenly, the whole process operates fully automatic, and thus paint waste caused by human operation errorsis reduced.

Owner:PUJIANG SIHONG MASCH TECH CO LTD

Matt waterproof ink-jet printing supplies coating machine

The invention relates to a supplies coating machine, in particular to a matt waterproof ink-jet printing supplies coating machine. The invention aims to provide a matt waterproof ink-jet printing supplies coating machine which is waterproof, easy to dry and uniform in frictioning. In order to solve the technical problems, the invention provides the matt waterproof ink-jet printing supplies coating machine. The matt waterproof ink-jet printing supplies coating machine comprises a first conveying device, a first gluing device, a second gluing device, a supporting plate, a first drying device, a second air heater, a second drying device and a second conveying device, and the first drying device comprises a first air heater, a fixing rod, a connecting rod, an electric push rod and a fixing plate. The matt waterproof ink-jet printing supplies coating machine has effects of waterproofness, easiness in drying, uniform frictioning, simple structure, easiness in operation, low cost and high practicability.

Owner:海森印刷科技滨海有限公司

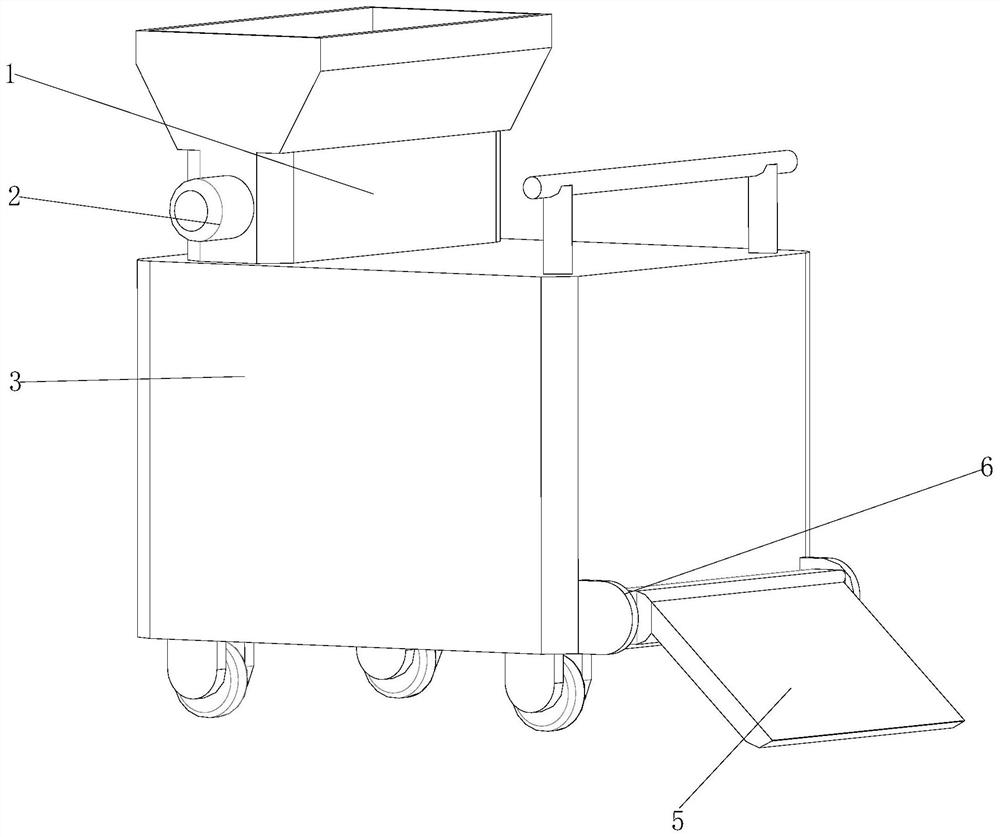

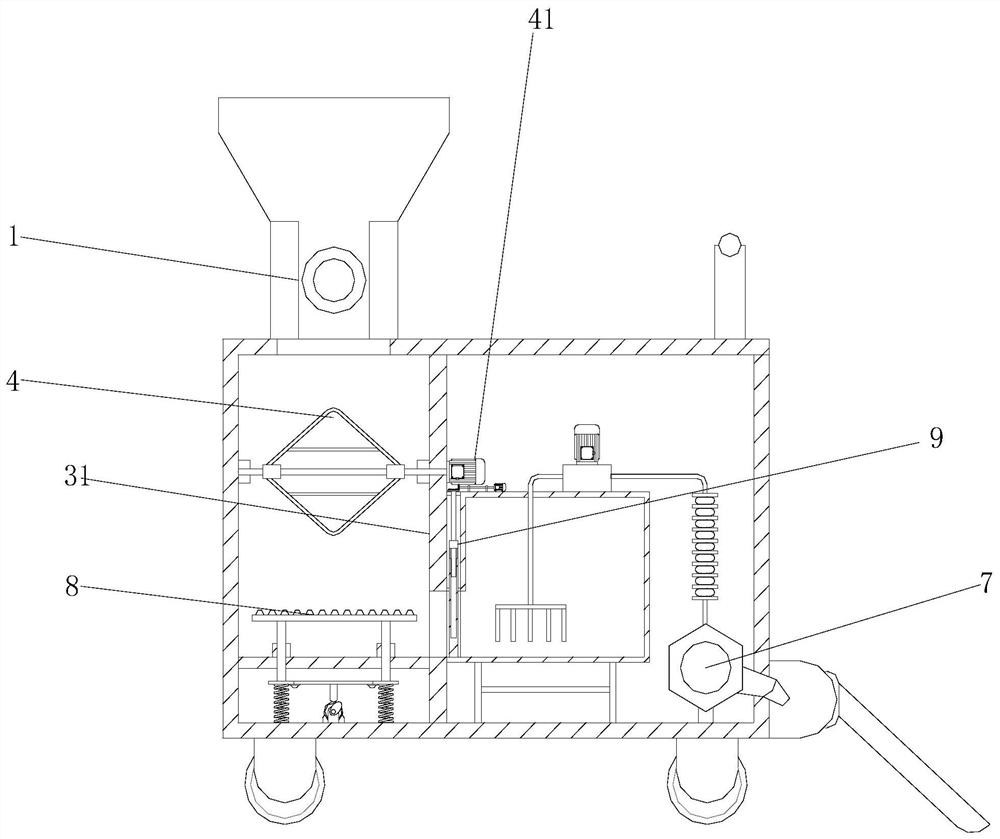

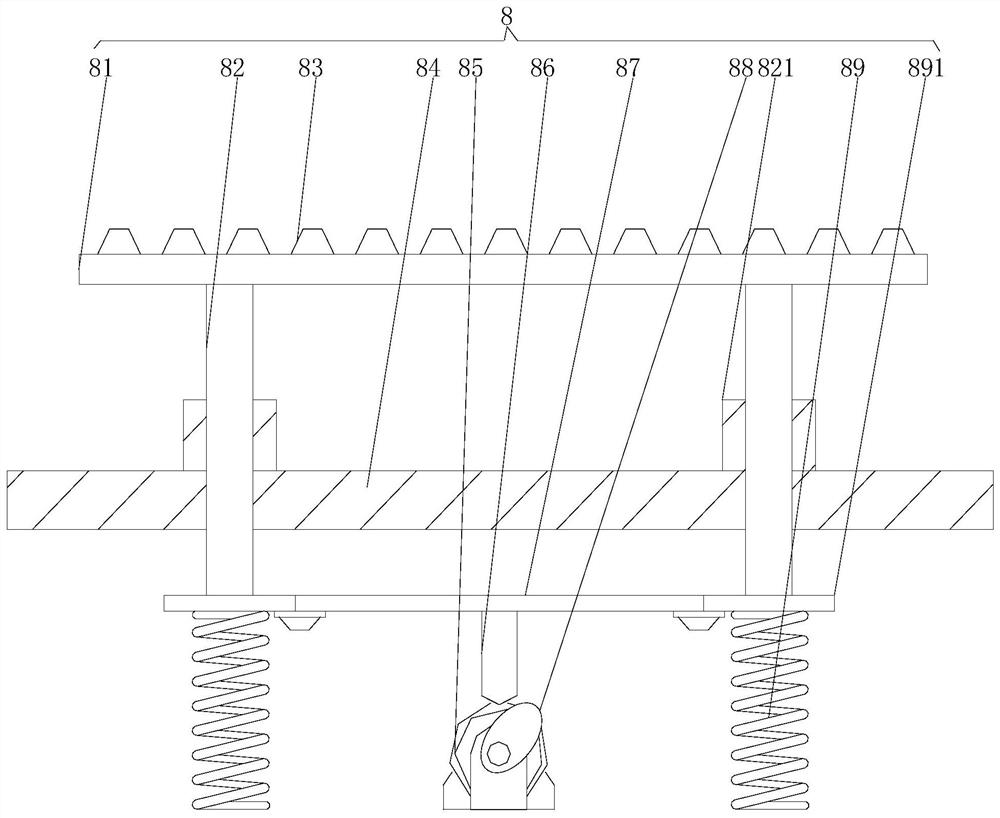

Industrial floor leveling device

InactiveCN113530181AAchieve the purpose of openingWell mixedBuilding constructionsElectric machineCam

The invention relates to the technical field of industrial floors, and discloses an industrial floor leveling device. A fixing piece is fixedly connected to the bottom of the right side of a box body; a scraping plate is fixedly connected to the inner side of the fixing piece; a spraying mechanism is fixedly connected to the right side of the bottom in the box body; a sealing mechanism is fixedly connected to the position, on the left side of the spraying mechanism, of the bottom in the box body; a partition plate is fixedly connected to the left side of the sealing mechanism; and a vibration mechanism is fixedly connected to the left side of the partition plate. According to the industrial floor leveling device, through the arranged vibration mechanism, a floor material is placed on the left side of the partition plate in the box body through a funnel, at the moment, a second motor works to drive stirring blades to rotate, the rotating stirring blades can ensure that the floor material is uniform, meanwhile, a third motor drives a cam to rotate, the rotating cam continuously impacts a contact rod, at the moment, a vibration rod vibrates up and down at a certain frequency under the cooperation of a spring, so that a vibration plate and a vibration block are driven to vibrate, and the uniformity of the floor material is further guaranteed.

Owner:DEQING YANGTAI BUILDING MATERIAL

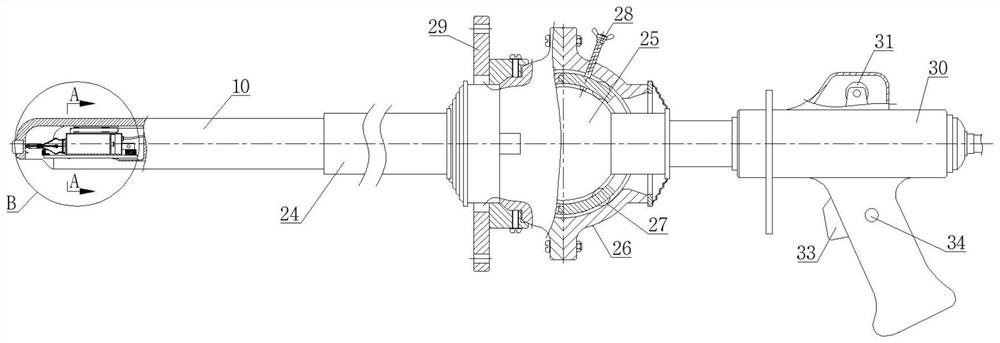

Laparoscope-based gastrointestinal perforation repair device

The gastrointestinal perforation repairing device based on the laparoscope belongs to the field of medical instruments and comprises a laparoscope tube, one end of the laparoscope tube is provided with a storage space with an opening in one side, a mounting plate is arranged in the storage space in a hinged mode, and a storage box for storing repairing liquid is fixedly arranged at the top of the mounting plate; a first discharging pipe is fixedly arranged at the outlet end of the storage box, and a second discharging pipe facilitating coating of repairing liquid is arranged at the end of the first discharging pipe. The repaired second discharging pipe and the storage box are stored in the storage space, so that when the whole endoscope tube enters the abdominal cavity of a patient, the position of the endoscope tube can be freely changed along with the endoscope tube, the interior of the abdominal cavity can be detected through the endoscope tube, the detection position can be conveniently and rapidly found, repairing liquid is coated and integrated on the endoscope tube, and the repairing efficiency is improved. Openings of the body of the patient can be reduced, and the controllability of the device is high.

Owner:岳阳职业技术学院 +1

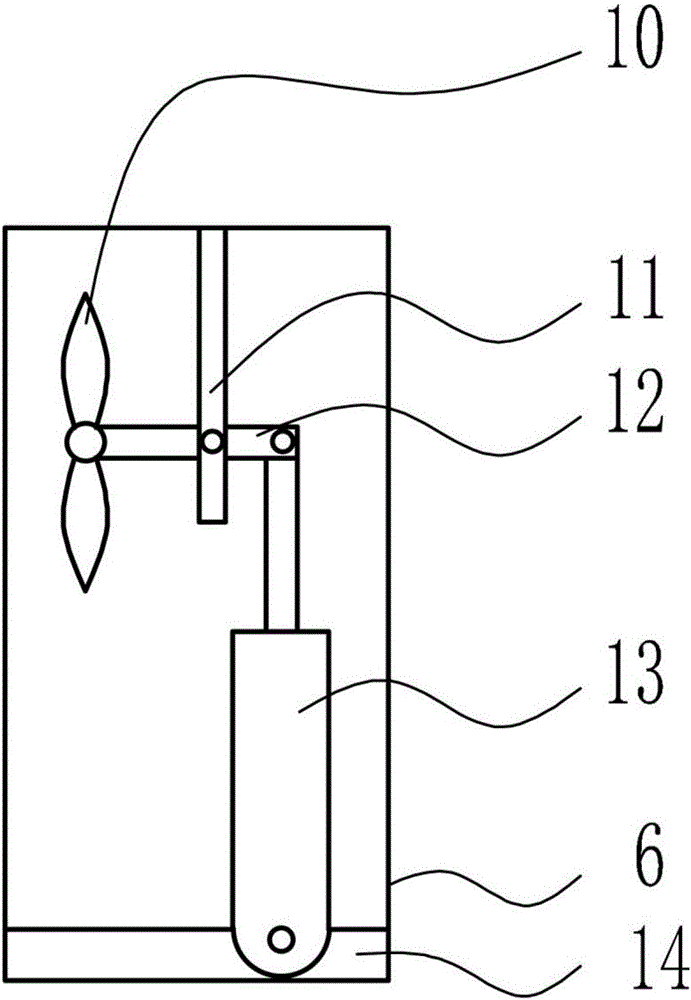

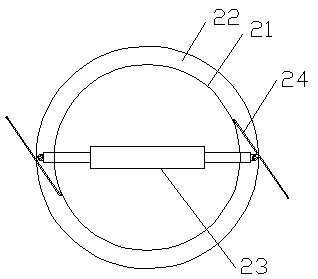

Large-diameter in-pipe spraying device

InactiveCN110639744AImprove work efficiencyEasy to operateSpraying apparatusMechanical engineeringPhysics

The invention relates to the field of spraying, in particular to a large-diameter in-pipe spraying device. The invention provides a large-diameter in-pipe spraying device which is simple in structure,facilitates spraying and improves the working efficiency. The large-diameter in-pipe spraying device comprises a base, an inner supporting mechanism, a driving mechanism and a spraying mechanism; theinner supporting mechanism comprises an inner cylinder which is rotatably and movably connected with the base; an outer annular rack is arranged on the surface of an upper cylinder opening of the inner cylinder; an inner scraping and coating assembly is arranged on the inner cylinder; a pipe body is arranged on the outer side of the inner cylinder; the center lines of the inner cylinder and the pipe body are positioned in the same straight line; the pipe body is rotatably and movably connected with the base; and an inner spray gun is positioned between the pipe body and the inner cylinder. The working efficiency is improved and the operation is reliable.

Owner:谈骏

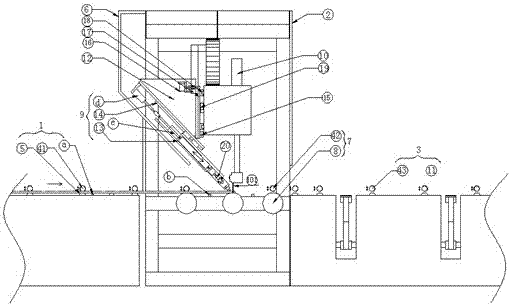

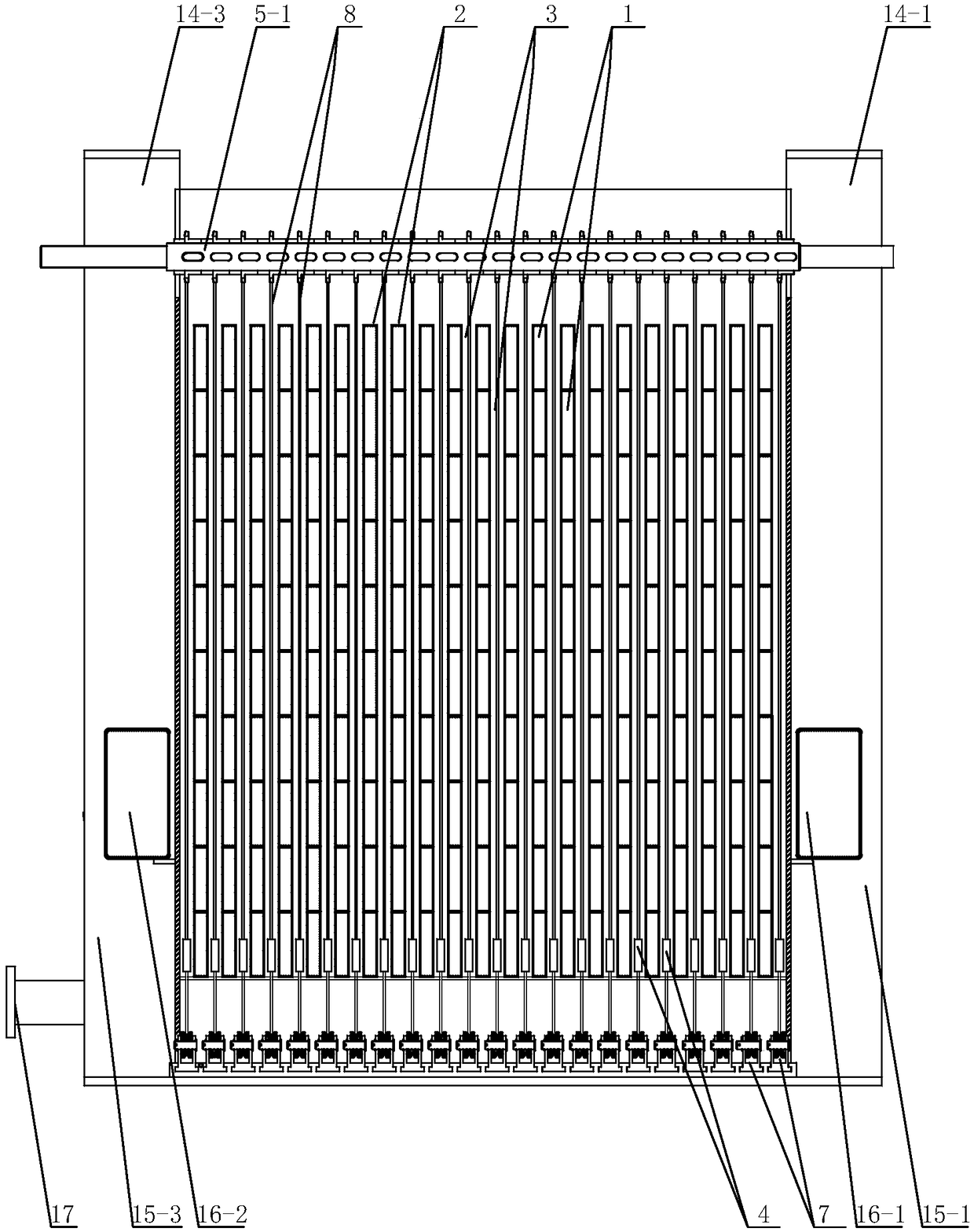

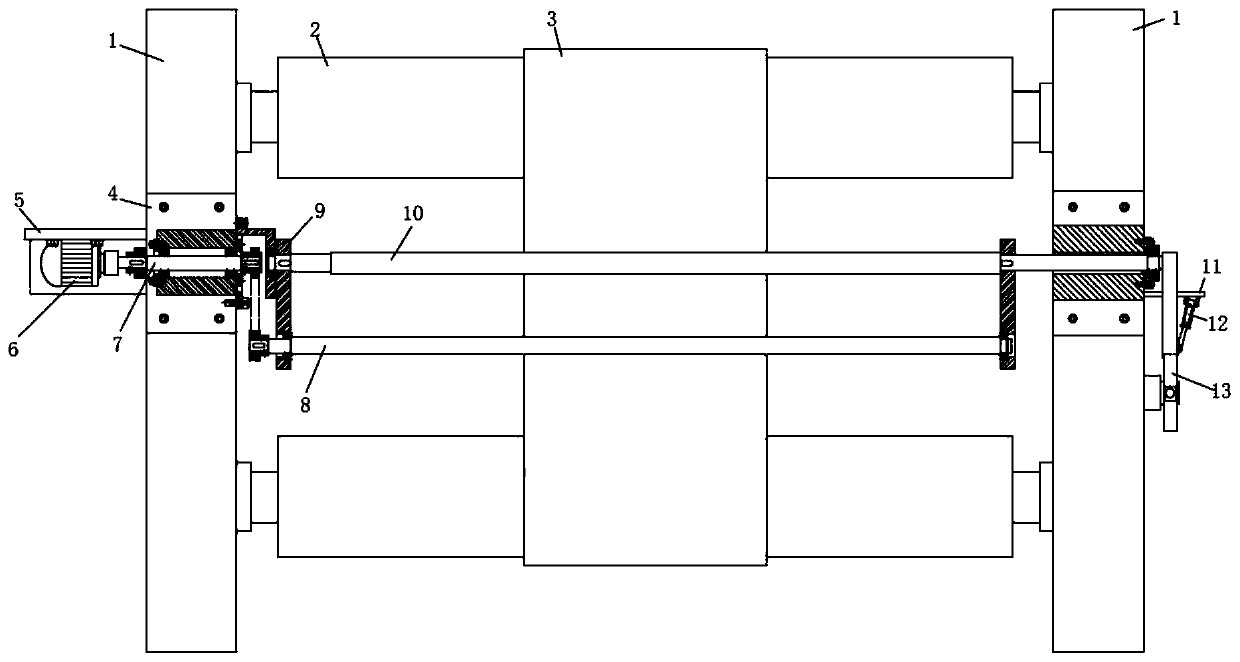

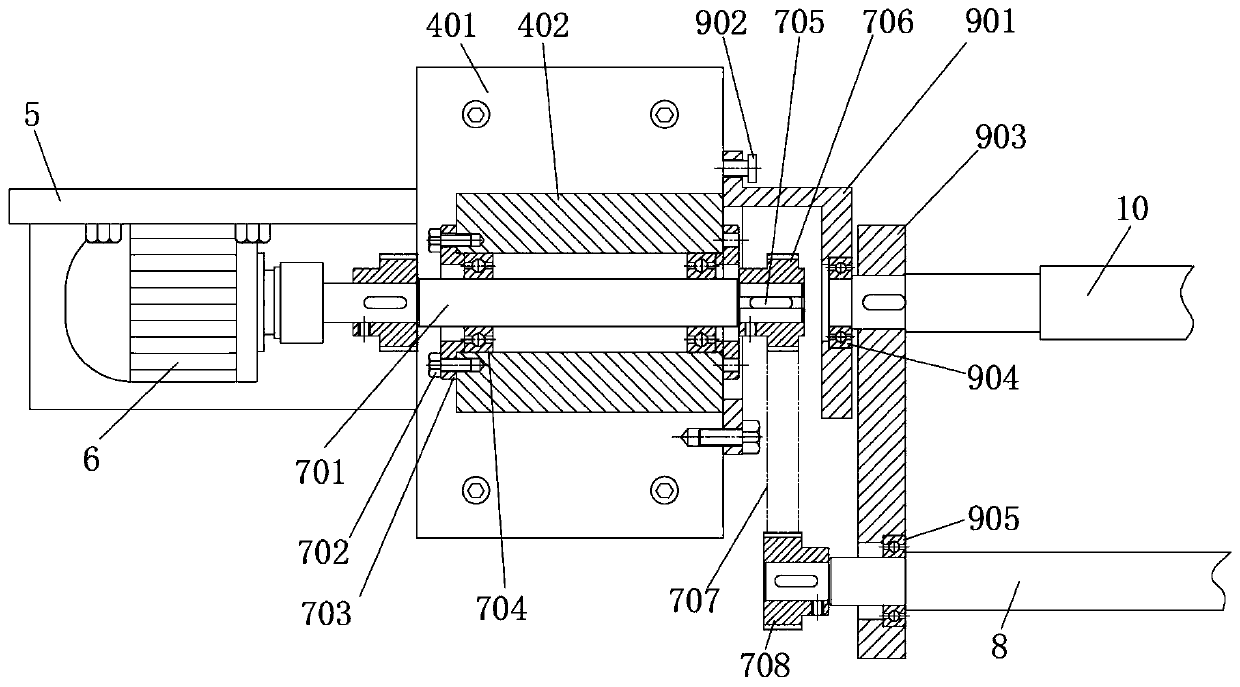

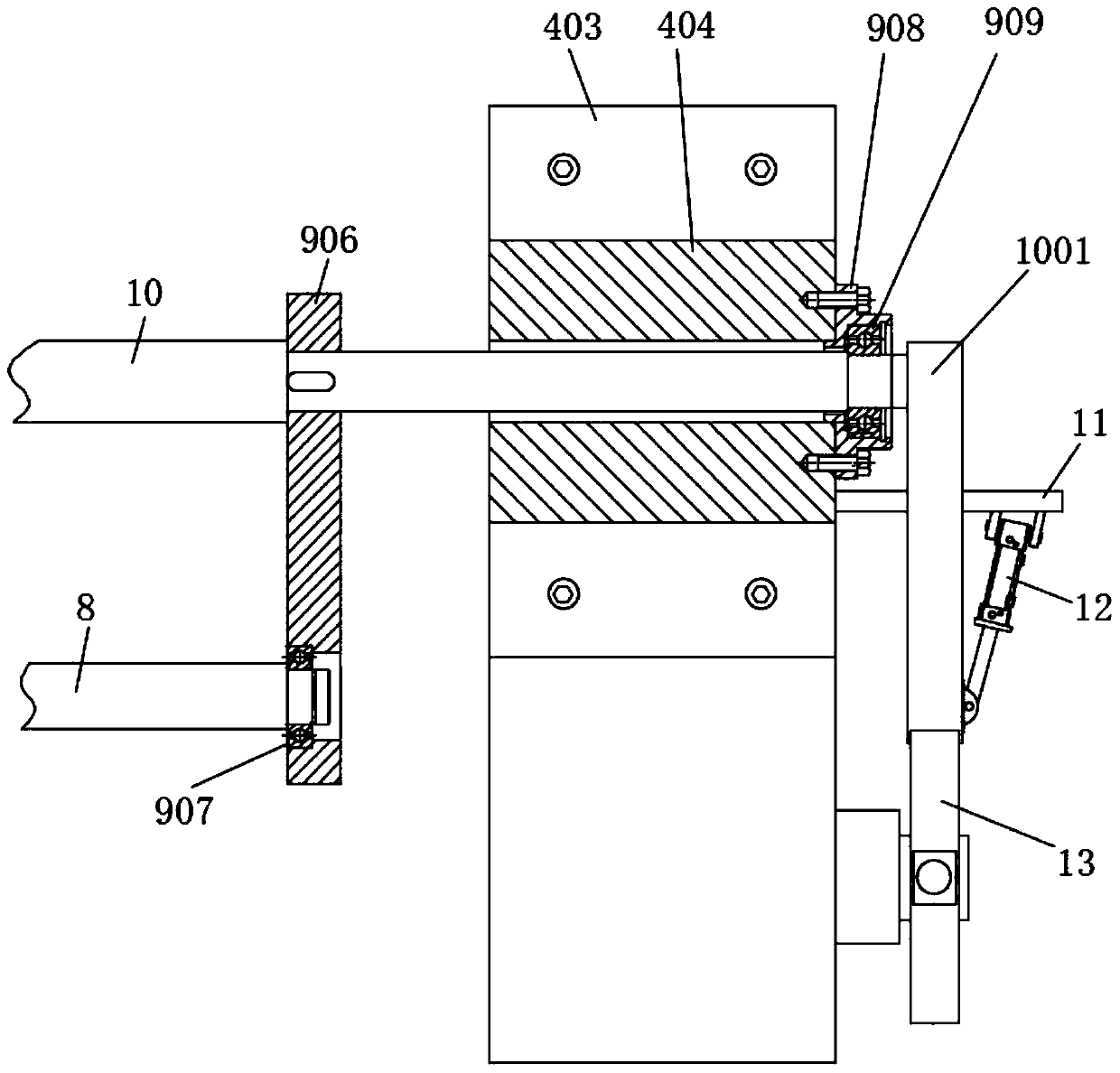

A lining scraping coating equipment and scraping coating method thereof

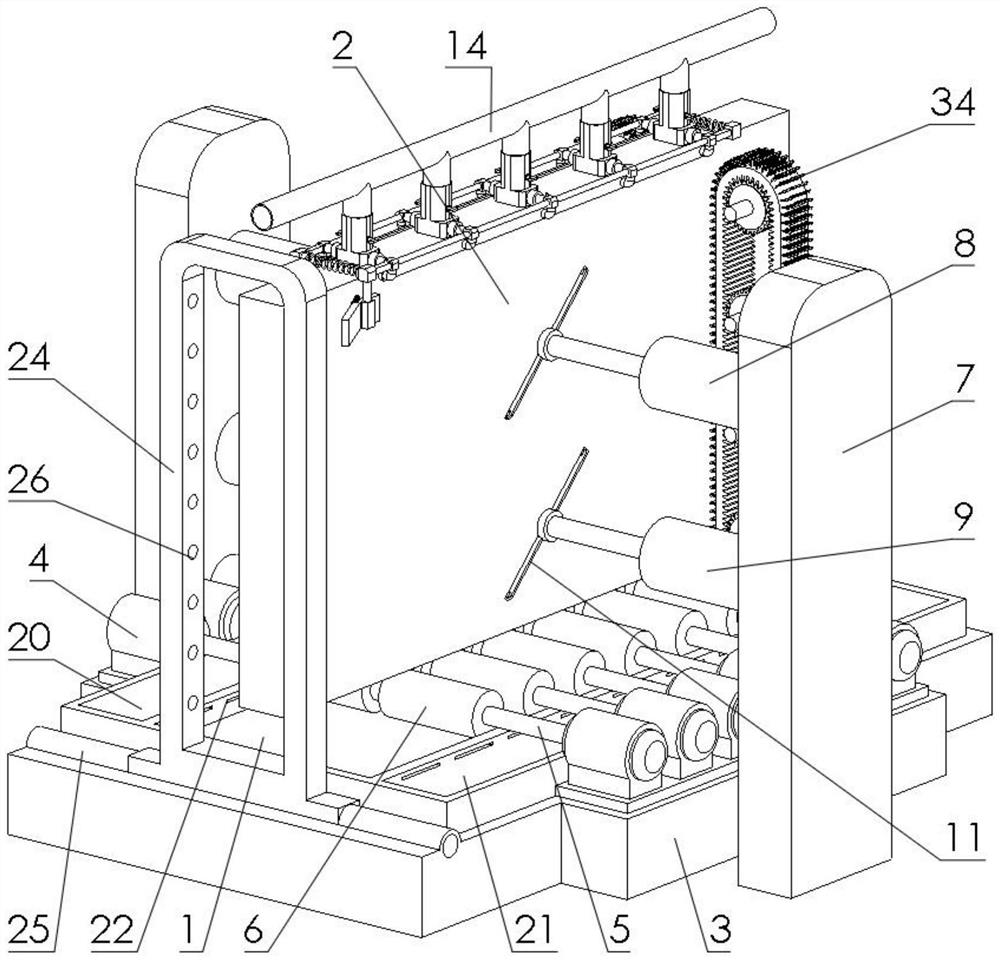

ActiveCN105127061BSqueegee evenlyPlay the role of thickness positioningLiquid surface applicatorsCoatingsEngineeringSlurry

The invention discloses a liner scraping coating equipment and a scraping coating method thereof. The equipment includes a base, a feeding system is installed on the base, a lifting mechanism is installed on the feeding system, a supporting plate is installed on the lifting mechanism, and a A hopper and a screw extrusion device are installed, and a scraper assembly is installed at one end of the supporting plate; the scraper assembly includes a master and a scraper, and one end of the screw extrusion device is connected to the hopper, and the other end is connected to the scraper. When scraping, first install the engine on the pulley, then adjust the height of the supporting plate so that the part of the engine to be scraped matches the master model, and add the slurry into the hopper; control the engine to rotate on the pulley, and the slurry passes through The screw extrusion device reaches the scraper, and the slurry is scraped onto the engine through the scraper. The invention solves the quality problem that the local thickness of the lining is out of control and improves the production efficiency by controlling the uniform rotation of the engine to be scraped, the accurate positioning of the feeding system, the lifting mechanism and the master, and the accurate feeding of the screw extrusion device.

Owner:HUBEI SANJIANG AEROSPACE JIANGHE CHEM TECH +1

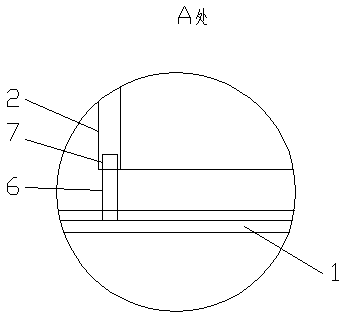

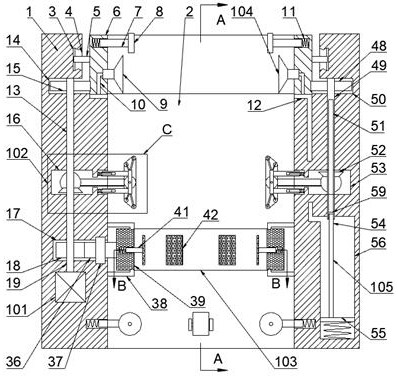

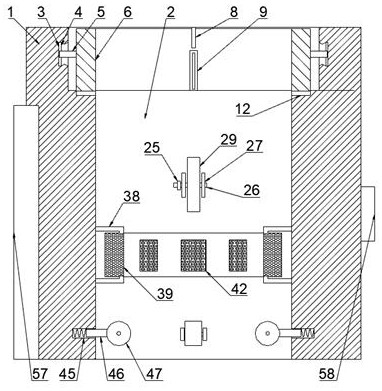

A kind of wood processing equipment

ActiveCN109483670BFast fusionFit tightlyAdhesive application devicesRubber materialElectric machinery

The invention discloses a kind of wood processing equipment, which includes a wooden board to be processed, a rubber material collection pool and a rubber material static pool arranged on both sides of the rubber material collection pool are arranged under the wooden board; There is a motor base, and the motor base is equipped with motors at even intervals in the longitudinal direction; a glue discharge device is installed above the wooden board; a scraping device is provided on both sides of the wooden board, and a brushing device is provided at the discharge end; There is a preheating frame in front of the feeding end; the present invention can quickly perform preheating, gluing, scraping and gluing operations on wooden boards, and is suitable for boards of different widths and sizes, and the coating is comprehensive and uniform, and the glue can be Recycling, single and double-sided rubber coating are optional; the whole process is automatically controllable, reliable and efficient.

Owner:湖南省杨林木业有限公司

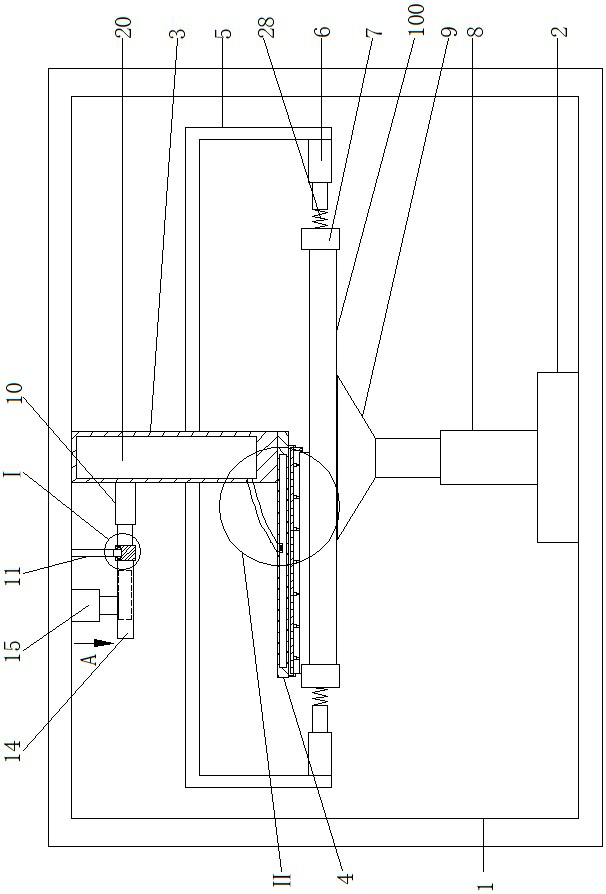

Ink scraping driving mechanism for printing machine

InactiveCN110893721ASqueegee evenlyEvenly distributedInking apparatusPrinting press partsElectric machineryEngineering

The invention discloses an ink scraping driving mechanism for a printing machine. The ink scraping driving mechanism for the printing machine comprises a motor, the motor is connected with a first connecting rod through a gear, the first connecting rod and a second connecting rod are mutually connected through an eccentric bearing, the second connecting rod and a third connecting rod are perpendicular to each other, the third connecting rod is connected with a fourth connecting rod on an ink scraping piece, and the motor is connected with a PLC. The PLC controls the rotating speed of the motor, and the motor drives the first connecting rod to rotate. Due to the effect of the eccentric bearing, the second connecting rod drives the third connecting rod to move left and right, and the ink scraping piece enables ink on the ink scraping piece to be uniformly distributed in the moving process, so that the ink can be uniformly scraped and applied to a roller during ink scraping.

Owner:黄翔

A kind of printing and dyeing method of butterscotch silk

ActiveCN112458757BSimple production processShorten the timeGrip property fibresDyeing processTextile printerPolymer science

The application discloses a method for printing and dyeing acanthus silk, which includes the following steps: choose dyeing or printing according to customer needs, wherein the dyeing step: prepare the blank; dyeing: dye according to customer needs; scraping: scraping paint and adhesive; Baking; sand washing; finishing; finished inspection. Among them, printing steps: blank thick preparation; sizing: using sodium alginate and other pastes as the main slurry; digital printing: digital printing according to the customer's pattern; steaming: making the digital printing products fully develop color; washing: washing Removal of slurry; Stiffening finishing: Adding stiffeners; Scraping: Scraping coatings and adhesives; Baking; Sand washing; Finishing; Inspection. By adopting the method of the present invention, the traditional method of processing silk can be completely abandoned, and there is no need to use the juice and special pond mud, so as to obtain silk products similar to the style of traditional silk; it breaks the complicated production process of traditional silk and low production efficiency , The limitation of high labor intensity effectively shortens the delivery cycle of silk silk processing, and breaks through the geographical restrictions of the necessary special pond mud, which is easy to be widely promoted and greatly meets the market demand.

Owner:ZHEJIANG HSDP SILK TECH

Printing and dyeing method of gambiered canton silk

ActiveCN112458757ASimple production processShorten the timeGrip property fibresDyeing processTextile printerProduct inspection

The invention discloses a printing and dyeing method of gambiered canton silk. The method includes the following step of selecting dyeing or printing according to customer requirements. The dyeing step includes the steps of blank thickening preparation; dyeing: dyeing according to the customer requirements; blade coating: blade coating a coating and an adhesive; baking; sand washing; finishing; and finished product inspection. The printing step includes the steps of blank thickening preparation; sizing: paste materials such as sodium alginate are used as main slurry; digital jet printing: carrying out digital jet printing according to customer patterns; ageing: enabling a digital jet printing product to fully develop color; washing: washing off the slurry; stiffening finishing: adding a stiffening agent; blade coating: blade coating a coating and an adhesive; baking; sand washing; finishing; and finish product inspection. By the adoption of the printing and dyeing method of the gambiered canton silk, a traditional gambiered canton silk processing mode can be completely abandoned, and gambiered canton silk juice and special pond sludge do not need to be used, so that gambiered canton silk products similar to traditional gambiered canton silk in style are obtained, the limitation that a traditional gambiered canton silk manufacturing process is complex, low in production efficiency and large in labor intensity is broken through, the delivery period of gambiered canton silk processing is effectively shortened, the geographical limitation of the necessary special pond sludge isbroken through, wide popularization is easy, and the market requirement is greatly met.

Owner:ZHEJIANG HSDP SILK TECH

Ink scraping drive device

ActiveCN104191813ASqueegee evenlyEvenly distributedPrinting press partsMotor drivePulp and paper industry

Owner:江阴市汇通包装机械有限公司

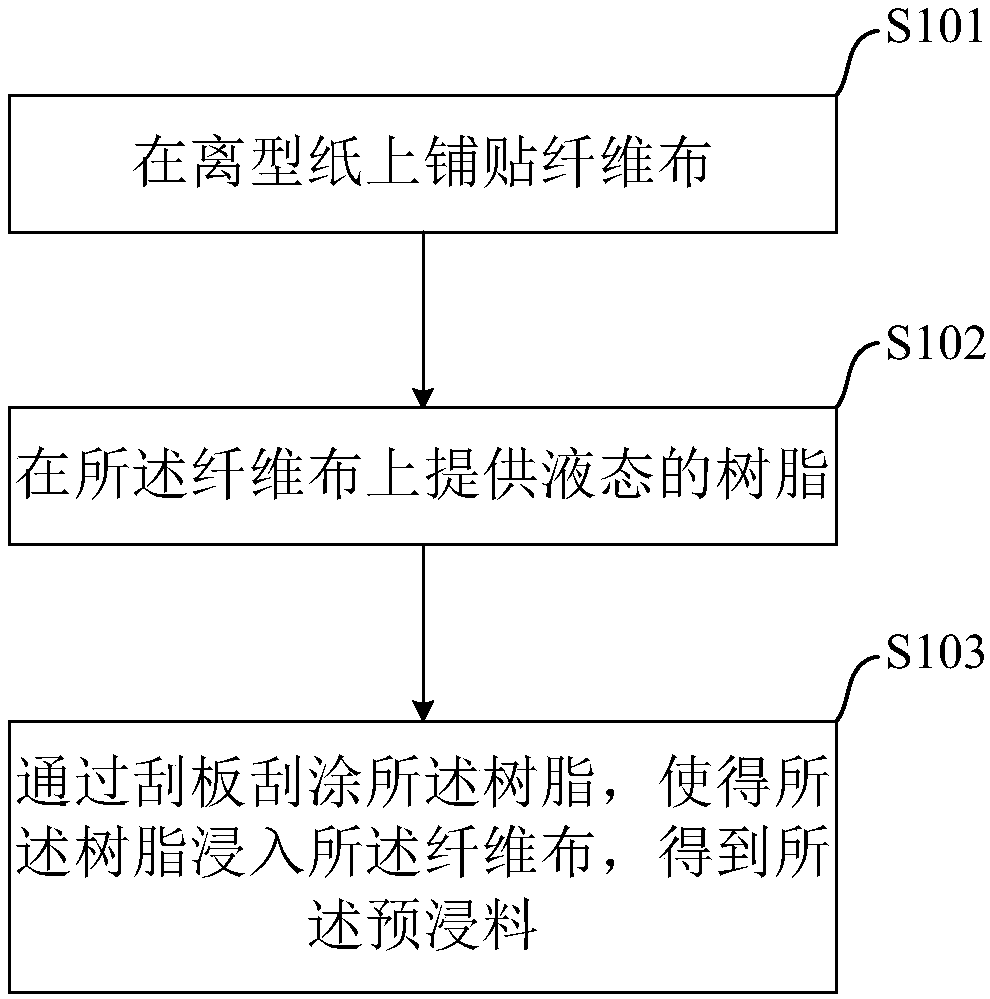

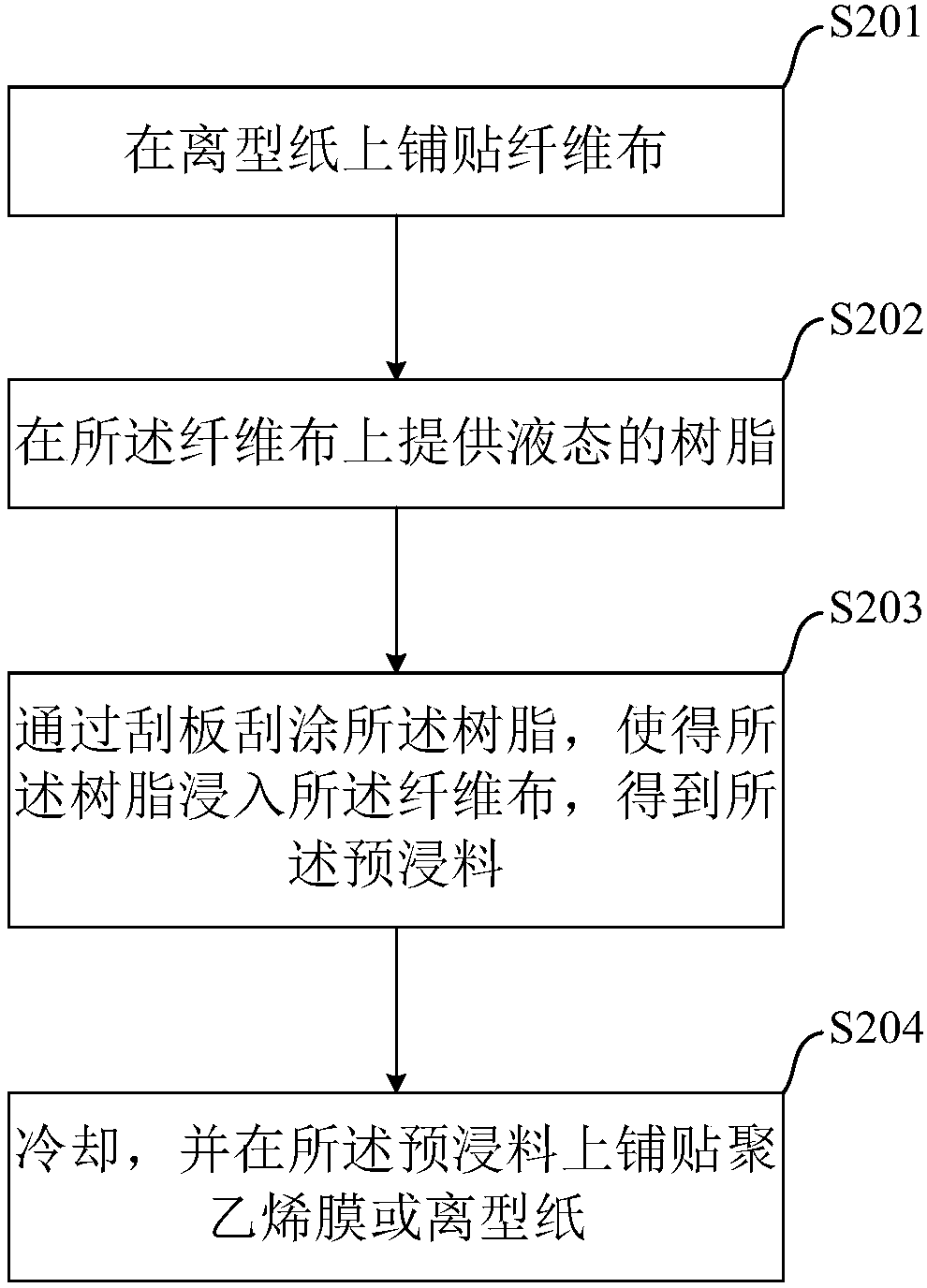

Manufacturing method of prepreg

The invention discloses a manufacturing method of a prepreg. The manufacturing method comprises the following steps that fiber cloth is paved and attached on release paper; liquid resin is provided onthe fiber cloth; and scraping and coating of the resin are achieved through a scraping plate, so that the resin is immersed into the fiber cloth to obtain the prepreg, wherein the scraping and coating step comprises the following sub steps that the scraping plate is used for performing scraping and coating at the position away from the fiber cloth by a first preset height, and then the scraping plate is lowered, so that the scraping plate is used for performing scraping and coating at the position away from the fiber cloth by a second preset height. According to the manufacturing method of the prepreg, the scraping plate is used for performing scraping and coating of the resin, so that the equipment investment of a production line is simplified, and the uniformity of the distribution of the resin on the fiber cloth is ensured by sequentially performing scraping and coating of the resin at different heights.

Owner:KUANG CHI INST OF ADVANCED TECH

Coating equipment for preparing special coated glass fiber cloth

ActiveCN110013930BImprove cleanlinessIncreased flexibility of useSpraying apparatusGlass fiberElectric machinery

Owner:镇江安之盾高温纤维制品有限公司

Stack glue scraping mechanism of single-face corrugating machine

InactiveCN103331954AAvoid stickingSimple structureLiquid surface applicatorsMechanical working/deformationEngineeringMechanical engineering

The invention belongs to the technical field of packaging machinery, and relates to a glue scraping mechanism, in particular to a stack glue scraping mechanism of a single-face corrugating machine. The stack glue scraping mechanism comprises a wallboard, a glue roller is rotationally installed in the wallboard, an air cylinder is fixedly installed on the wallboard, the top of a push rod of the air cylinder is connected to one end of a connecting arm, and a scraper device is arranged at the other end of the connecting arm. The stack glue scraping mechanism is simple, compact and reasonable in structure, existing glue scraping and glue mixing modes are changed, a scraper tightly presses a roller surface in the process of working, therefore, the phenomenon of large glue amount can be avoided by adopting the gluing mode, the phenomenon that glue is stained on a corrugating roller can be effectively avoided, abnormal using of the device is avoided, and forming speed of the corrugating roller and production speed are effectively guaranteed; meanwhile, gluing amount can be further excellently controlled, gluing is even, and therefore quality of products is improved.

Owner:WUXI YUTAI PACKING MACHINERY TECH

Gluing device for improving gluing uniformity

InactiveCN110369228ASpread evenlySimple structureLiquid surface applicatorsLaminationAdhesiveEconomic benefits

The invention discloses a gluing device for improving gluing uniformity. The device comprises a rack, a transmission roll and a plastic thin film; a fixed mechanism is arranged below the transmissionroll; a support frame is arranged on the left side of a left fixed seat; the lower end of the support frame is connected with a speed control motor through a bolt; a left fixed boss on the left fixedseat is provided with a transmission mechanism; the input end of the transmission mechanism is connected with the output shaft of the speed control motor; a rotation arm mechanism is arranged on the right side of the transmission mechanism; an active sleeve is arranged at the output end of the transmission mechanism; the right end of a connection rod horizontally passes through a right fixed boss;a rotation arm is fixedly arranged at the end of the connection rod; a fixed block and an air cylinder are arranged at the right end of the right fixed boss; the output end of the air cylinder is hinged with the rotation arm; and a limiting mechanism is arranged below the rotation arm. The device is reasonable in design, and is capable of uniformly spreading the adhesives on the thin films so asto avoid the quality problems such as grains and white dots on the plastic thin films after compounding, thereby making the operation convenient, improving the product quality, reducing the rejectionrate and production cost and improving the economic benefits of the enterprises.

Owner:湖南佳年华包装有限公司

Glue scraping equipment

PendingCN114472086AFit compactPrecise positioningLiquid surface applicatorsPaper-makingScreen printingPolymer science

The invention relates to the technical field of screen printing, in particular to glue scraping equipment which comprises a rack, a screen printing platform, a glue scraping execution assembly and a plate type material transplanting assembly. The glue scraping execution assembly comprises a silk screen plate and a glue scraping module; the silk screen plate is arranged on the silk screen platform; the glue scraping module comprises a glue scraping ink knife and a glue returning ink knife which are movably arranged above the silk screen plate, the glue scraping ink knife is used for scraping glue in the silk screen plate, and the glue returning ink knife is used for returning glue in the silk screen plate; the plate-type material transplanting assembly is used for sequentially moving the fed plate-type materials to the silk-screen printing platform and / or discharging the plate-type materials subjected to glue scraping on the silk-screen printing platform, an assembly line type operation mode is adopted, the plate-type materials can be automatically taken, adjusted and positioned, glue scraping operation and the like, connection and matching are compact, positioning is accurate, glue scraping is uniform, and the production efficiency is improved. Manual intervention is not needed, the labor intensity of workers is reduced, the glue scraping efficiency and quality are improved, and the device is suitable for large-scale industrial automatic production.

Owner:湖南裕同印刷包装有限公司

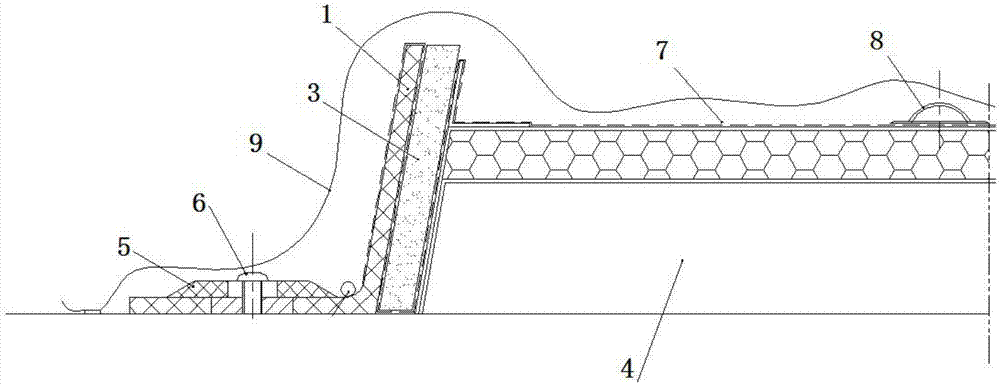

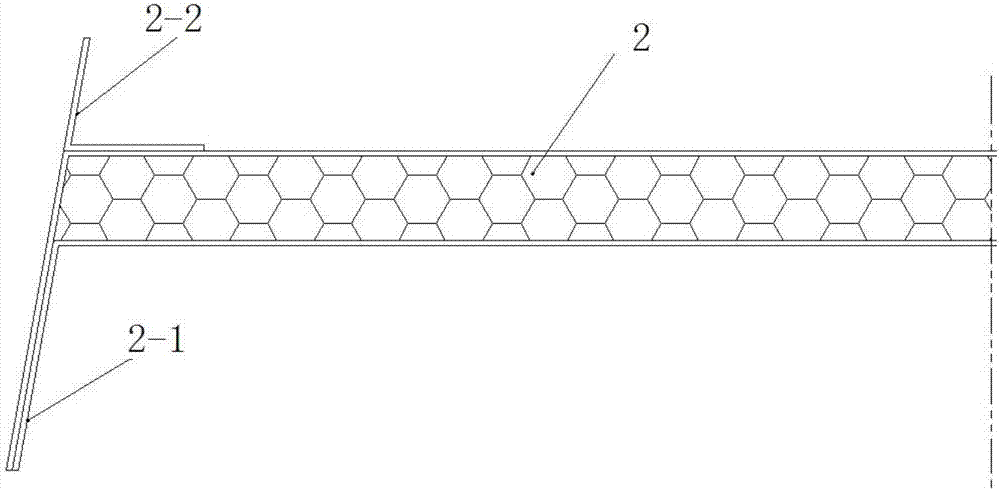

Preparation method of wind turbine blade web of wind power generating set

ActiveCN106113528BPracticalConducive to smooth transition of stiffnessFinal product manufactureFiberGlass fiber

The invention discloses a preparation method for a wind turbine blade web of a wind turbine generator set. The preparation method comprises the steps that according to the layer laying order of the web (2), an inner web skinned cloth, an outer web skinned cloth and a core material are laid, and meanwhile, a release cloth is laid in a main adhering corner area of the web; a silica gel board (3) is placed in a main adhering area of the web (2), and a glass fiber reinforced plastic movable blocking flange (1) is in lap joint with a web main body mold (4); according to a hole in the glass fiber reinforced plastic movable blocking flange (1), a locating block (5) is installed; and a fiber cloth is laid on an adhering-connection face of the web (2), then a web pouring system is laid, a vacuum system is built, and vacuum integral pouring is conducted to obtain the web. The preparation method is reasonable in process design and high in operability. An integral pouring forming process is adopted, rigidity smooth transition of the blade web and a shell adhering-connection face is facilitated, uniform scrape coating of adhesive is facilitated, and defects caused by out-of-tolerance of adhering-connection of the web can be reduced greatly. The prepared I-shaped web is high in precision and practicability.

Owner:LIANYUNGANG ZHONGFU LIANZHONG COMPOSITES GRP

Squeegee drive

ActiveCN104191813BSqueegee evenlyEvenly distributedPrinting press partsMotor drivePulp and paper industry

Owner:江阴市汇通包装机械有限公司

A rotary spraying device

InactiveCN108686858BSqueegee evenlyQuality improvementSpraying apparatusEngineeringMechanical engineering

The invention discloses a rotary spraying device, relates to the field of spraying, and particularly relates to a rotary spraying device of a pipe body. The rotary spraying device is simple in structure and convenient to spray, and improves the working efficiency. The rotary spraying device comprises a base, an inner supporting mechanism, an outer supporting mechanism, a driving mechanism and a spraying mechanism. The inner supporting mechanism comprises an inner cylinder, the inner cylinder is rotatably and movably connected to the base, an outer annular rack is arranged on the surface of anupper cylinder opening of the inner cylinder, and an inner scraping smearing assembly is arranged on the inner cylinder. An inner spraying gun is located between the pipe body and the inner cylinder,and an outer spraying gun is located between the pipe body and an outer cylinder. The rotary spraying device improves the working efficiency and operates reliably.

Owner:YANGZHOU DONGFANG HANGER FRAME CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com